Abstract

This paper is purported to highlight issues on warehouse operational challenges that profoundly will hinder supply chain warehouse performance. Furthermore, warehouse management through inventory control is vital for every firm and its supply chain. This study focuses on several shortcomings in warehouse operation across the supply chain such as lack of a centralized inventory hub, difficulty in managing inventory waste & defects, keeping up with the stocks, the difficulty in identifying incorrectly located materials, tracking of obsolete materials, the inefficient inventory management process, and the limited visibility to inventory issue. This study looks into various warehouse challenges published in the warehouse literature. The warehousing operational challenges in this paper cover the issues of inventory and supply chain. While this study was limited in scope to one single issue which is the warehouse operational challenges within the scope of literature, solutions, or recommendations to mitigate the challenges can be drawn from this study. Solutions such as implementing a real-time inventory management system, stock auditing system, and Modern inventory management software are ideal. The application of scholarly articles contributes to the derivation of the factual information presented.

Keywords: Challenges, inventory, supply chain management, warehouse pain point

Introduction

Proper warehouse management decides the success of a business organization. Consumers require the proper delivery and the correct products. Firms try as much as possible to manage the warehouse and daily operations to avoid the complaints that might arise that in turn can lead to a damaged reputation. Every firm is trying as much as possible to ensure the efficiency and effective aspect of managing the inventory but there are challenges in the process. A firm that intends to be successful must ensure the solution to the changes to ascertain the efficiency, effectiveness, and ideal warehouse management and operations. The report focuses on the challenges of inventory management as a methodology of warehouse management and the recommendations for the solution to such problems.

Literature Review

The warehouse is now more important than ever in the success or failure of a firm, warehouses serve as an important intermediary between supply chain participants, influencing both supply chain costs and service levels (Faber et al., 2013; Mkumbo et al., 2019). In general, warehouse management is to achieve reduced costs while boosting warehouse operation efficiency and enhancing customer response, and measuring warehouse performance gives information on how the warehouse compares to the requirements or industry peers (Bakar et al., 2016; Faber, 2015). According to the previous study, mismanagement of the warehouse and inventory function can harm a company’s economic returns by creating excessive inventories (Marziali et al., 2021). Therefore additional research is required on the relationships and effects between supply chain variables and warehouse management performance. Warehouse operations have an immediate influence on customer service, operation costs, and business profitability. The warehouse must be well-designed to be cost-effective and give better customer service (Suvittawatt, 2016).

If you run a warehouse, then you know that there are a ton of different things that all have to work together to create an efficient workplace. Unfortunately, because there are so many moving parts on the floor, it can seem impossible to manage everything all the time, which is why so many warehouses have inefficient operations (Vatumalae et al., 2020a). This not only leads to decreased productivity but can cost a lot of money in the long run as time and energy wasted is the same as pouring money down the drain (Vatumalae et al., 2022). Today we are going to look at pain points in the warehouse, as well as how to identify them and what you can do to fix them. The best thing about correcting these problems is that you can see noticeable results each time, meaning that if you make incremental changes over time, then you can gradually turn your warehouse into a peak performer.

Methodology

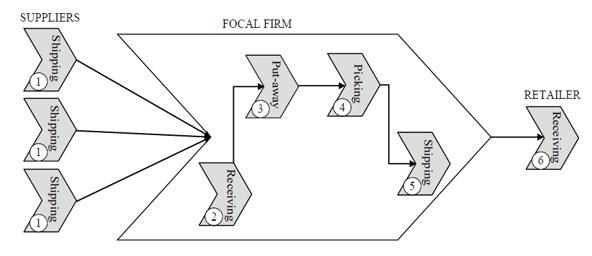

This study on warehouse challenges is based on the data on the warehousing operations collected through several warehouse literatures. The main objective of the study is to highlight some of the challenges faced in warehouse operation which eventually influence the overall performance of the warehouse. The selection of literature was random with easy use of a current open-access database. By using the text analysis, the present warehousing operational challenges is discovered, identified, and discussed. This encompasses mainly issues on inventory, operation, and warehouse supply chain. While this study was limited in scope to one single issue which is the warehouse operational challenges within the scope of literature, solutions, or recommendations to mitigate the challenges can be drawn from this study. The focus of this study falls within the radius of the warehouse supply chain comprising a supplier, focal firm, and retailer [three-layered supply chain] which is indicated in Figure 1. In this study, the challenges were identified based on the six-pain point in the warehouse supply chain.

