Abstract

Industrialised Building Systems (IBS) is a construction method that produced building components manufactured in a factory, transported and assembled into a structure using appropriate machinery and equipment with minimal workers on site. The project life cycle is a project independent series of activities from the starting point until the moment it was successfully delivered. Generally in a construction project, the phases or stages are initiating, planning, executing, monitoring and controlling and closing stage. This paper is part of on-going research on the Industrialised Building System (IBS) project management life cycle through the IBS approach in the Malaysian construction industry. The data and information presented is the review of the available relevant literature on this research topic. This paper incorporates an analysis of the definitions and IBS best practice or project life cycle outside from Malaysia. The identification of the project life cycle from the analysis is essential so that people and industry players will provide the basis of a guideline for the industry players to support and enhance the Malaysian construction industry.

Keywords: Industrialised Building SystemIBSLife CycleProject Management Life Cycle

1. Introduction

In view of meeting the government's ambition to transform the Malaysian construction industry into using the modern method of construction and to expedite the implementation of the IBS Roadmap and Construction Industry Master Plan (CIMP) 2006-2015, there is a call for the industry players for a proper and structured planning and implementation strategy for IBS to be established.

In the year 2008, a circular from the Malaysian Treasury Department of the Ministry of Finance denotes that the policy on full utilisation of IBS to be imposed for all government projects in Malaysia (Alshawi, & Hamid, 2009). CIDB (2010) had launched 2nd IBS Roadmap 2011-2015 to replace the current roadmap (IBS Roadmap 2004-2010) initiated in late 2010. This strategic plan was aimed to introduce of high level intended outcomes in implementing the IBS. The new roadmap focused on the adoption of IBS by the private sector. The four policy objectives were quality, efficiency, competency and sustainability. Furthermore, the newly introduced Construction Industry Transformation Programme (CITP) has highlighted the importance of IBS towards the Malaysian construction industry (CITP, 2015). Hence, IBS industry contributes to the competitiveness of the construction sector and the adoption of sustainable agenda lead by the government.

With better productivity, quality and safety, IBS can help towards a better construction industry, as well as enhance the global competitiveness of Malaysia construction industry.

2. Project Life Cycle/ Plan of Works & Best Practice

The project life cycle is a project independent series of activities that start from the beginning until it was successfully delivered. Generally in a construction project, the phases or stages are initiating, planning, executing, monitoring and controlling and closing stage. It is sequential and seems to be typical of waterfall implementation.

The best practices are method or techniques that have consistently shown the expected result and being learnt to benchmarks similar exercises or task of activities. One of the aims of this approach is to maintain the quality of product and process. It can be classified as a knowledge that underpins the examples of excellence and could seem like one of the management standards. There are cases of an organisation that offer the ‘pre-made templates' to share their best practices in business.

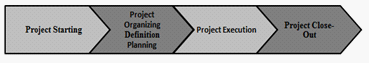

The four broad, generic project phases are as shown in Fig.

3.Problems and Issues

According to CIMP (2007) & Faizul (2006), IBS has already been introduced in Malaysia long time ago in 60’ that the system promised to solve and improve Malaysia construction industry process, but the grudging acceptance of the relevant parties and the challenging task of establishing the integration and cooperation between parties involved.

The establishment of the IBS provision in the integration of construction supply chains must take place and stated that IBS chain players need to find integration success factors in IBS project management to improve a close working relationship with them to overcome the problems encountered (Abd Shukor et. al, 2009). There is thought by (Kamar et. al., 2010) that IBS need to be a process that required synchronisation in design, manufacturing and construction. It will focus on supply chain, planning, project management, standardisation and repetition (Kamar et. al., 2010).

Traditional Construction Life Cycle was based on the client brief; the architect produced the design following by structural design by the engineer. Next the design/drawing passed to quantity surveyor to do the estimate to generate the bill of quantities. The tender document is given to the contractors who get the project. The contractor consults with the manufacturer and builds the structure and takes the responsibility for it. This conventional approach is known as “over the wall” syndrome (Evbuomwan & Anumba, 1998). This process only allows the manufacturers and contractors to be involved during the construction stage thus; this creates problems in the supply chain process and constructability related issues.

