Abstract

Five- and six-membered nitrogen heterocycles are common structural units that have been studied due to their importance in natural compounds, synthetic drugs and medicines. In this study, the development of new synthetic methods towards the formation of fused nitrogen heterocyclic (γ-lactam) rings system were successfully established. The key intermediate γ-lactam ring unit which exists in the more stable enol form and also appears as racemic mixture, was successfully prepared

Keywords: Bicyclic fusedenamine hydrogenationlactam

Introduction

The five-membered nitrogen-heterocycles are key elements that typically found in naturally occurring substances. The wide-ranging spectrum of pharmacological effects of this type of compound has attracted significant interests especially in synthetic drugs researches ( Hameed & Akhtar, 2011), in agricultural industry and in organic synthesis. The pyrrolidine (also known as tetrahydropyrrole) ring structure especially γ-lactam (α-carbonyl pyrrolidine) possess significant Structure-Activity Relationship (SAR) and versatile reaction intermediates for pharmaceutical drug’s productions for example doxapram, aniracetam, lactacystin and cotinine. Likely, the alkaloid cotinine that found in tobacco is verified for antipsychotic-like effects ( Buccafusco & Terry, 2009), thus it was widely used biomarker to cure Alzheimer’s diseases ( Grizzell \7 Echeverria, 2014), schizophrenia and depression.

The synthetic approaches of α-carbonyl pyrrolidine include 1,3-dipolar cycloaddition ( Li, Tong, Li, Tao, & Wang, 2011), ring-closing metathesis ( Majumdar, Muhuri, Islam, & Chattopadhyay, 2009), solid-phase synthesis ( Vergnon, Pottorf, Winters, & Player, 2004) and multicomponent reaction ( Wei & Shaw, 2007). Moreover, Friedel- Crafts alkenylation of ionic liquids ( Song, Jung, Choung, Roh, & Lee, 2004), Rhodium-catalyzed arylation-cyclisation of N-tosylarylimines ( Wang, Feng, Xu, & Lin, 2007) and an intramolecular Wurtz-Fittig coupling reaction ( Campbell, Dedinas, & Trumbower-Walsh, 2010) similarly have been conveyed on the formation of the respective cyclic ring system. Whereas, a classic approach to synthesize six-membered (δ)-lactam ring are involved the formation of heterocyclic ketene aminal ( Huang & Liu, 1989), (3,3) sigmatropic rearrangement ( Cheung & Yudin, 2006) and Huisgen (3+2) dipolar cycloaddition ( Kumar & Rode, 2007).

Problem Statement

A review of the literature discloses that no inclusive syntheses of fused 5,5- and 6,5-bicyclic

Research Questions

What are the simplest and approachable synthetic methodologies to transform the 2,3-pyrrolidinedione into fused bicyclic 6,5-lactam and 5,5-lactam ring systems?

Purpose of the Study

To design and construct the chemical conversions of highly substituted 2,3-pyrrolidinedione that serve as a core to synthesize a new fused bicyclic 5/6-nitrogen-heterocyclic-lactam ring moieties employing an amine (either enamine or imine) initial product.

Research Methods

General

All chemicals and reagents were purchased from Merck and Aldrich. Column chromatography (CC) was carried out using Merck Kieselgel 60 with 70-230 mesh ASTM. Thin layer chromatography (TLC) was performed using 20x20 (cm) aluminium sheets coated with Merck Kieselgel 60 F 254. The TLC plates were visualized at λ = 254nm under ultraviolet light and was exposing to I 2 vapour or staining with KMnO 4 solution. The qualitative MS was analysed on LCMS/MS Q-TOF Agilent Technologies 6520 (for liquid sample) or MSI-High Resolution Mass Spectrometer (HRMS) Model CO-1600 Autoconcept (for solid sample). Melting points (m.p.) were determined

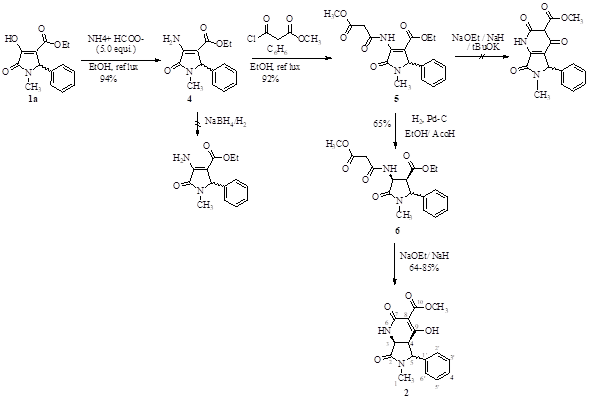

Preparation of Compound (4)

