Abstract

Studied in the article the impact of digitalization on the efficiency of technological processes of modern production. The research was carried out at a specific enterprise that produces meat products. It turned out that despite the fact that many enterprises currently use modern technological lines with a high degree of automation, they still distrust the digital counterparts of production processes. Creating a digital double of a production line, although it requires specific applied knowledge, is not an impossible task. The next stage of digitalization is the simulation of processes that allows you to identify the time and material resources used, as welll as fixed costs. Conducted basic, semi-automated and automated modeling options. Research has showen that emi-auttomated systems can come close to automated ones in terms of theur capabilities, thereby ensuring an increase in labor productivity and laying the foundation for further development in the form of accumulated data and highly efficient processes.

Keywords: Digitalization, industry 40, modeling, quality, sausages

Introduction

Providing the population of the Russian Federation with safe food is an important component of the national program, as evidenced by the Decree of the President of the Russian Federation of January 21, 2020 No. 20 “On Approval of the Food Security Doctrine of the Russian Federation”.

Also, on December 9, 2011, the Commission of the Customs Union adopted Decision No. 880 on the approval of the Technical Regulations of the Customs Union "On Food Safety". This means that all enterprises engaged in the production of food products are required to develop, implement and maintain procedures in the organization based on the principles of HACCP. Food enterprises fulfill the requirements of the legislation in several ways: development of the HACCP system in accordance with the requirements of GOST R 51705.1-2001 “Quality systems. Food quality management based on HACCP principles. General requirements”, as well as the development of a food safety management system in accordance with the requirements of GOST R ISO 22000-2019 “Food safety management systems. Requirements for organizations involved in the food production chain. On the other hand, it is necessary to take into account the requirements for the quality of food products imposed by consumers and the current trend towards the development of food technology, characterized not only by quality, but also by useful properties, therefore, many enterprises integrate management systems, food safety management systems in accordance with with the requirements of GOST R ISO 22000-2019 and a quality management system in accordance with the requirements of GOST R ISO 9001-2015, which allows enterprises to obtain additional economic benefits (Leonov & Shkaruba 2019b).

Problem Statement

Many enterprises understand the introduction of a food safety system in production only as the development of the necessary documentation, which will be submitted for verification by Rospotrebnadzor (Akhmetova et al., 2019).

Not all enterprises seek to implement the HACCP system, first of all, this applies to small food enterprises and public catering enterprises. The main reasons for the unwillingness of enterprises to work on a food safety system are material costs, this is filling in the necessary documentation, which requires additional time, the lack of competent personnel able to explain the principles of work in the conditions of innovation (Dunchenko et al., 2018). Staff training is a key step after the development of documentation. The most important thing is that everyone, from an ordinary employee to top management, should be aware of the HACCP system and its principles. Personnel must know and follow all rules and regulations. It should be borne in mind that training can take place both with the involvement of external specialists, and on its own. The main thing is that the staff should know what HACCP is, why it is being implemented, how to carry out the developed procedures, critical control points of production, how to correct errors (corrective actions), what and how to control, understand and know the possible risks for the consumer (Leonov & Shkaruba, 2021).

An example of this can be scientific developments in meat production, where special attention is paid to the analysis of the quality of the control process and metrological support.

Sausage products are popular and occupy one of the leading places in the structure of the population's nutrition. This is due to the high nutritional value, calorie content, as well as consumer advantages, do not require cooking or long-term heat treatment. Based on this, it follows that ensuring the safety of these products is a paramount task.

The main raw material for the production of boiled sausages, frankfurters and sausages is beef, pork and pork fat. According to the thermal state, meat is used both in chilled and frozen form. The use of multifunctional additives, including in its composition: phosphates, thickeners, color stabilizers, etc., allows obtaining products with improved consistency, with good organoleptic properties and increasing the yield of finished products.

The main processes for the production of boiled sausages are: deboning of cuts (consists in determining the meat from the bones), meat trimming (separation of cartilage and tendons from muscle tissue), meat sorting (separation of trimmed meat into grades depending on the content of connective and fatty tissues in it), preliminary grinding and salting of meat, preparation of bacon, secondary grinding, preparation of minced meat in accordance with the recipe, filling of casings, heat treatment (roasting), cooking and cooling.

However, in case of violation of technological processes or in case of non-compliance with temperature regimes during storage, defects appear in sausage products, presented in Table 1.

Manufacturers are responsible for producing safe and quality products. Therefore, enterprises, in conditions of fierce competition, strive to produce products that meet the requirements of regulatory documents, meet consumer demand, and maximize profits. To this end, it is necessary to reduce their costs associated with the occurrence of defective products, the main reason, which is often the human factor, leading to non-compliance with technological production modes.

