Abstract

A clean and safe water supply for daily used for people in the rural area has always been a challenge in Malaysia where at rural areas do not have access to the public water supply. A few houses at Kampung Siput, Baling District, Kedah is solely depending on water stream from the nearby hill for daily use of water. The raw and unfiltered fresh water is contaminated and risks to the health of the villagers. Hence, this paper proposes a solution on the project under Corporate Social Responsibility (CSR) between the Micron Sdn Bhd and Universiti Sains Malaysia, Engineering Campus to supplying filtered water to the villagers at the hill water retention pool. This is achieved by using a microcontroller for automatic filtering processes in which otherwise require an operator to manually operate the sand filter regularly. This project involved trans-disciplinary of engineering area, i.e., School of Electrical and Electronic Engineering designed the microcontroller to control the backwash process. The Pelton Wheel motor is designed to supply the alternating current of green technology to run the microcontroller.

Keywords: Backwashsand filterwater treatmentrural area water supplygreen technology

Introduction

Waterborne diseases can infect human system by the consumption of raw and unfiltered water due to the presence of viruses and bacterial ( Asami, Katayama, Torrey, Visvanathan, & Furumai, 2016; Sibanda & Okoh, 2013; Steyer, Torkar, Gutierrez-Aguirre, & Poljsak-Prijatelj, 2011; Ye et al., 2012). Hence water treatment is an essential human need for a safe and healthy life. Water sand filtration is one of the many ways for water treatment among others. Sand filtration commonly divided into two types, slow sand filtration and rapid sand filtration. According to Miklas ( 2016), slow sand filtering has advantages compared to other methods such as no pre-treatment required, no chemicals used, less skilled supervision, good bacterial removal efficiency and long periods of filtration operation between cleanings. But it also comes with some disadvantages, require a large area of land, poor colour removal efficiency, poor turbidity removal, and a large labour force required for construction and cleaning.

In other study by ( Pompei et al., 2017) found that slow sand filtration is capable of removing chemical compounds. Another research by ( Smith et al., 2017) employed modified slow sand filter by adding active bio sand filter embedded with nails at the top layer of the filter to remove Arsenic present in the water and with smaller size scale. The study found a positive impact on arsenic removal with removal rate averaged at 92% and was never dropped below 86% and suitable for rural areas affected by arsenic contamination due to the low-cost of this filtration method

The other type of sand filtration that widely being used is the rapid sand filtration which has higher filtration rate output roughly 10 times those of slow sand filters but still capable of removing unwanted chemical compounds in water to produce safe drinking water. Miklas ( 2016) stated that rapid sand filter can support an underdrain system to remove filtered water and to release backwash water. When the inlet water used as the outlet backwash water by controlling the flow through the filter.

Problem Statement

Safe and clean water supply is the basic human need to sustain a healthy living but not everybody has access to the state public filtered water supply especially those who live in rural area. A few houses at Kampung Siput, Baling District, Kedah still depend on unfiltered fresh water supplied through a pipeline from nearby water stream for their daily needs. The unfiltered fresh water poses high risk to the villagers’ health and wellbeing if it’s not properly boiled before consumed.

Research Questions

-

Evaluate possible water filtering systems that can be deployed and suitable for the rural area. Slow sand filtering system and rapid sand filtering systems will be investigated.

-

How to generate electricity to power up the automatic electronic systems in environment far from the grid and covered with high forest trees.

-

How to automate the water filtering systems through a mean of electronic control systems

Purpose of the Study

To design and engineered a suitable water filtration system for rural area.

To design and develop a system that capable to generate electricity in a forest environment.

To design and develop electronic control system to automate the water filtration processes.

Research Methods

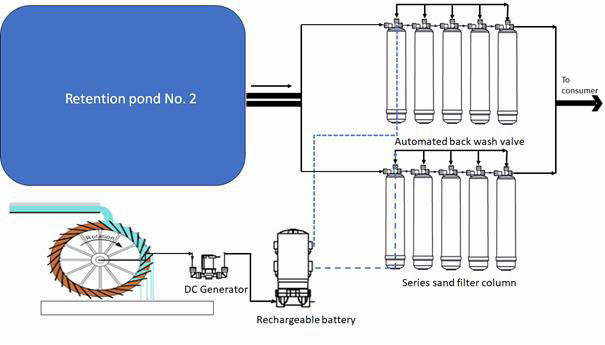

Rapid sand filter has advantages as higher rate of filtration output and require minimal land space. Hence this research will design and investigate the feasibility of rapid sand filtration on treatment of hill water retention pool. However rapid sand filter has their own disadvantage, it requires human labour to operate the filtering process quite frequently. This research is divided into two main section where the first section described the design and implementation of the automatic electronic control of the rapid sand filter and the second section described the design of the green technology power system.

