Abstract

Materials science and engineering combine science and engineering of creation and processing materials, and adapting their properties. Knowledge concerning materials are needed in the economic activity carried out for the production of industrial goods, such as the manufacturing processes, contributing to their rational use, energy saving and environmental protection, to the development of processing procedures simpler, more direct. The competences accomplished in the fields of engineering require knowledge in the area of materials (structure and properties) as well the requirement to permanently learning, about the progress made by the new materials and technologies. Design engineer must have an opening at new, or at least to keep up with his time, using materials with properties appropriate, affordable and with an index of use as good, in accordance with their limitations and performance. The engineer must take into account the permanent processing properties of materials and the influence of processing on the structure and properties. Only appropriate knowledge of materials, permanent taking into account the relationship composition-microstructure-property, can ensure a fair use.

Keywords: Materialspropertiesknowledgeabilitycompetences

1.Introduction

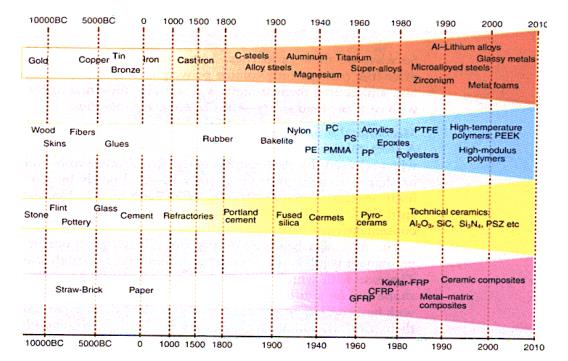

From historical experience of various human communities it shows that a material is especially

important for a society since it can be used on a larger scale. Spectacular progress that it has achieved the

materials science in recent decades, supported by technology and industrialization of certain materials,

have made possible the use of high performance materials in place of the classics and the rise of the index

to use traditional materials. The figure

In the future, to deal with the shortage of materials, the project engineer must consider both a

functional design, with a high material utilization, as well as the possibilities of replacing the deficient

materials with new materials or recycling and the classics (Ashby, Bréchet, Salvo,2001). It is essential

that the engineer possess basic knowledge regarding material properties and limits for the correct choice

and use of them at a higher index, so as to satisfy the requirements of operation, economic and aesthetic

properties of the product. In recent years the European Commission has placed special focus on how six

‘Key Enabling Technologies’ (Advanced Materials, Advanced Manufacturing, Nanotechnologies,

Photonics, Industrial Biotechnologies, and Micro- and Nano-electronics. Materials science and

engineering combines science and engineering of making and processing materials, and adapting their

properties. The social challenges of urbanisation, resource reduction and climate change, demand for a

friendly environment and more sustainable economy. The atomic structure and chemical composition

were the main focuses of materials science research. However, over the last few decades, this focus has

changed considerably as analytical chemistry, the electron microscope, X-ray diffraction, and

spectrometry have been developed so as to can analyse materials with accuracy. Because scientists can

now understand what materials are made of (chemical composition) and how they work (physical

properties), the main attention of materials science has shifted to understanding how materials can be

improved and what new materials can be developed to meet society’s needs. These scientific advances

caused a revolution in knowledge in materials.

2.The Importance of Knowing the Classification of Materials

Objective reality which surrounds us, existing independently of our consciousness, but reflected in

it in various forms, is made up of matter. It manifests itself in various forms of concrete known as generic

materials. These are characterized by their behaviour in the transformation process (technological

properties) and during their use in the form of finished products (properties of use and aesthetics).Always,

the materials were crucial for the production of goods necessary for human communities. Therefore, the

diversity and level of their processing could constitute criteria for characterizing the level of civilization

of a social group at a time. For some useful objects, the materials are used in the form of: substances, raw

materials and finished products.

