Abstract

Logistics is a vital element of monetary development, serving as a catalyst for a country's firm competitiveness. Its theatres a decisive role in driving both countries and firms towards success. Nevertheless, the logistics commerce now grapples with exorbitant costs and subpar efficiency. The appearance of keen logistics presents a promising avenue to address these challenges. These characteristics show a key role in fostering the advancement of intelligent logistics. The primary objective of smart warehouses is to enhance the overall superiority, proficiency, and competence of warehouse operations, all while minimizing expenses and setbacks. This article delves into the technological facets of warehouse operations and efficiency within third-party logistics service providers in Tamilnadu. A qualitative-descriptive method, through an inclusive review of the applicable studies, remained used in this learning to develop a technology in warehouses. Designed to simulate warehouse operations in private companies in TN. Statedly, a stratified random sample assortment was applied in this study. The proposal put forward a framework that is suitable for creating an IoT-driven warehouse infrastructure. By utilizing information congregated from a specific company, the suggested design for a shrewd warehouse infrastructure effectively achieved real-time discernibility and traceability, leading to enhanced overall warehouse efficiency, among other benefits. The research framework was implemented in Tamilnadu; however, the outcomes of this study can lay the groundwork for future research in the realm of IoT smart warehouses. The empirical findings showcase the utilization of IoT technologies in different companies, which can be effectively implemented to enhance warehousing processes and yield positive outcomes.

Keywords: IoT, technology, Tamil Nadu, warehouse

Introduction

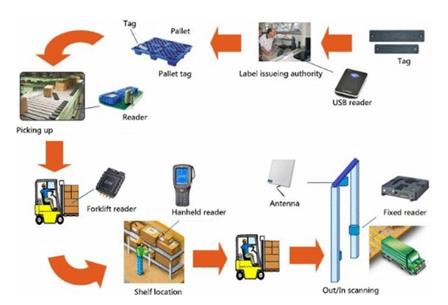

In the entire force chain, there's a need to store the force temporarily for committing certain deals Knight Frank (2014) demands a connection, payload, etc. Figure 1 Shows warehouse operations. Affia and Aamer (2022). The place where this force is stored is nominated as a Storehouse. Senthil et al. (2020) Base processes of the storehouse remain of entering, storing, order processing, and dispatch of force base, the client orders including some value-added services. The storehouse plays a pivotal part in the force chain operation for the client orders rightly served Richards (2017) The optimal completion of storehouse operations is achieved through the well-organized society of force movement within the storehouse, Ding (2013) which is commonly referred to as Warehouse Management. Čolaković et al. (2020) Third-party logistics (3PL) companies specialize in providing a range of services related to the logistics of the force chain. Lam and Chi (2016). This encompasses transportation, storage, selection and packaging, predictive analytics, order completion, packaging, and cargo forwarding.

Technology in 3PL

Enforcing a comprehensive storehouse operation system enables a 3PL company to organize data on storehouse stock and an informal method to retain track of goods belonging to multiple guests. Sivakumar and Ruthramathi (2019) WMS technology can ameliorate slotting and picking patterns and increase communication between transportation operations and storehouse operation systems. Farhan et al. (2018) WMS schemes can also join with labor operation software, which helps companies optimize their pool. 3PL drivers’ moment also extends services beyond introductory warehousing and gives consulting and advising the retailer or manufacturer on the stylish course of action.

Statement of the Problem

Technology has been growing in the previous few eras; however, the competitive positions of technology users need to be strengthened. Sivakumar et al. (2020a,b). The potential of technologies in Indian industries is enormous and an intensive study in creating knowledge on technologies theatres an energetic role fashionable today`s business. Lim et al. (2013), Luthra et al. (2018), and Lee and Lee (2015) Hence in today`s competitive scenario, customer service needs to be better utilized by the logistics service providers thereby providing better value to customers and improving the warehousing services through IoT technology in the logistics industries and logistics service providers.

Research Questions

- How far are applications of IoT Technology used by the warehouse sector?

- What are the technologies used in the WMS

- How to describe the development services in the granary organization system.

