Abstract

Transformation in a global context is reduced to digital transformation and transition to the so-called Industry 4.0. For the first time, the term "Industry 4.0" was used in a project of the German Federal Government, which is presented as a strategic document of economic development aimed at the digital transformation of the industrial sector. However, in return for other countries where social networks, communications and entertainment account for the majority of IT-technologies, German specialists set a goal to create a digital space based on digital technologies and automated systems, which facilitates the functioning of effective mechanisms of interaction in production: "man-machine", "machine-machine", "man= machine- machine". Industry 4.0 includes several concepts used with the word "smart", which aim is to build industry platforms for digital technology. One such concept, for example, is the development of "smart production", which is based on the ability to independently transmit and receive the information necessary for work, to reconfigure and optimize the production capacity of "smart enterprises" by means of "smart equipment". This fact is reflected in the normative acts of different countries, but it should be noted that the process of transformation is considered in the context of development, of a whole country, which depends on its territorial units, i.e. regions. Thus, it becomes necessary to introduce elements of Industry 4.0 into the territorial development of the Russian Federation for further integration into the new industrial space. This topic is reflected in the basis of the research and development of the article.

Keywords: Industry 40smart manufacturingdigitalizationautomationindustrial revolution

Introduction

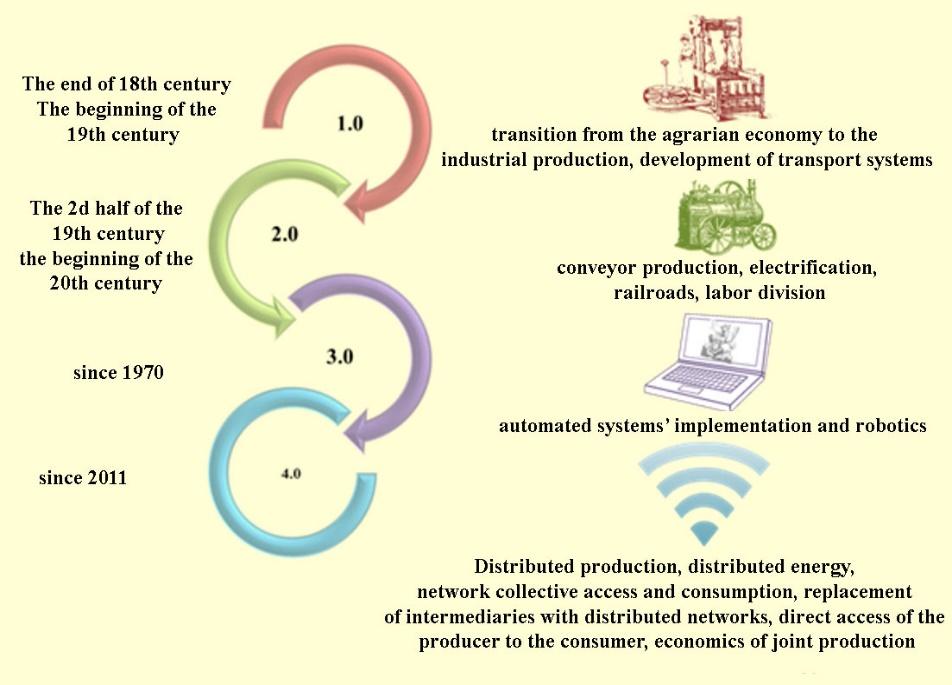

Within the modern framework of modernization, the globalization of the world economic space comes in parallel with the transformation into a new technological space - Industry 4.0 (i4.0). The fourth industrial revolution, or Industry 4.0, aims at understanding the world through the prism of innovative transformations, through digital technologies and automated processes. In the modern development context, the fourth industrial revolution includes a number of projects aimed at the implementation of digital technologies and the Internet in the production sectors of the economy through the introduction of cyber-physical systems and the provision of material and technical base with artificial intelligence, which is used to automate production. In historical retrospect, the era of industrial transformation dates back to 1784 to the present day, with four major upheavals taking place during this period, which are isolated as industrial revolutions. Each revolution was the result of an event or process. (Fig. 01).

