Abstract

Ergonomics can be defined as the relationship between humans and their working environment. It is vital for the workers to understand and knowing their job tasks and the possible work risk because it could endanger with musculoskeletal disorders (MSDs) if they did not understand the risk factors. In order to ergonomically fit the workplace for maximum workers at various conditions, it is necessary to make an ergonomic evaluation of the workplace. There are various types of tools that can be used to conduct ergonomics evaluation, thus, it is important to choose proper tools for each analysis. Hence, a selection methodology of the ergonomics assessment tools has been derived that helps one to select an appropriate tool for evaluating purpose with ease. Using the right tools on the right job task would help in determining the job risk, a worker’s biomechanical load and this will lead to the possibility to decrease the prevalence of musculoskeletal disorders (MSDs).

Keywords: Ergonomicsergonomics assessment tools

Introduction

Ergonomics is about the study of the relationship between humans and their working environment. In August 2000, the International Ergonomics Association (IEA) asserted that “Ergonomics (or human factors) is the scientific discipline concerned with the understanding of interactions among humans and other elements of a system and the profession that applies theory, principles, data, and methods to design in order to optimize human well-being and overall system performance” (IEA Council, 2000). In general, the goal of ergonomics is to fit the job to the individual, not the individual to the task.

An ergonomically deficient workplace can cause physical and emotional stress, low productivity and poor quality of work (Karwowski & Marras, 1998). Neglect of ergonomics principles brings inefficiency and pain to the workers and at last the workers will be suffering from musculoskeletal disorders (MSDs). Musculoskeletal Disorders (MSDs) are among the most serious consequences caused by the improper work-related musculoskeletal load. Symptoms of MSDs are defined as pain in one or more regions of the body. Accumulated minor injuries that resulted from repeated long-term work-related load can be considered as the main caused of MSDs (NRC, 2001).

Many researchers say and confirm that the relationship between musculoskeletal load expressed as a function of parameters that describe posture, force and time sequences, and the incidence of MSDs (Van Nieuwenhuyse et al., 2006). This means that a suitable workload can reduce the risk of MSDs that could endanger the workers. In order to ergonomically fit the workplace for maximum workers at various conditions, it is necessary to make an ergonomic evaluation of the workplace. There are various types of tools that can be used to conduct ergonomics evaluation, thus, it is important to choose proper tools for each analysis.

Some parameters such as tools’ analyst capability, the task being analyzed, the tools’ characteristics and data needed from the analysis need to be considered in order to choose the right ergonomics analysis tools. The most common tools that are used by ergonomist are as follows:

Rapid Upper Limb Assessment (RULA)

Rapid Entire Body Assessment (REBA)

Ovako Working Posture Analysis System (OWAS)

Strain Index

Rapid Office Strain Assessment (ROSA)

Manual Handling Assessment Chart (MAC)

These tools can be classified into self-reports, observational and direct measurements (David, 2005; Li & Buckle, 1999). These tools differ in their stages of assessment and also differ in the body area they assess and the types of work tasks they focus on. Therefore, it is important to know which tool to be used before the evaluation started. In this paper, the factors for selecting the right ergonomics assessment tools before the evaluation is carried out will be discussed. In addition, a selection methodology of ergonomics assessment tools will be proposed too.

Ergonomics Assessment Tools

Rapid Upper Limb Assessment (RULA)

RULA is a survey method developed for use in ergonomics investigations of workplaces where work-related upper limb disorders are reported (McAtamney & Corlett, 1993). This tool was specifically designed to examine the upper-limb risk level of an individual, it consists of arm, wrist, neck, trunk and legs analysis. According to McAtamney and Corlett (1993), RULA has previously been shown to be reliable with adults.

Also, it does not require any special equipment as it was a quick method of written assessment for the exposure of adults during work and gives a result that explains the conditions of work posture. This provides the opportunity for a number of investigators to be trained in conducting the assessments without additional equipment expenditure. As the investigator only requires a clipboard and pen, RULA assessments can be done in confined workplaces without disruption to the workforce. Those who are trained to use it do not need previous skills in observation techniques although this would be an advantage.