Research Questions

To optimize the costs of developing HACCP and digital twins, it is advisable to carry out programs in the BPM environment that allow not only creating processes and updating them based on accepted security standards, but also modeling various situations.

When choosing a program of this type, it is necessary to be guided not only by the ability to build graphical models, but also by the supported notations, the possibility of modeling the process and integration with ERP systems. These actions can be considered the initial stage on the way to the digitalization of production.

At the same time, the creation of a digital twin of a production line, although it requires specific applied knowledge, is not an impossible task, especially for quality management specialists.

Purpose of the Study

The influence of digital technologies on the efficiency of technological processes in the meat processing industry.

Research Methods

Quality control of products at the enterprise during production is carried out at control points, the most important of them are called critical. In them, hazards can exceed acceptable risk values, thereby leading to the production of unsafe products and serious consequences for consumers. For the production of cooked sausages, they are:

Control of the heat treatment mode

Control of the aftercooling mode

Residual oxygen control

An important stage in the development and implementation of the HACCP system is the determination of the limits of controlled parameters at critical control points and the creation of a system for their monitoring (Leonov et al., 2020). For each critical control point (CCP), a worksheet is developed that includes information about the process step, the hazard, the source of the hazard, controlled parameters, critical limits, the person responsible for monitoring this CCP, corrective actions and a document that records the fact of control. The set of worksheets is called the HACCP plan. An important point in creating a food safety system is not only the creation of the system itself, but also its maintenance in working order, the constant updating of the documentation system.

Findings

As an example, a control critical point is chosen at the stage of the heat treatment mode of the production process.

Despite the use of modern technological lines with a high degree of automation, enterprises are distrustful of digital twins of production processes, preferring to keep documentation in tabular text form, which is sometimes supplemented with flowcharts.

With this method of description, the production process turns out to be static; it is difficult to correct it in real time. Suppose that in our CCP there was a serious temperature deviation from the specified parameter, it is planned to carry out repairs that can last for a long time, while the process is stable on the neighboring line, which raises the question of the possibility of using the equipment of the neighboring line, and it is necessary to carry out not only a comparison of heat treatment modes but to analyze its loading, and in cases of a positive decision to restructure the technological process under new conditions without compromising the quality of products. When using a static system, changing data may not even be considered because they will require a lot of time and may no longer be relevant at the end of development, while if the processes were digitized in advance, then the change can be carried out in a few hours, including simulation modeling of the rebuilt processes.

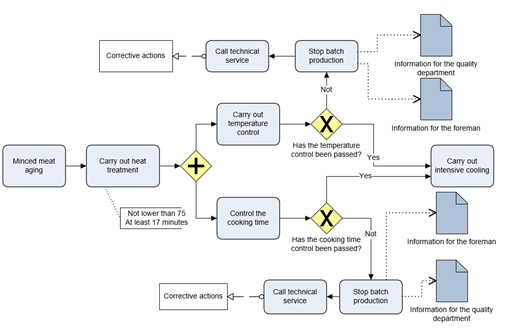

Using specialized software, we built a part of the technological process that is directly related to CCP in BPMN notation (Figure 1)

When using this block diagram, the perception of the parameters of the technological process by the personnel is increased, which makes it possible to convey information as accessible as possible during training, increasing its comprehensibility, and in case of emergency situations, it will increase the reaction speed. This construction requires a detailed study of the process under consideration, since the correctness of further steps in the digitalization of production will depend on this stage. The next stage of digitalization can be considered a simulation of processes that allows you to identify the time and material resources used, as well as fixed costs.

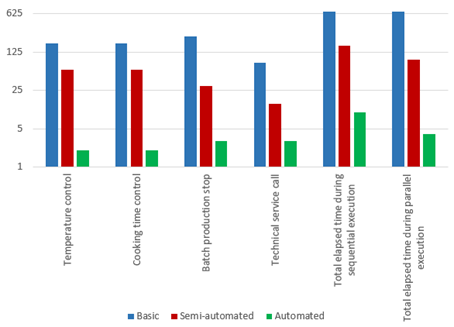

At present, the leaders of processing enterprises believe that digitalization can be useful only with a fully automated process in which the human factor is practically excluded. Therefore, we chose the following options for modeling:

Basic - this option uses static processes; control is carried out by the technologist according to worksheets with the display of the entire process in the form of a block diagram.

Semi-automated - the process is controlled by a technologist according to a model built in BPMN notation.

Automated - the process is controlled by the equipment according to the loaded BPMN model.

The initial data for our simulation were taken from real production, which consistently applied various control methods. Initially, the simulation is carried out for a stable process i.e. without taking into account the costs of corrective actions associated with the appearance of rejected products (Figure 2).

