Abstract

Nowadays the issue of waste recycling is one of the main issues both in the Russian Federation and in the world since the landfill area is increasing every day, which leads to negative consequences. In Russia, only 10.5 % of waste is processed, the remaining 89.5 % is delivered to landfills where it would lie for years. The only safe way to get rid of waste is through recycling. Although garbage processing plants in Russia burn solid household waste, their smoke emissions still remain very dangerous. To solve this problem, the experience of foreign countries needs to be approached and taken into account. The article considers the types of technologies that make it possible to safely process waste as well as highlights the environmental and economic aspects of recycling. As a result of the research, it was revealed that such technologies as Hitachi Zosen Inova, Bio Energy Holding, and Alin undoubtedly have many positive aspects helping the society not only in the fight against waste but also in bringing profit. .

Keywords: Processingwasteecologyenergypollution

Introduction

Waste is one of the big problems facing society (Bovkun, Andreevskaya, & Kolodin, 2018). Over the years, people have tried various ways to get rid of it, from burial to incineration. However, all such methods had only a negative impact on the environment.

During the internship period, the analysis of new technologies for waste processing was performed as well as positive aspects from the environmental and economic side were identified. Based on the obtained materials, the article was written (Bovkun, Koroduk, & Arkhipkin, 2018).

Nowadays humanity is facing a number of problems on its way. Unfortunately, the humanity is the one who is guilty. Everything comes from people whether it is planet climate change, glaciers melting, spoiled land, or various diseases. If we create a chain of events that led to such consequences, it would not be difficult to find the culprits. Certainly, this is not just one or two people but all the people living on Earth.

Man is a highly evolved being. This is what everyone has been told since childhood. This could be heard at schools, universities, on television, in books, and in newspapers. But is it really true? Does everyone take into account that they are harming themselves with their actions?

Problem Statement

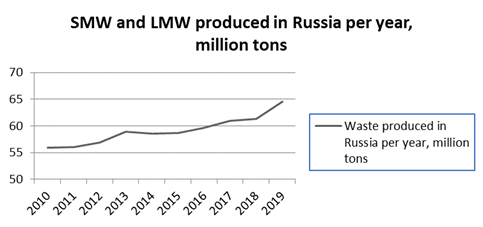

At the moment the population of the entire Earth faces the main problem which is waste. In 2019, Russia produced more than 7.4 billion tons of waste including about 65 tons of solid and liquid municipal waste. On average, one person produces 450 kg of waste per year and the amount of waste increases with population growth (Odaryuk, Tronin, & Skantsev, 2017). For an evident example, consider Figure

From Figure

In Russia, landfills cover an area of more than 4 million hectares. In comparison with the territory of the Russian Federation, such scales seem insignificant. The entire waste volume in the country could be compared to the territory of Switzerland (Yashalova & Gridnev, 2016).

In Russia, only 10.5 % of waste is processed, the remaining 89.5 % is delivered to landfills where it would lie for years.

Research Questions

The only safe way to get rid of waste is through recycling. Although garbage processing plants in Russia burn solid household waste, their smoke emissions still remain very dangerous. To solve this problem, the experience of foreign countries needs to be approached and taken into account.

Purpose of the Study

It is very difficult to arrange a landfill for waste storage in small territories because the area could be used for other purposes. That is why there a technology for safe and environmentally friendly waste recycling was developed which allows generating energy. Japanese-Swiss technology Hitachi Zosen Inova makes it possible to deal with waste in countries such as Japan, Canada, Switzerland, Austria, Germany, Norway, Sweden, and many others.

Research Methods

This study analyzes advanced foreign technologies for recycling waste.

Findings

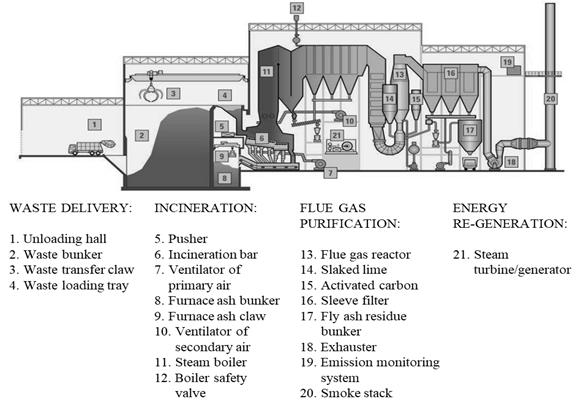

Hitachi Zosen Inova is a state-of-the-art facility for processing waste into energy. Waste is delivered to the plant. However, as a rule, all waste is raw. Therefore, the first step is to put the waste into the drying chamber. Each of the drying cabinets is about the size of 3 basketball courts. There, with the help of a special claw, the waste is mixed, which speeds up the drying process. Then the dry waste is sent to the mill and then to the furnace where at a temperature of 1200 ˚С up to 100 thousand kg of waste is burned each hour.

