Abstract

The article is devoted to the organization of industrial production of nanostructured crystals of partially stabilized zirconium dioxide. The stages of preparatory work in the field of technological process formation are considered. The results of studying the structure and phase composition of crystals, the results of studying the influence of the crystallization rate of the melt on the crack formation process during cooling are presented. The main stages of the technological process of synthesis of crystals are substantiated. The physico-mechanical properties of the synthesized crystals give reason to recommend their widespread introduction into various fields of industry and medical technology. The first samples of products for testing were obtained. Examples of practical application of zirconium dioxide crystals in friction assemblies of devices and machines are shown. Die blanks are used for drawing copper and aluminum wire in drawing mills in the cable industry. Journal bearings for friction assemblies are designed to operate in a vacuum. Support bearings bushings of submersible centrifugal pumps are used for oil production. The prospects of using crystals in the supports of the axes of precision instruments are formulated.

Keywords: Zirconium dioxide crystalscrystallization of crystalssupport axes of precision instrumentstribological properties of crystalscrack resistance of crystals

Introduction

Intensive work is underway in the world to create new structural non-metallic materials in which strength, high fracture toughness and chemical inertness are combined with high resistance in an oxidizing atmosphere over a wide temperature range (Myshkin & Goryacheva, 2016). Such materials are especially in demand for friction units operating in high temperature and extremely aggressive environment. Such materials are needed in mechanical engineering, aerospace industry, chemical industry, and medical production. Especially new materials are needed for friction units. The reliability and service life of machines and devices is mainly limited by the performance of friction units (Vagin et al., 2017). The efficiency of a friction unit depends on the tribological properties of the materials used in movable connections of machine parts. Therefore, progress in the development of modern machines is focused on the creation of new materials related to high-tech products, the production of which requires innovative approaches and is based on qualitatively new operations using advanced methods of melting and mixing various components of the composition (Agarkov, 2018). New technological operations, which include high-frequency melt in a cold container, wave technologies for melt mixing, laser technologies for processing materials, methods of ion-laser surface treatment and others, allow obtaining materials with a unique combination of strength and tribological properties. With respect to tribotechnical materials, materials based on zirconium compounds are promising because they have a very high setting resistance (Borik et al., 2015). The initial raw mineral deposits are studied. The main volume of proven reserves of zirconium is in Australia, South Africa and Ukraine. Most of zirconium dioxide is used in its natural form. In the general structure of consumption of zirconium dioxide, the manufacture of ceramics covers almost a third of this niche of the economy, which is described by numerous reviews and marketing research. World production of zirconium dioxide is estimated at 40-50 thousand tons per year. A full cycle of manufacturing zirconium products: USA, Canada, France, Japan and Russia. In Russia, there are resources, a raw material base and technological personnel with sufficient experience in this area for organizing the mass production of partially stabilized zirconium dioxide (PSZ) crystals. Zirconium production in the world is growing rapidly every year, it finds new areas of application.

High-tech products include nanostructured crystals of partially stabilized tribotechnical purpose zirconium. The nanostructured crystalline zirconium partially stabilized by yttrium oxide has these very properties (Borik, 2017). The material under optimal manufacturing conditions has very high mechanical characteristics. In terms of bending strength, up to 1000 MPa, in compression, up to 2000 MPa, in fracture toughness, up to 15 MPa * m0.5, in hardness, up to 17 GPa, and in modulus of elasticity, up to 400 GPa. The physico - mechanical properties of nanostructured zirconium dioxide crystals are described in (Borik et al., 2014). PSZ crystals are highly resistant to acids, alkalis, water vapor, and abrasion. It is known (Chevalier et al., 2009) that there are two polymorphic transformations between pure crystallization and room temperature between ZrO2: at 2300 0С, the high-temperature cubic phase transforms into the tetragonal phase, which, in turn, at 1200-1000 0С it goes into monoclinic. In PSZ crystals, the first of these transitions occurs in the compositions range ZrO2 - (2.5-5) mol% Y2O3. An increased interest in ceramic materials based on zirconium dioxide is manifested in connection with their ability to be used in high-temperature friction units of devices and machines. In comparison with the most commonly used ceramics and tribotechnical crystals, they have advantages in tribological and strength properties. Ceramic materials are associated with the future of friction units operating at high temperatures, for example, aircraft engines, because they retain acceptable mechanical characteristics at a relatively low specific gravity. However, all ceramic materials are very fragile, and the fracture toughness characteristics are among the most important when choosing a ceramic material for use in friction units. A lot of attention is paid to the improvement of the ceramics crack resistance. One of the promising methods for improving the physicomechanical properties of composite ceramic materials is boron carbide particles hardening (Ağaoğulları et al., 2012; Karlsdottir et al., 2010). The mechanical activation is used for the synthesis of zirconium carbide nanoparticles (Corral et al., 2010). Improving methods for producing (Xiang et al., 2011) materials by heating in high-density electric fields up to 600 V / cm, the use of self-propagating high-temperature synthesis (Sua et al., 2018), bombardment by high-energy protons to produce isotopes by nuclear reactions. The role of manganese additives in reducing the activation energy of the synthesis of the material was studied (Bokov, 2018). To improve the mechanical characteristics of nanocrystalline functional oxides, computer digital technologies, transmission electron microscopy are used (Borik, 2007), ultimately improving fracture toughness. The crack resistance of PSZ crystals is significantly superior to all known ceramic materials.