If, in order to pass from stone to metal, human communities had tens of thousands of years, for

discovering and inventing various range of materials that come in contact, people had only need two,

three centuries of searching and sometimes stronger nor both. The continuation of this work requires a

systematic study on the classification criteria and characterization, which must correspond to the best the

demands imposed by technological development and the increasingly complex demands of industrial

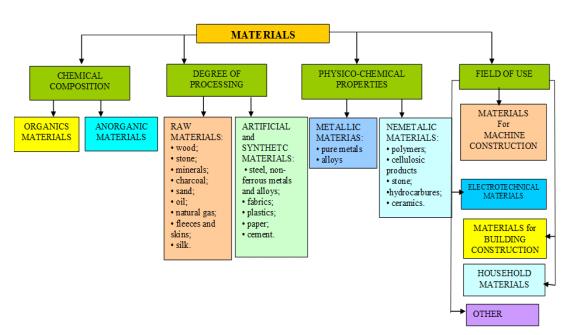

products. In the diagram in figure

composition, degree of processing, field of use, properties).

Knowledge concerning materials are needed in the economic activity carried out for the

production of industrial goods, such as the manufacturing processes, contributing to their rational use,

energy saving and environmental protection, to the development of processing procedures simpler, more

direct.

Grouping in organic and inorganic materials can be satisfactory in a first phase of study, but to

have a more complete picture of them-must be taken into consideration and processing technologies most

appropriate to achieve a finished product.

At present, we can say that the material is only a possibility of obtaining the necessary

characteristics of the finished product, the processing technology that ensures the level of being taxed

property contemplated by the user. In other words, the material turns into finished products in accordance

with the general level of knowledge of the human community that uses them, as a result of processing,

more or less complex, brought together in the form of a manufacturing process. Spectacular progress that

it has achieved the materials science in recent decades, supported by technology and industrialization of

certain materials, have made possible the use of high performance materials in place of the classics and

the increase of the index to use traditional materials. In the present society, the volume of information is

impressive. It is essential that the engineer possess basic knowledge regarding material properties and

limits for the correct choice and use of them at a higher index, so as to satisfy the requirements of

operation, economic and aesthetic properties of the product (Materials Science and Engineering Expert

Committee, 2013).

3.The Importance to Understand Principal Properties of Materials

Means that it is interesting for a human community, at one point, because of the type and level of

their determinable value, either in surface area, either in body mass resulted from the processing carried

out in the production process (Ashby, Shercliff, & Cebon, 2007).

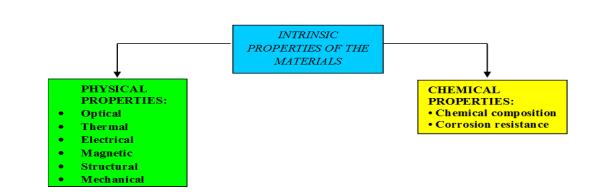

The classification criterion of the characteristics of a material is given by their nature. From this

point of view, intrinsic properties differ (which is due to the intimate structure of the material) and

extrinsic properties or assigned. In the first category are part of the physical properties and chemical

properties (fig. 3), and since the second technological properties and properties to use. Physical properties

take into account interactions between bodies and physical phenomena from the environment. Thus, the

optical properties show bright radiation interaction: insofar as they are absorbed or reflected certain

wavelengths of light, of bodies have certain colours can be glossy or mate. In terms of thermal properties

(thermal conductivity, specific heat, dilation, refraction), the electric (conductivity, resistivity,

respectively) or magnetic (magnetic susceptibility, magnetization intensity, magnetic induction, magnetic

permeability, etc.), they are strongly dependent on the properties of the material (metal, polymer, ceramic,

etc.), i.e. the type of atoms, how links between them, etc.

Given the current technological development, in which hot processing and/or magnetic field are

increasingly used, knowledge of these properties became especially important for the manufacture of

industrial products in conditions of maximum efficiency.

From the point of view of machinery construction and equipment/machines, a special place in this

group of properties they occupy mechanical properties: hardness, resistance to damage by static or

dynamic requests, tenacity, creep, elasticity and plasticity, etc. Physical properties are of great practical

importance because they derive most of their technological properties and usage.

