Abstract

The managers face a problem of quality assurance of the realized processes during functioning of the construction and operating organizations. One of the most effective methods of the solution of this problem is application of mathematical modeling. The authors prove the necessity of construction production quality assessment based on the complex system of indicators and characteristics that help to estimate not only mandatory technical requirements, but also wishes of consumers. The paper gives the main requirements to indicators of quality of construction production and reveals the possibility of application of various methods of data processing for not only tracking of actual state of these or those characteristics of the studied object, but also their modeling. The researchers prove the relevancy of application of mathematical-cybernetic modeling as one of the trends of modeling of control systems of construction. The paper also describes the stages of modeling and their maintenance. This research aims to develop elements of a quality assurance system for construction work based on the use of mathematical modeling methods and to justify the use of this method in construction. The problem of the implementation of mathematical modeling lies in the availability of the necessary software in the enterprise, which allows developing models, and attracting specialists of the required level. In construction, as in one of the most resource-intensive industries, special attention is paid to the efficiency and rationality of material management.

Keywords: Qualitycompetitivenessmathematical modellingconstructionproductionmathematical statistics

Introduction

All production and operating enterprises are aimed at ensuring competitiveness as of the released types of production and the rendered services, and of the enterprise under modern operating conditions. The competitiveness is defined by a large number of both external and internal factors that are particularly important for value formation of a product or service and also indicators of their quality.

The issue of quality assurance is particularly acute at the enterprises of construction field and a housing-and-municipal complex as activity in these spheres is connected with interaction of a large number of participants of production and huge capital costs. Erection of construction objects and their subsequent operation always assume performance in pre-established and regulated sequence of a significant amount of works of productive and non-productive character.

In construction and operation of objects of a housing-and-municipal complex the problem of ensuring quality doesn't lose the relevance because of high number of the risks which are constantly accompanying these kinds of activity. Risks have to be estimated and considered constantly at all stages of realization of organizational and administrative functions.

The decisions made at various stages have to be thorough and be reasoned with either qualitative or quantitative indices and at the same time to be optimum. The choice and decision-making, especially under economically unstable conditions, in difficult probabilistic dynamic systems to which, certainly, the sphere of construction and housing and communal services belongs, can't be carried out without active application of methods of mathematical modeling and mathematical statistics (Zineldin, 2000).

Problem Statement

Construction and operation of objects of a housing-and-municipal complex are initially focused on the strict principles of quality control. It is necessary to create complex system of indicators and characteristics by means of which it would be possible to estimate not only mandatory technical requirements, but also wishes of consumers for objective and full-measured assessment of construction production quality (Bakhitov, 2008).

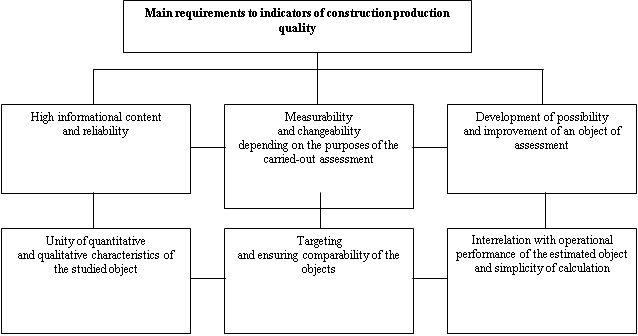

Indicators have to meet the following requirements (figure

Research Questions

The enterprises of the construction industry and the housing-public utilities complex need to solve a set of tasks in order to eliminate problems in the field of quality:

to consider the factors of problems in the quality assurance in construction;

justify the use of individual methods of mathematical modelling;

use statistical methods of quality management to ensure the reliability of mathematical modelling;

develop an algorithm for mathematical modelling on the example of inventory management in construction.

Purpose of the Study

The research objective is to work out the elements of the quality assurance of construction works system based on the methods of mathematical modelling.

Research Methods

The attention should be paid to such methods as correlation, regression, dispersion, factor analysis considering the specific character of construction. With their help, it is possible to determine the degree of reflection of a sample of properties of the population, to evaluate the characteristics of the population.

One of the main tasks of mathematical statistics is the selection or development of the necessary method for analyzing the characteristics of an object that corresponds to certain collected and grouped data (Gorbacheva, 2005). Particular attention should be paid to assessing the probability of an event, functions and distribution parameters, dependencies of values on ordinary and random causes, determining the limits of regulation, testing statistical hypotheses (Al Zarqa, Ozkul, & Al-Ali, 2014).

Analysis of the results of a passive and active experiment allows us to assess the impact of various factors on the object under study and to avoid negative consequences during the performance of work or further operation of a building or structure.

The choice of specific methods for use should be made directly for the organization, taking into account the specifics of its activities, the characteristics of the object and the current tasks and capabilities of this organization.

