Abstract

Plastic, it is known to be the most widely used product in the world today. Although its existence is common nowadays, the rises of environmental threat caused by current plastic waste amount have reached its alarming heights. The consumed plastic is integrated into concrete to diverge it from being a waste into a beneficial product in the construction industry. This paper’s main purpose is to explore the development of plastic incorporated concrete as a sustainable building material. In addition, reuse and recycling of plastic waste specifically Polyethylene Terephthalate (PET) is implemented to reduce energy consumption in the construction sector, as well as improving waste management in resulting in an eco-friendly environment. Methods include laboratory experimental analysis by measuring engineering parameters including density tests, compressive strength and thermal properties test using four types of concrete mixes including 0% PET, 5% PET, 15% PET and 25% PET in concrete block. Finally, a sustainable approach to these new concrete materials, the outcomes acquired feature their improvements in thermal properties test, but with a low resistance to compression compared to traditional concrete mixes with the same test type. Through this implementation, optimisation of sustainable building materials towards efficient thermal performance could be achieved in building construction.

Keywords: Re-use plastic, energy efficiency, concrete mixture, sustainable building material

Introduction

Risings of the population in communities living on the coast have witnessed the phenomenon of plastic waste that increases rapidly with every passing day. Plastic pollutants that initially come from the land, flows into the river, finally dragged into the sea, have led to The Great Pacific Garbage Patch (GPGP) formation. The GPGP, the largest of five coastal areas with large plastic collections in the global ocean, is known as Scrap Island. GPGP is a vast area, about 1.6 million square kilometres in size which is almost the triple the size of France or double the size of Texas (Lebreton et al., 2018). Plastic amounts in GPGP are determined to be about 80,000 tonnes; the previous calculations are 4 to 16 times less. This sum is equal to the combined number of 500 Jumbo Jets (Lebreton et al., 2018).

After manufacturing and usage of plastic in half a decade, to date, the amount of plastic waste has risen. Since 2013, a total of 299 million tonnes of plastics have been produced and disposed of, which is a growth of 4 percent over the previous year (Global Plastic…, 2015), thereby increasing the trend of its use in previous years. In 2015, a total of 6300 million tonnes of plastic waste is calculated around the world. Likewise, it is estimated the amount of plastic waste is expected to gain a number of 12,000 million tonnes in 2050. (Geyer, Jambeck, & Law, 2017) (Figure 01).

Beneficial, multi-purpose, lightweight, versatile, durable, and cost-effective plastic properties are the best features that result in excessive consumption as consumer products (O'Hara, Iudicello, & Bierce, 2014). Although it is highly useful, plastic is difficult to recycle as the amount of energy required to separate, clean, process besides producing air pollutants (Saptoadi, Rohmat, & Sutoyo, 2016). Whereas reusing plastic does not require additional energy and does not result in pollution.

According to experts, by 2050, the measure of plastic in the sea will surpass the measure of fish in the ocean (Bathauer, 2016). Creatures living at sea or on land may be harmed by plastic waste. Fish, shellfish, and birds can be confused with plastic when it breaks into food. A total of 100,000 aquatic animals die in the sea each year due to plastic recruitment (Gall & Thompson, 2015). However, there are methods that can be used to minimize the effect on the environment. One approach to limit the waste is to utilize plastic waste as a construction material, such as roads, building envelope, roof, wall, and others.

Concrete as construction materials in the building industry has been widely used since the 1850s (Neville, 1973). In this paper, the scope has been reduced to the use of concrete as the main theme of sustainable building materials for the flexibility of building construction. Plastic waste usage as aggregates could be an alternative to solve the issue of the reduction in natural substance for concrete production. This paper studies the performance of concrete properties derived from the incorporation of plastic waste and comparison with standard concrete.

Problem Statement

Although there are many useful features, plastics are difficult to recycle, either because they are produced or because they are too expensive and complicated to be made (Yoshioka & Grause, 2015). For example, a certain cup of coffee has an inner plastic coating for waterproofing, which is not suitable for recycling (Ma, 2018). A lot of energy is needed in the recycling process, especially in the process of segregation and cleaning (George, 2019). Instead, plastic re-use requires fewer usage of energy plus does not contaminate the earth.

