Abstract

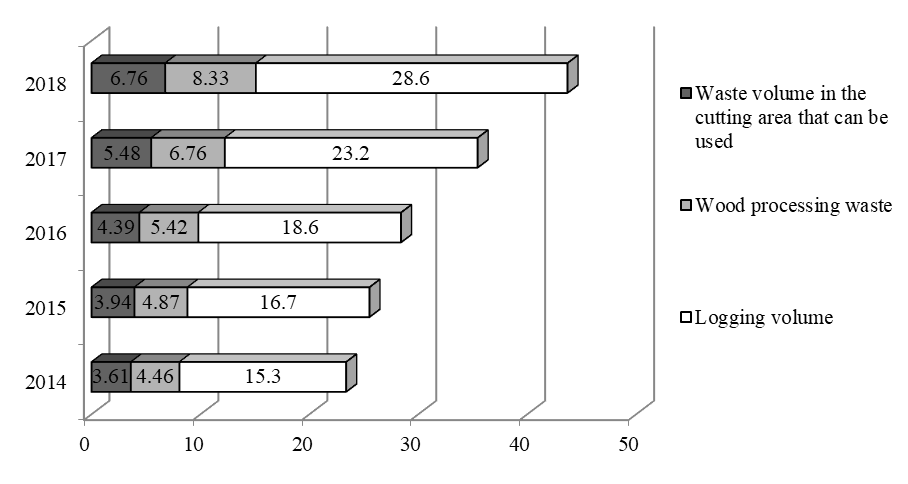

Forestry complex is of great importance for the Krasnoyarsk region, as it makes a significant contribution to regional development. Investment projects in the field of forest development and complex wood processing are also being implemented in the Krasnoyarsk region. The dynamic development of the forestry complex in the region is accompanied by an increase in the volume of wood harvesting and processing. Thus, the volume of wood harvesting in 2018 reached 28.7 million m3, which is 87.4% higher than the same indicator for 2014. Increasing volumes of wood processing products lead to an increase in wood waste. The volume of wood waste increased almost 2 times over the period 2014-2018. Almost 50% of the harvested volume of wood is not processed. Utilization of such a large amount of wood waste is a big problem for enterprises of the forestry industry of the Krasnoyarsk region. In accordance with global trends, wood waste can be used as a complete raw material for the production of environmentally friendly fuel, as well as for the production of products for development of the construction sector and the furniture industry. The current potential of the regional forestry complex, the presence of large investment projects in harvesting and wood processing, regional governmental support and the perspective directions of Krasnoyarsk region forestry complex development is a necessary basis for wood deep processing and innovative products producing.

Keywords: Forestry complexwood wastecomplex waste processinginnovative products

Introduction

The Krasnoyarsk territory is a region in the heart of Siberia, 70% covered by forest stands with an area of 158.7 million hectares. The total wood reserve of the region is about 4% of the world's reserve stock (about 12 billion m3). This is more than 35 % of the forest reserves of the Siberian Federal district. The structure of forest stands is dominated by coniferous stands, the share of which is about 88%. Operational forests make up about 40% of the area of the regional forest fund (Draft of Forest plan for the Krasnoyarsk region 2019-2028, 2018; Burdin et al., 2000).

The Krasnoyarsk region is one of the leading Russian regions in terms of the number of priority investment projects being implemented in forest development. There are ten investment projects for forest development being implemented on a total area of 6.8 million hectares with an annual wood harvesting by continuous cutting of mature and overgrown forest stands 11.9 million m3 of liquid reserve. In addition, five investment projects for forest development have been successfully implemented, including: LLC "Priangarsky LPK", JSC "Novoeniseysky LHK", LLC "Yenisei Plywood Plant", LLC "UK Mekran", LLC "Sibles Project " (Draft of the Strategy for the Development of the Forest Complex of the Krasnoyarsk Region for the period until 2030, 2017). All these projects provide wood waste processing.

Despite the considerable potential available, the problem of complex wood processing remains unsolved, which leads to increasing volumes of logging of available stands, low rates of reforestation (compared to logging) and, as a result, depletion of forest reserves.

Problem Statement

The organization of raw material complex processing in the Krasnoyarsk region is established at such enterprises as JSC "Novoeniseysky LHK", LLC "Sibles Project", JSC" Kraslesinvest", LLC "DOK Yenisei", LLC "Priangarsky LPK". In the Krasnoyarsk region, the problem of wood waste utilization is one of the most urgent, since at present, the level of wood processing remains at a low level under existing methods.

Complex use of wood resources consists in processing the entire volume of wood, including waste from harvesting and wood processing. But the utilization of wood waste has always been a big problem for logging and wood processing enterprises, since wood waste is generated in large volumes at almost all stages of the production process: logging – sawmilling – woodworking. The reasons for the low utilization rates of wood waste at present are the next:

territorial dispersion of small sawmills and woodworking plants;

complexity of collecting and organizing intermediate waste storage sites;

the lack or moral obsolescence and physical depreciation of the wood waste processing equipment;

lack of legal regulations for logging and woodworking waste;

lack of moral and material incentives.