Methods of solution of organizational tasks in construction

The organizational and production tasks for administrative-and-management personnel of the organizations and enterprises define set of these or those methods of the mathematical analysis and modeling (table

As a system object, construction assumes existence of a large number of elements, processes of which are characterized by dynamism and the probabilistic nature of behaviour. Similar properties also deal with the interrelations between them.

Mathematical modelling has one of the leading positions in the process of analysis, planning, organization and quality assurance in construction that can be characterized by uncertainty and dynamism of indicators and criteria.

Creation of universal model in construction is almost impossible, but improvement of modelling in this field and creation of adequate model for display of real processes and their interaction constantly take place.

Modeling

In general, modeling is a development of a certain model or representation of the studied object (systems, process) in which its properties and specifics, available for the analysis and a research remain. Models have two main classification groups: physical and sign. The first assume maintaining physical properties of the studied object, the second – application of any language: graphic, algorithmic, mathematical, etc.

We consider that mathematical and economic-mathematical models for the solution of the tasks are most often applied according to the properties.

The main conditions, to which the model developed for practical application has to correspond, are lack of mathematical, economic, technological and other types of contradictions and accuracy of reflection characteristic to the studied object of indicators and criteria.

As the main objectives that are achieved by mathematical modelling method in the sphere of construction and operation of objects of a housing-and-municipal complex, are connected with optimization organizational and production processes, special attention is paid to economic-mathematical modelling that include the following stages:

statement of the purpose;

development of criteria;

identification of restrictions;

development of economic-mathematical model;

preparation of an algorithm of calculation;

software;

collecting necessary basic data;

classification and coding of information;

creation of model;

the analysis of the received results;

implementation of results of modelling into practical activities.

Issues of quality of final products are relevant in all fields of activity nowadays. Special attention to them is paid in the branches connected with life sustainment and maintenance of ecosystems’ balance.

Mathematical-cybernetic modelling

Application of various methods of data processing allows not only to keep track of actual state of these or those characteristics of the studied object, but also to model them.

Special attention in construction should be paid to mathematical-cybernetic modeling as to one of the trends of modeling control systems in construction. Administrative activity provides realization of all production and non-productive processes in construction, and, therefore, special attention has to be paid to it.

Mathematical-cybernetic modeling represents set of methods, including the mathematical multilevel systems of problem-solving, imitating processes of management systems, the description of information flows, structuring administrative and managerial nets (Alaybeyoğlu & Kuntman, 2016).

Realization of mathematical-cybernetic modeling for the purpose of quality assurance of works construction works assumes certain stages of modeling and their content:

definition of goals of modeling, factorial and productive indicators and their interrelations, a possibility of quantitative assessment of indicators and characteristics;

mathematical formalization, empirical check of starting positions (whenever possible), quantitative expression of qualitative content of system elements;

creation of the formalized scheme with application of quantitative data and their consecutive interrelations;

development of mathematical model on the basis of the formalized scheme with selection of the corresponding mathematical algorithms and functions;

statistical analysis of parameters of a studied object;

assessment of adequacy of model by comparison of results of modeling with reality;

additional specifications and simulation modification (if necessary).

It is necessary to carry out constant assessment of the created model from a position of its complexity and adaptability. In a similar case it is necessary to correct an objective. Traditionally the necessity to return to the previous stages arises at a stage of preparation of initial information because of high expenses or its absence. In this case it is necessary to reconsider an algorithm of tasks performance, to change number of the considered factors, etc. These matters arise especially often as it is necessary to consider a large number of both internal and external factors in construction (Mireille, 2003).

The process of formalization during creation of mathematical model should be paid special attention due to the creation of a certain artificial language with replacement of concepts with symbols is very difficult, especially in complicated systems that also include construction.

Cybernetic modeling is a rather capacious science representing set of other sciences united by the unified purpose – a research of management in various systems and operating with such basic concepts as "model", "system", and “information". It is necessary to distinguish the theory of modeling, the theory of information, the system analysis, and the general theory of management, the general theory of systems and others among cybernetic sciences.

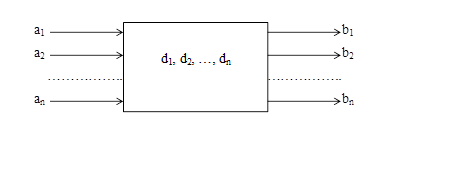

Mathematical-cybernetic modeling in relation to construction branch assumes formal creation of systems with application of the concepts "entrance" and "exit" and the characteristic of the bond of an element with the environment. Each element (d1, d2, …, dn – its states) can have several "entrances" (а1, а2, …, аn) and "exits" (b1, b2, …, bn) (figure

While solving question of application of cybernetic modeling it is also necessary to consider that the cybernetics assumes the system as a unity of controlling and operated elements, and the operating system on the channel of direct link makes impact on the operated object. This influence, in turn, deforms impact of the external environment on the operated object. Cybernetic modeling also assumes that feedback in this interaction can be both internal and external.