Problem Statement

The organization of industrial production of nanostructured crystals of partially stabilized zirconium dioxide is considered in the paper.

Research Questions

Market analysis of synthetic zirconium dioxide partially stabilized by yttrium oxides. Refinement of the nanostructure of PSC crystals. Determination of the parameters of the synthesis process of nanostructured crystals based on partially stabilized zirconium dioxide by direct high-frequency melting in a cold container. The selection of the optimal composition for the synthesis in the industrial plants "Crystal 403" the mixture composition and the concentration of yttrium oxide and zirconium dioxide.

Purpose of the Study

Creation of industrial production of nanostructured crystals of partially stabilized zirconium dioxide.

Research Methods

The surface and inner nanostructure of the synthesized PSZ crystals directly depends on the composition and synthesis conditions and, to a large extent, determines their mechanical characteristics. A large and many-sided volume of studies of the structure and properties of PSZ crystals was performed.

The effect of the amount of stabilizing yttrium additive on the structure and properties of PSZ crystals was studied. Crystals of partially stabilized zirconium dioxide of the compositions ZrO2 - (2.5-4 mol%) Y2O3, mainly with a smooth shiny surface. With a lower content of yttrium oxide, the surface of the crystals becomes rough and dull. The size of the crystals decreases significantly when the concentration of Y2O3 is less than 1 mol%, and when the content of yttrium oxide is from 5 mol% to 8 mol%, a large number of cracks appear in the bulk of the crystals.

The effects of the rate of the melt crystallization were investigated. The influence of thermal conditions of crystallization during crystal growth showed that in the case of using a lower thermal screen, the height of which is 2 times higher than in the previous processes, the proportion of crystals with a large cross section significantly increased. The crystals mainly had a smooth, shiny surface. The number of cracks and areas with a matte structure in the crystals was significantly less compared with crystals of the same composition grown with growth rates of 3 and 10 mm / h. Thus, growing conditions with a high lower thermal screen and growth rates of the order of 10 mm / h are most favourable for obtaining large PSZ crystals with smooth edges. Studies of the chemical composition of crystals showed that, when growing crystals by the method of directed crystallization, the starting materials are purified by trace materials. A decrease in the crystallization rate leads to a decrease in the content of additional impurities compared with their content in the initial charge. In this case, a fairly uniform distribution of the main components of the solid solution is observed (at crystallization rates of 3–40 mm / h), but local deviations of the Y2O3 concentration within ± 0.5 mol% are possible.

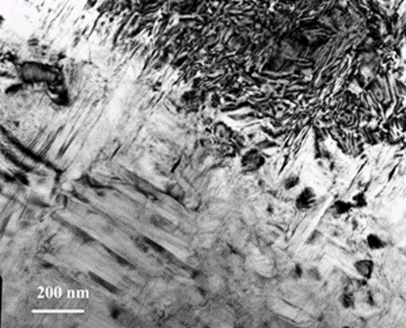

The phase composition of crystals was investigated. It was established (Kurbatkina et al., 2018) that at a growth rate of 3-10 mm / h, fused zirconium dioxide had a monoclinic phase; when the content of yttrium oxide is 2 mol%, the crystals were a mixture of monoclinic and tetragonal phases; in crystals with a content of yttrium oxide of 2.5 mol%, the monoclinic phase is found only in certain regions of the sample, most of it contains only the tetragonal phase; starting from a concentration of Y2O3 = 3 mol%, the crystals have a tetragonal structure up to a concentration of Y2O3 = 5 mol%; at a yttrium oxide content of 8-35 mol%, the crystals were cubic solid solutions. A study of the nanostructure of crystals of the composition ZrO2-2.5 mol% Y2O3 showed that at these concentrations of yttrium oxide the formation of a system of parallel domains begins (Figure

