Abstract

The transition of economic systems to new business conditions related to the development of the digital economy has made it urgent to develop and introduce new approaches to the management of modernization of industrial facilities into scientific and practical activities. The article aims to systematize the critical trends of Industry 4.0 in the Russian economy and designate further trajectories of its development. The article identifies groups of crucial characteristics of enterprises of Industry 4.0: tangible and intangible resources, organizational structure, information systems, organization culture. For each group, business processes' specificity is structured concerning such functional areas as development, production, logistics, maintenance, marketing, and sales. The trends of digital transformations for macro and mesoscale economies are described. The study made it possible to systematize the structural components of Industry 4.0 by blocks: material and non-material resources, information system, organizational structure, organizational culture; of which the latter is decisive in the direction of development of other components. It was found that cooperative ties in the implementation of technological innovations, as the basis for the formation of open business models and open innovations, are not considered as a significant factor of innovative activity in industry and, accordingly, are weakly expressed Based on the analysis, the possible directions of changes in economic systems' digitalization to increase their efficiency and adaptability are identified.

Keywords: Business processdigital economyeconomic systemindustry 40micro and mesoscale management

Introduction

One of the large-scale and in-depth studies of Industry 4.0 is the acatech project of the National Academy of Sciences and Technology of Germany, which systematizes the results of studying the industrial value chain to determine the current level of readiness of industrial enterprises and national economies in general for the fourth industrial revolution, as well as identify strategic trajectories subsequent innovative development and digital transformation. According to the reports of the expert group, at the micro-level of management, the specifics of the implementation of Industry 4.0 is determined, first of all, by the organizational structure formed by four structural areas: material and intangible resources, information systems, organizational structure and organizational culture, each of which has its own stage of maturity of Industry 4.0. Noteworthy is the fact that in the acatech research methodology, significant importance in the transition to Industry 4.0 is paid to the change in corporate culture.

However, the problem of the culture of managing industry 4.0, according to the acatech experts, with which we fully agree, is dominant and decisive in the formation of the trajectories of the new industrial revolution and the transition to the technological structure of the next generation. We believe that open communication, open innovation, “turquoise” organizations are the “basis” for the rest of the structural areas of Industry 4.0, which can be characterized as a “superstructure”. It is the characteristics of the organizational culture, fixed in the form of formal and informal institutions, that will determine the specifics of material and intangible resources, information systems and organizational structure, which ultimately affects the efficiency of the industrial value chain.

Problem Statement

Industry 4.0 is a determining factor in the economic development of national economies and predetermines the trajectory of their competitiveness. In this regard, the issues of determining the key factors of Industry 4.0 become of paramount importance. We believe that the task here is reduced to the systematization of the main factors of digital transformations, taking into account their dynamics for the economic system as a whole, as well as for the meso-level of management. This technique will be tested by us on the example of the Russian economic system.

The problems of the development of Industry 4.0 are widely reflected in the works of many researchers: security and privacy in industry 4.0 (Alcaraz et al., 2020); safety digitalization (Savon et al., 2019); machine diagnostic methods applicability in the perspective of industry 4.0 (Asad et al., 2018); business intelligence (Bordeleau et al., 2019); national and regional comparative advantages in key enabling technologies (Ciffolilli & Muscio, 2018); model compression for IoT applications (Fu et al., 2020); prospects of using virtual technologies in modern corporate business systems (Klochko & Brizhak, 2019); modeling the management system of open innovation in E-economy (Kudryavtseva et al., 2018); Big Data approach (Kumar et al., 2018); digital supply chain model (Lizette Garay-Rondero et al., 2019); digitization and industry 4.0 optimization potential (Wirth & Klein, 2018); deep learning model in industry 4.0 (Ma et al., 2020); data science challenges (Piccialli et al., 2020); modelling of energy efficiency factors of petrochemical industry (Shinkevich et al., 2020); smart job shop under industry 4.0 (Wang et al., 2020); the impacts of industry 4.0 (Zheng et al., 2019) and ext.