In construction as one of the most resource-intensive branches, special attention is paid to efficiency and rationality of management of material resources. Under modern conditions the solution of a task of resource-saving, optimization of deliveries and storage of stocks becomes more and more relevant due to the constant growth of resources cost and providing conditions of their storage. The limitation of resources also demands continuous efforts on search of an effective control algorithm of stocks.

During search and the organization of the movement of stocks of the construction organization, as well as to the enterprises in the sphere of housing and public utilities, it is necessary to be guided by scientific approaches, including methods of economic and mathematical modeling (Rinke, Berkhahn, Neumann, & Berner, 2017). It is necessary to prevent the repeated count that is possible only at the accurate organization of definition of requirement, order, use and storage of stocks. There exists an issue of updating of stocks due to expenditure, uninterrupted operation and reliability of productions among problems of modeling of stocks in construction.

While choosing methods of the analysis and modeling of stocks it is also necessary to consider specifics of activity of the enterprises: variety of material resources, sequence of their application and technological interrelation. This is the question of origination of demands in some certain resource which, in turn, is result of the demand in another material resource.

In research papers it is mentioned that formation of stocks of different types of material resources differs in unevenness and irregularity depending on the schedule of works (Kaverin & Morozova, 2015). In this case application of the following methods of calculation of stocks is expedient:

dynamic programming;

Silver and Mill's method;

method of the minimum variable costs;

method of the minimum unit costs specific;

theory of lot by lot;

optimum economic order and others.

Level change of demand in certain physical resources can be unarranged. Respectively, the applied models have to be probabilistic, stochastic (Minocha, Singh, & Bawa,, 2016).

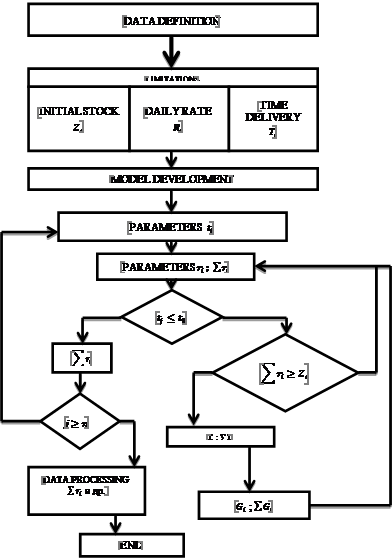

One of the most frequently used inventory model in construction and housing and public utilities can be represented in the following way

Z(t)=Za+P(t)–R(t),

(2)

where Z(t) – current stock of physical resource at the moment of time t;

Za – original stock at the moment of time t=0;

P(t) – arrival of physical resources in the period of time t;

Pi – the volume of physical resource supply;

R(t) – consumption of physical resource in the period of time t;

Rj – lot size of the physical resource consumption;

n – the number of delivery lots;

m - the number of consumed lots.

The model can include restrictions depending on the maximum of volume of delivery lot, number of deliveries, etc.

Statistical data of providing a stock with physical resource is a repeatedly process for the purpose of definition of its optimum numerical characteristics while developing imitation models (figure

time of a delivery cycle tj and a daily expense ri are defined according to the law of distribution with the set parameters;

as there are restrictions to the maximum and to a minimum of values of these sizes, the algorithm provides data updating;

process of modeling of the value ri precedes the time point of tk under a condition

Source: Lukinsky & Butrin (2009).

The emergence of random variables of Z – total resources expense, W – warehouse stock balance at the moment of new lot supply, F – number of days of a lack of resources, G – physical resources shortage volume is possible during the modelling the current and reserve stocks (Koehler, 2014).

(3)

(4)

The use of such an algorithm for determining the parameters of material resources reserves allows us to predict the flow rate and the possibility of a shortage, which, in turn, ensures the efficiency of work in the construction industry and utility services.

Findings

Modern construction production as a system object is characterized by a high level of complexity, stochastic behavior, dynamism, a significant number of elements with complex functional connections and other properties.

For qualitative analysis and management of such complex system objects, it is necessary to apply the methodology of the theory of modelling. Simulation allows analysing the final results, including the quality of construction products, not on a real object, but on its abstract model, using computer software for this purpose.

However, it is necessary to take into account that the model is only a means of obtaining information about the object under study, and not a way to work out necessary decisions. This model allows to identify the most important, typical features of a real system.

Special attention in construction should be paid to mathematical-cybernetic modelling, since management activities ensure the implementation of all production and non-production processes in construction.

The use of mathematical modelling methods in order to improve the quality of products is advisable to apply in international practice.

