Abstract

The rationale for the choice of optimal solutions for efficient variant of sugar beet harvesting technology alternative is suggested. Harrington's function for the formation of desirability scales and weight coefficients of particular evaluation indicators of technology when calculating a generalized complex criterion for its evaluation, the maximum value of which determines the best option, has been modernized. Thus, variants of cleaning sugar beet harvesting by different ways technology (one- or two-phase, with transfer to field or without clamps it) and beet harvesting machinery with its co-ma-economic indicators are compared. The dependences of the conversion of the estimated indicators of beet harvesters with the actual values according to the results of production tests into dimensionless ones for the y' scale were obtained, according to which the Harrington desirability function is calculated, and then a generalized criterion for a comprehensive assessment of beet harvesters and an analysis of the influence of the weight coefficients of the estimated indicators on the calculation results. Based on studies an effective alternative cleaning technologies of sugar beet self-propelled combines WKM-9000 of the six studied harvesters has been established. Generalized evaluation criterion complex cleaning technologies said harvester has a maximum value tends to unity, which amounted to 0.925 when calculating the weighting coefficients with performance indicators and 0.711 - without them. The directions of improving harvesters having substantially inferior to the best embodiment of the generalized estimation criterion are given.

Keywords: Efficiency, costs, yield, sugar beet, harvesting technology

Introduction

All other things being equal, favourable opportunities for the efficient production of factory sugar beet in the beet-growing farms of the Krasnodar Territory are constrained by the correct choice of the most effective root harvesting technology. The latter is determined by the quality of harvesting, the timing of its implementation and costs, which mainly depends on the harvesting equipment. When justifying a complex of harvesting machines, specialists take into account many factors, including organizational, weather, financial, the condition of the harvested batwa, etc. Harvesting equipment is also differently adapted to the prevailing harvesting conditions. At present, a reliable market for modern beet-harvesting equipment has developed in the world practice. Known combines produced in Germany (HOLMER, SF-10, Stoll), Holland (WKM-9000), France (Moro-lektra), in the Republic of Belarus (sugar beet harvester for the UES-280 power unit: root digger KSN-6- 2 m and pick-up PPK-6), in Ukraine (complexes based on KS-6 and RKS-6 combines: with a BM-6 haulm harvester), in the USA (WIC complex with a haulm and root digger).

Problem Statement

Specialists always have a difficult task deciding which of the complexes to give preference to. To make the right decision, it would be logical to propose a system of estimated indicators for each machine, but, unfortunately, none of them gives such a result when, without exception, the estimated indicators of the selected machine have advantages over alternative ones: always some of them are better, others worse. We have proposed a method for selecting the best beet harvester from those compared using the modernized Harrington function (Harrington, 1965). To make a decision, the method of expert assessments (Nagirny, 1990), experimental design (Adler et al., 1976; Melnikov et al., 1980), etc. (Elizarov & Pilyugin, 1985; Kantorovich & Goretko, 1972; Zapalev, 1998).

Research Questions

Our research envisaged modernizing the Harrington function in relation to the task at hand, substantiating an effective version of the sugar beet harvesting technology from among the alternatives. The modernization provided for the exclusion of expert assessment, as not very effective, to justify desirability scales, methodological issues of converting the values of the estimated indicators of machines into dimensionless ones on the Harrington y' scale, the graphic construction of this translation before calculating the desirability function. The calculation of the last and generalized indicator of a comprehensive assessment of options is carried out using a well-known method.

Purpose of the Study

The aim of the study is to substantiate, using the modernized Harrington function, an effective version of the technology for harvesting sugar beets from alternative ones.

Research Methods

The studies used methods of generalization of the results of production testing of beet-harvesting machines in beet-growing farms of the Krasnodar Territory, the results of tests of beet-harvesters at the Kuban Machine Testing Station (2006), as well as the results of our own research on the modernization of the Harrington function. As an assessment criterion for the best option for making a decision, a generalized indicator of a comprehensive assessment was adopted, calculated as the geometric mean of particular indicators, taking into account their weight (1):

(1)

where: – generalized indicator of a comprehensive assessment of the machine; – the desirability of each estimate of the machine; – the weighting factor of each estimated indicator.