Although plastic re-use in buildings is not difficult, the most important factors for making sustainable building materials are quality, cost and time (Haggar & Hatow, 2009). The quality of the concrete block produced will determine the quality of construction work. Good quality concrete block will produce the appropriate product function as expected.

Plastic reuse in some construction work has been analysed in many studies. Researchers participating in this study performed tests to see the potential of using plastic materials in the construction of concrete material. Some examples of plastic incorporated concrete include the use of aggregate road construction, concrete aggregates, asphalt pavements, and many other applications. Batayneh, Marie, and Asi, 2007) examines waste plastic usage as concrete aggregates.

The concrete block properties are determined by mix design. The appropriate mix design must meet the requirement of water ratio, cement, and aggregates (Ahmad & Alghamdi, 2014). The choice of the appropriate type of material to be used in the mix design also affects the strength of the resulting concrete (Shi et al., 2015). Therefore, the use of various plastic amounts in each concrete block sample is discussed.

Research Questions

This study investigates the correct utilization of plastic waste in concrete will result in a better slump, density, compressive strength, and thermal properties, comparing to traditional concrete. Two (2) questions are assumed in response to this hypothesis:

- How waste plastic can be used as an alternative substance and contributes to sustainable building materials.

- How do concrete properties be affected when waste plastic is used as aggregate in the concrete mix?

Purpose of the Study

This study aims to explore the possibility of enhancing the concrete’s mechanical properties, such as slump, density, compressive strength, along with thermal properties, by the addition of waste plastic in concrete. Experimental laboratory tests were performed, where shredded plastic was used as a concrete’s additional aggregate. The investigation’s objectives are as follows:

- Investigate the feasibility of incorporating plastic wastes in concrete that are potentially used as sustainable building materials.

- Investigate the performance of the proposed concrete block with the addition of plastic waste designed to enhance slump or workability, density, structural strength, and thermal property, and to study the potential benefits provided by newly constructed concrete blocks.

Research Methods

Laboratory testing is applied in this methodology. This study was conducted through the incorporating of unresolved plastic residue waste from the environment into the concrete mix. In this experiment, concrete block samples will be constructed and developed by re-using PET bottles and empty containers, shredded them and using them as aggregates in concrete blocks. The plastic waste will be collected and sorted according to the various plastic components and are classified and narrow down to PET plastic bottles and containers. When the bottle is collected, the lid is removed, and the bottle's body is shredded into an irregular piece. After that, it is put into the conventional concrete mixture. Percentages of PET in concrete are the variables that are manipulated in the study of this experiment.

- Manipulated variables: Percentage of PET in concrete

- Fixed variables: Dimension and thickness of the concrete blocks

- Responding variables: Concrete Properties; Thermal conductivity of concrete blocks, Compressive strength, Density, and Slump

There are many test methods that can be used to test concrete samples. In this research, the experimental method is used to study the effects of concrete properties with PET additives in concrete. The Grade 20 concrete sample measured the engineering parameters that include the test of a slump, density test, compressive strength and thermal test using four types of concrete mixture mix including 0% PET, 5% PET, 15% PET and 25% PET in concrete.

Preparation of Plastic Waste as Aggregate

Figure 2 shows PET bottles are collected and are shredded into irregular pieces of approximate 30mm to 50mm in size. The point here is to change the plastic waste as aggregate to the concrete mix. Containers and bottles were collected in the Universiti Sains Malaysia compound and crushed in nearby recycling plants.

Preparation of Plastic-Concrete Specimens

The experimental program includes a test of 32 concrete specimens with a fixed block size of 100 x 100 x 100 mm and are standardized to be 7, 14 and 28 days of curing parameters with different percentages of PET aggregates in concrete (0% PET, PET 5%, PET PET 15%, and PET 25%). The mixed design used is based on a ratio of 1: 1: 2 with cement type, ordinary Portland cement (OPC). Table 1 shows the details of the sample model.