Conclusion

Providing high quality products is an integral aspect of the activities of industrial enterprises. The release of products of this level provides the manufacturer with competitive advantages (Gorbacheva, 2005). In the construction industry, the problem of high-quality facilities is more relevant than ever due to the high number of risks, both internal and external. Quality assurance issues in the industry should be addressed not only during the implementation of the investment and construction project, but also during the operation of the erected building or structure (Zarenkov, 2010). In order to guarantee quality, construction organizations need a strict quality management system consisting of separate segments covering all areas and levels of activity of an enterprise.

At present, in construction, the application of standards that implement the principles and indicators of the ISO 9000, ISO 9001 series, including GOST R ISO / TO 10017-2005 “Statistical methods. Application Guide in accordance with GOST R ISO 9001". In addition to ensuring high quality indicators of work performed, the presence of a quality management system in the organization based on the application of these standards guarantees additional advantages over competitors (2005). ISO series standards involve the use of mathematical statistics methods to ensure product quality, which are subsequently used in mathematical modeling. In general terms, this is the development of solutions aimed at achieving specified indicators and characteristics based on the statistical processing of arrays of quantitative and qualitative data. Most calculations use probability theory, since this data is often limited, for example, determining the required sample size to assess the state of the total volume of the object under study or to identify patterns in mass random phenomena.

References

- Al Zarqa, A., Ozkul, T., & Al-Ali, A. (2014). “Comparative Study of different Methods for Measurement of “Smartness” of Smart Devices” In Proceedings of the 2014 International Conference on Communication, Signal Processing and Computers (рр. 145-150). Switzerland.

- Alaybeyoğlu, E., & Kuntman, H. (2016). A new CMOS ZCCDTA realization and its filter applications. Turkish Journal of Electrical Engineering & Computer Sciences, 24(3), (746-761).

- Bakhitov, R.Kh. (2008). System modeling of management processes of the design organization of an oil and gas complex. Economic Analysis, 1(106), (120-127).

- Boldyrev, Yu.Ya., Klimshin, D.V., Romanov, S.V., & Shanina, A.S. (2010). Modern technologies of mathematical modeling for engineering analysis and design in construction. Scientific and technical achievements in SPbGPU. Computer science. Telecommunications. Management, 4(103), (106 -111).

- Gorbacheva, L.B. (2005). Economic and organizational aspects of quality management in a construction organization. Construction Economics, 5, (36-43).

- GOST R ISO / TO 10017-2005. (2005). Statistical methods. Guidelines for use in accordance with GOST R ISO 9001 [electronic resource] URL: http://libnorm.ru/Files2/1/4293800/4293800602.pdf (date of use 02.09.2018).

- Kaverin, A.V., & Morozova A.R. (2015). Application of the theory of probability and mathematical statistics in the construction of the Natural and mathematical sciences in the modern world. Collection of articles. st. on mater. XXX Int. scientific-practical Conference, 5 (29), (17-20).

- Koehler, J. (2014) The Theory of culture-specific total quality management. Academy of Management Review. 1, (140-142).

- Lukinsky, V.V., & Butrin, A.G. (2009). Formation of models and algorithms of inventory management in supply chains. ENGECON Bulletin. Series: Economy, 5 (32), (203-211).

- Minocha, S., Singh, H., & Bawa, S. (2016). HadoopWeb: MapReduce Platform for Big Data Analysis, International Research Journal of Engineering and Technology, 3(5), (552-556).

- Mireille, G. (2003). Quality management practice in highway construction. International Journal of Quality and Reliability Managemen, 20, (532-550).

- Rinke, N., Berkhahn, V., Neumann, I., & Berner, F. (2017). Simulating quality assurance and efficiency analysis between construction management and engineering geodesy. ScienceDirect magazine. 3(76), (24-35).

- Zarenkov, V. A. (2010). Project management is a necessary factor in ensuring the competitive advantage of domestic companies. Economic Revival of Russia, 4 (26), (47–54).

- Zineldin, M. (2000). Total relationship management (TRM) and total quality management (TQM). Managerial Auditing Journal. 1,20-28.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

20 March 2019

Article Doi

eBook ISBN

978-1-80296-056-3

Publisher

Future Academy

Volume

57

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1887

Subjects

Business, business ethics, social responsibility, innovation, ethical issues, scientific developments, technological developments

Cite this article as:

Kornilova, A., Knyazkina, E., Akri, E., & Suslova, N. (2019). Mathematical Modeling As A Method Of Quality Assurance In Construction. In V. Mantulenko (Ed.), Global Challenges and Prospects of the Modern Economic Development, vol 57. European Proceedings of Social and Behavioural Sciences (pp. 720-729). Future Academy. https://doi.org/10.15405/epsbs.2019.03.71