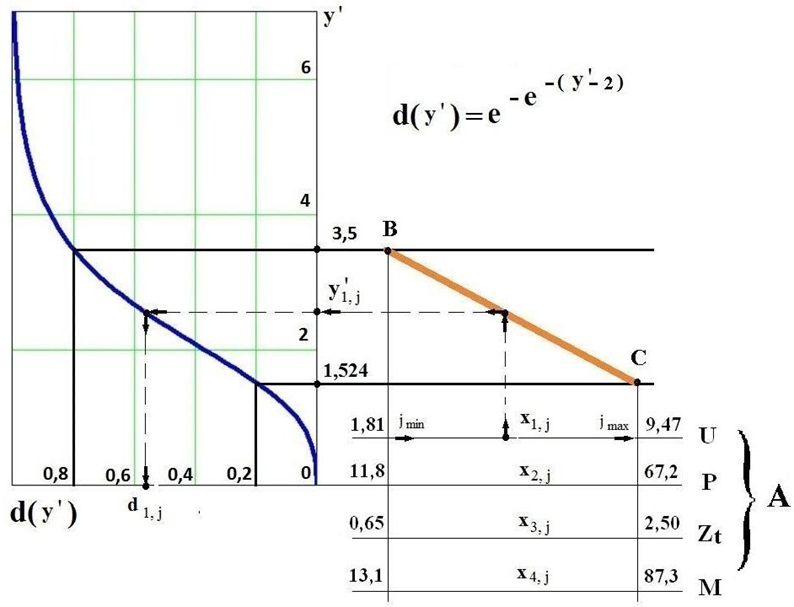

A new approach in the proposed methodology when calculating formula (1) is the absence of expert judgment to determine the weight of each estimated indicator, and its automatic determination in a graphical way using actual data from the test results of compared machines. The compared machines, estimated indicators, their weight coefficients and generalized indicators Di of the complex assessment are given in Table 1. The sequence of graphical construction of desirability scales and boundary values of estimated indicators is shown in Figure 1.

The results of the analysis of the compared machines according to their estimated indicators are presented in Table 1. Calculations of the criterion Di were performed in two versions: taking into account the weight coefficients and without them. Considering that modern sugar refineries are equipped with reliable high-performance equipment and process roots in a short time, it is possible to participate in the analysis of alternative combine designs that allow a high percentage of root damage, i.e. damaged roots do not retain their technological properties for a long time. Poor-quality cleaning of the roots from the ground by the working bodies of the combines also affects the purchase price of raw materials. These factors must be considered when deciding on the best design.

Judging by Table 1, the highest value of the generalized criterion for the integrated assessment of Di beet harvesters was obtained for the brand WKM-9000 (Holland). Taking into account the weight of the value was 0.925 for this brand (Table 1), and without Di = 0.711. In both cases, this is the maximum value of the criterion Di in comparison with other beet harvesters, in connection with which the WKM-9000 harvester should be preferred. The minimum value of criterion D is observed for the Stoll combine (Table 1), respectively, 0.720 and 0.273, as a result of which it was in last place. The HOLMER and SF-10 harvesters are similar in terms of the complex criterion (Table 1). The French Moro-Lektra combine and the WIC Complex (USA), taking into account the weight coefficient, take the fourth place (Table 1), and without weight, the French combine is more preferable (0.565 versus 0.482, Table 1).

To explain the reason for the low values of the criteria and Di (Table 1) for the variants of combines, let us analyze the values of their estimated indicators (Table 2).

Judging by Table 2, none of the j-th estimated indicators based on the results of production tests (2006) for the Stoll beet harvester has no advantages over the WKM-9000 harvester, and only in terms of labor costs Zt, the value for the Stoll harvester is lower than the highest in the interval (2.5 people-h/ha).