The technological process of the synthesis of PSZ crystals includes several main stages. Starting melting by introducing metal zirconium into the melted material, then the charge is loaded. The heating of the metal and the surrounding charge in the process of starting melting occurs due to the absorption of the RF field energy. Based on the results of the synthesis processes, depending on the composition of the PSZ crystals, an analysis of the physicomechanical properties of the selected samples was carried out. As a criterion of optimal concentrations, the best growth indices of PSC crystals obtained during the experiments were chosen. According to the results of a series of experiments, it was found that the composition with yttrium oxide and zirconium oxide concentrations of 6.3 and 93.7 mass%, respectively, is optimal for synthesis in Crystal 403 industrial production plants. This is close to the composition represented by the pure tetragonal phase and containing 3 molar% yttrium oxide. The necessity of holding the melt without moving the container before directed crystallization was found out for better mixing of the melt and nucleation of a smaller number of large single crystals. The container moving speed was determined that the crystal growth occurs uniformly, without the formation of tension cracks in the crystals, layers and growth bands are not formed due to crystallization supercooling. The boundaries of the optimal electrical parameters of the RF heating of the charge were established.

During the formation of the production site, a vacuum furnace was installed, and an experimental site was organized to study the effects of thermal annealing of PSZ crystals. During trial launches of this equipment, a stable annealing temperature in the chamber was obtained within 2000 deg. within 30 hours. A container was made for placement of experimental samples of crystals of PSZ. The main stages of the production process are applicable both for the production of cubic zirconia and for the manufacture of PSZ crystals. In Russia, the industrial production of PSZ crystals has been created (Figure

Findings

Zirconium dioxide has a great future. The physicomechanical properties of PSZ crystals give a reason to recommend their widespread adoption in various fields of industry and medical technology. The first samples of products for testing have been obtained.

Die blanks

They are used for drawing copper and aluminum wires in drawing mills in the cable industry. Die blanks can be made of sintered hard alloys of the tungsten-cobalt group or synthetic diamonds. Ceramic materials based on partially stabilized zirconium dioxide (PSZ) are distinguished by high strength, hardness, fracture toughness, elastic modulus and corrosion resistance, low friction coefficient (0.17 - 0.3) when used in conjunction with most metals, the ability to obtain very clean surface (table

Figure

Journal bearings

Spacecraft drives operating in outer space have bearing assemblies that operate under lubrication conditions. Lubrication is a source of vapor that contaminates the optical elements of a spacecraft. Therefore, for the normal operation of spacecraft, friction pairs are required that can operate without lubrication in open space. These circumstances make promising the use of PSZ crystals for use in spacecraft drives. Table

Figure

Figure

The different color of the bushings s is explained by the fact that the bushings made of PSZ crystals doped with various rare-earth elements are shown. The size of the crystals and the achieved mechanical properties of the PSC crystals give reason to recommend them for replacing all types of crystals in “supports on stones” in precision instruments and clockworks.

Conclusion

Currently partially stabilized zirconium dioxide is widely used in various fields of production. The consumption and use of rare earth elements in the world is growing, and especially in the most strategically important areas - engineering, electronics, energy, etc. Strength characteristics, cost and availability of raw materials create tangible competitive advantages for PSZ crystals over their analogues. The existing demand for the material has a tendency to increase, the demands of consumers are not fully met now. For this reason, the creation of a new production facility for the production of partially stabilized zirconium dioxide is economically feasible and efficient.

References

- Ağaoğulları, D., Gökçe, H., Duman, I., & Öveçoğlu M. L. (2012). Characterization investigations of ZrB2 / ZrC ceramic powders synthesized by mechanical alloying of elemental Zr, B and C blends. Journal of the European Ceramic Society, 32(7), 1447-1455.

- Agarkov, D. A., Bredikhin, S. I., Kuritsyna, I. E., Agarkova, E. A., Borik, M. A., Kulebyakin, A. V., Lomonova, E. E., Myzina, V. A., Osiko, V. V., Milovich, F. O., & Tabachkova, N. Y. (2018) Structure and transport properties of zirconia-based solid solution crystals co-doped with scandium and cerium oxides. Russian Journal of Electrochemistry, 54(6), 459-463. https://doi.org/10.1134/S1023193518060022

- Bokov, A. (2018). Energetic design of grain boundary networks for toughening of nanocrystalline oxides. Journal of the European Ceramic Society, 38(12), 4260-4267.