However, insufficient attention is paid to the issues of modeling the key components of Industry 4.0, which predetermined the choice of the research topic, the setting of goals and objectives..

Research Questions

In the course of the research, we posed the following questions:

1) the formation of key components of Industry 4.0, their system characteristics;

2) determination of the main trends of Industry 4.0 at the macro and meso-level of management according to the statistic indicators used, the structuring of which based on the method of principal components and factor analysis will allow determining the trajectories of modernization transformations for economic systems that can be used in programs and projects for the digitalization of sectors of the economy and their increase competitiveness.

Purpose of the Study

The purpose of the article is to systematize scientific approaches to determining the structural components of Industry 4.0 and their description in relation to Russian industry. The set of research objectives includes:

presentation of structural areas of the level of development of industry 4.0;

description of the characteristics of the structural components of Industry 4.0;

identifying trends in technological development and cooperation ties in the Russian industry in the development of Industry 4.0;

identification of critical factors of the digitalization of the economy at the meso-level of management.

Research Methods

The following research methods are used in the article.

1) a description method that allows describing the structural components of Industry 4.0;

2) the method of dynamic analysis, which makes it possible to determine the main trends in the development of Industry 4.0 according to the dynamic series of statistical indicators;

3) the method of principal components - to determine the number of factors into which the set of statistical indicators of the digitalization of the economy at the meso-level can be divided;

4) the method of factor analysis, which makes it possible to include indicators of the digitalization of mesoeconomics into factors in terms of their level of influence on the trends of digitalization of the economic system.

The time series for building models included shows from 2003-2018. The tool for the analysis was the software product Statistica.

Findings

The systematization of national approaches made it possible to identify 4 structural areas of Industry 4.0 and to characterize them.

1) Tangible and intangible resources include components such as: ensuring digital competencies, automated data acquisition by means of sensors and activators, decentralized (preliminary) data processing, effective communication, task-based interface;

2) Information Systems: data analysis and data management, contextualized data delivery, dedicated user interface, resilient it infrastructure, horizontal and vertical integration, it security;

3) Organizational Structure: agile communities and agile governance, focus on customer benefits, collaboration within the network, motivational systems of decision goals, management of the rights to make management decisions;

4) Organizational Culture: open communication, openness to innovation, confidence in processes and information systems, recognizing the benefits of mistakes, continuous professional growth, shaping change.

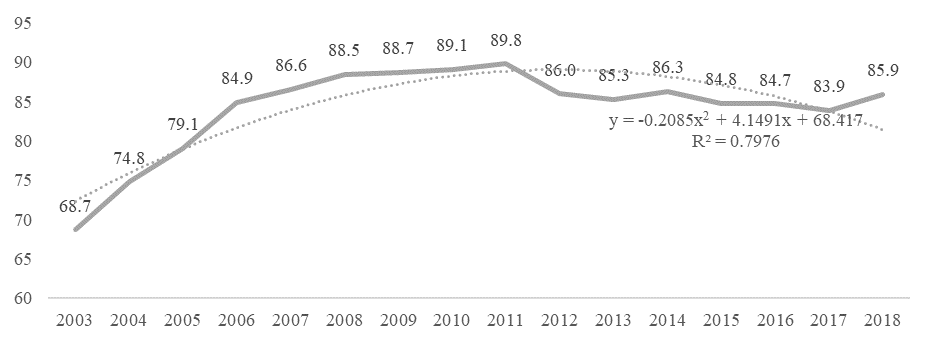

Based on the designated goals and objectives of the study, we proposed to analyze the dynamics of the use of special software that characterize the trends in the spread of digitalization in macro and mesoeconomic systems. Thus, the share of organizations using special software increased from 68.7% in 2003 to 85.9% in 2018. The increase was 17.2 percentage points (Figure

We believe that the level of development of the organizational culture of Industry 4.0 in the Russian economy can be assessed using the indicator of cooperative ties in organizations carrying out technological innovations. The implementation of new forms of strategic alliances, partnerships and other cooperative ties with product consumers, suppliers, Russian and foreign manufacturers was noted in 21.8% of industrial enterprises, of which in the high-tech industry - 36.1%, medium-tech high-level - 25%, medium-tech low level - 30.2%, low-tech - 15%.