Analysis of Warehouse Pain Point through Literature using Text Analysis

In using text analysis from literature or any specific text, the study could strengthen discussion if offers valuable insight from the text as evidence. Rather than simply dropping in quotations and expecting their significance and relevance to the argument to be self-evident. As such this study provides sufficient analysis of the passage. Furthermore, the overriding goal of analysis writing is to demonstrate some new understanding of the text. The following Table 1 depicts the steps involved in the text analysis.

Key for Six Pain Point

- Inbound Shipping

- Receiving

- Put Away

- Picking;

- Outbound Shipping

- Receiving

Findings on the Various Challenges in a Warehouse Operation

The Limited visibility to inventory

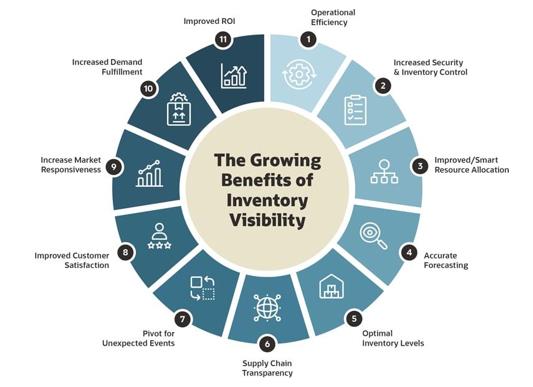

The challenges of stock identification in the inventory can create commotion in the warehouse since the order taken might not tally with the inventory in the warehouse (Sundram et al., 2016; Yiğit, 2020). The entire situation contributes to the imperfections and the confusion among warehouse managers that in turn exposes the firm to vulnerabilities (Vatumalae et al., 2022). The situation further leads to the delay in shipping the stock. The entire aspect impacts the firm negatively since the delay in the access or the reception of goods contributes to the lack of stocks in hand. It further means that the firm will have to ensure an increased concentration on time management (Yiğit, 2020). It further leads to an incomplete, inaccurate, and hard-to-find inventory that pushes a firm to the bottom line. It further damages a firm reputation due to the consumers’ complaints of the lack of ease of access to goods and the improper keeping of the inventory. A firm that delays inventory management is bound to face real issues that move towards consumer disloyalty, decreased number of consumers, and decreased revenues (Sundram et al., 2018; Yiğit, 2020). The more the firm is facing this challenge, the higher the chances of loss of opportunities to attract the consumer due to disorganization. Since consumers require the goods at a stipulated time, the failure to provide them the goods due to the delay in shipments caused by limited visibility of the inventory is a threat to the entire firm’s supply chain success and stability in the market (Wahab et al., 2022; Yiğit, 2020). Every form that operates in the competitive environment must be proactive enough in inventory management to avoid the issues that arise as far as warehouse management is concerned. The limited visibility to inventory has been a case in most firms leading to the needed solutions to solve the issue and ensuring the increased concentration on better warehousing management and operations to ensure effectiveness and efficiency (see Figure 2).

The inefficient inventory management process.

The other issue is the inefficient inventory management process. The application of the manual process of managing a large inventory leads to human error due to exhaustion and burnout (Babenko & Ivanovich, 2016; Sundram et al., 2018). It further arises from a lack of keenness and demotivation in ease of the large inventory that cannot be managed within the specified time. In a case where there is an increased focus on the schedule, the firm will face the challenge since productivity or accuracy will be dealt a blow. The situation exposes the firm to more issues such as poor management, the loss of goods, and the loss of records that might in turn lead to more losses than expected. The more the firm believes in proactive measures, the higher the chances of the application of the best and most recognized procedures to solve the issues (Babenko & Ivanovich, 2016). The laxity in this situation leads to the loss of goods and errors in inventory management which is a threat to the stability of this firm. Every manual procedure of managing a warehouse has errors due to the application of human labor in the entire process (Vatumalae et al., 2020b). Inventory management is not an exception. The situation has contributed to the need for solutions.