- Borik, M. A. (2017). Structure and conductivity of yttria and scandia-doped zirconia crystals grown by skull melting. Journal of the American Ceramic Society, 100(12), 5536-5547. https://doi.org/10.1111/jace.15074

- Borik, M. A., Bublik, V. T., Kulebyakin, A. V., Lomonova, E. E., Milovich, F. O., Myzina, V. A., Osiko, V. V., Seryakov, S. V., & Tabachkova, N. Yu. (2015) Change in the phase composition, structure and mechanical properties of directed melt crystallized partially stabilized zirconia crystals depending on the concentration of Y2O3. J. Eur. Ceram. Soc., 35, 1889–1894. https://doi.org/10.1016/j.jeurceramsoc.2014.12.01.01

- Borik, M. A., Bublik, V. T., Kulebyakin, A. V., Lomonova, E. E., Milovich, F. O., Myzina, V. A., Osiko, V. V., Seryakov, S. V., & Tabachkova, N. Yu. (2014). Phase composition, structure and mechanical properties of PSZ (partially stabilized zirconia) crystals as a function of stabilizing impurity content. J. Alloy. Comp., 586(1), 231–235. https://doi.org/10.1016/j.jallcom.2013.01.01.126

- Borik, M. A. (2007). Preparation and properties of Y2O3 partially stabilized zro2 crystals. Inorganic Materials, 43(11), 1223-1229. https://doi.org/10.1134/S0020168507110118

- Chevalier, J., Gremillardw, L., Virkar, A. V., & Clarke, D. R. (2009). The tetragonal-monoclinic transformation in zirconia: lessons learned and future trends, J. Am. Ceram. Soc., 92, 1901-1920.

- Corral, E. L., Luke, S., & Walker, A. (2010). Improved ablation resistance of C – C composites using zirconium diboride and boron carbide. Journal of the European Ceramic Society, 30(11), 2357-2364.

- Karlsdottir, S. N., Norton, S. J., Tucker, J. C., & Halloran, J. W. (2010). In situ microscopy observation of liquid flow, zirconia growth, and CO bubble formation during high temperature oxidation of zirconium diboride – silicon carbide. Journal of the European Ceramic Society, 30(11), 2365-2374.

- Kurbatkina, V. V., Patsera, V. V., Levashov, E. A., & Timofeev A. N. (2018). Self-propagating high temperature synthesis of refractory. Journal of the European Ceramic Society, 38, 1118-1127.

- Myshkin, N. K., & Goryacheva, I. G. (2016). Tribology: trends in the half-century development. Journal of Friction and Wear, 37(6), 513-516. https://doi.org/10.3103/S106836661606009X

- Sua, X., Baia, G., Jiaa, Y., Wanga, Z., Wub, W., Yana, X., Aia, T., Zhaoa, P., & Zhou, L. (2018). Flash sintering of lead zirconate titanate (PZT) ceramics: Influence of electrical field and current limit on densification and grain growth. Journal of the European Ceramic Society, 38(10), 3489-3497.

- Vagin, A. V., Sidorov, M. I., Albagachiev, A. Y., & Stavrovskii, M. E. (2017) Antiwear properties of coatings on artillery barrels. Russian Engineering Research, 3(12), 1052-1058. https://doi.org/10.3103/S1068798X17120188

- Xiang, J. Y., Liu, S. C., Hu, W. T., Zhang, Y., Chen, C. K., Wang, P., He, J. L., Yu, D. L., Xu, B., Lu, Y. F., Tian, Y. J., & Liu, Z. Y. (2011). Mechanochemically activated synthesis of zirconium carbide nanoparticles at room temperature: A simple route to prepare nanoparticles of transition metal carbides. Journal of the European Ceramic Society, 31(8), 1491-1496.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

21 October 2020

Article Doi

eBook ISBN

978-1-80296-089-1

Publisher

European Publisher

Volume

90

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1677

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Alisin, V. (2020). Innovative Production Of Nanostructured Zirconium Dioxide Crystals. In I. V. Kovalev, A. A. Voroshilova, G. Herwig, U. Umbetov, A. S. Budagov, & Y. Y. Bocharova (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST 2020), vol 90. European Proceedings of Social and Behavioural Sciences (pp. 1233-1240). European Publisher. https://doi.org/10.15405/epsbs.2020.10.03.141