Purpose of the Study

The Internet of Things can produce massive quantities of data and analyze the intricate interconnectivity of the transactions represented in that data Ruthramathi and Sivakumar (2022) using a variety of mathematical analysis techniques is a notion of systems industrialized by relating a big quantity of smart devices into a network. Trab et al. (2018) IoT-enabled systems production a decisive role in revolutionizing warehousing operations and enhancing automation. They effectively optimize inventory management processes and effectively cut down on operational expenses. Sivakumar et al. (2020a) by leveraging IoT, warehouses gain the ability to monitor and track every single component within their facility. Jagatheesaperumal et al. (2021) The premises are monitored by interconnected sensors that track the location of every asset. Through the use of connected sensors, each asset within the premises is continuously tracked. Raja and Venkatachalam (2022) Tracking of assets across the premises is made possible by a net of consistent devices. Interconnected sensors enable the tracking of each asset throughout the premises. The facilities are furnished with interconnected sensors that enable the monitoring of every asset. Ruthramathi et al. (2022) Smart shelves installed in warehouses can spread real-time record data and alert warehouse managers about various issues such as low stock levels, misplaced items, unfavorable temperatures, theft, and more Van Geest et al. (2021).

Research Methods

Research Design: Descriptive research & Explorative research

Sources of Data Collection:

Primary data:

From the survey using a structured questionnaire and interview schedule.

Secondary data:

Articles, and news from journals, books, magazines, and Web sites.

Sampling and Population:

The study area employed stratified random sampling methodology. The population of Chennai was 281 and the Coimbatore region was 376 and the total population is 657.

Questionnaire development and Statistical Tools

In December 2022, a survey was suggested that comprised of 13 questions. The survey encompassed various aspects, starting with the demographic profile of service providers, followed by the utilization of technology by these providers. Additionally, it aimed to identify the challenges encountered by transporters when utilizing technology, and lastly, the advantages of employing digital technology. A successful combination of both digital and physical methods was used to conduct the survey. The study area employed fundamental descriptive and inferential analysis tools to analyze the collected data.

Justification for the sampling

Stratified sampling is a sample technique that allows researchers to obtain a sample population that is representative of the entire population under study. In this sampling technique, we utilized offline as well as online techniques to administer the poll. When stratified random sampling is used, the population is divided into different and standardized groups called strata. Therefore, the questionnaires have different subgroups like gender, age, and Designation like that. The first justification is that data from the entire 657 population. The collected sampling size is 381, From the formula Sample proportion, p = 0.05, Confidence level, Z = 1.96. The margin of error, e = 0.05, N- Total Population, in this formula finds out the sampling size is 381.

Findings

Applications in the Logistics Sector

Figure 2 designates the strongly agree of Location and Route Management (192), Inventory Tracking and Warehousing (252), CBM and Breakdown Prevention (262), IoT and Blockchain for Digital BOL (119), and Drone-Based Delivery (168).

Percentage Analysis

Male category was highest percentage. Master degrees are high in number. Table 1 denotes the outline of the defendants.

Chi-Square

The critical values within the table 2 are often compared to the test statistic of a Chi-Square test. If the test measurement is superior than the perilous value found in the table, discard the null premise of the Chi-Square test and conclude that the results of the test are statistically important.

ANOVA

Above table 3 embodies the Types of Warehouses and the Warehouse Technologies in the Logistics Sector. Various factors are Automated Picking Tools, Automatic Guided Vehicles (AGVs), Automated Inventory Control Platforms, Internet of Things (IoT) Implementation, Collaborative Robots (Cobots), and Systems for Intelligent Storage and Retrieval. Only two factors do not sign the proposition. The P-value is less than the implication value of 0.05.

Correlations

Table 4 nominates the Numerous factors are Video surveillance and real-time alerts, Product quality management, Eco-friendly smart warehouses, linked supply chain, improved connectivity, and the types of warehouses.

Factor Analysis

Factor analysis can be carried out because Table 5's KMO value of 0.640 indicates that the variable's notch of common discrepancy is rather high.

Communalities indicates table 6, Explicates the variance of the 12 variables ranging from .496 to .959. It shows that the 12 variables exhibit a considerable variance from 50 percent to 95 percent. Hence it is finalized that these entire 12 variables are capable of segmenting themselves with respect to the factors affecting the development of technology.

Based on the finding of more than one eigenvalue, there have been four unique elements that recognized. These factors condense the twelve variables into four primary factors, each exhibiting variance of 26.665, 21.232, 16.692, and 13.134 respectively. To meet the requirement, the total sum of squared loading after rotation must exceed 50 percent. Furthermore, the total variance of the twelve variables is determined to be 77.723 percent, surpassing the benchmark value of 77 percent. This reaffirms the importance of the factor segment, as highlighted in table 7.

IoT development- Rotated Compound Matrix

The cumulative percentage of variance, which is 77.723, is indicated by the rotated sum of the square value. This highlights the significance of utilizing the rotated component matrix in IoT development, as factorization proves to be more suitable for the associated costs.