Tracking of obsolete materials

Tracking obsolete materials is another issue of inventory management. The obsolete materials in the warehouse might cause the loss of the products and goods that in turn lead to losses experienced in the firm. Also, the warehouse managers will abandon the obsolete goods and the products which in turn will lead to the loss and the waste of the products (Ran, 2021). The efficiency of inventory management will be compromised through obsolete material leading to disruptions of the perfect stock keeping and imperfections in the firm (Sundram et al., 2018; Vatumalae et al., 2022). The abandonment of the goods leads to the laxity of the warehouse managers to trace the obsolete goofs and keep the proper inventory due to the perception that they have already failed to materialize (Ran, 2021). The firm facing this issue will face many management challenges that will in turn expose the firm the vulnerabilities due to the lack of proper concentration of the warehouse managers on the products that have been deemed as weak. The more the firm believes in such a notion, the higher the opportunity required as far as the changes needed are concerned. A firm that fails to track obsolete materials will be unstable due to the needed concentration on perfection (Ran, 2021). The avoidance of the use of obsolete materials and the appreciation of the new materials when the needs arise such as the increased consumer number leads to more exposure to inventory management since the warehouse manager will fail to utilize the obsolete materials (Ran, 2021; Wahab et al., 2022). A firm that does not care about obsolete materials but appreciates the new ones incur more expenses in inventory management leading to negativity and instability in such a firm. This issue affects a firm negatively.

The difficulty in the identification of the incorrectly located materials

Another issue is the difficulty in the identification of the incorrectly located materials. This arises due to the lack of the proper systems in the warehouse to assist in the tracking of goods in real time (Chan et al., 2017). The situation leads to disorganization in the warehouse which in turn leads to difficulty in locating the product within the specified time. The more the firm is failing to take stock due to poorly arranged inventory. The higher the chances of the failure to ascertain the required threshold in inventory management (Sundram et al., 2017). The proof has exposed several firms to poor management and the loss of goods that could have led to more revenues. It has further led to difficulty in finding the specific product in the warehouse (Chan et al., 2017). Such a situation leads to time wastage and the loss of consumers due to the difficulty in the access to the required products. The more the firm concentrates on the realization of access to stocks, the higher the chances of the need for the perfect arrangements of the goods in stores to ensure that there are factors placed that lead to the difficulty in warehouse management (Chan et al., 2017; Vatumalae et al., 2020a). Picking the wrong materials leads to delays and affects consumer satisfaction since he or she will lose trust in the firm due to the delays and the presentation of the goods to the consumers. It is further evidence that a firm that fails to manage the inventories will be exposed to the instabilities and the loss of consumers.

Keeping up with the stocks

Another challenge of warehouse management using the inventory method is keeping up with the stocks. A firm that stocks more goods without seeking the ones in stores will contribute to confusion or the lack of space to store the bought goods. The situation further exposes the firm to eventualities such as misplaced stocks, lost stocks, and obsolete materials. Such a firm faces loss due to the wastage of goods or the elapse of time before their expiry (Munir et al., 2021). It also causes issues in warehouse management since the manager will hate to take stock of the new and the old products at once to ensure perfect and efficient inventory management (Sundram et al., 2017). The entire situation exposes the firm to the imperfection that in turn leads to the need for engagement in various ways or strategies to ascertain the situation of this issue. The poor stock control and the management by the managers further lead to more losses since the bought and the existing stocks might not be appreciated by the consumers. The lack of proper accountability for the new stock further exposes the firm to imperfections since the product will go down. The losses will be more than the profit due to the unnecessary expenses used when transporting the goods in the warehouse and the lack of clearing of the warehouse due to the reduced consumer number (Vatumalae et al., 2020b). A firm that faces this issue will be in a position to rectify it as soon as possible.

The difficulty in managing inventory waste & defects

The other issue is the difficulty in managing inventory waste & defects. Defective inventory and waste contribute to the imperfection due to the application of non-standard procedures that might arise due tit her untrained storekeepers (Atieh et al., 2016; Sundram et al., 2016). This affects the daily aspects and the perfection required by the warehouse manager. The more the firm concentrates on laxity in training the storekeepers, the higher the chance of the application of non-standard procedures that are a threat to proper inventory management (Atieh et al., 2016). The firm experiencing this kind of issue is bound to be imperfect and unstable in the market. The issue further leads to the increased costs associated with lost inventories. The wastes and the defects affect the smooth operation of the warehouse since the firm will have to ensure the availability of more personnel to assist in the identification of the defects (Atieh et al., 2016; Selvaraju et al., 2017). It further creates confusion in inventory management since the firm is in a pole position to ascertain the perfection required as far as warehouse management is concerned. The more the concentration on this issue, the higher the chance of the need for the perfect strategies to expose every firm to the identification of the perfect inventory (Atieh et al., 2016; Vatumalae et al., 2020a). A firm facing this kind of challenge is bound to have issues with a competitive advantage. The warehouse must be managed to ensure ease in the availability of the products. It is quite a hurdle to face challenges in the firm regarding warehouse management (Alawneh, 2018).