In Figure 3, the waste PET aggregate is added to the normal concrete mixture according to the calculated percentage. Standard concrete blocks of the common mix were set as well in order to differentiate the blocks of concrete with PET. The blocks are left dry overnight. The concrete blocks are separated from moulds and cured by water curing methods by submerging the blocks in a tank filled with water.

Laboratory Experimental Methods

This test is done with a duration of 7 days, 14 days, and 28 days of curing age. Below is Figure 4 showing the tests taken on stated days, except that the thermal properties of this block sample are only tested on day 28 using the Transient plane source technique (TPS) to analyse thermal conductivity of concrete samples.

Findings

The results of the study identified by the effect of plastic aggregate incorporated to concrete blocks are explained in this part of the paper. The concrete properties are slump, density, compressive strength, and thermal conductivity.

Slump Test

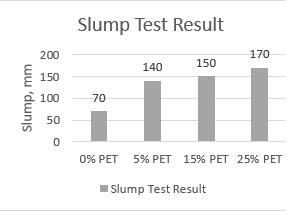

A slump test is a measurement technique used to estimate the workability of concrete. Concrete workability is characterized by the convenience of mixing, transporting, configuring and settling concrete effectively without the needs to segregate. Concrete that can be mixed, transported, placed and compacted easily is a very workable concrete. This means that if the concrete has a high tendency to work easily, it can be an important role in contributing to sustainable development and reducing the environmental impact of concrete products in development. Slump tests are widely used on site. A 300 mm high cone is used as a reference in the test of the slump. It is coordinated according to ASTM C 143-78. The concrete is subsequently filled in the cone. Afterward, the cone is gradually lifted, so the unsupported concrete will collapse. Then, the fall will be measured by the decrease in the height of the concrete.

Based on the test, the slump value is determined for a concrete mix containing PET revealing the data shown in Figure 5. It is considered that a rise of slump value is achieved with the incorporated PET residues into the concrete mix. Concrete mixtures containing 5% PET reach twice the value of slump compared to the concrete mixture without adding PET. The PET aggregate does not have the ability to absorb water in a concrete mixture. Due to this non-absorbent property, there will be more free water in concrete mixes that includes PET. Therefore, will result in an increase in slump value. Thus, the aggregate PET effect on the fresh concrete mix’s workability seems apparent and quite consistent.

However, concrete workability is inversely proportional to the strength quality of the concrete. The concrete’s strength will decline with the increases of workability, which affects the durability of the concrete.

Density Test

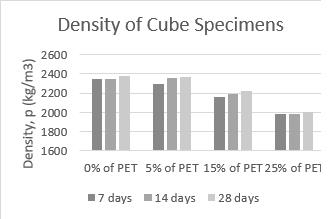

Testing a concrete’s density is about measuring the solidity of the concrete. The concrete mixing process can be modified to build the final concrete product with higher or lower densities. To determine the density of the concrete is to first find out the mass of newly hardened concrete while in the air and the other mass while submerged in water. To achieve the density, it is calculated along with the volume of concrete. Density is calculated directly by the ratio of mass to volume. Meanwhile, only focusing on concrete, about 2,400 kg for one cubic meter of density is found in an ordinary weight concrete. The density of the concrete is based on the aggregate’s density, the considerate entrapped air, and the amount of cement plus the limited aggregate’s size used.

According to the test, the results shown in Figure 6 determine the decreasing of concrete density by increasing the amount of PET that is incorporated into the concrete. Density reduction is straightforwardly corresponding to the amount of PET, which summarizes the reduction of 0.3%, 6.3% and 15% concrete density for concrete with 5%, 15%, and 25% PET additions, respectively. The decline in the value of density is due to the lower PET unit weight. This concludes the concrete with a high percentage of plastic, such as a sample with 25% PET, achieve the lowest density and can be used and utilize as lightweight concrete in construction.

However, lightweight aggregates influence the elasticity, compressive, and tensile strength of concrete. Structural purposes are not suitable to be used by lightweight concrete. Hence, it is more suitable to use lightweight concrete as insulation or lightweight filler.