Table 8 displays the factor loadings for the four factors extracted via factor analysis. The initial factor comprises four sub-factors Vision picking, Hands-off inventory management, Precise location monitoring, and Enhanced inventory tracking. The first factor is named “Inventory Tracking”. The second factor contains four subfactors; Automated tasking, Remote health monitoring, Blockchain item tracking, and Optimization of energy consumption. Hence, it is named “Item Tracking”. The third factor contains another two factors Drone, Environmental monitoring, Hence the factor is named “Monitoring”. Finally, the four factors contain another two factors Remote operation of machinery/appliances and preventive equipment maintenance. Hence the factor is named “Remote operating”. It is therefore concluded that IoT development gives much importance to twelve variables.

Conclusion

To assist rapidity up the storehouse, supervision, and distribution of force, storage is counting further on IoT- enabled bias including wearables, smart spectacles, and stoked reality (AR) technology Jiang et al. (2015). Robotic and artificial intelligence consequences are too existence second-hand in storehouse and logistics operations along with storehouse workers to ameliorate performance and reduce crimes. Tsang et al. (2018) IoT bias is fleetly getting a cost-effective and effective result for force operation. A large quantum of real-time data from IoT bias can help associations identify openings to ameliorate overall logistics, force, and force chain operations TradeGecko (2017). The emergence of technology in the logistics industry is currently happening at an unprecedented pace. Through the utilization of IoT, businesses can leverage the combined outcomes to analyze data and generate valuable insights, thereby enhancing the efficiency and swiftness of goods transportation. Raja and Venkatachalam (2022, 2023) IoT implementation in logistics is a foundational element, augmenting its fundamental components Nižetić et al. (2020). The global demand for logistics services is already experiencing significant growth, and with the integration of innovative mobile technologies, companies can accomplish source hawser processes and distribution systems.

Acknowledgments

Ms. R. Ruthramathi is a recipient of the Indian Council of Social Science Research Doctoral Fellowship. His/her article is largely an outcome of his/her doctoral work sponsored by ICSSR. However, the responsibility for the facts stated, opinions expressed and the conclusions drawn is entirely that of the author. File No. RFD/2021-22/GEN/MGT/72, 16 December 2021.

References

Affia, I., & Aamer, A. (2022). An internet of things-based smart warehouse infrastructure: design and application. Journal of Science and Technology Policy Management, 13(1), 90-109. DOI: 10.1108/jstpm-08-2020-0117

Čolaković, A., Čaušević, S., Kosovac, A., & Muharemović, E. (2020). A Review of Enabling Technologies and Solutions for IoT Based Smart Warehouse Monitoring System. New Technologies, Development and Application III, 630-637. DOI:

Ding, W. (2013). Study of Smart Warehouse Management System Based on the IOT. Intelligence Computation and Evolutionary Computation, 203-207. DOI: 10.1007/978-3-642-31656-2_30

Farhan, L., Kharel, R., Kaiwartya, O., Quiroz-Castellanos, M., Alissa, A., & Abdulsalam, M. (2018). A Concise Review on Internet of Things (IoT) -Problems, Challenges and Opportunities. 2018 11th International Symposium on Communication Systems, Networks & Digital Signal Processing (CSNDSP). DOI: 10.1109/csndsp.2018.8471762

Jagatheesaperumal, S. K., Rahouti, M., Ahmad, K., Al-Fuqaha, A., & Guizani, M. (2021). The duo of artificial intelligence and big data for industry 4.0: Applications, techniques, challenges, and future research directions. IEEE Internet of Things Journal, 9(15), 12861-12885,

Jiang, J., Yang, D., & Gao, Z. (2015). Study on Application of IOT in the Cotton Warehousing Environment. International Journal of Grid and Distributed Computing, 8(4), 91-104. DOI:

Knight Frank. (2014). India Logistics and Warehousing Report. http://content.knightfrank.com/research/677/documents/en/india-warehousing-and-logistics-report2326.pdf

Lam, K.-Y., & Chi, C.-H. (2016). Identity in the Internet-of-Things (IoT): New Challenges and Opportunities. Information and Communications Security, 18-26. DOI: 10.1007/978-3-319-50011-9_2

Lee, I., & Lee, K. (2015). The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Business Horizons, 58(4), 431-440, DOI: 10.1016/j.bushor.2015.03.008

Lim, M. K., Bahr, W., & Leung, S. C. H. (2013). RFID in the warehouse: A literature analysis (1995-2010) of its applications, benefits, challenges and future trends. International Journal of Production Economics, 145(1), 409-430. DOI: 10.1016/j.ijpe.2013.05.006