At this temperature, everything including toxic dioxides burns and all dangerous substances disappear. Then there is the process of secondary combustion where the gases formed during the heat treatment of waste move. Here, temperatures reach 850˚С at which all remaining dangerous substances are destroyed, for certain. In addition, a special urea solution is injected into the chamber to remove organic compounds and neutralize flue gases completely (Yashalova & Gridnev, 2016).

Then the slag and gas enter the reactor where processed with activated carbon and ammonia, then chemical elements are added for neutralization.

The ash goes through several stages of purification during which all metal objects are removed from it using magnets.

The purified gas leaves the reactors and enters bag filters where thin tubes select any fraction, up to microparticles (Yashalova & Gridnev, 2013).

Waste incineration produces a huge amount of energy but it needs to be turned into electricity. The heat of the oven heats up the boiler which works as a huge kettle. The water is heated by passing through a tubular structure and turns into 95 tons of steam per hour. Then under high pressure the steam enters the room with the turbines which are located above the boiler. Under the influence of steam, these turbines produce electricity sufficient to boil 20 million kettles (Yashalova & Gridnev, 2013).

The waste calorific value is from 1000 to 3000 kcal/kg.

According to the conducted study, it was found that by burning 10.5 tons of waste, the same amount of heat is produced as if 1 ton of oil is burnt. The generated heat is equivalent to burning 250 kg of fuel oil when burning 1000 kg of waste.

Such plants are built as a safe alternative to landfills.

In addition to this technology, there is also the German BIO ENERGY HOLDING technology. It combines not only the incineration of solid waste and waste from landfills but also the production of biogas, the disposal of medical waste, old tires, and the purification of water from silty waste.

What is biogas? Biogas is a gas obtained by hydrogen or meta-new fermentation of biomass. It includes: methane (up to 70 %), carbon dioxide (up to 30 %). Biomass consists of manure, bird droppings, animal remains, and silage.

The energy obtained from 1m3 of biogas is comparable to 0.6 m3 of natural gas, or 0.74L of oil, or 0.65L of diesel fuel, or 0.48L of gasoline.

About 9 kW/hour of heat energy is released when burning 1m3 of biogas. This would be enough for the heating of a residential area of about 80m2 within one hour.

There is also a Japanese technology called Alin. Here the waste is processed with subcritical water. Medical waste, especially contaminated waste, is the most difficult to recycle. All waste is sorted into liquid, solid and contaminated which is packed in sealed containers. These wastes were eliminated by incineration until recently. New equipment and technologies made it possible to reach a new level. It is the first stage of processing (Ponomarev, 2013).

First, plastic containers are loaded inside the reactor, where there is a disintegrator that allows dumping large items, then vinyl containers, oilcloth, film, bags, and finally, diapers and fabric items. This equipment allows not sorting waste. Then, after 1 hour, the processed material resembles black earth in composition. There is no expected sharp smell, only a barely noticeable soy sauce scent.

What could this product be called? Most likely, it is an oil squeeze and having been further processed, it is easily ignited. Metal items that have not been processed could be removed.

After processing, the volume of waste was reduced by 70 %. Due to the high temperature, all dangerous substances disappear.

Subcritical water is a special state of water. Under normal atmospheric pressure, water boils at a temperature of 100 degrees. If we put water in a sealed vessel and raise the pressure, the water will not change its structure at least at 300 degrees because water molecules cannot evaporate freely at high atmospheric pressure. If the temperature is raised to 200 degrees and the pressure is up to 20 atmospheres, water is transformed into steam. This state is called subcritical (Rzaev, 2017).

Water molecules do not withstand the pressure, break up and actively move inside the vessel.

When water molecules collide with the molecular structure of other substances, they break it up into smaller components.

This equipment uses the characteristics of subcritical water. After loading the waste, steam brought to subcritical parameters is released. Paper, plastic, vinyl, and wood are all organic substances that contain carbon. Subcritical water splits them into smaller molecular structures then split organic materials change their structure and dangerous compounds are transformed into safe ones. Then the processing product can be moved from the container (Markova, Ivanova, & Ponomarev, 2017).

This equipment can process plant waste, plastic, food waste, timber waste, paper, sewage waste, fabrics.

Recycling with water promotes safety for the environment. No dioxide or other dangerous gases are released into the atmosphere.

For an enterprise, it is sufficient to have a small space with a pipe outside the building for steam output. No fuel is needed. There is no smell and smoke. So, it could be stated that this is environmentally friendly equipment.

The system can be supplemented with equipment for deodorization, flotation, membrane installations with the use of activated silt, thus it is possible to process any types of waste.

Sorted waste is a collection of organic substances which Alin converts into a good-quality fertilizer. By controlling the pressure, waste could be processed either as a liquid or as a dry fertilizer.