A NH 4CO 2H (5.0x10 -3 mol) was poured into

Preparation of Compound (5)

In a flask, a reaction mixture of

Preparation of Compound (6)

The 10% Pd-C (1.3x10 -3 mol) was added into the solution of

Preparation of Compound (2)

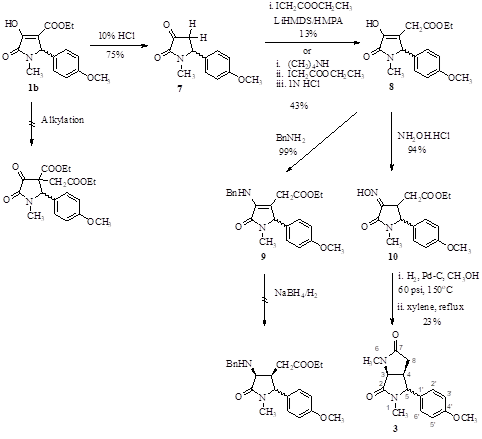

Preparation of Compound (7)

Compound

Preparation of Compound (8)

Preparation of Compound (9)

Benzylamine (2.0x10 -3 mol) was added into a solution of

Preparation of Compound (10)

To a solution of

Preparation of Compound (3)

A catalytic amount of 10% Pd-C (1.0x10 -3 mol) was added into a solution of

Findings

Among a list of the produced reaction products of our prior work ( Mohammat et al., 2012), compound

The coupling reaction between

Table

In short, the five-steps pathway successfully synthesize the targeted fused lactam 2 from 1a with an overall yield of 21% (Figure

Compared to 6,5-lactam ring system that need the CO functionality at C 4 position, the synthesis of 5,5-lactam ring system is likely contrariwise. The elimination of ethyl ester group at C 4 position and the replacement by ethyl acetyl group are essential prior to intramolecular cyclisation step. A

The nucleophilic addition reaction was designed for a next step by treating 8 with NH 2OH·HCl and BnNH 2 to give hydroxyl-imine 10 and

In brief, fused lactam 3 was well synthesized with an overall yield of 4% in the six-steps pathway (Figure

Conclusion

Both bicyclic fused 6,5- and 5,5-lactams were successfully produced and reported for the first time from highly substituted and accessible 2,3-dioxo-5-(substituted)arylpyrroles. Both synthetic methodologies require

Acknowledgments

Authors thanks the Institute of Science (IoS), Integrative Pharmacogenomics Institute (iPROMISE) and Faculty of Applied Sciences (FSG) Universiti Teknologi MARA (UiTM) for providing research facilities. This research was funded by Malaysian Ministry of Education through 600-RMI/FRGS TD 5/3 (1/2014) of Fundamental Research Grant Scheme (FRGS) Top Down Grant.

References

- Buccafusco, J. J., & Terry, A. V. (2009). A Reversible Model of the Cognitive Impairment Associated with Schizophrenia in Monkeys: Potential Therapeutic Effects of Two Nicotinic Acetylcholine Receptor Agonists. Biochemical Pharmacology, 78(7), 852-662.

- Campbell, J. B., Dedinas, R. F., & Trumbower-Walsh, S. (2010). Preparation of Isoindolones by a Lithium-Iodide Exchange-Induced Intra-molecular Wurtz-Fittig Reaction of O-Iodobenzoyl Chloride/Imine Adducts. Synlett, 3008-3010.

- Cheung, L. L. W., & Yudin, A. K. (2006). Synthesis of Aminocyclobutanes through Ring Expansion of N-Vinyl-β-Lactams. Org. Lett., 11(6), 1281-1284.

- Dahaen, W., Metten, B., Kostermans, M., Baelen, G. V., & Smet, M. (2006). Synthesis of 5-aryl-2-oxopyrrole Derivatives as Synthons for Highly Substituted Pyrroles. Tetrahedron, 62, 6018-6028.

- Grizzell, J. A., & Echeverria, A. (2014). New Insights into the Mechanisms of Action of Cotinine and Its istinctive Effects from Nicotine. Neurochemical Research, 40, 2032-2046.

- Hameed, S., & Akhtar, T. (2011). Recent Advances in the Synthesis of Five-Membered Heterocycles. Current Organic Chemistry, 15, 694 -711.

- Hosseini, M., Grau, J. S., Sorenson, K. K., Sotofte, I., Tanner, D., Murray, A., & Tonder, J. E. (2007). Short and efficient diastereoselective synthesis of pyrrolidinone-containing dipeptideanalogues. Org. Biomol. Chem., 5, 2207-2210.