The most typical form of cooperation in the Russian industry is cooperation within the framework of a project - it was indicated by 78% of organizations that carried out technological innovations and participated in joint research and development projects; constant cooperation is typical for 41.8% of organizations; one-time, informal cooperation not related to a specific project - 10.2%. It should be noted that at Russian industrial enterprises the lack of cooperative ties is not considered as a factor hindering innovation, its rating in the survey of innovatively active economic entities was 1.4 in 2017, the same as in 2010. At the same time, the most significant inhibitors are the lack of own funds - 2.2 (in 2010 - 2.3); high cost of innovations - 2.1 (2.2); high economic risk - 2 (2), which allows us to draw a conclusion about the importance, first of all, of the financial component of innovation and production and technological activities in Russian industrial companies, while the issues of corporate cooperation in the framework of open business models and open innovations as the basis of the industry 4.0, with their low values they are still in secondary positions.

To assess the three remaining components of Industry 4.0 – tangible and intangible resources, information systems and organizational structure we will use indicators of the digitalization of the economy.

The most actively used are such special software tools for making financial settlements in electronic form - 56.4%, for solving organizational, managerial and economic problems - 54.9%, electronic reference and legal systems - 53.2%.

To carry out the simulation, we introduce the following designations for the special software used:

to solve organizational, managerial and economic problems – Х1, for making financial settlements in electronic form – Х2, electronic legal reference system – Х3, to manage purchases of goods (works, services) – Х4, to manage sales of goods (works, services) – Х5, to provide access to databases through global information networks – Х6, training programs – Х7, for the management of automated production and / or individual technical means and technological processes – Х8, for design – Х9, editorial and publishing systems – Х10, CRM, ERP, SCM – systems – Х11, for scientific research – Х12, others – Х13.

At the first stage of modeling using the principal component method, it was established on the basis of the eigenvalues of indicators that the most rational is to divide the set of indicators into 2 groups of integral factors characterizing the level of digitalization of the mesoeconomic system and their impact on the trends of digital transformations in the macroeconomic system as a whole, since their eigenvalues are greater than 1. The results of the principal component analysis are presented in Table

Further, at the second stage of modeling, the digitalization indicators were grouped into two groups of integral factors (Table

So, the first factor most influencing the level of digitalization of the economic system includes such indicators as: special software to manage purchases of goods (works, services) – Х4; to manage sales of goods (works, services) – Х5; to provide access to databases through global information networks – Х6; for design – Х9. This factor is conventionally named by us as product design and marketing. In general, its influence on the level of digitalization of the macroeconomic system is 39.8%.

The second most important factor in the digitalization of the economy includes indicators such as: special software to solve organizational, managerial and economic problems – Х1; for making financial settlements in electronic form – Х2; training programs – Х7; others – Х13. It is conventionally designated by us as cash flow and personnel management. In general, it accounts for 33.8% of changes in the level of digitalization of the economic system. Thus, 2 integral factors together explain 73.6% of the trends in the digitalization of the economic system, taking into account the achievements of Industry 4.0.

Conclusion

Thus, the study made it possible to systematize the structural components of Industry 4.0 by blocks: material and non-material resources, information system, organizational structure, organizational culture; of which the latter is decisive in the direction of development of other components. It was found that cooperative ties in the implementation of technological innovations, as the basis for the formation of open business models and open innovations, are not considered as a significant factor of innovative activity in industry and, accordingly, are weakly expressed. In the process of modeling, it was found that the primary importance for the development of digitalization of the economy is characterized by indicators that describe the design and marketing of a product, as well as cash flow and personnel management. We believe that this article will serve as a source for further scientific and theoretical study of the phenomenon of Industry 4.0 for the subsequent improvement of tools for managing the innovative economy in the face of new technological challenges.