Luthra, S., Mangla, S. K., Garg, D., & Kumar, A. (2018). Internet of Things (IoT) in Agriculture Supply Chain Management: A Developing Country Perspective. Advances in Theory and Practice of Emerging Markets, 209-220. DOI:

Nižetić, S., Šolić, P., López-de-Ipiña González-de-Artaza, D., & Patrono, L. (2020). Internet of Things (IoT): Opportunities, issues and challenges towards a smart and sustainable future. Journal of Cleaner Production, 274, 122877. DOI: 10.1016/j.jclepro.2020.122877

Raja, R., & Venkatachalam, S. (2022). Adoption of Digital Technology in Global Third-Party Logistics Services Providers: A Review of Literature. FOCUS: Journal of International Business, 9(1), 105-129. DOI:

Raja, R., & Venkatachalam, S. (2023). Factors Influencing the Adoption of Digital Technology in Transportation Among Logistics Service Providers. In Blockchain Applications in Cryptocurrency for Technological Evolution (pp. 147-159). IGI Global. DOI:

Richards, G. (2017). Warehouse management: A complete guide to improving efficiency and minimizing costs in the modern warehouse. Kogan Page Publishers.

Ruthramathi, R., & Sivakumar, V. (2022). Digital technology on third-party logistics service providers in supply chain: Tamil Nadu. International Journal of Advanced Research in Commerce, Management & Social Science (IJARCMSS), 1, 73-81. https://inspirajournals.com/uploads/Issues/940306392.pdf

Ruthramathi, R., Sivakumar, V., & Saranya, P. R. (2022). Digital technology assessment of logistics and supply chain efficiency- Tamilnadu. Journal of Management & Entrepreneurship, 16(1), 22-30. https://www.researchgate.net/publication/358262924_Digital_Technology_Assessment_Of_Logistics_And_Supply_Chain_Efficiency-_Tamilnadu

Senthil, M., Ruthramathi, R., & Gayathri, N. (2020). Technology Embracing by 3PL Service Providers in India: Tuticorin Port Trust–A Case Study. International Journal of Scientific & Technology Research, 9(3), 138-144.

Sivakumar, V., & Ruthramathi, R. (2019). Challenges and features of warehousing operations with respect to logistics warehouse companies in Chennai, International Journal of Innovative Technology and Exploring Engineering (IJITEE), 9, 3304-08.

Sivakumar, V., Ruthramathi, R., & Leelapriyadharsini, S. (2020a). Internet of Things: Benefits and challenges of logistics service providers in India. International Journal of Scientific and Technology Research, 9(2), 1949-1953.

Sivakumar, V., Ruthramathi, R., & Leelapriyadharsini, S. (2020b). Challenges of Cloud Computing in Warehousing Operations with Respect to Chennai Port Trust, In Proceedings of 2020 the 3rd International Conference on Computers in Management and Business, 162-165. DOI:

Trab, S., Zouinkhi, A., Bajic, E., Abdelkrim, M. N., & Chekir, H. (2018). IoT-based risk monitoring system for safety management in warehouses. International Journal of Information and Communication Technology, 13(4), 424. DOI: 10.1504/ijict.2018.095049

TradeGecko. (2017). Inventory Management Software — TradeGecko. https://www.tradegecko.com

Tsang, Y. P., Choy, K. L., Wu, C. H., Ho, G. T. S., Lam, C. H. Y., & Koo, P. S. (2018). An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks. Industrial Management & Data Systems, 118(7), 1432-1462. DOI:

Van Geest, M., Tekinerdogan, B., & Catal, C. (2021). Smart Warehouses: Rationale, Challenges and Solution Directions. Applied Sciences, 12(1), 219. DOI:

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

06 May 2024

Article Doi

eBook ISBN

978-1-80296-132-4

Publisher

European Publisher

Volume

133

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1110

Subjects

Marketing, retaining, entrepreneurship, management, digital marketing, social entrepreneurship

Cite this article as:

Raja, R., & Venkatachalam, S. (2024). Technological Features of Warehouse Operations in Third Party Logistics Services in Tamilnadu. In A. K. Othman, M. K. B. A. Rahman, S. Noranee, N. A. R. Demong, & A. Mat (Eds.), Industry-Academia Linkages for Business Sustainability, vol 133. European Proceedings of Social and Behavioural Sciences (pp. 499-509). European Publisher. https://doi.org/10.15405/epsbs.2024.05.42