As a result of modeling various types of control of the considered part of the process, the greatest time costs are associated with the human factor, at the same time, it is the delay at these stages that can lead to both significant financial losses and negative consequences associated with risks to the health of the consumer.

Not one production process can be defect-free, therefore, rejected products arise, and therefore the digital model must also provide for corrective actions. Table 2 shows the percentage of rejected products and the time spent on corrective actions.

At the same time, it should be noted that semi-automated systems are primarily aimed at preventing the occurrence of deviations; therefore, it is possible to reduce the percentage of rejects in a timely manner as part of scheduled maintenance and achieve indicators comparable to fully automated systems (Leonov & Shkaruba, 2019a).

Over the past decades, many industries have been actively developing and investing in digital technologies in order to reduce costs and generate profits (Leonov & Shkaruba, 2020). And if, until recently, IT technologies were used mainly in the field of personnel and financial management, now digital technologies are used in the design, production and maintenance of products to optimize processes, reduce costs and produce defective products (Erohin et al., 2019a). But the introduction of digital technologies requires a certain level of knowledge from technologists, which is not enough in the labor market (Erohin et al., 2019b). Therefore, it is necessary to introduce the most automated technologies for conducting business processes.

Conclusion

Currently, a steady trend has been formed for the digitalization of all areas of activity, including in production (industry 4.0), while there is an opinion that this is a complex and expensive process, the benefits from which can only be obtained in the distant future, when a large amount of data has been accumulated and only with the presence of expensive equipment, but even without serious investments, following an evolutionary path, you can significantly approach the desired results. As can be seen from our research, it is advisable to start with existing developments, create digital copies of the HACCP system processes, as a result of which we can already reduce labor intensity, and direct the freed time of employees to improve production technology. It is also worth noting that semi-automated systems, with proper development of processes, can come close in their capabilities to automated ones, thereby ensuring an increase in enterprise productivity and laying the foundation for further development in the form of accumulated data and highly efficient processes.

References

Akhmetova, S. O., Suleimenova, M. S., & Rebezov, M. B. (2019). Mechanism of an improvement of business processes management system for food production: Case of meat products enterprise. Entrepreneurship and Sustainability Issues, 7(2), 1015-1035. DOI:

Dunchenko, N. I., Voloshina, E. S., Kuptsova, S. V., Cherkasova, E. I., Sychev, R. V., & Keener K. (2018). Complex estimation of effectiveness of quality system processes at food industry enterprises. Foods and Raw Materials, 6(1), 182-190. DOI:

Erohin, M. N., Leonov, O. A., Shkaruba, N. Zh, Amelin, S. S., & Bodunov, D. M. (2019b). Application of Dimensional Analysis for Calculating the Total Misalignment between a Seal and a Shaft. Journal of machinery manufacture and reliability, 50(6), 524-529. DOI:

Erohin, M., Leonov, O., Kataev, U., & Vergazova, U. (2019a). Calculation of fits for cylindrical connections with key for reducers in agricultural machinery 18th international scientific conference engineering for rural development. Book SeriesEngineering for Rural Development, 18(014), 469-474. DOI:

Leonov, O. A., & Shkaruba, N. Zh. (2019a). A Parametric Failure Model for the Calculation of the Fit Tolerance of Joints with Clearance. Journal of friction and wear, 40(4), 332-336. DOI:

Leonov, O. A., & Shkaruba, N. Zh. (2019b). Elements of the HACCP system in the production of cooked-smoked sausages. Food industry: science and technology, 2(40), 44-52. https://foodindustry.belal.by/jour/article/view/328/326

Leonov, O. A., & Shkaruba, N. Zh. (2020). Calculation of Fit Tolerance by the Parametric Joint Failure Model. Journal of machinery manufacture and reliability, 49(12), 1027-1032. DOI:

Leonov, O. A., & Shkaruba, N. Zh. (2021). Quality and safety monitoring production of boiled-smoked sausages. IOP Conference Series: Earth and Environmental Science, 22089. DOI:

Leonov, O. A., Shkaruba N. Zh., Cherkasova, E. I., & Odintsova, A. A. (2020). Quality assessment of temperature measurements in incoming inspection of raw meat. JOP Conference Series: Metrological Support of Innovative Technologies, 32030. DOI:

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

29 August 2022

Article Doi

eBook ISBN

978-1-80296-126-3

Publisher

European Publisher

Volume

127

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-496

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Cherkasova, E., Golinitskiy, P., Vergazova, J., Antonova, U., & Toygambaev, S. (2022). Digital Transformation In The Meat Processing Industry. In I. Kovalev, & A. Voroshilova (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-III 2022), vol 127. European Proceedings of Social and Behavioural Sciences (pp. 21-28). European Publisher. https://doi.org/10.15405/epsbs.2022.08.4