A studied had been done by Blismass & Wakefield (2008) stated that the traditional construction process is unsuitable for Offsite Manufacturing (or IBS construction) and poses a substantial barrier to its adoption (Blismass & Wakefield, 2010). The finding of the study is supported by other previous studies CIDB (2009), Nawi

4.IBS Project Life Cycle/ Plan of Works

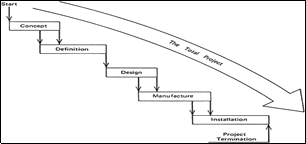

Archibald (1976) explains the project life span as the project life cycle has identifiable start and end points, which can be associated with a time scale. A project passes through several distinct phases as it matures. The life cycle includes all phases from the point of inception to final termination of the project in Fig.

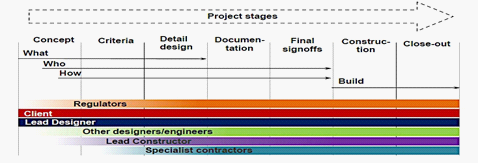

In the United Kingdom, a model of Best Practice for Hybrid Concrete Construction (HCC) showed in Table

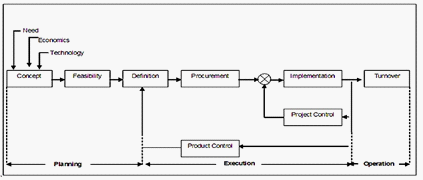

Fig.

Based on Fig.

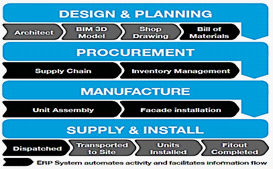

Hickory Building System (2014) from Australia produced a process that can be called Off-site Construction Process based on their product (Fig. 5.). The process had four main phases with supported by several sub-phase in each phase. The key factors in the process are in used of Building Information Modelling (BIM) and Enterprise Resource Planning (ERP). ERP guides each step of the project sequence by managing information flow and processes. By using the ERP software, it feeds project information and the bill of materials through to the machinery and controls key functions including supply chain, payroll, manufacturing program, inventory management and financial forecasting (Hickory Building System, 2014).

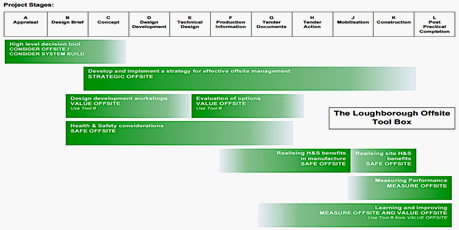

The Loughborough University (2014) had develop a process that is The Loughborough Offsite Tool Box (Fig. 6.) comprises a series of interactive tools to evaluate the use of offsite manufacturing, standardisation and pre-assembly techniques in construction projects from the early stage of construction until it completion.

5.Research Methodology

The methodology of the research is on literature review. The search for documentation and discussion involve an extensive review of the current and development of IBS project life cycle through definitions and overview of project life cycle across the sectors from another country. The information is gathered from the secondary data comprises of relevant books, journals, reports, web page and conference proceedings. It attempts to review the definitions, and the best IBS project life cycle had been produced.

6.Significance of Research

The introduction of IBS project life cycle model is relevant to CIMP 2006- 2015 and IBS Roadmap 2011-2015. The importance of the Industrialised Building System (IBS) has been highlighted under the Strategic Thrust 1: Integrate the construction industry value chain to enhance productivity and efficiency in the Construction Industry Master Plan (CIMP) 2006 – 2015 (CIDB 2007). Also furthermore, the essential element in IBS Roadmap 2011-2015 has focused on four policy objectives which are quality, efficiency, competency and sustainability on IBS implementation which is important to identify the critical factors in project life cycle to produced IBS Project Life Cycle based on our construction industry. Furthermore, the newly introduced Construction Industry Transformation Programme (CITP) has highlighted the importance of IBS towards the Malaysian Construction industry (CITP, 2015).