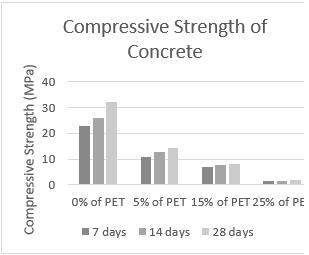

Compressive Strength Test

According to the tests investigated, this segment will discuss the results of the addition of PET to the concrete’s most vital property which is compressive strength. Concrete blocks are produced with the same size, but with different percentages of crushed PET pieces. Test results are shown in Figure 7, where the compression strength is found to decrease to an increase in PET percentage. Findings show that the rate decreases in compression quality due to the expansion of PET volume. Generally, it is noted the increase in PET amount has caused a decrease in strength rate. Concrete made with 5%, 15% and 25% of PET having compression strength reduced to 55%, 75%, and 94% respectively. The decline in compression quality caused by PET inclusions may be due to weak bonds between cement blends and PET pieces, as well as PET plastic low strength properties. The concrete block crack surface shows that most of the PET is being pulled out during the compression as rather to splitting apart shown in standard concrete. Concrete specimens with PET additives fail under a load of compression did not indicate the normal types of brittle failure typically taken by standard concrete. Observation of the failures is rather a gradual failure, subject to the additional PET amount. It is observed during the test, when the PET percentage increases, the failure style turns out to be more ductile. Concrete blocks with PET additions are able to restrain the load for a few minutes after failure with the absence of a complete breakdown. It has been observed that this pattern is increasingly clear as PET percentage levels increase.

Thermal Conductivity Test

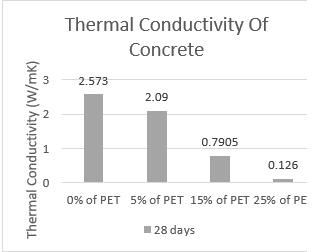

In previous years, most researchers have given more concentration on the study about mechanical properties of concrete. Only recently, more research assesses thermal conductivity in mechanical properties of concrete due to the importance of building energy efficiency in building. In general, materials with low-value k are considered as a good option for energy saving in the building construction industry.

Thermal insulating performance of four varied concrete samples (ordinary concrete 0% PET, concrete containing 5% PET content, concrete with 15% PET content and concrete with 25% PET content) was investigated through thermal conductivity test of concrete samples. Low heat conductivity of the material will result in greater thermal insulation.

The transient thermal conductivity measurements for all different concrete samples are shown in Figure 8. Concrete heat conductivity is reduced by inverse with higher PET content in concrete. The specimen with the highest thermal conductivity after 28 days of curing was concrete with PET 0% and then concrete with 5% PET, 15% PET and the lowest was concrete with 25% PET. This means we can conclude that thermal conductivity reduction is observed with higher PET percentages in concrete. It is agreed that for concrete samples with 25% PET with the lowest thermal conductivity value, the ability to perform or heat transfer is lower than others. This suggests that the concrete insulating property improves up to 95% by incorporating 25% PET additives. Therefore, the sample has a better heat insulation capacity.

Conclusion

The growing concern of environmental issues caused by waste management leads to the quest for significant alternatives to plastic waste product. This has shown different perspectives on the implementation of plastic in concrete production, where it is concluded and summed up as follows:

- Waste plastic can effectively be utilized and viable as additives in traditional concrete. The use of reusable plastic PET incorporated concrete decreases the total density of ordinary concrete. The difference from ordinary concrete shows the density decreases by 0.3-15% for concrete containing 5% to 25% of reused PET. Concrete blocks which include PET waste can be used as lightweight concrete because of its lower mass, compared to conventional concrete blocks.

- The concrete compression strength of 5% to 25% reuse PETs varies between 1.9 and 48 MPa. Due to the percentage increase in PET, the resistance to compression decreases. It has been found that the reduction in compressive strength is between 55% and 94% of aggregate concrete with 5% to 25% of plastic PET waste. Although this result is inevitable, concrete with PET additions exhibits more ductile behaviour than normal concrete. These ductile behaviours can be an important factor in reducing crack formation. It can be concluded that, even with a low value of strength to compression, the concrete is suitable for a non-structural component in construction.