In table

machinery and equipmentneed to have frequently, their value is strongly dependent of their intrinsic

structure. It is put inevidence the importance of mechanical properties for both processing operations and

use of the finished product. A material which has low hardness in surface area will be machined with a

machining work differently for a material with high surface hardness. Similarly, in service, the product

with low hardness will not be able to be used in operating conditions requiring a good resistance to wear

(for example: in the manufacture of gear wheels), these two characteristics being intertwined. The

material with low hardness can be used if superficial hardness increased his need.The best complex of

mechanical properties of resistance is atmetallicmaterials, which explains their use at very wide-ranging

scale (intensively and extensively). This does not mean that at the other materials (composite materials,

plastics, hard materials, etc.) is not partially achieving some aspects of this group of properties (Dobrescu,

Plaiasu, & Denape, 2008).

The materials science engineering has to develop the following professional skills:

1.defining the principles and the basics on the materials used in industry;

2.using knowledge of engineering materials for the achievement of the correlation

composition - microstructures - properties;

3.explain the characteristics of the physical and mechanics properties, comprehend the

technological process by various means, distinguish the resistance to the conditions of

operation of materials, depending on preparation and microstructure;

4.appropriate use criteria and standard methods of assessment in the state of the art of

engineering materials for the identification, analysis and control of the quality of the

materials, comprehend the phenomena which appear in various conditions of use,

5. assessment of the defining parameters leading to change properties in specific processes.

The transversal competences which have to be achieved are:

1.development of the capacity to documentary and permanent upgrade of knowledge

on the progress of the traditional materials and the development of new materials

with applications for specific areas;

2.the capacity of synthesis and the correlation between the fundamental knowledge

required for certain applications technological developments;

3.the capacity of organization and the autonomy correlated to the ability to be

integrated and to work in a team;

4.using a computer, software tools in the characterisation and the choice of materials;

5.the capacity to achieve a synthesis bibliographical reference;

6.cultivation of the values and ethics of the profession of engineer.

Learning the basic concepts required on the structure, material properties and criteria for choosing

materials and concepts on materials are the starting knowledge has to acquire a future engineer (Tudor,

2015, p. 985).

4.Conclusions

It may be concluded that a material behaves in a certain way during processing (transformation) to

which it is subjected or service (as a finished product), according to its specific properties/features. The

design of an installation or a product demands a combination of materials. From the large number of

possibilities and combinations, the designer must choose the combination most suited to its objective and

avoid the occurrence of accidents. The competences accomplished in the fields of engineering require

knowledge in the area of materials (structure and properties) as well the requirement to permanently

learning, about the progress made by the new materials and technologies. For the graduates what they will

be working on in design, the knowledge gained will allow them to choose the correct materials in

accordance with the requests of the operation, the interaction with the environmental factors, technologies

available processing and in economic favourable conditions.

References

- Ashby, M., Bréchet, Y., & Salvo, L. (2001). Sélection des matériaux et des procédés de mise en oeuvre.

- Lausanne: Presses Polytechniques et Universitaires Romandes, Retrived from

- https://books.google.fr/books/about/Selection_des_materiaux.

- Ashby, M., Shercliff, H., & Cebon, D. (2007). Materials: engineering, science, processing and design.

- Oxford: Elsevier, Retrived from

- www.academia.edu/10546976/Materials_Engineering_Science_Processing_and_Design.

- Dobrescu, R.N., Plaiasu, A.G., & Denape, J. (2008). Stiinta si ingineria materialelor. Pitesti: Editura

- Universitatii din Pitesti.

- Materials Science and Engineering Expert Committee. (2013). Materials Science and Engineering in

- Europe: Challenges and Opportunities. Printing: Ireg – Strasbourg, www.esf.org/matseec.

- Tudor, S.L. (2015). The Role of School Activities in Training /Development of the Professional Skills

- Specific for the Teaching Profession, in Procedia - Social and Behavioral Sciences, 180, 984-989.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 May 2017

Article Doi

eBook ISBN

978-1-80296-022-8

Publisher

Future Academy

Volume

23

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2032

Subjects

Educational strategies, educational policy, organization of education, management of education, teacher, teacher training

Cite this article as:

Plaiașu, A. (2017). The Challenge to Teach Materials Engineering. In E. Soare, & C. Langa (Eds.), Education Facing Contemporary World Issues, vol 23. European Proceedings of Social and Behavioural Sciences (pp. 250-256). Future Academy. https://doi.org/10.15405/epsbs.2017.05.02.32