This method uses diagrams of body posture and 3 scoring table to get the last result. Table

Rapid Entire Body Assessment (REBA)

REBA provides a quick and easy measure to assess a variety of working postures for risk of MSDs that developed by Hignett in the year of 2000 (Hignett & McAtamney, 2000). It shares the same principle with regard to the procedure on the evaluation of risk factors and designated body parts for assessment as RULA. Yet, there are slightly different between RULA and REBA. REBA was improved in the definition of the neutral postures and leg postures from those of RULA. While RULA defined the neutral position of the wrist, neck, and trunk with 0° of corresponding joint motion angle and changeable leg positions are classified into only two balanced and unbalanced classes, REBA defined the neutral posture as postures with some ranges of the angular deviations of the related joints and by classifying leg positions into four classes (Kee & Karwowski, 2007).

REBA adapts better than RULA to highly varied workstations. This can be attributed to the development of RULA within a specific research context that makes it unreliable when applied in a different context (Chiasson et al., 2012).

Table

Ovako Working Posture Analysis System (OWAS)

Ovako Work Posture Analysis System (OWAS) is one of the methods used to identify and analyze work posture to ensure safety and comfort in work. It is a simple method to verify safety level which are related to work posture and to evaluate risk level which leads to corrective action (Caputo et al., 2006). This method can define the movement of all parts of the body and also recommends suggestions to safer and comforter feeling while working. Besides, OWAS is more suitable in examining manual material handling.

Conventional OWAS is based on sampling from typical working postures for the whole body, which covers the most common and easily identifiable working postures for the trunk, arms, and legs, along with an estimate of the worker’s force. OWAS uses a four-digit code to describe various postures and force combinations (Table

Strain Index

Strain Index is a tool that uses both qualitative and quantitative methods to identify job risk factors that may bring the distal upper extremity (DUE) disaster to the workers (Moore & Garg, 1995). Distal upper extremity (DUE) includes elbow, forearm, wrist, and hand. This tool is used when it comes to evaluating the risk of developing musculoskeletal disorders (MSDs) in hand-intensive tasks such as assembly activities.

Strain Index multiplies 6 task variables which are Intensity of Exertion, Duration of Exertion, Exertion per minute, Posture, Speed of work and Duration per day to get the final score of strain index (Moore & Garg, 1995).

Rapid Office Train Assessment

The ROSA method is a diagram based checklist that was developed to quickly quantify the exposure of workers to risk factors in office workplaces and if an office workplace requires additional assessment or intervention. This method was created using posture that was described in CSA standards for Office Ergonomics (CSA-Z412) (Canadian Standard Association (CSA), 2000).

Same as RULA and REBA, ROSA did not require any special equipment in conducting it. The scoring chart was divided into 3 different sub-sections such as the chair, monitor and telephone, and mouse and keyboard. The final score of ROSA is combined with the scores from each subsection. The research found that there is a correlation between discomfort level and increasing of ROSA scores (Sonne et al., 2012). Besides, interrater and intra-rater reliability has also been shown to be very good (ICC – 0.88, 0.91, respectively) (Sonne et al., 2012), further shows the effectiveness of the tool.

Manual Handling Assessment Chart

Manual Handling Assessment Chart (MAC) was developed by Health and Safety Executive (HSE) as a tool used for risk assessment of manual handling. MAC can help in assessing the most common risk factors like lifting and lower, carrying and team handling operations and it was aimed to identify high-risk manual handling.

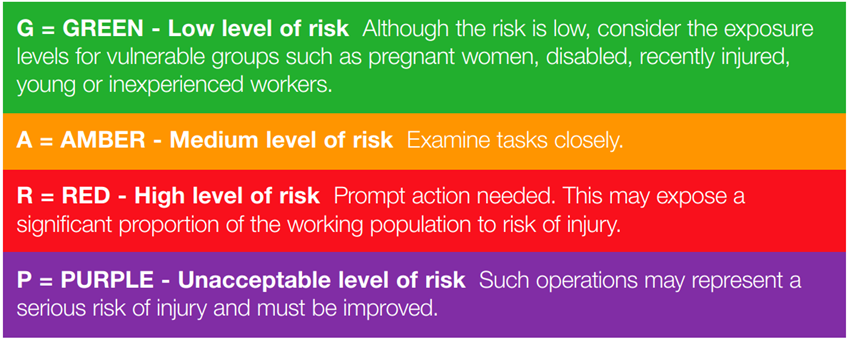

Yet, this tool is not appropriate to use in manual handling operation that includes pushing and pulling, assessing people handling and assessing workplace risk associated with upper limb disorders. MAC uses the traffic light approach in indicating the risk level (Figure

