Abstract

The globalization of the economy and conditions of fierce competition determine the companies’ need for searching new forms of production organization. The application of the quality management system To achieve the desired level of (QMS) and lean production concept allow to achieve the desired level of the production system and, accordingly, increase the production efficiency. In countries that have been able to achieve the advanced development level, the lean production concept is recognized as an industrial development strategy, which enables to achieve a leading position in the market. The formation of a new model or the adaptation of an existing proven concept is associated with the emergence of many problems that require immediate solutions. In a well-thought-out management system, key processes help any organization to achieve short-term and long-term production goals. The key condition is that the used "lean" tools need to be adapted so that they contribute as much as possible to the elimination of major losses. Based on the analysis of a variety of different studies, methods of the concept application, the authors propose a mechanism of the lean production concept implementation. This mechanism is divided into operational, tactical and strategic steps that allows to take into account specific features of service enterprises with the production process, determine the importance of various losses in the allocated business-processes and choose appropriate tools of lean manufacture concept.

Keywords: Management modelmechanism of lean production implementationmanagement levelsforms of management

Introduction

The application of a lean production system means the company's transition to a new level of high quality with the participation of all employees in this process. Nowadays, the use of principles of the lean production concept is one of the key methods of improving the business competitiveness. However, simply repeating the experience of third-party companies, business entities will not achieve desired results (Gaisina et al., 2019). In Russia, more and more people are trying to apply the lean production concept at industrial and service enterprises because this management concept involves the optimization of all business processes and the elimination of possible losses (Rudov, Khairullina, Gareev, Koltunov, & Skifskaja, 2017; Belysh, 2018).

Problem Statement

As a rule, the introduction of lean production is a disordered and chaotic process at Russian industrial enterprises, because:

there is no unified consolidated platform of knowledge and values for this concept and there is no understanding of its philosophy among employees (Shiyanova, Valitova, Munasypov, Kayashev, & Hardina, 2014);

enterprises grab all the lean production tools not taking into account that in some business processes the use of these tools is impossible, or will not lead to anything (Chernova & Ageev, 2016);

there is no model for managing this concept;

there is no single mechanism for the concept implementation.

Research Questions

The relevant research questions (tasks) include:

to identify main stages of implementation of the lean production concept;

to define a clear sequence of actions in each stage of the developed mechanism for more effective concept implementation;

to form a concept management model.

Purpose of the Study

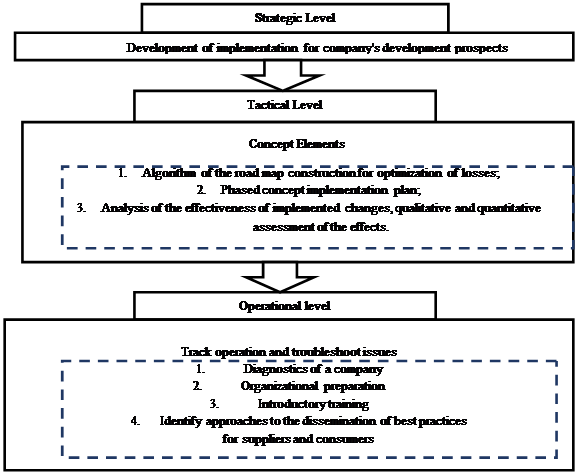

The purpose of the study: to develop a mechanism for adaptation of the lean production concept to modern conditions and specific features of service enterprises (Fig. 01). This mechanism is necessary for the competent business management.

Research Methods

The methodological base for this research consists of scientific works devoted to the essence and formation of the lean production concept, as well as modern approaches to the production systems management and mechanisms of implementation and development of lean production in Russia (Shibanov, 2019). The authors use methods of system and situational analysis, historical and critical analysis, methods of expert assessments, logical constructions, comparison, observation. The application of these methods allows to estimate objectively conditions for introduction and adaptation of the lean production at Russian enterprises (Vanchukhina, Leybert, Khalikova, & Luneva, 2018).

Findings

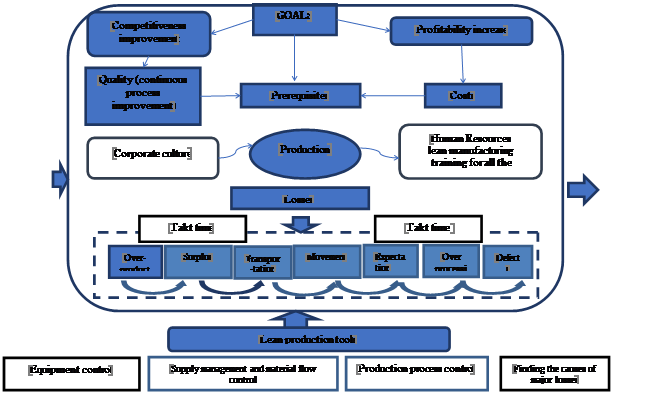

The mechanism consists of three levels of management: strategic, tactical and operational (Fig.01). The purpose of the strategic stage is to determine the main priority directions of the enterprise development. The basis of the tactical stage is formed by elements of the concept itself developed by the authors. In the conceptual model, tools are divided according to the directions that are related to the loss chain of each business process, so that the improvement of one key point does not have a negative impact on the other and taking into account prerequisites, in order to achieve the company’s goals. The authors propose to form a model of lean production management by creating a special algorithm (Fig. 02), which allows to identify losses of each business process, the impact of these losses on each other.