The best WKM-9000 harvester out of the intervals of the estimated indicators given in Table 1, only for one of them - damage to roots during harvesting (P = 11.8%) has a minimum value, and for all the rest - intermediate and nevertheless comprehensive assessment, received preference. The minimum damage and loss of root crops is ensured by the WKM-9000 harvester due to the rational design of the diggers. In addition, the WKM-9000 combine in one pass performs the entire range of technological operations for harvesting tops and root crops, ensuring the flow of harvesting sugar beets, a rational wheel track provides less soil compaction. The disadvantage of the combine is that it requires oils not produced in Russia for the engine, transmission and hydraulic system. According to the results of a production test (2006), the WKM-9000 self-propelled beet harvester is the most efficient for the conditions of the Kuban.

The quality of the compared beet harvesters is also determined by the amount of losses of root crops during harvesting. According to production tests of combines (2006), the value of losses as a percentage of the harvest was by car brands:

- WKM-9000-1.8

- HOLMER-1.7

- SF-10-1.47

- Stoll-4.4

- Moro-Lektra-33.0

- WIC-7.2

In the current conditions for harvesting beets, the best quality indicators were obtained for the brands of combines WKM-9000, HOLMER, SF-10. Other brands of machines did not fulfill the agricultural requirements for the amount of root crop losses, especially the Moro-Lektra combine, which did not have an automatic row guidance and due to design flaws in the excavating working bodies.

The minimum labour costs during testing of combines (2006) were ensured by inline harvesting with Moro-Lektra, WKM-9000, HOLMER, SF-10 combines. When using a Stoll combine, labor costs are 2.0-2.9 times higher, which is explained by its low productivity.

When using self-propelled harvesters, the direct operating costs ranged from 3.74 thousand rubles/ha (WKM-9000) to 4.74 thousand rubles/ha (HOLMER), which significantly exceeds their value compared to the two-phase harvesting technology. trailed WIC complex (1.96 thousand rubles/ha).

As a result of our research, we have obtained dependencies for converting the numerical values of all estimated indicators with their units of measurement into dimensionless ones on the y’ scale (Figure 1):

- for the operating costs of the beet harvesters (y1'):

(2)

where: – any natural value of operating costs on the U scale (in Figure 1 A);

- for the amount of damage to root crops by the working bodies of the combines (y2'):

(3)

where: – any natural value of the magnitude of damage to root crops on the P scale (Figure 1 A);

- for labor costs for the operation of combines (y3'):

(4)

where: – any natural value of labor costs on the Zt scale (Figure 1 A);

- for the metal consumption of the beet harvesting process with various combines (y4'):

(5)

where: – any natural value of metal consumption on the M scale (Figure 1 A).

After converting the values of the j-th estimated indicators to the dimensionless scale y ’find the value of their desirability d according to the Harrington functions:

(6)

In this case, all the boundary values of the indicators are determined by the graphical construction of the straight line BC (Fig. 1), on which point B corresponds to the maximum desirability (d = 0.8 in Figure 1), and point C corresponds to the minimum (d = 0.2 Figure 1). All intermediate values of the estimated indicators calculated by the formulas (1-4) are converted into dimensionless values on the y' scale, then used to calculate the desirability function (5) and then to calculate the generalized criterion Di for the integrated assessment of the combine (1). To determine the weighting coefficient of each estimated indicator, a matrix of their paired comparison is proposed (Table 3).

The weighting factors of theestimated indicators are shown in Table 4.

As follows from Table 4, the greatest value has the coefficient of weighting of the indicator of operating costs for the process of harvesting sugar beet (k1 = 0.44), then comes the indicator of root damage by combines (k2 = 0.31), then labor costs (k3 = 0.18) and metal consumption of the cleaning process (k4 = 0.07).

The desirability of the j-th estimated indicators was determined by the formula (2 - 5) and presented in Table 5.