Factors for Selecting Ergonomics Tools

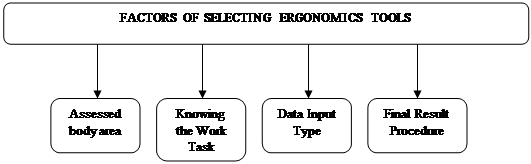

It is vital to know which kind of assessment tools is suitable to be used for each case as it will affect the accuracy of the final results. In Figure

Understand the tools and knowing the work task

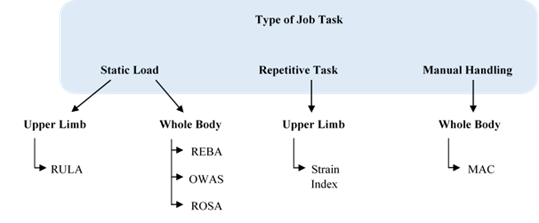

There are many types of ergonomics assessment tools that can be used for ergonomics evaluation. It is vital to know and understand each of the assessment tools before proceeding to the evaluation. Different types of tools assess different body areas. Some assess the back, upper and lower limbs independently of each other, some assess the whole body and some assess only the upper part of the body (Figure

REBA, OWAS, and ROSA are common ergonomics assessments for the whole body, and these 3 are part of static load. The static load can be defined as workers maintain in the same posture for a long time during their work and it is one of the factors that lead to rises of risk of getting musculoskeletal disorders (MSDs). Besides, RULA is another type of tool used in assessing static load but it is more suitable in upper limb evaluation.

RULA and Strain Index assesses posture that is related to the upper limb only. Unlike RULA, Strain Index is a tool used for repetitive tasks. Repetitive task refers to workers to perform a similar task again and again in everyday work (Kilbom, 1994a). Repetitive tasks can be considered as one of the physical workload factors associated with musculoskeletal disorders (MSDs) (Kilbom, 1994b).

MAC is dedicated to assess load resulting from manual handling. Manual Handling is another type of task that can increase the risk of developing musculoskeletal disorders (MSDs) and need to be considered. Any activity that requires the use of force exerted by a person to lift, lower, push, pull, carry, move, hold or restrain a person, animal or object is defined as Manual Handling (Clemes et al., 2010). Research has confirmed the relationship of manual handling in developing musculoskeletal disorders (MSDs), it means that if the manual handling task is not carried out correctly and safely, the risk of injury will be very high (Clemes et al., 2010; Hoozemans et al., 1998).

Input Data and Final Result Procedures

Different tools define posture in different ways. Some of it defines using codes, some with a range of values and some with points. Figure

In OWAS, the codes are distinguished according to the posture that is separate to different body part which is back, arms and legs with an additional load. While for RULA and REBA, both assess quantitatively the posture of the trunk, neck, arm, and leg. The range values of these 2 types of assessment consider the same, the only differ them is the value of the wrist and legs. For RULA, there are 3 range of values for wrist part and no range values for leg part, whereas for REBA there are only 2 range values for wrist and 2 range values for leg. As for ROSA, the codes are separated into 3 different sections, chair, monitor and telephone, mouse and keyboard, and final score with the combination of the codes from all 3 sections. These 4 methods share the same concept in getting the final result of the assessment. They use table to group combinations of data. Each of the combinations is assigned with a code, in order to get the result, ones need to look-up the code from the table itself.

Strain Index uses multiplier in indicating the final results. It multiplies 6 task variable which is Intensity of Exertion, Duration of Exertion, Exertion per minute, Posture, Speed of work and Duration per day to get the final score of strain index (Moore & Garg, 1995). It was found that the job task associated with distal upper extremity had scored more than 5 in the final results.

The procedure in MAC is the same for all lifting, carrying and team handling. Load weight and frequency need to be analyzed before others. As for this method, the traffic light approach is used to indicate the level of risk and scores from each question need to total up in order to get the final results.

The Values of Ergonomics

Ergonomics is a scientific discipline that focuses on understanding the interaction of human beings and the other elements of the system. Ergonomic aimed to optimize safety, health, comfort, and efficiency of humans with their working system. A proper ergonomic design is necessary in order to prevent unsafe, unhealthy, uncomfortable and inefficiency of work.