Conclusion, Recommendations, and Future Research

Warehouse firms can implement a real-time inventory management system for better stock identification and inventory management. The system ensures the identification and access to real-time data on the stock location and availability. Also, the location of the shipment will be available and accurate leading to access to goods and arranging them in the warehouse ease of access. Since the real-time data dwells on the exact figures and the flow of goods to the warehouse, concentrating on a real-time inventory management system will ensure there is perfect visibility of the inventory and perfection in warehouse management. The perfect inventory improves customer satisfaction leading to consumer loyalty and more revenue. Every firm facing visibility issues regarding inventory must ensure the use of a real-time inventory management system to ensure the perfection and the competitive advantage that arises from efficient and effective warehouse management and operations.

Tracking of obsolete materials issues can be solved through the application of the stock control system. The situation exposes a firm to the need for the identification of the dead stock and the obsolete inventory and uses them effectively to avoid the losses that might be caused by the abandonment of the dead stock. The more the firm concentrates on perfection in warehouse management, the higher the chances of the control of the dead stock to ensure reduced losses as far as the goods and the revenues are concerned. Appreciation of this app assists inventory managers in controlling the stocks and taking care of obsolete materials. This solution will assist in the reduction of expenses and expose every other member of the organization more so the warehouse managers to the skills of managing the stock which in turn will assist in future management. The more the firm is concentrating on this solution, the higher the chances of competitive advantage in the market.

Concerning stock-taking, warehouse operators should keep up with the stocks, a firm should ensure the availability of a stock auditing system. This system assists the warehouse manager in stock-taking to ensure the identification of new and old stocks. The identification of the user and the used stocks improves the efficiency and effectiveness of inventory management. The situation exposes the firm to stability since there will be not much exposure and the goods will not be lost in the warehouse. The more the firm is concentrating on perfection regarding the stock keeping, the higher the chances of stability. This solution leads to the saving of goods, money, and increased profit. The more the firm is trying as much as possible to use this approach, the higher the chances of perfect warehouse management with a high level of efficiency and an effective approach.

Conclusively, warehouse management misses mostly the inventory management methods are evident. Issues such as solving the lack of a centralized inventory hub, difficulty in managing inventory waste & defects, keeping up with the stocks, the difficulty in the identification of incorrectly located materials, tracking of obsolete materials, the inefficient inventory management process, and the limited visibility to inventory issue are evident. The recommendation to delve into all these issues is through technology and digitization. All these systems are in the perfection of the firm regarding warehouse management. Every warehouse manager must be in a perfect position and have the best skills to ensure improved focus in warehouse management by trying as much as possible to solve the issues mentioned.

References

Alawneh, F. (2018). Warehousing and inventory management in dual channel and global supply chains. Electronic Theses and Dissertations. 7492. https://scholar.uwindsor.ca/etd/7492

Atieh, A. M., Kaylani, H., Al-abdallat, Y., Qaderi, A., Ghoul, L., Jaradat, L., & Hdairis, I. (2016). Performance Improvement of Inventory Management System Processes by an Automated Warehouse Management System. Procedia CIRP, 41, 568-572. DOI: 10.1016/j.procir.2015.12.122

Babenko, I., & Ivanovich, P. (2016). Issues of forming inventory management system in small businesses. International Review of Management and Marketing, 6, 522-527.

Bakar, N. A., Peszynski, K., Azizan, N., & Sundram, V. P. K. (2016). Abridgment of Traditional Procurement and E-Procurement: Definitions, Tools and Benefits. Journal of Emerging Economies and Islamic Research, 4(1), 74. DOI:

Chan, S. W., Tasmin, R., Nor Aziati, A. H., Rasi, R. Z., Ismail, F. B., & Yaw, L. P. (2017). Factors Influencing the Effectiveness of Inventory Management in Manufacturing SMEs. IOP Conference Series: Materials Science and Engineering, 226, 012024. DOI:

Faber, N. (2015). Structuring Warehouse Management: Exploring the fit between warehouse characteristics and warehouse planning and control structure, and its effect on warehouse performance. [Doctoral Thesis, Erasmus University, Rotterdam].

