Abstract

The purpose of this study is to examine the significance of purchasing strategies and effective negotiation, collaborative relationship and interaction, effective cost management, and supply base management towards manufacturing performance. Applying the strategic-choice theory and the resource-based view of firms to the purchasing strategies, in this study a research model is developed to demonstrate the premise that implementing proper purchasing practices to support and execute the manufacturing industry will enhance the performance. The study utilizes survey data from respondents in the purchasing functions of manufacturing firms in Malaysia. The results are based on regression analysis and execution modeling by using SPSS software. The study finds that purchasing strategies, namely, effective negotiation and effective cost management have a positive relationship with manufacturing performance. Manufacturing firms should focus on purchasing strategies, effective negotiation, supplier collaborative relationship and interaction; effective cost management, and supply base management as navigators for their excellent performance in the current volatile market conditions. The paper theoretically develops logic for and empirically shows that all of the purchasing strategies are appropriate practices for mediating the impact on manufacturing performance. Considered at a higher-level abstraction, these relationships indicate a contribution to the theory that explains how purchasing strategy can result in manufacturing performance, through the concurrent deployment of appropriately matched purchasing practices.

Keywords: Manufacturing performance, purchasing strategy

Introduction

Purchasing strategy is the most crucial part of any business organization. A hole in the purchasing strategy will affect the whole manufacturing performance (Tarigan & Siagian, 2021). The causes of purchasing function activities to fail are due to the lack of understanding or knowledge of the nature of demand and not having a good relationship with suppliers (Greer et al., 2020; Sundram, Bahrin, et al., 2018). Purchasing functions tend not to have a good relationship with suppliers. This can cause a failure to have effective negotiation about the cost of material and quality of the product (Paesbrugghe et al., 2017). Besides, it can cause late delivery supply the material to the firm (Ali et al., 2020; Sundram, Atikah, et al., 2016). Manufacturing needs a large amount of material to produce products (Sivan et al., 2022). Purchasing function needs to purchase a large number of materials that meet manufacturing requirements. The process of purchasing might take time due to finding the right supplier and negotiating the price of the product (Paesbrugghe et al., 2017). This will affect the interruption of production in manufacturing. In this current economic turmoil in the country, it is essential to make every Ringgit and time count (Sundram et al., 2017b). Any sort of waste, either an internal or external occurrence they are a large number of expenses of time and money (Atikah & Sundram, 2014; Sudusinghe & Seuring, 2022). It can be improved through more efficient purchasing strategies. Thus, the experts in the industry need to have a thorough review in solving these issues by adhering to the supply chain activities and strategy so that they can achieve purchasing strategy on manufacturing performance.

Literature Review

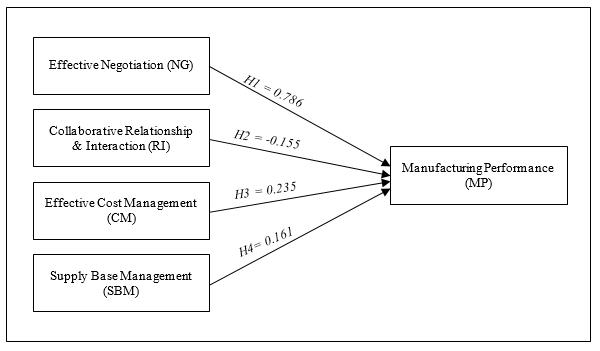

The research framework in Figure 1 depicts the relationship between particular purchasing strategies and manufacturing performance. We next describe the rationale for the research hypotheses. Figure 1 provides a summary of the relationship between H1, H2, H3 and H4 as described below:

Relationship between NG and MP

Cooperative negotiation can build up win-win formula whereby both purchaser and supplier are satisfied with the outcome of the negotiation process and believe their interest in the negotiation process is well protected (Janda & Seshadri, 2001). Cooperative negotiation attempts to achieve goals through tactics such as creating an atmosphere of aggressive price competition, imposing time pressure, lack of flexibility, and threatening process as a zero-sum win-lose game (Karrass, 1974; Zachariassen, 2008). Have a good relationship with a supplier for the supplier to provide a better quality of incoming items and provide timely deliveries (Akmal et al., 2016). It could lead to reduced hidden costs for the buyer in the long run.