According to the report of the Minister of Forestry of the Krasnoyarsk region, Maslodudov (2018), the key vectors of the region's forestry complex development are deep processing of harvested wood and the most effective use of the forest resource base. Thus, the problem of wood waste utilization is one of the most urgent at the present time, since almost half of the wood biomass is lost under current processing methods, which, of course, indicates a low level of technological processes for wood raw material processing.

Research Questions

-

Analysis of the current level of forestry complex functioning of the Krasnoyarsk region;

-

Study of current ways of using wood waste;

-

Analysis of the world experience in processing wood waste into innovative products;

-

Calculation of the expected efficiency of waste processing into innovative products on the example of forestry complex enterprises of the Krasnoyarsk region.

Purpose of the Study

The purpose of the work is to develop proposals for wood waste utilization in order to increase the level of complexity of the use of wood raw materials and obtain additional benefits.

Research Methods

Analysis of the current level of the Krasnoyarsk region forestry complex functioning

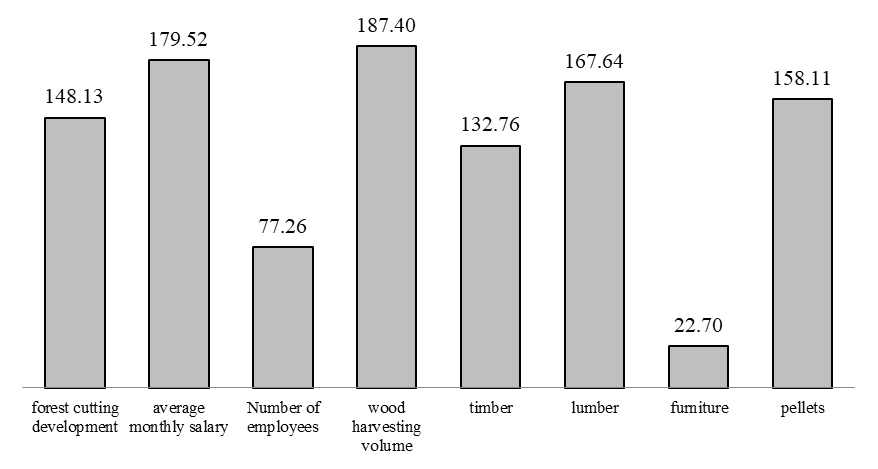

At the moment, the Krasnoyarsk region forestry complex is a fairly dynamically developing sector of the region's economy. There is a significant increase in the indicators of development of the estimated cutting area, the volume of wood harvesting and the output of lumber (table

The increase in the production of pellets indicates an increase in the wood waste processing. In general, the positive dynamics of the development indicators of the Krasnoyarsk region forestry complex indicates a stable and uniform development of the industry. At the same time, there is a decrease in the dynamics of furniture production (by 10 times) and a reduction in the number of employees, which indicates a decrease in the prestige of the industry profession (figure

In 2018, the volume of logging amounted to 28.6 million m3. At the same time, the volume of waste, mainly coniferous wood, in the cutting area was 9 million m3 (table

From the point of view of economic feasibility, wood waste can become a resource for the production of innovative products and heat generation, which will reduce the negative impact of waste on humans and the environment. However, despite the obvious solution to the problem, wood waste continues to accumulate on the territories of logging and wood processing enterprises, increasing the level of fire hazard. The percentage of lumber output varies between 47-50%. From 15.09 million m3 of wood waste (55% according to data in 2018) accounts for the share of woodworking. About 60% of which (9.05 million m3) are large or lumpy waste (slab, slats, clippings, etc.) and 40% (5 million m3) are small or soft (sawdust, shavings, etc.) (Korpachev et al., 2019). The latter are used irrationally.

Thus, forestry complex of the Krasnoyarsk region has a sufficient potential to implement wood waste processing plants in order to reduce the amount of unused waste and extract additional economic benefits.

Areas of wood waste use

To identify the areas of wood waste use, it is necessary to classify them. Classification of wood waste depending on the type of treatment is as follows (table

production of biofuels (fuel pellets and briquettes, pellets, charcoal);

generation of heat and electric energy (pyrolysis, simple combustion, generation of generator gas);

waste water treatment (from oil by filtration through wood shavings);

production of materials for construction and finishing (wood-chip and chip-cement slabs, roofing, thermal insulation and finishing materials, hollow timber, brick, gypsum Board, piezothermoplastik, tyrsolit, parkelit);

production of forest chemical products (cellulose, alcohol, feed yeast, vitamin flour, essential oils, linnosulfonates);

agricultural use (feed, fertilizer, compost, land);

production of consumer goods (toys, containers, tableware, furniture).