- This research investigates the influence of waste plastic PET on thermal conductivity (or insulation) in ordinary concrete. Thermal conductivity tests are carried out using hot-wire techniques. The findings have shown that plastic waste reduces thermal conductivity (or better insulation properties) than ordinary concrete. It has been revealed that insulation is fixed up to 95% with PET aggregate admission in standard concrete. Each percentage for PET aggregate varies between 18% and 94%, depending on the amount of additional PET content. It can be concluded that concrete with PET is suitable for the use of low insulation walls where thermal gain inside the building will be lower than the use of ordinary concrete.

The incorporation of plastic PET materials in concrete is a great result in initiatives towards cleaner environments and sustainable construction. Therefore, concrete blocks containing plastic waste as aggregates are suitable for use as sustainable building materials. .

References

Ahmad, S., & Alghamdi, S. A. (2014). A statistical approach to optimizing concrete mixture design. The Scientific World Journal.

Batayneh, M., Marie, I., & Asi, I. (2007). Use of selected waste materials in concrete mixes. Waste management, 27(12), 1870-1876. DOI:

Bathauer, D. (2016). Putting a Charge into Conductive Plastics. Plastics Engineering, 72(2), 26-27. DOI: 10.1002/j.1941-9635. 2016.tb01475.x

Gall, S. C., & Thompson, R. C. (2015). The impact of debris on marine life. Marine pollution bulletin, 92(1-2), 170-179. DOI: 10.1016/j.marpolbul.2014.12.041

George, S. (2019). Microplastics have even been blown into a remote corner of the Pyrenees. Retrieved from https://www.pri.org/stories/2019-04-26/microplastics-have-even-been-blown-remote-corner-pyrenees

Geyer, R., Jambeck, J. R., & Law, K. L. (2017). Production, use, and fate of all plastics ever made. Science Advances, 3(7). DOI:

Global Plastic Production Rises, Recycling Lags. (2015). Retrieved from http://vitalsigns.worldwatch.org/vs-trend/global-plastic-production-rises-recycling-lags

Haggar, S. E., & Hatow, L. E. (2009). Reinforcement of thermoplastic rejects in the production of manhole covers. Journal of Cleaner Production, 17(4), 440-446. DOI:

Lebreton, L., Slat, B., Ferrari, F., Sainte-Rose, B., Aitken, J., Marthouse, R., ... & Noble, K. (2018). Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Scientific reports, 8(1), 4666. DOI:

Ma, Y. (2018). Problems and resolutions in dealing with waste disposable paper cups. Science progress, 101(1), 1-7.

Neville, A. M. (1973). Properties of Concrete A.M. Neville. New York: Wiley.

O'Hara, K. J., Iudicello, S., & Bierce, R. (2014). A Citizens Guide to Plastics in the Ocean: More Than a Litter Problem. Washington, D.C.: Center for Marine Conservation.

Saptoadi, H., Rohmat, T. A., & Sutoyo. (2016, June). Combustion of char from plastic wastes pyrolysis. In AIP Conference Proceedings, 1737(1), 030006.

Shi, C., Wu, Z., Xiao, J., Wang, D., Huang, Z., & Fang, Z. (2015). A review on ultra high performance concrete: Part I. Raw materials and mixture design. Construction and Building Materials, 101, 741-751.

Yoshioka, T., & Grause, G. (2015). Recycling of waste plastics. In Topical Themes in Energy and Resources. Tokyo: Springer.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

26 December 2017

Article Doi

eBook ISBN

978-1-80296-950-4

Publisher

Future Academy

Volume

2

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-882

Subjects

Technology, smart cities, digital construction, industrial revolution 4.0, wellbeing & social resilience, economic resilience, environmental resilience

Cite this article as:

Halim, N. F. A., Azis*, Z. A., Taib, N., & Ismail, H. (2017). Development Of Sustainable Building Material By Incorporating Plastic Waste In Concrete Block. In P. A. J. Wahid, P. I. D. A. Aziz Abdul Samad, P. D. S. Sheikh Ahmad, & A. P. D. P. Pujinda (Eds.), Carving The Future Built Environment: Environmental, Economic And Social Resilience, vol 2. European Proceedings of Multidisciplinary Sciences (pp. 415-424). Future Academy. https://doi.org/10.15405/epms.2019.12.40