Abstract

Rail transport in Russia is one of the largest rail distribution systems in the world. According to PJSC "Russian Railways" data, the largest share in the delivery structure of the company is coal (26%), oil, gas and oil products (22%), and construction cargo (13%). Currently, Russian railways mainly use locomotives, wagons, and special machines produced in the Soviet Union and its republics. Poor quality of logistics infrastructure and railway vehicles directly affect efficiency of the transportation process, because the total cost of performing transport operations is more than half of all logistics activity costs of any company. In this regard, the paper analyses the economic performance of PJSC "SG-TRANS", which is the Russian largest railway operator to deliver oil and gas, and petrochemical cargoes. The authors of the paper studied the power balance in the market of liquefied gases delivery: the current market situation is determined, short- and long-term perspectives of carriers’ activity are defined, key issues of railway vehicles operation when delivering liquefied gases by rail are identified (malfunction growth of components in logistics infrastructure, poor cleaning of railway tracks in the winter time, lack of an automated system to account gas loading on elevated structures, and customers reluctance to pick up a load in time), the optimal option of the car traffic volume of PJSC "SG-TRANS" from the base depot to the loading station is determined, and the economic efficiency of the proposed option to facilitate car traffic volume when delivering liquefied gases by rail is specified.

Keywords: Carrierdeliveryefficiencylogisticslogistics infrastructurerail transport

Introduction

Rail transport is a special area of economic activity, which is an important part of most logistics chains that are developed in the frame of national economic systems (Jarašūnienė, Sinkevičius, & Mikalauskaitė, 2017). Promising rail transport system should be active and flexible in terms of the quantity and quality of customer delivery orders (Khodakivskyi, Khodakivska, Kuzmenko, Shcherbyna, & Kolesnichenko, 2019). Many scientists directly relate current issues of rail transport development to the limited capabilities of the logistics infrastructure and its carrying capacity (Dolinayova, Ľoch, & Camaj, 2016; Costa, Martins, Santos, Felgueiras, & Calçada, 2017). There has recently been a gap between the carriers’ capabilities and cargo owners’ expectations (Zhang, Li, & Jian, 2019). Due to this fact, we need to search for ways to improve the cargo traffic efficiency, which determines the relevance of the study. The result of optimizing the cargo traffic by rail is considered to be a reduction in costs for a transport company and improved offers for cargo owners (Vojtek, Kendra, & Stoilova, 2019).

Thus, this study covers a set of issues to determine the sources to improve efficiency of transportation by rail. To achieve this purpose, the following issues were studied: the analysis of production and economic activity of the study object was made, the market of liquefied gases delivery by rail in Russia was evaluated and the main prospects for its development were identified, the main problems of railway vehicles operation of the study object were distinguished, and the options for car traffic volume movement from the base depot to the loading station were proposed.

Problem Statement

Under modern conditions, one of the main tasks in the field of operational work of the railway is the logistization of transportation activities with the effective use of carrying and processing capabilities of PJSC "Russian Railways" to timely provide the required load volumes with loading resources. It is also worth noting that now, in the work of railway transport, the percentage of empty mileage of cars is about 44 % and it continues to grow. This leads to a decrease in carrying capability, difficulties in shunting operations, a time increase of cars inactivity at stations, and violation of delivery terms. The identified problems were the reason for conducting the study to determine the sources of increasing the efficiency of cargo transportation by rail.

Research Questions

The study included several stages. At the first stage, the problem, the purpose and research methods were defined and the analysis of the main activity indexes of the study object were carried out. At the second stage, the need to improve the efficiency of liquefied gases delivery by rail was justified. At the third stage, the sources that contribute to saving the maintenance expenses of the study object in the process of goods delivery by rail were identified.

Purpose of the Study

Key propriety areas to develop companies at the market of delivery by train are maintaining of high quality of cargo carriers service, efficiency increase in inner business processes, and operational perfecting of delivery activity. In its turn, the presence of a wide range of special characteristics while delivering by train liquefied gases, which directly influence operational efficiency of carriers' activity, reflects the scientific problematics of the study. Therefore, the purpose of the study is to develop practical recommendations to improve the efficiency of the railway vehicles use in the process of liquefied gases delivery by rail.

Research Methods

The study draws on the methods of logistics analysis based on such principles as scientific approach, system approach, dynamism, priority areas distinction, complexity, completeness and reliability of the information base, and practical operability of research results. "SG-TRANS" company, the largest Russian railway operator of oil and gas, and petrochemical cargoes delivery, was determined as the experimental base for the study to identify sources to increase the efficiency of cargo transportation by rail.

Findings

The railroad complex is of strategic importance for Russia, providing its needs in freight and civil passenger traffic, and stability in national security and international cooperation (Karpova, Noskov, Toymentseva, & Shvetsova, 2018). The largest company in the market of liquefied gas delivery by rail is PJSC "SG-TRANS". The company provides export of about half of the total volume of all liquefied petroleum gases transported in tankers in Russia.