In the production of boards and the chemical industry, logging and woodworking waste is used to a greater extent (both lump and small waste-sawdust, trimmings, plate residues, bark, crown, etc.). These types of waste processing are the most common in comparison with the production of feed as well as pulp and paper (table

Modern technologies allow using any waste of woodworking in the production of biofuels: sawdust, shavings, wood dust, wood chips, humps, cuttings, and fine-grained wood. As for the types of wood, there is also a variety of possible: from spruce, pine, fir, cedar, larch, for example, pellets, briquettes, euro firewood are produced, and from large waste of birch and oak-quality coal is produced. Even "stale" waste, which has been accumulated in excess, can be used (Mironov, 2018). From the above-mentioned options for processing wood waste in the Krasnoyarsk region, the production of pellets, fuel pellets, and wood-fiber boards is being implemented.

World experience in processing wood waste into innovative products

The world experience of wood waste processing shows that raw material wood waste can be a not only for environmentally friendly fuel, but also for full-fledged products of finishing and construction materials (table

To date the woodworking industry has accumulated extensive experience in the development and implementation of numerous technological projects for the processing wood raw materials mainly in three areas: construction materials, raw materials for the production of chemical products and biofuels.

Wood waste has become the basis for the production of effective substitutes for business wood, economical materials and products. Also, waste is used in the construction materials industry (various structural and thermal insulation and finishing materials, doors, Windows, etc.). of Great interest is the new technology being developed recently for converting lumpy sawmill waste into a homogeneous wood-fiber fraction, the areas of further processing of which are practically unlimited (Vlasov, 2016).

The most interesting are multifunctional types of products. For the enterprises of the regional forestry complex, the optimal options for waste processing can be the production of dendrolite, werzalite and velox, since the collection of such waste does not require much labor, and it is possible to organize production at the processing plant.

The use of technologies for the production of innovative products will meet the demand of the population and manufacturers in environmentally friendly, high-quality, cheap and domestic materials for the construction and furniture industries.

Calculation of economic efficiency of production of innovative products from wood waste

Production of the offered types of products can be organized at all stages of processing and harvesting of wood, so suitable objects for the implementing of such productions are JSC "Novoeniseysky LHK", LLC "Sibles Project", JSC "Kraslesinvest", LLC "DOK Yenisei", LLC " Priangarsky LPK", where the process of complex wood processing has already been established. The main products of recycling are pellets and plates.

In order to expand the range of products and reduce waste, it is proposed to implement the production of dendrolite, werzalite and velox. The cost of purchasing the necessary equipment will amount to 3.3 billion rubles (table

According to preliminary estimates of experts, the volume of wood waste available for harvesting and having suitable quality characteristics is for waste from logging activities 60-65% of the available volume of waste from logging (4.4 million tons).m3) and 80% of the volume of wood processing waste (6.66 million m3).

The distribution of available wood waste can be made as follows: logging waste is directed to the production of dendrolite, since this technology provides for the processing sawmill waste and low-grade wood; wood processing waste it provides to the production of werzalite and velox (table

The total revenue from the production and sale of innovative products with enlarged calculations will amount to 5 billion rubles.

When organizing production facilities for processing wood waste, there is a problem of their low concentration. To solve this problem, there is a need to organize the collection and transportation of wood waste to the place of processing, which will entail additional costs, and, as a result, an increase in the cost of production. Thus, the expected rate of return will be 10%, while the return on investment may be 6.5 years.

Findings

Currently, the use of wood waste in re-production is not fully established. Wood waste is mainly used in the production of various types of ecological fuel, as well as in the production of stoves. However, there is still a huge amount of unprocessed waste and low-quality wood. Meanwhile, innovative technologies for the production of wood raw materials of various quality have already been developed and actively used abroad. The results of the study showed that the use of only sawmilling and woodworking waste for production purposes has a significant economic benefit. Additional effects can also be:

1. Production effects:

development of innovative production technologies;

organization of the processes of wood deep processing;

expansion of the product range.

2. Economic effects:

increasing the competitiveness level in national and global wood market;

decrease in imports of finished wood products;

increasing the volume of tax payments to budgets of all levels.

3. Social effects:

meeting the demand for domestic construction materials at affordable prices;

creation of additional jobs;

increase in the level of remuneration.

4. Environmental effects:

reducing the amount of logging;

reducing the level of pollution of forest territories and industrial zones of enterprises;

reducing the level of fire hazard in forest.

The sale of products from wood waste will allow getting additional benefits and redirect it to the organization of development of hard to reach forests and increase reforestation rates.