Source: authors.

Applying tools for optimizing the selected losses, it is necessary to analyze the effectiveness of the implemented changes, conduct a qualitative and quantitative assessment of effects. After the introduction of the concept in the production process, already at the strategic level, a long-term plan of the enterprise’s development is developed taking into account new ideas.

The operational phase is to monitor the process functioning and correct possible problems. It includes the following steps:

1. Diagnostics of the company. Any change in the company's activities, especially one that relates to a holistic change in the concept of business functioning, requires diagnostics in the main areas:

a) processes (to collect data about the company in the context of the following aspects: production planning, operational management, quality, equipment maintenance, equipment changeover, change management, internal logistics, standardization, restrictions management);

b) system (to collect data about the company in the context of the following aspects: strategic management, financial management, risk management, process management, TQM, service and warranty, project management, external logistics, competency management system and recruitment);

c) culture (to collect data about the company in the context of the following aspects: customer focus, continuous improvement, loyalty of engineers, loyalty of workers).

After the diagnostics of the company and identifying its need for changes, it is necessary to organize the preparation for the lean production concept implementation, which includes 2 stages: project planning and meetings. Once organizational training has been completed, introductory training for all staff is required.

If we take into account that lean production is for 80% a philosophy, then the key to the successful implementation of this concept lies in changing the people’s minds in the context of business management, business process management, implementation of any activity at the enterprise. Accordingly, the next stage should be training of all participants involved in the implementation of the lean production concept. Applying tools for optimizing the selected losses, it is necessary to analyze the effectiveness of the implemented changes, conduct a qualitative and quantitative assessment of their effects.

Conclusion

According to the fact that the lean production concept has improved the company's activities, was competently integrated into the business processes that really needed it, allows eliminating losses, as well as avoiding the emergence of new ones. That’s why the authors propose to extend their successful experience to all suppliers and customers of the company to avoid losses from the outside. This mechanism will enable to properly integrate the philosophy of lean production into the enterprise’s business processes, taking into account the policy of Russian companies, specific features of service companies with the production process.

References

- Belysh, K. V. (2018). Multipurpose approach to implementation and evaluation the efficiency of the projects on lean production in industrial enterprises. Issues of Innovative Economy, 8(3), 513-530. https://doi.org/10.18334/vinec.8.3.39364 [in Rus.].

- Chernova, V. A., & Ageev, I. T. (2016). The concept of lean production: Steady reduction of losses. Young Scientist, 26, 407-410. [in Rus.].

- Gaisina, L. M., Burhanova, F. B., Minakov, P. A., Yaminova, S. A., Rakhimkulova, L. A., & Gainanova, A. G. (2019). Quality management system of social policy on students' healthy lifestyle in Russia. Espacios, 40(17), 18.

- Rudov, S. V., Khairullina, N., Gareev, E. S., Koltunov, A. L., & Skifskaja, A. L. (2017). Labor motivation management in the oil and gas sector enterprise: A sociological approach. Quality - Access to Success, 18(156), 119-124.

- Shibanov, K. S. (2019). Lean production: Continuous flow and pulling systems. Colloquium-Journal, 2-6(26), 41-43. [in Rus.].

- Shiyanova, N. I., Valitova, E. G., Munasypov, R. A., Kayashev, A. I., & Hardina, A. E. (2014). Quality assessment system for milk acceptance and a mathematical model of dairy produce drying. Automation and Remote Control, 75(4), 767-772. https://doi.org/10.1134/S000511791404016X

- Vanchukhina, L. I., Leybert, T. B., Khalikova, E. A., & Luneva, N. N. (2018). Modern approaches to operational planning in oil refinery using the PIMS software product. Quality - Access to Success, 19(S2), 123-129.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

09 March 2020

Article Doi

eBook ISBN

978-1-80296-078-5

Publisher

European Publisher

Volume

79

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1576

Subjects

Business, business ethics, social responsibility, innovation, ethical issues, scientific developments, technological developments

Cite this article as:

Burenina, I. V., Battalova*, A. A., & Battalov, A. M. (2020). Lean Production Implementation Mechanism. In S. I. Ashmarina, & V. V. Mantulenko (Eds.), Global Challenges and Prospects of the Modern Economic Development, vol 79. European Proceedings of Social and Behavioural Sciences (pp. 140-144). European Publisher. https://doi.org/10.15405/epsbs.2020.03.19