Four industrial revolutions have occurred in the course of human development since 1784 to this day, each with its own specific parameters, as shown in Figure

The first industrial revolution (the end of the XVIII - beginning of the XIX centuries), is an integration from the agrarian type of management to industrial production by means of scientific and technical innovations in the steam power industry, which had an impact on the development of key industries: mechanical engineering, metallurgy and transport.

In the second industrial revolution (the second half of the 19th century - the beginning of the 20th century), as a result of the ongoing changes in the industry appeared a conveyor production. This epoch is also marked by great discoveries in electric power and biochemistry.

The third industrial revolution (since 1970) is characterized by the development and implementation of automated systems in the production process. A specific feature of this time is the attempt to replace the human resources with machine ones, i.e. robotics appears (Artto, Martinsuo, & Dietrich, 2008; Silvius, Schipper, Planko, van den Brink, & Kohler, 2012).

Fourth Industrial Revolution (XXI century). The beginning of this period is the adoption of a strategic document in 2011 within the framework of cooperation between the state and the private sector in Germany - "Industry 4.0". The main purpose of this document is the formation and implementation of a new economic system for the means of digitalization and automation of the production process in the relationship with external contractors, as well as the personalization of innovative technologies.

Problem Statement

Analyzing the periodization of industrial revolutions and their specific characteristics, it should be noted that each of them predetermined the appearance of the other. Thus, despite the activation of development and implementation of IT-technologies and innovative mechanisms in the production processes of Industry 3.0, it did not lead to the formation of a single digital system, the reason for which is the local nature of the enterprises of introduction and use of advanced technologies.

Research Questions

However, primitive information technologies have been replaced by such phenomena as the following

Big Data. According to the McKinsey Global Institute (MGI) report: "Big data: The next frontier for innovation, competition and productivity, the term "big data" refers to data sets that are larger than typical databases (DBs) that can record, store, manage and analyze information";

Additive manufacturing AM - a direct process of digital production, which involves the manufacture of parts by means of 3D-data with the lack of mechanical processing, or its minimal use if necessary;

Augmented Reality (AR);

Integrative system;

Internet of Things (IoT) are sensors and actuators built into physical objects and connected via wired or wireless networks using the Internet Protocol (IP), which connects the Internet;

Artificial Intelligence (AI) is a scientific and technological system for creating intelligent machines and software for understanding and modeling human intelligence processes;

Cyber security;

Modelling;

Cloud computing (CC) - technological network for data processing access and resource support, which is provided through the Internet service.

All the above factors together contribute to the emergence of open information systems and global industrial networks, which have an impact on the sectoral development of the economy through digitalization and automation and contribute to the integration of Industry 4.0.

A specific feature of the fourth industrial era is the separation of data as the main value, rather than material products. Accenture predicts that by 2030, the IoT (Internet of Things) sector will add $14.2 trillion to the world's GDP (for the world's top 20 economies, this is plus 1% over the projected growth rate), and the number of items connected to the network is projected by IHS to be $75.4 billion in 2025.

In terms of the pace of implementation of the main directions of the fourth industrial revolution, Germany is the main leader, but other countries have developed programs such as this: "Connected Factories (Japan), Industrial Internet (USA), Made in China 2025" (China) This trend is being updated in the Russian reality as well, which is a consequence of the "Digital Economy of the Russian Federation" program adopted by the Order of the Government of the Russian Federation dated 28.08.17.

In terms of the pace of implementation of the main directions of the fourth industrial revolution, Germany is the main leader, but other countries have developed such programs as: "Connected Factories (Japan), Industrial Internet (USA), Made in China 2025" (China) This trend is being updated in Russia as well, which is a result of the "Digital Economy of the Russian Federation" program adopted by the Order of the Government of the Russian Federation of 28.08.17.