H1: There is a relationship between effective negotiations toward manufacturing performance.

Relationship between RI and MP

Long-run collaborative relationships with key suppliers contribute to the firm’s financial performance (Carr & Pearson, 1999; Sundram, Rajagopal, et al., 2018). Good relationships and interaction with suppliers are key elements of a good purchasing strategy (Syakirah et al., 2020; Thrulogachantar & Zailani, 2011). According to Janda and Seshadri (2001) and Sundram et al. (2020), supplier integration is important to provide information and technical assistance that can increase product quality and be involved in competitiveness. A good quality relationship supplier can be an effective outcome where both parties can have good supplier relations and suppliers willing to make adjustments for the buyer.

H2: There is a relationship between collaborative relationships and interactions towards manufacturing performance.

Relationship between CM and MP

Total cost ownership is a purchasing tool and philosophy that aimed to understand the relevant cost of buying a particular good or service from a particular supplier (Bakar et al., 2016; Ellram & Siferd, 1998). Total cost ownership is an important tool to support strategic cost management. It is a complex approach where firm have to asses and measures the cost which is relevant and significant (Selvaraju et al., 2017). According to Newman and McKeller (1995) and Mkumbo et al. (2019), target costing is also one of the purchasing techniques to support alliance relationships. It is focused on purchasing firms developing and producing only those items it can sell at a reasonable profit.

H3: There is a relationship between effective cost management towards manufacturing performance.

Relationship between SBM and MP

Supplier selection based on quality, pricing, delivery, and performance of the product has a significant relationship with four elements of customer satisfaction (product quality, product variety, delivery service, and competitive pricing) and firm performance (Sundram et al., 2017a; Tracey & Leng Tan, 2001).

H4: There is a relationship between supply base management towards manufacturing performance.

Research Methods

It is important to follow the format given to develop an effective questionnaire since its quality is so crucial to the success of the research (Sundram et al., 2013). Fieldwork was conducted to collect data on the influence of purchasing strategies on manufacturing performance. For the questionnaire, this study will be using the type of question that can measure the influence of purchasing strategies on manufacturing performance (Bhatti & Sundram, 2015). The items describe the main content of the definition of the constructs. All items were measured on Likert-type scales with response options ranging from 1 (strongly disagree) to 5 (strongly agree).

The pilot study was conducted by distributing sample questionnaires to 30 selected respondents to pre-assess the validity of all constructs by asking different areas of manufacturing to act as a judge and sort the items as well as their understanding of the questionnaire given (Sundram et al., 2013). All items are being assessed except for the items in the demographic profile. The results were then analyzed by using the SPSS on the reliability analysis test. All item's scores represent an excellent level of the agreement since several it is considered that scores greater than 0.5 are said to be acceptable (Bhatti et al., 2012).

Probability sampling can be either unrestricted (Simple random sampling) or restricted (complex probability sampling) in nature (Sundram & Chandran, 2010). In this study, proportionate stratified sampling will be adopted. This means that the members represented in the sample from each stratum will be proportionate to the total number of elements in the representative strata (Sundram et al., 2012).

The questionnaires were distributed to the respondents through self-administered questionnaires, the e-mail. The benefit of this method includes cheaper distribution and processing fees, faster turnaround time, more flexibility, and less paper chasing (Sundram, Chandran, et al., 2016). From a total of 250 manufacturing, 100 completed the survey in two rounds, representing a response rate of 45 percent. To ensure the completion of the survey, phone calls and e-mail reminders were sent exactly a week after the first attempt to contact them. A token of appreciation was also arranged in a form of a prize worth RM20 to encourage participation in the survey.

Data Analysis and Findings

Respondents’ Profile

Table 1 to Table 7 provides a profile of the respondents in the survey. Table 1 shows that most of the respondents were from consumer products. Table 2 shows that most of the respondents have 100-200 numbers of employees. Tables 3 and 4 provide the profile of the organization surveyed. Table 4 shows that the majority of the manufacturing industry is in the top 7 in the market of the reputation of the product. Tables 5 and 6 provide the profile of organization resources. Table 5 shows 25-50 of the suppliers used in the manufacturing industry. Table 6 shows that 20-40 of percentage purchases from outside Malaysia in the manufacturing industry.