- Huang, Z. T., & Liu, Z. R. (1989). Alkylation of Heterocyclic Ketene Aminals with Benzyl Chloride and Ethyl Bromoacetate. Synthesis of Heterobicycles Containing γ-Lactam-Fused Diazaheterocycles. Eur. J. Inorg. Chem., 122(1), 95-100.

- Kumar, I., & Rode, C. V. (2007). Efficient Synthesis of Fused 1,2,3-Triazolo-Delta-Lactams Using Huisgen [3+2] Dipolar Cycloaddition-Click-Chemistry‖ In Water. Chem. Lett., 36(5), 592-593.

- Li, Q. H., Tong, M. C., Li, M. C., Tao, J. H. Y., & Wang, C. J. (2011). Asymmetric construction of trifluoromethylated pyrrolidines via Cu(I)-catalyzed 1,3-dipolar cycloaddition of azomethine ylides with 4,4,4-trifluorocrotonates. Chem. Commun., 47, 11110-11112.

- Majumdar, K. C., Muhuri, S., Islam, R. U. and Chattopadhyay, B. (2009). Synthesis of Five- and Six-Membered Heterocyclic Compounds by the Application of the Metathesis Reactions. Heterocycle, 78(5), 1109-1169.

- Mohammat, M. F., Najim, N., Mansor, N. S., Sarman, S., Shaameri, Z., & Hamzah, A. S. (2012). Synthesis and bioactivity of some 2-oxo-5-aryl-3-hydrazone and 2-oxo-5-aryl-4-hydrazone pyrrolidine derivatives. ARKIVOV, IX, 429-438.

- Philip, L. S., & George, H. H. (1963). Compounds in the Pyrrolo[3,4-d] pyrimidine Series. Syntheses Based on 2,3-Dioxopyrrolidines. J. Org. Chem., 28(5), 1332-1336.

- Rylander, P. N. (1985). Hydrogenation Methods. New York: Academic Press Inc. Ltd.

- Song, C. E., Jung, D. U., Choung, S. Y., Roh, E. J., & Lee, S. G. (2004). The Employment of Hydrophobic Ionic Liquids Dramatically Enhanced the Activity of Metal Triflates in Friedel-Crafts Alkenylations of Aromatic Compounds with Various Alkyl- and Aryl-Substituted Alkynes. Angew. Chem., 116, 6309-6311.

- Vergnon, A. L., Pottorf, R. S., Winters, M. P., & Player, M. R. (2004). Solid-Phase Synthesis of a 4-Substituted γ-Lactam Library. J. Comb. Chem., 6(6), 903-910.

- Wang, Z. Q., Feng, C. G., Xu, M. H., & Lin, G. Q. (2007). Design of C2-Symmetric Tetrahydropentalenes as New Chiral Diene Ligands for Highly Enantioselective Rh-Catalyzed Arylation of N-Tosylarylimines with Arylboronic Acids. J. Am. Chem. Soc., 129(17), 5336-5337.

- Wei, J., & Shaw, J. T. (2007). Diastereoselective Synthesis of γ-Lactams by a One-Pot, Four-Component Reaction. Org. Lett., 9(20), 4077 – 4080.

- Wen, Y., & Lei, F. (2012). Effect of Solvent Polarity Properties on the Selectivity and Activity for 3,4-Dichloronitrobenzene Hydrogenation over Pd/C Catalyst. Advanced Materials Research, 396 – 398, 2379 – 2383.

- Zhang,L., Zhang, Y., Denga, Y., & Shi, F. (2015). Light-Promoted N, N-dimethylation of Amine and Nitro Compound with Methanol Catalyzed by Pd/TiO2 at Room Temperature. RSC Adv., 5, 14514-14521.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 March 2020

Article Doi

eBook ISBN

978-1-80296-080-8

Publisher

European Publisher

Volume

81

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-839

Subjects

Business, innovation, sustainability, development studies

Cite this article as:

Nurul Syafiqah, R., Ahmad Sazali, H., Zurina, S., & Mohd Fazli, M. (2020). The Syntheses Of Fused Cyclic 5/6-Membered Ring Lactams Via Enamine Hydrogenation. In N. Baba Rahim (Ed.), Multidisciplinary Research as Agent of Change for Industrial Revolution 4.0, vol 81. European Proceedings of Social and Behavioural Sciences (pp. 749-758). European Publisher. https://doi.org/10.15405/epsbs.2020.03.03.87