Current trends in the formation of the digital economy in the context of the development of states have many variations of research, which are reflected in international rankings, one of which is the International Digital Economy and Society Index (I-DESI). This index is calculated by the European Commission's Directorate General of Communication Networks, Content and Technology for non-EU countries (Table

Based on the data from the table, the process of Russia's integration into the new technological era is progressing positively, as the main index is ranked 10th, ahead of China. The formation and development of Industry 4.0 within the Russian reality requires the implementation of the digitalization process in the regional subsystems of the state, not only in the central zones of technological development, but also on the periphery.

Purpose of the Study

Within the framework of the research, we studied the main directions of the Industry 4.0 concept realization in Russia in the context of innovative development of the regions. In this context, the innovative development is understood as the equipment and implementation of the Internet in Russia, as well as the availability and equipment of the country's population with this mechanism.

Research Methods

In this context, there is a need to study the main base of indicators that are necessary for the formation of the digital environment in the federal subjects of the Russian Federation. As of today, one of three residents of the Russian Federation has access to the Internet and uses different functions for certain needs, but it should be noted that not the entire territory of the country is equipped with " hotspots". The existing imbalance in the innovative development of regions is becoming the most important threat to the transition to a new industrial era.

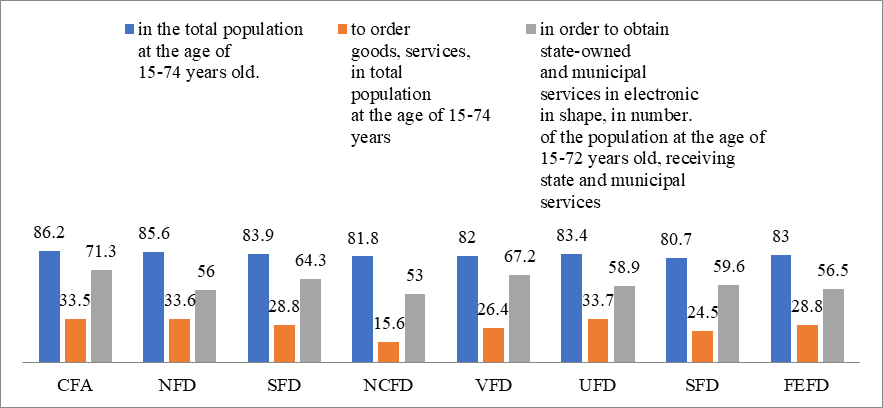

According to Fig.

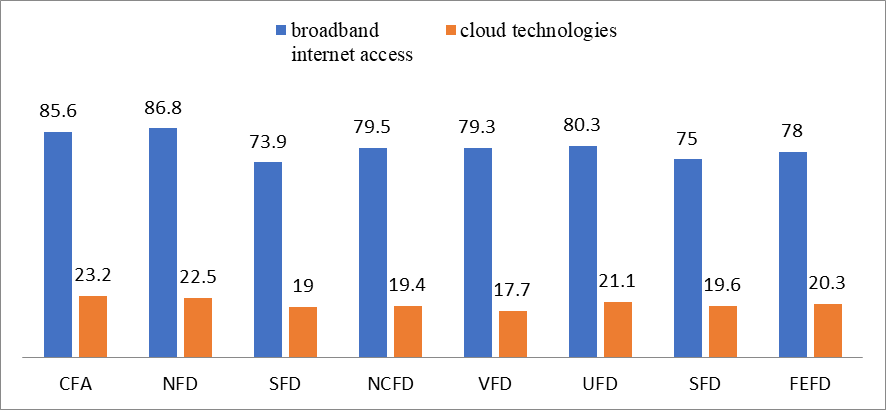

Over the past decade, various organizations in Russia have been actively using the Internet in their activities, but today, the trend towards the implementation of such an Industry 4.0 mechanism as cloud technologies is becoming more relevant.

Judging by Fig.