Descriptive Analysis and Reliability Analysis

The process of analysis begins after all data and information had been gathered through the data collection method (Bhatti et al., 2012). The first step in testing the hypothesis is to run the direct effect of effective negotiation, collaborative relationship and interaction, effective cost management and supply base management. Table 8 presents the mean values, standard deviations and the number of items for each variable. For the independent variables, supply base management yielded the highest mean (4.5367), followed by collaborative relationship and interaction (4.4540), effective negotiation (4.4500) and effective cost management (4.1986). Table 7 also shows Cronbach’s alpha values for the independent and dependent variables in this research. The result indicates that Cronbach’s alpha value range from 0.621 to 0.885. the value for Cronbach’s alpha of 0.6 or higher is considered acceptable. Thus, the data on these variables are reliable and consistent with research standards.

Table 8 reveals the correlation matrix of the conceptual variables. A two-tail test at a 0.05 significance level indicates that there are positive relationships between a dependent variable and the independent variables.

Regression Analysis

From Table 9, R=0.928 and R2-value=0.862. This means that 86.2 percent of the variation in Y can be explained by all 4 predictors (or accounted for by) the variation in X. It is shown that the maximum Mahalanobis Distance value is 11.445. Thus, there will be data that is removed. Cook’s Distance is in a good condition when the data is < 1.00. It is shown that the data is 0.100. Thus, the data is valid.

The results in Table 9 and figure 2 show the details of the estimated coefficients, where b (Constant) is 0.19, bNG is 0.786, bRI is 0.155, bCM is 0.235 and bSBM is 0.161. The result shows that all two variables are significant at a 0.05 significance level (0.05). This indicates that there is a linear relationship between the dependent variable (manufacturing performance) and the predictor variables (effective negotiation and effective cost management).

As shown in figure 2 this paper makes several significant and discussions of the study. Firstly, the results show the relationship between effective negotiations, collaborative relationship and interaction, effective cost management and supply base management towards manufacturing performance. Considered at a higher level of abstraction, these relationships indicate a contribution to the theory that explains how purchasing strategies can get manufacturing performance through their concurrent deployment in the industry.

Secondly, the result shows that effective negotiation contributes significantly to building manufacturing performance, as indicated by the significance of hypothesis H2. The result shows a positive relationship toward manufacturing performance which implies a greater extent of purchasing strategies. Effective negotiation requires the firm to negotiate with the supplier to have the lowest price in the manufacturing industry. Negotiation is needed to have a deal with the supplier about certain items between supplier and buyer.

Third, the result for hypothesis H3 indicates that effective cost management directly affects its relationship with manufacturing performance. It is shown that effective cost management is indicated by the significance of hypothesis H3. Having the concurrent presence of an effective cost management strategy will enhance the relationships, in that it creates a pathway to manufacturing performance. Additionally, effective cost management adds a new level of flexibility to lead to better way cost reduction and understanding the supplier skills and ways to communicate with.

Discussion and Conclusion

While past research examines different influence purchasing strategies and their impact on manufacturing performance, it does not provide theoretical or empirical guidance on how purchasing strategies can be used effectively and boost their impact on manufacturing performance. This paper shows the impact of four purchasing strategies effective negotiation, collaborative relationship and interaction, effective cost management and supply base management with manufacturing performance.

From a manager’s perspective, this study demonstrates the influence of purchasing strategies on manufacturing performance. Firms that manage to achieve this relationship benefit greatly by improving their operations, cost reductions, waste reduction, and delivery time, quality of products and gain sustainable competitive advantages. This study also demonstrates the relationship between buyer and supplier in dealing with each other. It is a must for managers to develop relationships amongst suppliers and downstream retailers and take them into their confidence before arriving at their purchasing strategy. This research has important for purchasing managers, especially those who have an interest in building deep supplier relationships. Aside from the objective to improve cost reduction, waste elimination and quality of the product through effective cost management, managers should also look into partnership relationships among selected suppliers. Positive partnerships will leverage collaboration and provide resources that are even more difficult to imitate by other competitors.