Fertilizer could be obtained from any organic waste which further increases the profitability of processing (Mazhorova, 2017).

Research has also shown that the fertilizer is rich in amino acid which increases the quantity and quality of the crop. Equipment for processing subcritical water creates the substances cycle in nature helping to create a modern and efficient recycling system.

The problem of waste disposal often bypasses people until it strikes them directly or affects protected areas, reserves, etc.

One of the main attractions of the Irkutsk region is the lake Baikal. This is one of the most unique places on the planet. Every year many tourists from all over the world come to visit this lake. Nearby there are mountains, the Olkhon island, and dense forests. Nature attracts tourists so they visit the region even in the most severe frosts. In winter, the temperature could drop to –45 ˚С. There are many cities and towns close to the Baikal banks. Waste is transported to the city of Irkutsk or to nearby landfills for recycling.

The authorities of the city of Baikalsk which is located near the lake are concerned about the amount of waste in landfills near the lake so they are aimed to build their own safe ecological waste processing plant on the territory of the landfill. In addition, at the moment there is an acute problem associated with the growth of waste in the cities which are located close to the lake. This is due to the tourist activity. Also, waste could be found in the forests, along the coast, and next to recreation centers (Devyatkin & Gaev, 2006).

To select a technology, their comparison needs to be made. It is shown in Table

Conclusion

Having considered three technologies, Alin technology has the greatest number of advantages because it allows not only processing solid household waste but also liquid and medical waste from hospital facilities located in the city and in neighboring cities. The choice of Alin technology is due to the fact that the production stocks will be located near the lake Baikal which means that it is necessary to use the most environmentally friendly technology that will not cause any harm to the environment (Bovkun & Korodyuk, 2019). Alin requires a minimum amount of space which will not spoil the aesthetic lake view. And sorted waste after processing could be sold to local residents and farms that are located across the Irkutsk region.

References

- Bovkun, A. S., Andreevskaya, T. S., & Kolodin, V. S. (2018). Construction of Innovative Business Based on Objects of Intellectual Property. International Conference on Research Paradigms Transformation in Social Sciences. European Proceedings of Social and Behavioural Sciences, 50, 239–245.

- Bovkun, A. S., Koroduk, I. S., & Arkhipkin, O. V. (2018). Detection and Analysis of Model Construction of Innovative Development in Russian Regions. International Conference on Research Paradigms Transformation in Social Sciences. European Proceedings of Social and Behavioural Sciences, 50, 246–250.

- Bovkun, A. S., & Korodyuk, I. S. (2019). Analysis of the development of small innovative enterprises in the construction industry. IOP Conf. Ser. Mater. Science and Engineering, 667.

- Devyatkin, V. V., & Gaev, F. F. (2006). Economic conditions of waste processing using low-tonnage technologies and recommendations for incentive measures in this area. Solid household waste, 6, 8–9.

- Markova, A. A., Ivanova, A. A., & Ponomarev, S. V. (2017). Economic problems of utilization of household and industrial waste. Young scientist, 21, 218–220.

- Mazhorova, O. (2017). Electronic waste in Russia: approaches are, culture is not. CNews Analytics, 11.05.2017. Retrieved from: http://www.cnews.ru/articles/2017-05-12_elektronnye_othody_v_rossii_podhody_ est_ kultury_net

- Odaryuk, V. A., Tronin, S. Ya., & Skantsev, V. I. (2017). Problems of industrial and consumer waste disposal. Civil security Technologies, 9(3), 72–79.

- Ponomarev, M. V. (2013). Trends and prospects for improving legislation in the field of waste management of production and consumption. Journal of Russ. law, 4, 22–32.

- Rzaev, K. V. (2017). Recycling of plastic waste in Russia. TKO, 1, 7–9.

- Yashalova, N. N. (2016). About necessity of transition of Russian regions to environmental-oriented economy. National interests: priorities and security, 12(2), 37–47.

- Yashalova, N. N., & Gridnev, A. E. (2013). Ecological and economic problems of waste disposal in the framework of the concept of green economy. National interests: priorities and security, 9(43), 28–36.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

07 December 2020

Article Doi

eBook ISBN

978-1-80296-095-2

Publisher

European Publisher

Volume

96

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-833

Subjects

Management, human resources, resource efficiency, investment, infrastructure, research and development

Cite this article as:

Konyukhov, V. Y. A., Druzhinina, T. Y. T., Zott, R. S., Mezina, A., & Sobolev, A. S. (2020). Environmental And Economic Aspects Of Waste Recycling. In A. S. Nechaev, V. I. Bunkovsky, G. M. Beregova, P. A. Lontsikh, & A. S. Bovkun (Eds.), Trends and Innovations in Economic Studies, Science on Baikal Session, vol 96. European Proceedings of Social and Behavioural Sciences (pp. 808-814). European Publisher. https://doi.org/10.15405/epsbs.2020.12.104