Efficiency Increase For Railway Stations And Non-Public Tracks Interaction In Oil-Refining Complexes

Abstract

The authors of this article consider specific features of interaction between stations of JSC "Russian Railways" and ways of non-public use of oil refineries. The production volume at well-known enterprises and the production distribution by production structures are given in this paper. The dependence of the output volume of finished products and the interaction with rail transport are determined and analyzed. The existing development method of the unified technological operation process of the railways does not provide a target function combining peculiarities of technology, planning and control elements of the oil-refining railway complex. It is necessary to study and develop recommendations to optimize the interaction between railway stations and ways of non-public use of oil refineries. The identified peculiarities of this interaction, and the carried out experimental calculations, enable to speak about the need for a systematic approach to the problem of the unified technological operation process development and the efficiency increase of such an interaction in modern conditions. Recommendations for improving the operation of the adjoining stations and private railways of oil refineries are based on the proposed digital simulation model and the integrated efficiency indicator for management decisions. The conducted research is based on the analysis of one of the largest refinery complexes in the European part of Russia.

Keywords: Oil-refining industrystationtechnologyinteractioncriteriaefficiency

Introduction

The Russian oil-refining industry is one of the largest in the world. In terms of total oil refining, Russia is one of the five world leaders, just after the United States and China in the world rating ( Russia in the 21 st century, 2013 ). To some extent, this is due to historical circumstances that almost all serious enterprises in this industry were built in Russia before 1991. At present, the domestic oil industry combines about 30 large refineries with refining volumes of more than 1 million tons of oil and several tens of small ones ( Russia in the 21 st century, 2013 ; Expert Online, 2019). Oil refineries and organizations of our state are divided into:

PCC – petrochemical complexes and companies;

ORA – oil refining associations;

ORP – oil-refining plants;

EOS – enterprises of "organic synthesis".

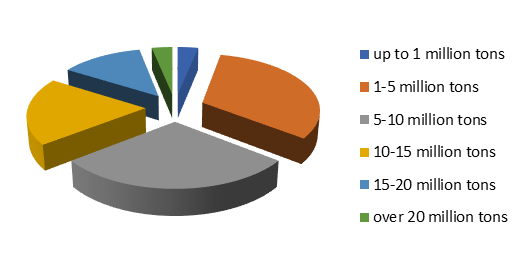

It is logical that the major share of large enterprises in this sector of the economy is concentrated in the European part of the country. They are concentrated either in places of the greatest consumption of products, or near oil fields. For example, only in the Samara region there are three large refineries. The total amount of processing capacity in Russia is more than 279 million tons per year ( Vygon Consulting, 2017). The distribution of enterprises in terms of their output volume is characterized by the diagram presented in Figure

One of the most popular transportation types for products of oil refineries is railway transport. It has more than 40% of all transportation of petroleum products ( Shiftman - transport and logistics portal, 2014). When fulfilling tasks of oil cargo transportation, there is a certain systemic interaction between the carrier represented by the adjoining railway station and the consignor – the oil refinery.

Problem Statement

The existing development method for a single technological process (STP) of the operation of non-public tracks and the junction station does not provide a target function that combines specific features of technology, planning and management of the oil-loading railway complex elements. It is necessary to study and develop recommendations to optimize the operation of the junction station and non-public tracks of petrochemical complexes and companies (PCC).

To solve this problem, the authors studied one of the largest refinery complexes in the European part of Russia, and on the basis of this research, they analyzed the main traffic flows of oil products, identified consequences of the lack of effective interaction of railway transport and oil refineries, as well as key opportunities for developing the cooperation between the refinery and rail transport in Russia.

Research Questions

The purpose of a single technological process is to link the operation technology of the junction station and the technology of the non-public tracks ( Kalushin & Soldatkin, 2018). The most important elements, in our opinion, of such an interrelated technology work are: organization of loading cars (including routes and groups of cars); execution order of shunting works; supply and appropriate distribution of cars supplied for the fronts of loading and unloading; arrangement order of cars for cargo operations, the implementation and regulation of operations for fixing cars; organization of document flows, characteristics of loading areas, standardization of operation time on the non-public tracks and at the station.

The revealed features allow us to conclude that it would be rational to create a certain “digital” simulation model, which should at least carry out the following functions: input of initial data for modeling the structure and technology of using the station and non-public tracks in a convenient form for users; transformation of the received source data to a standard form (for example, to the terms of a modeling language or other form); calculations based on the model; processing and adjustment of calculation results.

Thus, the following tasks are to be solved:

define the scope of delivery existence;

determine the load formation tree;

determine the delivery route of the formed cargo.

Purpose of the Study

The aim of this study is to form:

mathematical approach to solving this class of tasks;

requirements to the configuration and volume of source data depending on the task to be solved and imposed restrictions;

correct the algorithm for solving a problem, represented at the level of the flowchart.

In this case, the role of optimization criteria can relate to simple criteria: the existence of a delivery route; the shortest delivery path; the minimum time of delivery; the minimum delivery cost for a customer; the minimum delivery costs for a contractor, or their combinations as "delivery time is not more than a given one by costs of the customer are not more than specified ones".

In our case, the criterion of the performer’s maximum profit, which is often set in such tasks, is incorrect, since when it is used, the cargo will either stand idle for years at station N, conditionally bringing profit in the form of fines for delaying rolling stock, or travel along all the Russian railways. Instead of this criterion, the criterion of the minimum costs of the contractor is considered, free from these shortcomings ( Kalushin, 2001).