The paper has several limitations that suggest caution in interpreting its findings as well as directions for future research. First, this study is done at the firm level with one person from each organization responding to the survey. A single respondent was asked questions about purchasing issues dealing with strategies. Therefore, future research may benefit from having multiple respondents from each organization participate in a similar study. Future research could consider other contingent factors such as demand uncertainty or type of industry. In industries where demand is relatively stable or predictable or in industries that have short product life cycles, other gainful combinations of purchasing strategies may prevail. Research investigating such patterns would yield insights about broad industry-specific templates of how purchasing strategies can be gainfully aligned. Similarly, service industries, given their high degree of labor content and customer contact might see different findings concerning purchasing strategies. Finally, future research could examine the fit between purchasing strategy and manufacturing performance such investigation would provide insights about possible generalization and extension of the results.

References

Akmal, A. O., Sundram, V. K., Sayuti, N. M., & Atikah, S. B. (2016). The relationship between supply chain integration, just-in-time and logistics performance: A supplier’s perspective on the automotive industry in Malaysia. International journal of supply chain management, 5(1), 44-51.

Ali, S. N. R., Rajagopal, P., Sundram, V. P. K., Saihani, S. B., & Noranee, S. (2020). ERP System Implementation in a Leading LED Manufacturing in Malaysia: A Supply Chain Perspective. International Journal of Supply Chain Management, 9(2), 104.

Atikah, S. B., & Sundram, V. P. K. (2014). The Green Supply Chain Management Practices: A Green Approach.

Bakar, N. A., Peszynski, K., Azizan, N., & Sundram, V. P. K. (2016). Abridgment of Traditional Procurement and E-Procurement: Definitions, Tools and Benefits. Journal of Emerging Economies and Islamic Research, 4(1), 74. DOI:

Bhatti, M. A., & Sundram, V. P. K. (2015). Business research: Quantitative and qualitative methods. Effect of transformational leadership on job satisfaction and patient safety outcomes, 66, 180-189.

Bhatti, M. A., Hoe, C. H., & Sundram, V. P. K. (2012). A guide for beginners data analysis using SPSS and AMOS. Pearson Malaysia.

Carr, A. S., & Pearson, J. N. (1999). Strategically managed buyer-supplier relationships and performance outcomes. Journal of Operations Management, 17(5), 497-519. DOI: 10.1016/s0272-6963(99)00007-8

Ellram, L. M., & Siferd, S. P. (1998). Total cost of ownership: a key concept in strategic cost management decisions. Materials Engineering, 19(1), 55-84.

Greer, S. L., Klasa, K., & Van Ginneken, E. (2020). Power and Purchasing: Why Strategic Purchasing Fails. The Milbank Quarterly, 98(3), 975-1020. DOI:

Janda, S., & Seshadri, S. (2001). The influence of purchasing strategies on performance. Journal of Business & Industrial Marketing, 16(4), 294-308. DOI:

Karrass, C. L. (1974). Give and Take; the Complete Guide to Negotiating Strategies and Tactics. Thomas Y. Crowell Company.

Mkumbo, F. A. E., Ibrahim, A. R., Salleh, A. L., Sundram, V. P. K., & Atikah, S. B. (2019). The influence of supply chain practices and performance measurement practices towards firm performance. International Journal of Supply Chain Management, 8(3), 809-819.

Newman, R. G., & McKeller, J. M. (1995). Target Pricing—A Challenge for Purchasing. International Journal of Purchasing and Materials Management, 31(2), 12-20. DOI:

Paesbrugghe, B., Rangarajan, D., Sharma, A., Syam, N., & Jha, S. (2017). Purchasing-driven sales: Matching sales strategies to the evolution of the purchasing function. Industrial Marketing Management, 62, 171-184. DOI:

Selvaraju, M., Beleya, P., & Sundram, V. P. K. (2017). Supply chain cost reduction using mitigation & resilient strategies in the hypermarket retail business. International Journal of Supply Chain Management, 6(2), 116-121.

Sivan, S., Ghadiri, S. M., Rajagopal, P., Atikah, S. B., & Sundram, V. P. K. (2022). Adoption and Benefit of Industrial Revolution 4.0 in Logistics Industry: A Conceptual Paper. Journal of Entrepreneurship, Business and Economics, 10(2S1), 79-94.

Sudusinghe, J. I., & Seuring, S. (2022). Supply chain collaboration and sustainability performance in circular economy: A systematic literature review. International Journal of Production Economics, 245, 108402. DOI:

Sundram, V. P. K., & Chandran, V. G. R. (2010). Research methods. UPENA-University of Technology MARA.