Conclusion

The issue of recycling wood waste is very relevant in view of the constantly increasing volumes of waste from logging and woodworking. According to data for 2018 in the Krasnoyarsk region, with the volume of wood harvesting at 28.6 million m3, the volume of waste was about 53%. Almost half of the wood resources are not used for their intended purpose and do not bring economic benefits but remain in the forest areas and territories of industrial enterprises. The range of application of wood waste is quite wide, as sawdust, bark, pruning and other waste can be reused in all branches of the forest industry.

The main reasons that make it difficult to organize the wood waste processing are the territorial separation of forestry complex enterprises and the lack of legislation regulating this issue. Therefore, production with deep wood processing should be organized at large enterprises of the forestry complex. At the moment, such investment projects are being implemented in the province, but the predominant products of recycling are chipboard, pellets and fuel pellets.

Wood waste is a suitable base for the production of innovative effective substitutes for business wood and building materials. For the enterprises of the regional forestry complex edges optimal processing waste can be production of dendrolite, werzalite and velox as the use of these products is possible in the construction and furniture sectors. According to preliminary estimates the revenue from the production of innovative products may amount to 5 billion rubles, the investment payback period is 6.5 years.

The organization of the complex wood processing will reduce the pollution level of forest and industrial areas and will make it possible to reduce the annually increasing volume of logging due to deep and waste-free processing wood resources, and additional benefits will allow to organize the development of hard-to-reach forest plantations and reforestation activities.

References

- Artamonov, G. (2013). Dendrolite Olympic level. https://lesprominform.ru/jarticles.html?id=427

- Belyakov, G. P., & Pokonov, A. A. (2016). Modern trends and features of technological development of forestry industry enterprises. Theory and Practice of Social Development, 10, 56-60.

- Burdin, N. A., Shlykov, V. M., Egornov, V. А., & Sakhanov, V. V. (2000). Timber industry: state, problems, prospects. MGUL.

- Draft of Forest plan for the Krasnoyarsk region 2019-2028 (2018). http://mlx.krskstate.ru/lesplan

- Draft of the Strategy for the Development of the Forest Complex of the Krasnoyarsk Region for the period until 2030 (2017). Ministry of Natural Resources and Ecology of the Krasnoyarsk Region. http://mlx.krskstate.ru/dat/File/57/dokumenty/Proekt%20Strategii.pdf

- Ilyin, O. (2015). Story of «ROSSTO-VELLOX». http://www.rosstro-velox.ru/technology/rosstro-velox-history/

- Korpachev, V. N., Perezhilin, A. I., Andriyas, A. A., Vladykin, E. А., & Sukhoveev, A. I. (2019). Potential of unclaimed wood raw material resources for bioenergy. Coniferous Boreal Zone, XXXVII, 5, 295–300.

- Maslodudov, D. A. (2018). New projects and management approaches will be the impetus for the development of the forest industry of the Krasnoyarsk region. Siberian Forestry Complex, 1(5), 8–12.

- Mironov, G. (2018). From the Smoking Dumps to the Wood Processing Industry. https://lpk-sibiri.ru/forest-industry/analytics/ot-dymyashhihsya-svalok-k-industrii-pererabotki-othodov/

- Pinyagina, N. B. (2013). Methodological Foundations of Strategic Planning in the Forest Sector of the Russian Federation (Doctoral Dissertation). Moscow.

- Puchkov, V. V. (2012). Strategic Planning of Regional Timber Industry Complexes (Doctoral Dissertation). http://economy-lib.com/disser/360444/a?#?page=1

- Remezov, A. T. (2010). Dendrolite plates: eco-friendly, durable, light and profitable. Woodworking: Equipment and Tools, 1, 20-22.

- Socio-economic development strategy of the Krasnoyarsk region until 2030 (2018). Government of the Krasnoyarsk Region. http://docs.cntd.ru/document/550243058

- State report «About the state and protection of the environment in the Krasnoyarsk region for 2013-2017» (2018). Ministry of ecology and natural resource management of the Krasnoyarsk region. http://www.mpr.krskstate.ru/envir/page5849

- Stratanovsky, V. (2016). Chipboard Pallets “Werzalite”. https://lesprominform.ru/jarticles.html?id=1306

- Vlasov, D. (2016). Wood waste: utilization of wood waste and areas of use. lesnika.net/74-drevesnye-othody.html

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

20 October 2020

Article Doi

eBook ISBN

978-1-80296-089-1

Publisher

European Publisher

Volume

90

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1677

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Shishmareva, A. V., & Moiseeva, E. E. (2020). Complex Processing Assessment Of Wood Waste Of The Krasnoyarsk Region Forestry Complex. In I. V. Kovalev, A. A. Voroshilova, G. Herwig, U. Umbetov, A. S. Budagov, & Y. Y. Bocharova (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST 2020), vol 90. European Proceedings of Social and Behavioural Sciences (pp. 258-268). European Publisher. https://doi.org/10.15405/epsbs.2020.10.03.30