According to Vink et al. (2006), ergonomics contributes to the prevention of inconveniences and, to a considerable degree, improves system performance in terms of increased productivity. Vink et al. present several examples to support those good ergonomics is good economics. Some discussion have been carried out by Vink et al. (2006), to convince ergonomists to apply a positive approach to the outcomes of their work.

Ergonomics can also contribute to many different company strategies and can support the objectives of different business functions. This topic has been discussed by Dul and Neumann. They mentioned that in some countries, ergonomics is closely linked with their occupational health and safety legislation. Neuman & Dul (2010) suggested linking ergonomics to business strategies and goals such as:

Reduce costs and increase productivity

Maximize the use of valuable, rare and costly human resources

Design products for (easy) assembly, design for manufacturing

Integrate ergonomics into production engineering

Corporate communication; i.e. ergonomically designed products and/or the company's corporate social responsibility.

Most intervention studies looked into the effects of ergonomics on both human and system outcomes, including quality and productivity. The impact on productivity has been a more frequent focus. According to Neumann and Dul (2010), it showed that the main system effects of studies were productivity (89% of articles), while 31% reported quality effects of ergonomics. Furthermore, the results of quality improvement due to ergonomic intervention have varied considerably. Erdinc and Vayvay (2008) found a reduction in quality defects of about 4% after ergonomic intervention, while Yeow and Sen (2006) observed about 30% reduction in errors in a manual component insertion line of printed circuit assembly.

Not only in workplace, but in the academic community ergonomics played an important role too. A proper ergonomic design of the classroom furniture is important key factors in regular development of all abilities of students. Yet, before drafting a proper design of the classroom furniture, a proper evaluation should be taken for the students. Without knowing or understanding on the existing ergonomics assessment, it could affect the accuracy of the data and the final design of the classroom furniture if the wrong or unsuitable ergonomics assessment is applied. Being the workplace of future workers, classrooms must be equipped with furniture that safeguards the physical wellbeing of pupils through appropriate ergonomics and the ability to adjust to their individual physical needs (Gligorović et al, 2018).

Conclusion

Each assessment method has its own usability, and it will definitely function and meet its objective provided that it is used in the correct way. In order to have a better and accurate result for each different job task, the factors of selecting tools are really important and need to be considered every time before the start of the evaluation. Hence, a selection methodology of the ergonomics assessment tools has been derived that helps one to select an appropriate tool for evaluating purpose with ease. Using the right tools on the right job task would help in determining the job risk, a worker’s biomechanical load and this will lead to the possibility to decrease the prevalence of musculoskeletal disorders (MSDs).

Acknowledgments

We would like to express our gratitude to the fellow researchers of the College of Engineering (COE), College of Computing and Informatics (CCI), College of Business and Administration (COBA) and College of Energy Economics and Social Sciences (CES), UNITEN for their educational support. This work was supported by UNITEN R&D Sdn Bhd (URND) and UNITEN under the Seed Fund Grant Scheme.

References

- Caputo, F., Di Gironimo, G., & Marzano, A. (2006). Ergonomic optimization of a manufacturing system work cell in a virtual environment. Acta Polytechnica, 46(5).

- Chiasson, M., Imbeau, D., Aubry, K., & Delisle, A. (2012). Comparing the results of eight methods used to evaluate risk factors associated with musculoskeletal disorders. Int. J. Indust. Ergonom., 42: 478-488. https://doi.org/10.1016/j.ergon.2012.07.003.

- Clemes, S. A., Haslam, C. O., & Haslam, R. A. (2010). What constitutes effective manual handling training? A systematic review. Occupational medicine, 60(2), 101-107.

- David, G. C. (2005). Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occupational medicine, 55(3), 190-199.

- Erdinc, O., & Vayvay, O. (2008). Ergonomics interventions improve quality in manufacturing: A case study. International Journal of Industrial and Systems Engineering, 3(6), 727–745.

- Gligorović, B., Desnica, E., & Palinkaš, I. (2018, July). The importance of ergonomics in schools—Secondary technical school students’ opinion on the comfort of furniture in the classroom for computer aided design. In IOP Conference Series: Materials Science and Engineering (Vol. 393, No. 1).