Findings

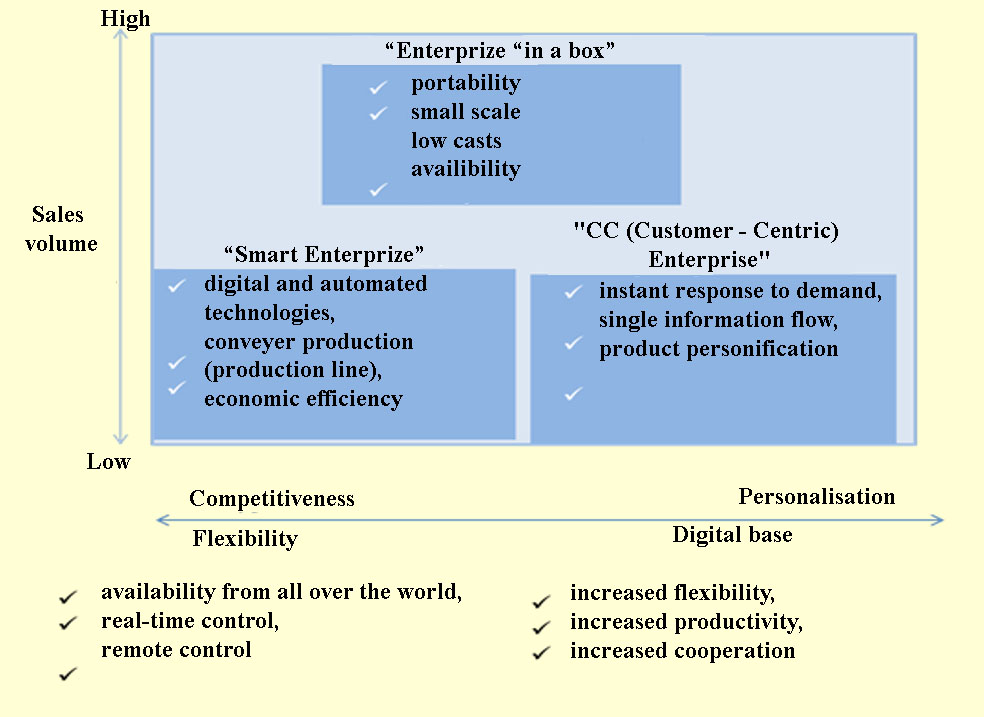

The modern process of integration into Industry 4.0 and the construction of digital space in the context of the territorial development of the Russian Federation, requires the formation of conceptually new participants in the industry markets. According to this trend, we propose to develop and implement new archetypes of enterprises: "Enterprise "in a box"; "Smart Enterprise", "CC - Enterprise", the main parameters, which are isolated in Fig.

The combination of these mechanisms in the process of integration of "Industry 4.0" is a promising direction for the development of the industrial sector (Novoselova & Novoselov, 2017), which will open up great opportunities for the enterprises that first introduced it. Introduction of "smart production" principles will allow companies to get a huge advantage over competitors:

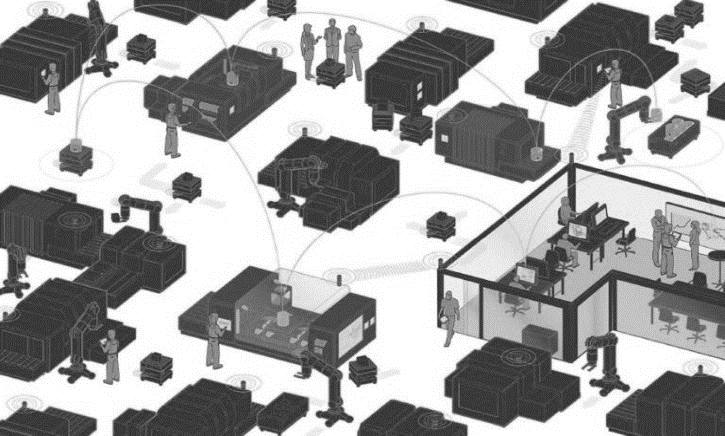

Technological equipment will interact with each other, suppliers, logistics systems and consumers by means of awareness of its environment. This will improve the quality of final products, eliminate defects in the work process and prevent the "human factor" in the enterprise, which contributes to improving the efficiency of the entire organization (Fig. 5).