7.Conclusion

Construction research that focuses on the IBS project management life cycle is at an initial stage and relatively new field, especially in developing countries as the Malaysian construction industry exemplifies. IBS is widely used, practiced and implemented in developed countries such as the USA and the UK for many years due to its benefits and advantages toward the end users in the respective countries. It suggested that more research on this scope of IBS needed to be conducted in the context of the Malaysian construction industry scenario. It is necessary to enable Malaysia to move forward from the conventional construction towards IBS, which will revolutionise the pattern and mode of the offsite construction industry.

The current study has established the definition and explored the IBS project life cycle or alike from outside Malaysia. The presented literature has shown that the definition, overview and best practice of IBS constitute the main challenges to the implementation of IBS in Malaysia.

The IBS life cycle also can contributes to sustainability in the built environment through the suitable and improved activities suited for IBS approach in a construction project. Furthermore, Mohammad has highlighted that IBS contributes to sustainability and improved the quality of life in the built environment (Mohammad, 2013). The outcomes of IBS project management life cycle adoption includes producing less waste (offsite and on-site), high quality products, reducing damage towards the environment and ecosystems, less air and sound pollution, safety on-site and in the factory vastly improve and reduce site disruption.

Future studies should examine on this topic, especially from the view of the overall process, the requirements and the implementation to produce the framework of the IBS project management life cycle in according to our construction industry. Finally, the current research is a part of a current on-going study that will enhance the process and the application of IBS in Malaysia. The results of the main research will hopefully provide the basis for a guideline to support and strengthen the Malaysian construction industry.

Acknowledgement

The Authors wish to thank the Construction Industry Development Board (CIDB), UniversitiTeknologi MARA and a remark of indebtedness to the Acculturation Grant Scheme (RAGS) - 600-RMI/RAGS 5/3 (134/2014) by the Ministry of Education, Malaysia for its grant award.

References

- A.M., Alshawi, M. & Hamid, Z. A. (2009), Barriers to Industrialised Building System (IBS): TheCase of Malaysia. in 9th International Postgraduate Research Conference (IPGRC), Salford, UK.

- Construction Industry Development Board (CIDB) (2010), IBS Roadmap 2011-2015. CIDB Malaysia.

- CITP (2015), Construction Industry Transformation Programme 2016-2020 (CITP 2016-2020), Kuala Lumpur, Construction Industry Development Board (CIDB).

- PMI (2008), Guide to the Project Management Body of Knowledge, 4th ed, Newtown Square, PA: Project Management Institute, (available online http://www.pmi.org/PMBOK-Guide-and-Standards.aspx.)

- CIMP (2007), Construction Industry Master Plan 2006 – 2015 (CIMP 2006 – 2015), Construction Industry Development Board Malaysia (CIDB), Kuala Lumpur.

- Faizul, N.A. (2006), Supply Chain Management in IBS Industry, Malaysia International IBS Exhibition, Kuala Lumpur.

- AbdShukor, A.S., Mohammad, M.F., Mahbub, R. and Halil, F. (2009), “Integration of Issues and Problems of Construction Supply Chain Management in Industrialised Building System (IBS)”, 2nd Construction Industry Research Achievement International Conference (CIRAIC 2009) 3-5 November, Kuala Lumpur.

- Kamar K. A. M., ZuhairiAbd. Hamid, Abdullah Sani S. F., Ghani M. K., MohdZin M. Z., Rahim A. H. and Abd. Karium A. Z. (2010), The Critical Success Factor (CSFs) for the Implementation of Industrialised Building System (IBS) in Malaysia, CREAM, IBS Survey 2010, CIDB Malaysia.