- Hignett, S., & McAtamney, L. (2000). Rapid entire body assessment (REBA). Applied ergonomics, 31(2), 201-205.

- Hoozemans, M. J., Van Der Beek, A. J., Fringsdresen, M. H., Van Dijk, F. J., & Van Der Woude, L. H. (1998). Pushing and pulling in relation to musculoskeletal disorders: a review of risk factors. Ergonomics, 41(6), 757-781.

- IEA, C. (2000). The discipline of ergonomics.

- Karwowski, W., & Marras, W. S. (Eds.). (1998). The occupational ergonomics handbook. Crc Press.

- Kee, D., & Karwowski, W. (2007). A comparison of three observational techniques for assessing postural loads in industry. International Journal of Occupational Safety and Ergonomics, 13(1), 3-14.

- Kilbom, Å. (1994a). Repetitive work of the upper extremity: Part I—Guidelines for the practitioner. International Journal of Industrial Ergonomics, 14(1-2), 51-57.

- Kilbom, Å. (1994b). Repetitive work of the upper extremity: Part II—The scientific basis (knowledge base) for the guide. International Journal of Industrial Ergonomics, 14(1-2), 59-86.

- Li, G., & Buckle, P. (1999). Current techniques for assessing physical exposure to work-related musculoskeletal risks, with emphasis on posture-based methods. Ergonomics, 42(5), 674-695.

- McAtamney, L., & Corlett, N. (1993). RULA: a survey method for the investigation of work- related upper limb disorders. Applied Ergonomics 24(2), 91e99.

- Moore, S. J., & Garg, A. (1995). The strain index: a proposed method to analyze jobs for risk of distal upper extremity disorders. American Industrial Hygiene Association Journal, 56(5), 443-458.

- Neumann, W. P., & Dul, J. (2010). Human factors: spanning the gap between OM and HRM. International Journal of Operations & Production Management, 30(9), 923-950.

- NRC, 2001. Musculoskeletal Disorders and the Workplace: Low Back and Upper Extremities. National Research Council and the Institute of Medicine. Commission on Behavioral and Social Sciences and Education. Panel on Musculoskeletal Disorders and the Workplace.

- Petriková, A., & Petrik, M. (2015). Modern methods of evaluation workplace factors in ergonomy. Acta Simulatio, 1(3), 7-11.

- Sonne, M., Villalta, D. L., & Andrews, D. M. (2012). Development and evaluation of an office ergonomic risk checklist: ROSA–Rapid office strain assessment. Applied ergonomics, 43(1), 98-108.

- Van Nieuwenhuyse, A., Somville, P. R., Crombez, G., Burdorf, A., Verbeke, G., Johannik, K., Van den Bergh, O. Masschelein, R. Mairiaux, P., & Moens, G. F. (2006). The role of physical workload and pain related fear in the development of low back pain in young workers: evidence from the BelCoBack Study; results after one year of follow up. Occupational and environmental medicine, 63(1), 45-52.

- Vink, P., Koningsveld, E. A., & Molenbroek, J. F. (2006). Positive outcomes of participatory ergonomics in terms of greater comfort and higher productivity. Applied ergonomics, 37(4), 537-546.

- Yeow, P. H., & Sen, R. N. (2006). Productivity and quality improvements, revenue increment, and rejection cost reduction in the manual component insertion lines through the application of ergonomics. International journal of industrial ergonomics, 36(4), 367-377.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 December 2020

Article Doi

eBook ISBN

978-1-80296-099-0

Publisher

European Publisher

Volume

100

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-905

Subjects

Multi-disciplinary, accounting, finance, economics, business, management, marketing, entrepreneurship, social studies

Cite this article as:

Shang, L. T., Thiruchelvam, S., Rusli, M. E., & Ghazali, A. (2020). A Systematic Approach Of Ergonomics Assessment Tool Selection. In N. S. Othman, A. H. B. Jaaffar, N. H. B. Harun, S. B. Buniamin, N. E. A. B. Mohamad, I. B. M. Ali, N. H. B. A. Razali, & S. L. B. M. Hashim (Eds.), Driving Sustainability through Business-Technology Synergy, vol 100. European Proceedings of Social and Behavioural Sciences (pp. 708-718). European Publisher. https://doi.org/10.15405/epsbs.2020.12.05.77