Acknowledgments

The reported study was funded by RFBR, project number 20-010-00655

References

- Alcaraz, C., Zhang, Y., & Cardenas, A. (2020). Special section on security and privacy in industry 4.0. Ieee transactions on industrial informatics, 16(10), 6530-6531.

- Asad, B., Vaimann, T., & Rassolkin, A. (2018). Review of electrical machine diagnostic methods applicability in the perspective of industry 4.0. Electrical control and communication engineering, 14(2), 108-116.

- Bordeleau, F., Mosconi, E., & de Santa-Eulalia, L. (2019). Business intelligence and analytics value creation in industry 4.0: a multiple case study in manufacturing medium enterprises. Production planning & control, 31(2-3), 173-185.

- Ciffolilli, A., & Muscio, A. (2018). Industry 4.0: national and regional comparative advantages in key enabling technologies. European planning studies, 26(12), 2323-2343.

- Fu, Sh., Li, Zh., & Liu, K. (2020). Model compression for iot applications in industry 4.0 via multiscale knowledge transfer. Ieee transactions on industrial informatics, 16(9), 6013-6022.

- Klochko, E., & Brizhak, O. (2019). Prospects of using virtual technologies in modern corporate business systems. Advances in Intelligent systems and computing, 726, 308-319.

- Kudryavtseva S., Galimulina F., Zaraychenko, I., & Barsegyan, N. (2018). Modeling the management system of open innovation in the transition to e-economy. Modern journal of language teaching methods, 8(10), 163-171.

- Kumar, R., Singh, S., & Lamba, K. (2018). Sustainable robust layout using Big Data approach: a key towards industry 4.0. Journal of cleaner production, 204, 643-659.

- Lizette Garay-Rondero, C., Luis Martinez-Flores, J., & Smith, N. (2019). Digital supply chain model in Industry 4.0. Journal of manufacturing technology management. https://www.emerald.com/insight/content/doi/10.1108/JMTM-08-2018-0280/full/pdf?title=digital-supply-chain-model-in-industry-40

- Ma, L., Wu, J., & Zhang, J. (2020). Research on sea clutter reflectivity using deep learning model in industry 4.0. Ieee transactions on industrial informatics, 16(9), 5929-5937.

- Piccialli, F., Bessis, N., & Jung, J. (2020). Data science challenges in industry 4.0. Ieee transactions on industrial informatics, 16(9), 5924-5928.

- Savon, D. Y., Aleksakhin, A. V., Skryabin, O. O., & Goodilin, A. A. (2019). Occupational health and safety digitalization in the coal industry. Eurasian mining, 2(32), 70-72.

- Shinkevich, A., Kudryavtseva, S., & Ershova, I. (2020). Modelling of energy efficiency factors of petrochemical industry. International journal of energy economics and policy, 10(3), 465-470.

- Wang, Ch., Zhou, G., & Zhu, Zh. (2020). Service perspective based production control system for smart job shop under industry 4.0. Robotics and computer-integrated manufacturing, 65.

- Wirth, A., & Klein, J. (2018). Digitization and industry 4.0 optimization potential in the value chain & priorities of the industry. Wochenblatt fur papierfabrikation, 146(12), 718-721.

- Zheng, T., Ardolino, M., & Bacchetti, A. (2019). The impacts of industry 4.0: a descriptive survey in the Italian manufacturing sector. Journal of manufacturing technology management. https://www.emerald.com/insight/content/doi/

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

16 April 2021

Article Doi

eBook ISBN

978-1-80296-104-1

Publisher

European Publisher

Volume

105

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1250

Subjects

Sustainable Development, Socio-Economic Systems, Competitiveness, Economy of Region, Human Development

Cite this article as:

Kudryavtseva, S., Shinkevich, M., & Ostanina, S. (2021). To The Question Of Assessing The Maturity Level Of Industry 4.0. In E. Popov, V. Barkhatov, V. D. Pham, & D. Pletnev (Eds.), Competitiveness and the Development of Socio-Economic Systems, vol 105. European Proceedings of Social and Behavioural Sciences (pp. 593-600). European Publisher. https://doi.org/10.15405/epsbs.2021.04.63