Design and implementation of the automatic electronic control of the rapid sand filter

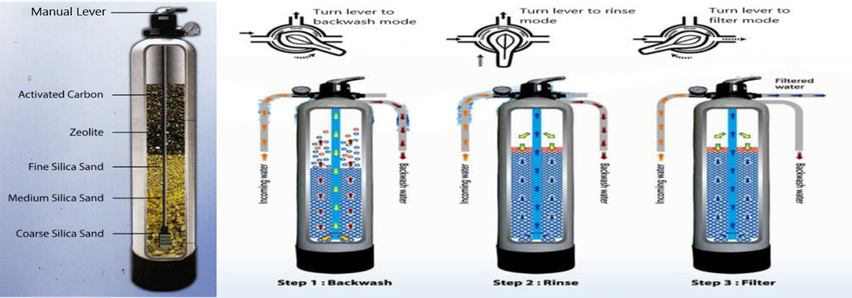

Figure

In filtration mode, the raw water flows from the incoming water inlet into the top of the tank and push through the layers of the sands. At the bottom of the tank, the water is channelled upward through a pipe into the filtered water outlet. This process is reversed in backwash mode, the raw water flows from the incoming water inlet straight to the bottom of the tank through a pipe, then push upward through the layers of sands cleaning them in the process and channelled out into the backwash water outlet. The rinse process is the same process as in filtering mode except the water output is channelled out into the backwash outlet. In standard filtering process, the backwash and rinse operations need to be carried out once every 24 hours to ensure proper clean and safe water filtration.

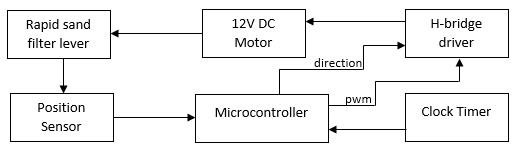

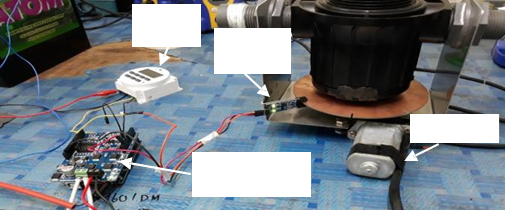

A 12V DC motor is used to replace and drive the manual lever where the H-bridge driver is connected to interface between the ATmega328P model microcontroller to automate the filtering process through electronic control system. Figure

The automatic control system circuit consists of the infrared sensor, clock timer, H-bridge driver, DC motor and the microcontroller are shown in Figure

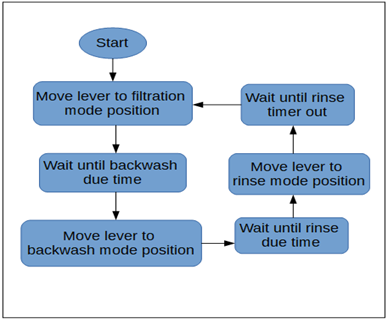

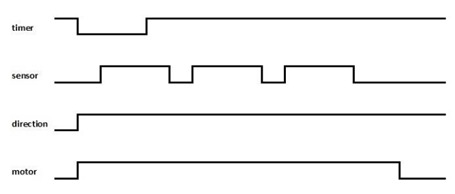

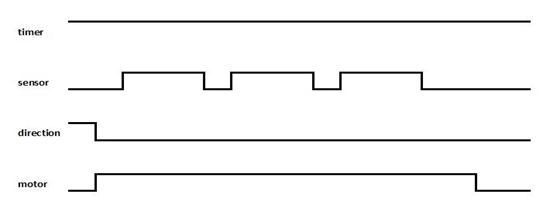

Since the design utilize only one sensor to locate three different positions, an intelligent algorithm written in C++ is created to control the 12V DC motor that enable the microcontroller to correctly select the 3 different modes of operations of the rapid sand filter accordingly based on the data from the position sensor (infrared sensor). Figure

Design and implementation of the green technology Power System using Pelton wheel micro-hydro