Production and economic activities of "SG-TRANS" are carried out through a network of branches for liquefied gas delivery and sales branches, located in 26 regions of the Russian Federation:

12 branches to sell liquefied gas (reception, storage, and sale ports). The main purpose is the wholesale supply of salable liquefied petroleum gas (LPG) in cylinders and tankers to consumers, as well as to the own gas filling stations (GFS),

14 branches to deliver gas. The main purpose is to provide services to deliver LPG and light hydrocarbon (LH) in specialized railway tank cars from the manufacturer to wholesale consumers in Russia and for export.

Let us evaluate the main performance indicators of PJSC "SG-TRANS" (Table

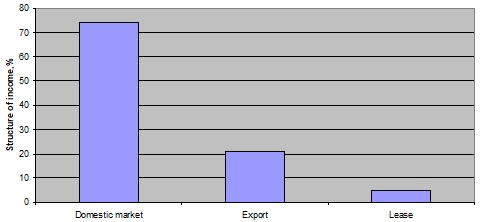

In 2017, sales revenue amounted to 364,3 mln rubles, in 2018 to 381,4 mln rubles, and in 2019 to 402,6 mln rubles. In general, within the reporting period, an increase was 10.52 %. In 2017-2019, the dynamics of cost of goods sold of the company's services increased by 15.77%. In 2017, the gross profit of "SG-TRANS" amounted to 67,77 mln rubles, in 2018 to 49,44 mln rubles, and in 2019 to 59,34 mln rubles (87.6% more than in 2010). The growth rate of net profit in 2019, in relation to 2018, was 119.5% and in relation to 2017, it was 86.9%. Gas delivery is carried out both in Russia and in export directions. The company is also a leasing holder of railway vehicles. Figure

Source: authors.

The largest share in the structure of cargo transportation is the volume of liquefied gases delivery in the domestic market (74%). The volume of liquefied gases delivery for export amounted to 21% of the total in 2019. The volume of transportation by railway vehicles was 5%. Table

In 2017, the company's delivery expenses amounted to 247,9 mln rubles, in 2018 to 261,7 mln rubles, and in 2019 the cost of cargo traffic amounted to 277,68 mln rubles. In 2019, tankers repair services had the largest share (30%). Table

According to Table

Figure

Source: authors

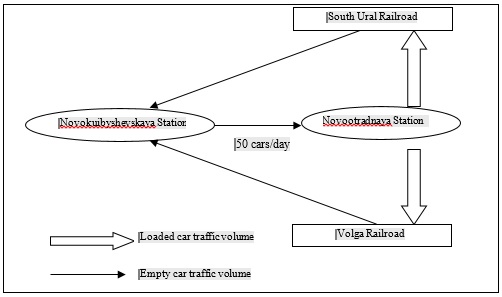

The key stations on Kuibyshev Railway, where liquefied gas is loaded and to which the cars of PJSC "SG-TRANS" are sent, are Novootradnaya, Kashpir, and Kryazh Stations. These operations are carried out by Otradninsky oil-processing plant on the private tracks of Novootradnaya Station. The average daily loading of the company's tankers at Otradninsky oil-processing plant is 50 cars/day. Kashpir Station is bordered upon the private tracks of Syzran oil-processing plant. The average daily loading of the company's tankers at the enterprise is 38 cars/day. Kuibyshev oil-processing plant tale on lease the private tracks at Kryazh Station and daily asks "SG-TRANS" of 30 cars for loading.

Reservoir trucks line at the base depot being prepared for loading, cleaned, and in good conditions. After clearing a requisition for cargo transportation, the required number of empty cars is delivered from the base depot to the loading station, where the plant loads the product. Then, the cars are sent to the contractual counterparty on Volga or South Ural Railroad, and from there empty cars, by the decision of the railway vehicle owner (PJSC "SG-TRANS"), are transported either to the base depot (Novokuibyshevskaya Station) or to the loading station (Novootradnaya Station). According to the signed contract of cars lease, the contractual counterparty is obliged to pay for the return of empty tankers to the loading station. If cars are transported to Novokuibyshevskaya Station, the car owner (PJSC "SG-TRANS") pays for the extra distance passed by empty cars.

There are no tracks leased from PJSC "SG-TRANS" at Novootradnaya Station, and in order not to pay fines to PJSC "Russian Railways" for abandoned cars on the infrastructure tracks, all empty reservoir trucks are sent back to their base depots, which, in turn, increases the empty car mileage and causes excess expenditures of the company.