Research Methods

In cases where it is necessary to monitor the operation of each particular technological device that is used, the model should fully display such an object. Devices are displayed using "linked" items. Linked elements are special logic elements that are engaged in time simultaneously with ordinary logic elements. The number of such technological devices, and, consequently, the number of related linked elements in the model is set by the user:

where:

Since the criterion chosen by the user, which needs to be improved, directly or indirectly affects the delays in the model, the functional is the cost indicator of total delays:

where:

The total cost indicator of delays:

where:

The process of optimizing interaction is a series of calculations to achieve a user-defined level with a selected polygon structure and control option. The user changes parameters to reduce delays based on the unit cost:

where:

In this case, the following costs should be taken into account: operating costs - (E); costs of loading and unloading operations (P); maintenance costs (formation, disbandment, etc.) - (О); costs of communication and document processing - (C); costs of loan interest on loans - (Z); management costs (L), forming the internal costs of the transport interaction:

The resulting effects are interdependent and cause each other. The results of management are manifested through the impact on system-wide costs and the amount of reduction in the delivery time. This provides an opportunity to optimize the costs of the carrier while reducing the total time of the final delivery.

The consistent compliance with the conditions of the developed algorithm when working based on the economic optimization criteria (

where:

Findings

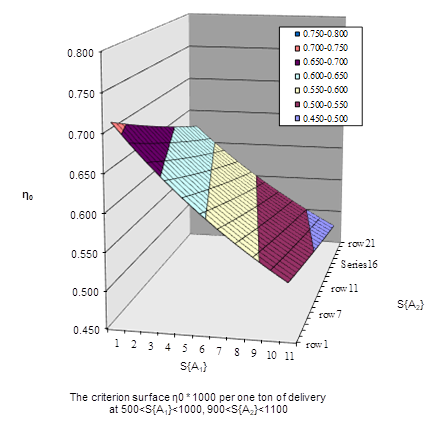

The results of the experimental calculation are shown in table

The calculated values of the criterion are shown in figure

Conclusion

According to the data of Shiftman - transport and logistics portal (2014), an oil loading railway complex can have as its component both one or several adjoining stations. The cost of transportation of oil products by railway is formed under the influence of a large number of parameters. The increase in the efficiency of interaction between railway stations adjacent to oil-refining associations and oil refineries is achieved by the selection of technological elements, operations and processes aimed at reducing the total specific (unit) in-transit and non-transport costs (Project Plaza, 2014).

The integral indicator reflects the productivity and is positively correlated with the concept of the intra-transport and non-transport delivery efficiency. The minimum value of the delay, equivalent to the denominator of the expression for an integral indicator of the effectiveness of management decisions, leads to the least costs associated with managing the interaction.

The revealed peculiarities of the interaction of the railway stations adjacent to oil-refining associations and oil refineries, and the performed experimental calculations, allow us to speak about the need for a systematic approach to the problem of both developing the single technological process and increasing the effectiveness of such interaction in modern conditions, as well as continuing more detailed research in this direction.

References

- Expert Online (2019). All the oil refineries of Russia. Retrieved from: http://expert.ru/ratings/vse-npz-rossii Accessed: 02.11.2019. [in Rus.].

- Kalushin, A. A. (2001). Management of export oil cargo flows in mixed traffic. (Ph.D. thesis.) Moscow: State Transport University. [in Rus.].

- Kalushin, A. A., & Soldatkin, V. I. (2018). Features of interaction of stations of adjunction of JSC "Russian Railways" and ways of non-public use of the Russian oil refineries. In D.V. Zheleznov (Ed.), Proceedings of the XI International Scientific and Practical Conference ”Science and Education for Transport”, 1 (pp. 84-91). Samara: Samara State Transport University.

- Project Plaza (2014). Transportation and processing of oil. Retrieved from: https://proekt-plaza.com/a147200-transportirovka-pererabotka-nefti.html Accessed: 03.11.2019. [in Rus.].

- Russia in the 21st century (2013). Modernization of the oil refining industry. Retrieved from: http://21russia.ru/article/economics/2013-05-20/767 Accessed: 02.11.2019. [in Rus.].

- Shiftman – transport and logistics portal (2014). Transportation of petroleum products by railway. Retrieved from: http://shiftman.ru/railway/zd-perevozka-nefteproduktov/ Accessed: 02.11.2019. [in Rus.].

- Vygon Consulting (2017). Russian oil industry: Results of 2016 and prospects of 2017-2018 (Part 1). Retrieved from: https://vygon.consulting/products/issue-905/ Accessed: 02.11.2019. [in Rus.].

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

09 March 2020

Article Doi

eBook ISBN

978-1-80296-078-5

Publisher

European Publisher

Volume

79

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1576

Subjects

Business, business ethics, social responsibility, innovation, ethical issues, scientific developments, technological developments

Cite this article as:

Kalushin*, A. A., Fokeev, A. B., & Soldatkin, V. I. (2020). Efficiency Increase For Railway Stations And Non-Public Tracks Interaction In Oil-Refining Complexes. In S. I. Ashmarina, & V. V. Mantulenko (Eds.), Global Challenges and Prospects of the Modern Economic Development, vol 79. European Proceedings of Social and Behavioural Sciences (pp. 1247-1254). European Publisher. https://doi.org/10.15405/epsbs.2020.03.178