Faber, N., de Koster, M. B. M., & Smidts, A. (2013). Organizing warehouse management. International Journal of Operations & Production Management, 33(9), 1230-1256. DOI:

Marziali, M., Rossit, D. A., & Toncovich, A. (2021). Warehouse management problem and a KPI Approach: A case study. Management and Production Engineering Review, 12(2), 51-62. DOI:

Mkumbo, F. A. E., Ibrahim, A. R., Salleh, A. L., Sundram, V. P. K., & Atikah, S. B. (2019). The influence of supply chain practices and performance measurement practices towards firm performance. International Journal of Supply Chain Management, 8(3), 809-819.

Munir, Z. A., Bhatti, M. A., & Sundram, V. P. K. (2021). The determinants of humanitarian supply chain efficiency- a case study of flood disaster in Malaysia. SMART Journal of Business Management Studies, 17(2), 10-16. DOI:

Patil, H., & Divekar, B. R. (2014). Inventory Management Challenges for B2C E-commerce Retailers. Procedia Economics and Finance, 11, 561-571. DOI:

Ran, H. (2021). Construction and optimization of inventory management system via cloud-edge collaborative computing in supply chain environment in the Internet of Things era. PLOS ONE, 16(11), e0259284. DOI: 10.1371/journal.pone.0259284

Selvaraju, M., Beleya, P., & Sundram, V. P. K. (2017). Supply chain cost reduction using mitigation & resilient strategies in the hypermarket retail business. International Journal of Supply Chain Management, 6(2), 116-121.

Shimels, D. (2019). The effectiveness of warehouse management in the case of (3f) Finfine Furniture Factory Plc. [Masters of Business Administration in General Management Thesis]. St. Mary’s University.

Sundram, V. P. K., Atikah, S. B., & Chandran, V. G. R. (2016). Supply chain management: Principles, measurement and practice. University of Malaya Press.

Sundram, V. P. K., Atikah, S. B., Akmal, A. O., & Munir, Z. A. (2017). Green supply chain management practices in Malaysia manufacturing industry. International Journal of Supply Chain Management, 6(2), 89-95.

Sundram, V. P. K., Rajagopal, P., Atikah, S. B., & Subramaniam, G. (2018). The role of supply chain integration on green practices and performance in a supply chain context. A conceptual approach to future research. International Journal of Supply Chain Management, 7(1), 95-104.

Suvittawatt, A. (2016). Majors factors for effective warehouse management: Eastern part of Thailand perspective. IJABER, 14(6), 3757-3763.

Vatumalae, V., Rajagopal, P., & Sundram, V. P. K. (2020b). Warehouse operations measurement in hypermarket retailers: A review of the literature. International Journal of Supply Chain Management, 9(5), 1276.

Vatumalae, V., Rajagopal, P., & Kaliani Sundram, V. P. (2020a). Warehouse Management System of a Third Party Logistics Provider in Malaysia. International Journal of Economics and Finance, 12(9), 73. DOI:

Vatumalae, V., Rajagopal, P., Sundram, V. P. K., & Hua, Z. (2022). A study of retail hyper market warehouse inventory management in Malaysia. SMART Journal of Business Management Studies, 18(1), 71-79. DOI:

Wahab, S. N., Sundram, V. P. K., & Annas, M. (2022). Modeling the trend of automated warehouse studies: A bibliometric analysis. Proceedings of Mechanical Engineering Research Day, 2022, 122-123.

Yiğit, F. (2020). Challenges in inventory management and a proposed framework. In theory and research in engineering. Gece Publishing, 8(1), 311-334.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

06 May 2024

Article Doi

eBook ISBN

978-1-80296-132-4

Publisher

European Publisher

Volume

133

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1110

Subjects

Marketing, retaining, entrepreneurship, management, digital marketing, social entrepreneurship

Cite this article as:

Ghapar, F., Osman, M. F., Sundram, V. P. K., Rashid, W. E. W., Lian, C. L., & Wahab, S. N. (2024). Top Challenges in Warehouse Management: A Supply Chain Perspective. In A. K. Othman, M. K. B. A. Rahman, S. Noranee, N. A. R. Demong, & A. Mat (Eds.), Industry-Academia Linkages for Business Sustainability, vol 133. European Proceedings of Social and Behavioural Sciences (pp. 929-937). European Publisher. https://doi.org/10.15405/epsbs.2024.05.76