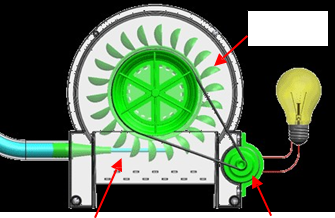

Pelton wheel micro-hydro is installed to generate an alternating current (AC) source of power energy that can be used to charge the battery. The installation of Pelton wheel micro-hydro in the remote location where there are no grid supply and shaded by the big tree canopy is suitable compared to the solar powered charging system. The general concept and operation of Pelton wheel micro-hydro is shown in Figure

The water flow from the retention pools channelled through a small nozzle pointed to Pelton’s buckets will rotate a 3 phase AC electric power generator to be used to charge a 12V battery through a charging controller. This power supply will be used by the motor which will move the filter backwash valve to the backwash position and will move the valve back to the normal position after the cleaning process has ended as it has been programmed. The Pelton wheel micro-hydro installed at the retention pond no. 1 is shown in Figure

Findings

The automatic rapid sand filter control system has four signals (timer, sensor, direction, PWM motor) that command the operation to move the lever around selecting three different modes as needed. The states of these four signals were captured and visualize in the form of timing diagram. Figure

The Pelton wheel micro-hydro power generator system output was measured. The voltage output was measured using Fluke multi-meter and the current output was measured using Fluke clamp meter. Figure

Conclusion

In this paper, the project is considered to achieve the objectives of designing the automatic backwash controlled by a microcontroller and building up the structure of the retention pools that produces the AC supply by the Pelton wheel for battery charging. This is subject to the green technology technique of energy sufficiency and sustainability.

Meanwhile, the feasibility studies of the suitable filters and the quality of the water is not yet carried out due to the validity of the samples taken. In the future, a few types of filter will be tested to ensure the quality of the water supply to the villager.

Acknowledgments

The authors gratefully acknowledge that this work was financially supported by Micron Technology Foundation Inc. (304/PELECT/6050394/M143).

References

- Asami, T., Katayama, H., Torrey, J. R., Visvanathan, C., & Furumai, H. (2016). Evaluation of Virus Removal Efficiency of Coagulation-Sedimentation and Rapid Sand Filtration Processes in A Drinking Water Treatment Plant in Bangkok, Thailand. Water Research, 101, 84-94.

- Miklas, S. (2016) Wetlands for Water Pollution Control (Second Edition). The University of Salford, Salford, UK.

- Pompei, C. M. E., Ciric, L., Canales, M., Karu, K., Vieira, E. M., & Campos, L .C. (2017). Influence of PPCPs On the Performance of Intermittently Operated Slow Sand Filters For Household Water Purification. Science of the Total Environment, 581–582, 174-185.

- Sibanda, T., & Okoh, A. I. (2013). Real-Time PCR Quantitative Assessment of Hepatitis A Virus, Rotaviruses and Enteroviruses in The Tyume River Located in The Eastern Cape Province. South Africa. Water SA, 39(2), 295-304.

- Smith, K., Li, Z., Chen, B., Liang, H., Zhang, X., Xu, R., Li, Z. L., Dai, H., Wei, C., & Liu, S. (2017). Comparison of Sand-Based Water Filters for Point-Of-Use Arsenic Removal in China. Chemosphere, 168, 155-162.

- Steyer, A., Torkar, K. G., Gutierrez-Aguirre, I., & Poljsak-Prijatelj, M. (2011). High Prevalence of Enteric Viruses in Untreated Individual Drinking Water Sources And Surface Water in Slovenia. Int. J. Hyg. Environ. Health, 214, 392-398.

- Ye, X. Y., Ming, Y., Zhang, Y. L., Xiao, W. Q., Huang, X. N., Cao, Y. G., & Gu, K. D. (2012). Real-time detection of enteric viruses in source water and treated drinking water in Wuhan, China. Curr. Microbiol., 65(3), 244-53.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 March 2020

Article Doi

eBook ISBN

978-1-80296-080-8

Publisher

European Publisher

Volume

81

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-839

Subjects

Business, innovation, sustainability, development studies

Cite this article as:

Kaharuddin, S., Hussin, R., Mohd Fadzil, A., Mohd Nazri, M., Mohd Ilyas, B. S., Zainal Abidin, I. S., Azniza, A. A., Mohd Zainuri, M. A. A., Hashim, N. Z. ‘., & Kamaruddin, M. A. (2020). Automatic Backwash Sand Filtering Of Hill Water Retention Pool Using Green Technology. In N. Baba Rahim (Ed.), Multidisciplinary Research as Agent of Change for Industrial Revolution 4.0, vol 81. European Proceedings of Social and Behavioural Sciences (pp. 631-638). European Publisher. https://doi.org/10.15405/epsbs.2020.03.03.73