Sundram, V. P. K., Atikah, S. B., & Chandran, V. G. R. (2016). Supply Chain Management: Principles, Measurement and Practice. University of Malaya Press.

Sundram, V. P. K., Atikah, S. B., Akmal, A. O., & Munir, Z. A. (2017a). Green supply chain management practices in Malaysia manufacturing industry. International Journal of Supply Chain Management, 6(2), 89-95.

Sundram, V. P. K., Atikah, S. B., Hafiz, M. Z., Azimah, D., Shahrin, N., & Thirunavukkarasu, K. (2017b). Supply chain logistics: A Malaysian perspective. Petaling Jaya, Selangor Malaysian Logistics and Supply Chain Association.

Sundram, V. P. K., Chandran, V. G. R., & Bhatti, M. A. (2012). Research Methods: A Work Book for Business Undergraduates. University Technology Mara.

Sundram, V. P. K., Chandran, V. G. R., Atikah, S. B., Rohani, M., Nazura, M. S., Akmal, A. O., & Krishnasamy, T. (2016). Research Methodology: Tools, Methods and Techniques. MLSCA, Selangor.

Sundram, V. P. K., Chhetri, P., & Bahrin, A. S. (2020). The Consequences of Information Technology, Information Sharing and Supply Chain Integration, towards Supply Chain Performance and Firm Performance. Journal of International Logistics and Trade, 18(1), 15-31. DOI:

Sundram, V. P. K., Rajagopal, P., & Bhatti, M. A. (2013). Social Science Research Methods: A Quantitative Approach. Petaling Jaya, Selangor: Malaysian Association of Productivity.

Sundram, V. P. K., Rajagopal, P., Atikah, S. B., & Subramaniam, G. (2018). The role of supply chain integration on green practices and performance in a supply chain context. A conceptual approach to future research. International Journal of Supply Chain Management, 7(1), 95-104.

Sundram, V. P. K., Bahrin, A. S., Abdul Munir, Z. B., & Zolait, A. H. (2018). The effect of supply chain information management and information system infrastructure: The mediating role of supply chain integration towards manufacturing performance in Malaysia. Journal of Enterprise Information Management, 31(5), 751-770. DOI:

Syakirah, N., Rajagopal, P., Sundram, V. P. K., Zuraidah, R. R., Ratna, M. N., & Zamry, G. (2020). Achieving Supply Chain Excellence through Effective Supplier Management: A Case Study of a Marine Organisation. International Journal of Supply Chain Management, 9(4), 11-23.

Tarigan, Z. J. H., & Siagian, H. (2021). The effects of strategic planning, purchasing strategy and strategic partnership on operational performance. Uncertain Supply Chain Management, 9(2), 363-372. DOI:

Thrulogachantar, P., & Zailani, S. (2011). The influence of purchasing strategies on manufacturing performance: An empirical study in Malaysia. Journal of Manufacturing Technology Management, 22(5), 641-663. DOI: 10.1108/17410381111134482

Tracey, M., & Leng Tan, C. (2001). Empirical analysis of supplier selection and involvement, customer satisfaction, and firm performance. Supply Chain Management: An International Journal, 6(4), 174-188. DOI:

Zachariassen, F. (2008). Negotiation strategies in supply chain management. International Journal of Physical Distribution & Logistics Management, 38(10), 764-781. DOI: 10.1108/09600030810926484

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

06 May 2024

Article Doi

eBook ISBN

978-1-80296-132-4

Publisher

European Publisher

Volume

133

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1110

Subjects

Marketing, retaining, entrepreneurship, management, digital marketing, social entrepreneurship

Cite this article as:

Chandran, S., Krishnasamy, T., & Sundram, V. P. K. (2024). The Relationship Between Purchasing Strategies and Manufacturing Performance in Malaysia. In A. K. Othman, M. K. B. A. Rahman, S. Noranee, N. A. R. Demong, & A. Mat (Eds.), Industry-Academia Linkages for Business Sustainability, vol 133. European Proceedings of Social and Behavioural Sciences (pp. 907-916). European Publisher. https://doi.org/10.15405/epsbs.2024.05.74