- Evbuomwan, N.F.O., & Anumba, C.J. (1998), An integrated framework for concurrent life-cycle design and construction.Advances in Engineering Software, 29 (7-9), 587-597.

- Blismass, N. and Ron Wakefield (2008), Drivers, constraints and the future of offsite manufacture in Australia, Construction Innovation, 9(1).72-83.

- CIDB (2009),Industrialised Building System (IBS): Implementation Strategy from R&D Perspective.Construction Industry Development Board Malaysia (CIDB), Kuala Lumpur.

- Nawi M.N.M.; Lee, A.; Arif, M.; and Haron, A.T. (2009), Collaboration among project participants towards sustainable construction: A study of IBS in the Malaysian construction industry. Proceedings of the 2nd Construction Industry Research Achievement International Conference (CIRIAC 2009), CIDB, Kuala Lumpur.

- Nawi, M.N.M., Jalaluddin, S.M.F.W.S, Zulhumadi, F., Ibrahim, J.A., Baharum, F. (2014), International Journal of Applied Engineering Research, A Strategy for Improving Construction Projects Sustainability through Value Management Approach, 9 ( 24), 28377-28385.

- Nawi, M.N.M., Shaharanee, I.N.M., Hashim, K.F., Azman, M.N.A., Ibrahim, S.H. (2015), Qualitative Analysis on the Barriers of Industrialised Building System (IBS) Uptake in Malaysia Construction Projects, Advanced Science Letters, 21 (6), 2135-2139

- Archibald R.D. (1976), Managing High-Technology Programs and Projects, (3rd Edition), New Yourk: R.D. Archibald, Wiley

- Glass J., (2005), A Best Practice Process Model for Hybrid Concrete Construction, Construction Management & Economics, 23(2), 169-184,

- Kelly J., Male S., and Graham D. (2004), Value Management of Construction Projects, Oxford: Blackwell Science Ltd.

- The American Institute of Architect (2007),"Integrated project Delivery (IPD), Guide, (available on-line www.aia.org/ipdg) [accessed on 1/11/2014].

- Konchar, M. (1998), Comparison of US project delivery systems, Journal of Construction Engineering and Management, 124 (6), 435-444

- Khemlani, L. (2009), Sutter Medical Center Castro Valley: Case Study of an IPD Project, AECbytes "Building the Future", (available online www.aecbytes.com/buildingthefuture/2009/Sutter_IPDCaseStudy.html) [accessed on 1/11/2014]

- Mossman, A. (2008), "More than materials: managing what’s needed to create value in construction”,the 2nd European Conference on Construction Logistics, Dortmund, (available online www.lci-uk.org/downloads/Lean_Construction_Logistics.pdf) [accessed on 15/11/2014]

- Hickory Building System (2014), Overview of Prefabricated Structural System by Hickory, (available on http://www.hickory.com.au/what-we-do/our-systems/hickory-building-systems/)[accessed on 15/11/2014])

- The Loughborough (2014), The Loughborough Offsite Tool Box. (availableonline on https://offsite.lboro.ac.uk/tools.php) [accessed on 15/11/2014]

- Mohammad, M.F. (2013), Construction Environment: Adopting IBS Construction Approach towards Achieving Sustainable Development, Procedia Social and Behavioural Sciences, 85, 8-15.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

22 August 2016

Article Doi

eBook ISBN

978-1-80296-013-6

Publisher

Future Academy

Volume

14

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-883

Subjects

Sociology, work, labour, organizational theory, organizational behaviour, social impact, environmental issues

Cite this article as:

Yusof, M. R., Musa, M. F., Samsudin, N. S., Mohammad, M. F., & Baharuddin, M. N. (2016). Industrialised Building System (IBS)/Off-Site Project Management Life Cycle. In B. Mohamad (Ed.), Challenge of Ensuring Research Rigor in Soft Sciences, vol 14. European Proceedings of Social and Behavioural Sciences (pp. 635-642). Future Academy. https://doi.org/10.15405/epsbs.2016.08.90