-

The production equipment will be able to make adjustments to the process itself by being informed of the changed requirements. Production systems will be capable of self-optimization and self-configuration. This will significantly increase the flexibility of the processes (it will be possible to produce single products industrially), reduce production costs, and reduce the development and production time of new products.

Conclusion

Programs for the introduction of "smart production" have already been launched in many countries - the Netherlands, France, Great Britain, Italy, Belgium, China, the United States and others, and if you do not start taking active steps in this direction today, then in 5-10 years it may lead to a significant backlog of domestic enterprises in the field of production technologies and labor productivity. And Russia has already started to take the first steps in this direction: Rostelecom, together with a number of large Russian companies, created the National Association of Industrial Internet Market Participants (NAPI), the main task of which is to develop and implement the principles of Industry 4.0 on the territory of the Russian Federation. In Russia, this concept is called "Industrial Internet of Things" (IIoT) - the concept of computer network, which combines industrial production systems at the level of technological processes, cyberphysical machines and intelligent control systems. Introduction of the concept of "smart production" in the enterprise is a complex, time-consuming, expensive, but necessary process, which should be part of the strategy of development of the enterprise.

First of all, it is necessary to assess the industrial and technological infrastructure of the enterprise. It will allow to understand the level of industrial and technological maturity of the enterprise, and also will help to formulate the strategy of development (to raise the level of technological maturity) and to plan stage-by-stage work on realization of the concept "Industry 4.0".

Thus, the systematic management of the digital flow using advanced technologies, allows you to visualize the entire production process, providing remote monitoring and control, which is the result of optimization in real time. This concept is applicable not only within a particular organization, but also within a global network of enterprises.

Managing the digital flow from start to finish of the production chain, facilitates the rapid exchange of information between suppliers and distributors, resulting in increased efficiency by optimizing the supply chain in real time and predicting demand based on data, which contributes to improved service levels by balancing demand and supply.

References

- Artto, K., Martinsuo, M., & Dietrich, P. (2008), Project Strategy: Types of Strategies and Their Content in Innovative Projects. International Journal of Project Management in Business, 49–70.

- Khubulova, V. V. (2017), Interregional Innovation System as a Structural Element of the National Innovation System. In Proceedings of the V All-Russian Scientific and Practical Conference "New Science: New Challenges". (pp. 40–48). Krasnodar: Institute of Standardization, Certification and Metrology.

- Khubulova, V. V., & Khachirov, A. D. (2018), Industry in the Context of Digital Economy. Bulletin of the Academy of Knowledge, 25(2), 226–232.

- Novoselova, N. N., & Novoselov, S. N., (2017). Investigation of the directions of development of the regional socio-economic system from the standpoint of institutional component and territorial localization. International scientific publication Modern fundamental and applied research, 1(24), 218–224.

- Silvius, A. J. G., Schipper, R., Planko, J., van den Brink, J., & Kohler, A. (2012) Sustainability in Project Management. Gower Publishing.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

28 December 2019

Article Doi

eBook ISBN

978-1-80296-075-4

Publisher

Future Academy

Volume

76

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-3763

Subjects

Sociolinguistics, linguistics, semantics, discourse analysis, science, technology, society

Cite this article as:

Khubulova*, V., Taimaskhanov, K., Salgiriev, R., & Shakhgiraev, I. (2019). Industry 4.0 And Building Digital Space In The Context Of Territorial Development. In D. Karim-Sultanovich Bataev, S. Aidievich Gapurov, A. Dogievich Osmaev, V. Khumaidovich Akaev, L. Musaevna Idigova, M. Rukmanovich Ovhadov, A. Ruslanovich Salgiriev, & M. Muslamovna Betilmerzaeva (Eds.), Social and Cultural Transformations in the Context of Modern Globalism, vol 76. European Proceedings of Social and Behavioural Sciences (pp. 1644-1651). Future Academy. https://doi.org/10.15405/epsbs.2019.12.04.223