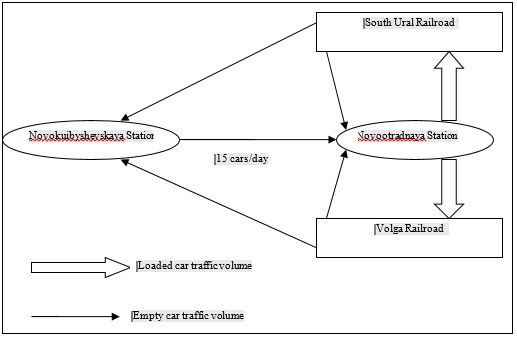

To optimize cars management, it is proposed that "SG-TRANS" signs an agreement with oil-processing plants for сars layover on the private tracks of the plants that load the product in "SG-TRANS" tankers. Therefore, the contractual counterparty will return empty cars to the loading station and independently pay the dead mileage cost. In addition, each oil-processing plant has malperformance due to faulty equipment or climatic conditions. In this case, loading is suspended at this enterprise, and the supplied cars do not move but occupy the railway tracks to the station. The concentration of cars standing on railway tracks to the station and waiting for loading may also occur as a result of uneven loading, which happens due to incorrect loading schedules. If the company "SG-TRANS" has its own car layover tracks at loading stations, respectively, during the break in the work of the plant, it will be able to deliver there temporarily non-demanded cars and will not be obliged to pay mandatory fines to PJSC "Russian Railways" for the public rail occupation. The proposed version to develop empty and loaded car traffic volume of "SG-TRANS" is presented in Figure

Source: authors.

The economic efficiency of the proposed option is shown in Table

According to the current principle to develop car traffic volume, annual expenses of "SG-TRANS" consist of the cost of leasing private tracks bordered upon the base depot, the cost of cars empty mileage from the loading station to the base depot, and the cost of using PJSC "Russian Railways" tracks if oil-processing plants do not make loading for some reasons. The company's operating expenses under the proposed option consist of the cost of leasing private tracks at the loading station, the cost of cars empty mileage that are not left on the leased tracks, and the cost of using PJSC "Russian Railways" tracks. The total savings in company’s operating costs under the proposed option will be 73,1 mln rubles.

Conclusion

The analysis of PJSC "SG-TRANS" activity revealed a number of key problems in the railway vehicles operation that are reflected in Table

The identified problems to operate railway vehicles of PJSC "SG-TRANS" are the causes of many economic imbalances and have a negative impact on the company's performance as a whole. The number of rail breakage has increased significantly, including deterioration of sleepers, crossing sleepers, tracks, clamps, and rail gage. Also, there is poor cleaning of railway tracks. This leads to additional company’s costs and also reduces the quality of loading-and-unloading and shunting work. The consumers are not often able to pick up loads in time. We believe that eliminating of this problem is possible only through closer information exchange with customers (for example, within the information logistic systems using announcements and reminders, material flow planning, etc.), and consideration of such factors when drawing up contracts on the services provision. PJSC "SG-TRANS" has significant losses due to the lack of an automated system to account loading on the elevated structures.

The review of the main problems of railway vehicles operation of PJSC "SG-TRANS" allowed to formulate practical proposals to improve the efficiency of liquefied gases delivery by rail. If there is a sufficient number of managed fleet, the company successfully manages deliveries, affects delivery costs, more accurately develops production and financial activities, and has all the conditions for capitalization growth and strengthening of its positions in the market. To improve the stability of PJSC "SG-TRANS" work, the repair of track facilities is required. In order to reduce the required number of railway vehicles and increase fixed-route group delivery, it is necessary to increase cargo fronts. To reduce the required number of railway vehicles and increase the static load, the maximum use of all types of tankers, including eight-axle ones, is required. To reduce the cost of empty delivery, it is necessary to lease private ranks at oil-processing plants.

References

- Costa, B., Martins, R., Santos, M., Felgueiras, C., & Calçada, R. (2017). Weighing-in-motion wireless system for sustainable railway transport. Energy Procedia, 136, 408-413.

- Dolinayova, A., Ľoch, M., & Camaj, J. (2016). liberalization of the railway freight market in the context of a sustainable transport system. Transportation Research Procedia, 14, 916-925.

- Jarašūnienė, A., Sinkevičius, G., & Mikalauskaitė, A. (2017). Analysis of application management theories and methods for developing railway transport. Procedia Engineering, 187, 173-184.

- Karpova, N., Noskov, S., Toymentseva, I., & Shvetsova, E. (2018). Sources of rail transport efficiency in supply chains. Helix, 8(5), 3607- 3614.

- Khodakivskyi, O., Khodakivska, Y., Kuzmenko, O., Shcherbyna, M., & Kolesnichenko, O. (2019). Improvement of the railway transport system by increasing the level of goal-oriented activity. Procedia Computer Science, 149, 415-421.

- Vojtek, M., Kendra, M., & Stoilova, S. (2019). Optimization of railway vehicles circulation in passenger transport. Transportation Research Procedia, 40, 586-593.

- Zhang, R., Li, L., & Jian, W. (2019). Reliability analysis on railway transport chain. International Journal of Transportation Science and Technology, 8(2), 192-201.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

01 April 2020

Article Doi

eBook ISBN

978-1-80296-081-5

Publisher

European Publisher

Volume

82

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1004

Subjects

Business, innovation, management, management techniques, development studies

Cite this article as:

Karpova, N. P., Toymentseva, I. A., & Korzhova, G. А. (2020). Sources To Improve Efficiency Of Liquefied Gases Delivery By Rail. In V. V. Mantulenko (Ed.), Problems of Enterprise Development: Theory and Practice, vol 82. European Proceedings of Social and Behavioural Sciences (pp. 470-478). European Publisher. https://doi.org/10.15405/epsbs.2020.04.61