Judging by the data in Table 5, the beet harvester WKM-9000 (Holland) has a clear advantage in terms of the estimated indicators and on average for them. All other studied machines were inferior to him: not significantly HOLMER and SF-10, more significantly Moro-Lektra and WIC and clearly inferior in quality to Stoll.

The arithmetic mean of the estimated indicators (Table 5) also differs insignificantly from the values of the generalized criterion Di for the integrated assessment of combines, calculated without taking into account their weight coefficients . Taking into account the coefficients of the weight of the estimated indicators (Table 1), the generalized criterion for the complex assessment of beet harvesters showed a significant difference in the quality of the machines only with the Stoll combine ( = 0.72 Table 1).

It should be noted the distinctive features of calculating the criteria Di, taking into account the weight coefficients of the estimated indicators and without them. The criteria, taking into account the weight, are somewhat overestimated: half of the studied beet harvesters are in the zone of the Harrington function "good" (Stoll, WIC, Moro-Lektra), and half (HOLMER, SF-10, WMK-9000) - in the zone of "excellent ". On the contrary, when calculating the generalized criteria for the integrated assessment of Di harvesters without taking weight factors into account, only three brands of beet harvesters (HOLMER, SF-10 and WKM-9000) are in the "good" zone, two (WIC and Moro-Lektra) are "satisfactory" and one (Stoll) - "unsatisfactory". Thus, taking into account the requirements of science and production, we substantiated an effective version of the technology for harvesting sugar beet based on the WKM-9000 combine.

Findings

The modernization of the Harrington function in the direction of constructing desirability scales in the range of 0.2–1.0 without subjective expert assessment according to the estimatedindicators obtained as a result of production tests of machines made it possible to substantiate the most effective version of the sugar beet harvesting technology based on the WKM- 9000. The weighting coefficient of each indicator is determined by the sum of points obtained by the method of paired comparison of indicators. The dependences of the conversion of the estimated indicators of beet harvesters into dimensionless ones for conversion to the y´ scale and further calculation of the desirability function and the generalized criterion for the comprehensive assessment of the best option have been obtained.

Conclusion

As a result of the studies performed on the choice of the best option for the harvesting technology of sugar beet and combines for its implementation, the analysis of the compared self-propelled beet harvesters and the WIC semi-trailer complex according to the generalized criterion for the complex assessment of the indicators and without taking into account the coefficients, the self-propelled combine WKM-9000 (Holland) was preferred. The values of the generalized criterion for evaluating combines Di, calculated taking into account the coefficients of the weight of the estimated indicators, are located in the zone of desirability of the Harrington function "excellent" and only one Stoll machine is in the zone "good", while when calculating them without taking into account the weight of the criteria were located in the following zones:

- “good” (WKM-9000, HOLMER and SF-10 combines);

- “satisfactory” (Moro-Lektra combine, WIC complex);

“unsatisfactory” (Stoll combine).

References

Adler, Yu. P., Makarova, E. V., & Granovsky, Yu. V. (1976). Planning an experiment to find optimal solutions. Nauka.

Elizarov, V. P., & Pilyugin, L. M. (1985). Improving the methodology for developing a system of machines. Problems of agricultural mechanization. Production, 23-25.

Harrington, E. (1965). The desirability function. Jndustrial Quality control, 21, 10.

Kantorovich, L. V., & Goretko, A. B. (1972). Optimal solutions in economics. Nauka.

Melnikov, S. V., Aleshkin, V. R., & Roshchin, P. M. (1980). Designing an Experiment in Agricultural Process Research. Kolos.

Nagirny, Yu. P. (1990). Making decisions in the face of uncertainty. Mechanization and electrification of socialist agriculture, 5, 6.

Zapalev, A. A. (1998). Modeling of production processes for harvesting fruits. Moscow.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Tsybulevsky, V. V., Maslov, G. G., & Ushakov, D. A. (2021). Effective Option Of Sugar Beet Harvesting Technology. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 1904-1911). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.213