Abstract

The purpose of this research is to investigate the impact of efficient buying methods for the improvement of logistics performance within the setting of Malaysia. Through an examination of the dynamic relationship that exists between buying strategies and the performance of logistics, this abstract sheds light on the consequences that this relationship has for organisations and provides significant insights for both scholars and practitioners. We used a quantitative study approach to evaluate the association between these two factors. For the first step in the process of establishing a theoretical framework, a comprehensive assessment of the available literature was carried out. In this study, the need to align buying strategies with logistics goals was brought to light, and the potential advantages of strategic purchasing in terms of increasing overall logistics performance were emphasised. Following that, a quantitative survey was given to a representative sample of businesses that are active in the logistics sector in Malaysia. An instrument for conducting surveys was developed to collect information on a variety of buying tactics, including supplier selection, relationship management, and negotiating techniques. The findings of this study have important repercussions for companies that are active in the logistics sector in Malaysia. Companies can proactively improve their logistics performance and achieve a competitive advantage if they acknowledge the importance of strategic buying. In addition, governments and industry stakeholders may make use of these insights to build interventions that are specifically targeted and to encourage the adoption of buying techniques that are successful throughout the sector.

Keywords: Logistics performance, purchasing strategy, procurement prowess, supply chain success

Introduction

In today's highly competitive and globalised business world, organisations are increasingly recognising the vital role that Abdul Munir logistics performance plays in attaining operational efficiency, customer happiness, and overall company success (Tan, 2001; Wagner & Bode, 2008). This is a trend that is expected to continue. According to Sundram, Rajagopal, et al. (2018), Syakirah et al. (2020), logistics, which encompasses the management of the flow of goods, services, and information from suppliers to customers, plays a pivotal role in meeting the demands of customers, lowering costs, and improving the responsiveness of supply chains. For organisations to achieve optimum performance in logistics, they must not only concentrate on operational factors but also build efficient strategies in critical areas such as buying. In the context of organisations, purchasing is a strategic activity that entails the acquisition of products and services from suppliers to support production and operations. In terms of the total performance of the supply chain, including logistics, it plays a significant influence in influencing the performance. The use of efficient buying methods may make a significant contribution to the enhancement of logistics performance. These strategies can guarantee the timely availability of supplies, minimise stockouts, reduce lead times, and enhance cost efficiency. However, the link between buying strategies and the performance of logistics is a complicated and nuanced one, and it is impacted by a variety of elements both internal and external in the organisation.

Understanding the link between buying strategies and logistics performance is of the utmost relevance in the context of Malaysia, which is a quickly rising economy with a booming logistics sector (Akmal et al., 2016; Bakar et al., 2016; Sundram, Atikah, et al., 2017). This is because Malaysia is a country that is experiencing fast economic growth. Several multinational corporations have established Malaysia as a regional logistics centre as a result of the country's advantageous location and solid infrastructure, which have attracted a large number of these enterprises. According to Ali et al.'s research from 2020, the logistics sector in Malaysia is experiencing new difficulties and opportunities as a result of the intensifying globalisation and e-commerce trends. This calls for a more in-depth study of the elements that influence the performance of the logistics industry. Empirical research that investigates the link between buying strategies and logistics performance in the Malaysian environment is scarce, even though the role of purchasing strategies in logistics performance is well acknowledged. Because of this, the purpose of this study is to investigate the link between buying strategies and logistics performance in Malaysia to address the research gap that has been identified. The purpose of this study is to give useful insights to companies, policymakers, and researchers by investigating this connection. These insights will enable these individuals to make choices based on accurate information and design strategies that improve logistics performance and boost overall competitiveness in the Malaysian logistics sector

To achieve these research objectives, a quantitative approach will be employed. This approach allows for a comprehensive investigation, combining a literature review to establish the theoretical foundation and a quantitative survey to gather empirical data. By combining these methods, the study seeks to provide a holistic understanding of the relationship between purchasing strategies and logistics performance in Malaysia, considering the unique contextual factors that influence this relationship (Mkumbo et al., 2019). The remainder of this research paper is structured as follows: Section 2 presents a comprehensive review of the relevant literature, highlighting the key theoretical frameworks and empirical studies related to purchasing strategies and logistics performance. Section 3 outlines the research methodology, including the survey design, sample selection, and data analysis techniques. Section 4 presents the findings of the study, followed by a discussion of the implications and recommendations in Section 5. Finally, Section 6 concludes the paper, by summarizing the key findings, limitations, and avenues for future research.

Literature Review

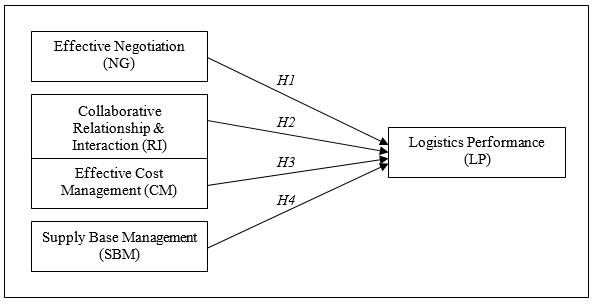

Figure 1 is a representation of the study framework that illustrates the link between certain buying methods and the achievement of logistical performance. An explanation of the reasoning behind the research hypotheses is provided in this section. As will be shown in the following paragraphs, Figure 1 gives an overview of the link between Hypotheses 1, 2, 3, and 4.

Relationship between NG and LP

Studies emphasize that successful negotiations lead to improved service levels, cost reductions, and enhanced overall logistics performance (Bowersox & Closs, 1996). Effective negotiation skills positively impact supplier relationships, resulting in improved logistics performance measures, such as on-time delivery and order fulfillment rates (Ellinger et al., 2002). Additionally, firms with strong negotiation capabilities in transportation management experience reduced costs and enhanced delivery reliability (Flynn et al., 2010). Prioritizing effective negotiation skills and strategies is crucial for achieving superior logistics outcomes and supply chain performance. As such, the literature indicates a strong relationship between effective negotiation and logistics performance.

H1: There is a relationship between effective negotiations toward logistics performance.

Relationship between RI and LP

The literature indicates a strong positive relationship between collaborative relationships, interaction, and logistics performance. Collaborative relationships characterized by trust, information sharing, and joint decision-making lead to improved performance outcomes such as reduced lead times and enhanced customer service levels (Mentzer et al., 2001). Meaningful interaction among supply chain partners facilitates the exchange of information and resources, contributing to improved logistics performance (Choy et al., 2012; Fawcett et al., 2008). Promoting collaborative relationships and fostering interactive communication is crucial for achieving superior logistics performance (Christopher et al., 2004).

H2: There is a relationship between collaborative relationships and interactions toward logistics performance.

Relationship between CM and LP

Effective cost management plays a crucial role in improving logistics performance (Selvaraju et al., 2017; Sivan et al., 2022). Research highlights that efficient cost management practices, including inventory management, transportation optimization, and streamlined warehousing operations, lead to cost reductions and enhanced logistics performance metrics (Arntzen et al., 2015; Gunasekaran & Ngai, 2009). Firms that prioritize effective cost management strategies achieve higher levels of logistics performance compared to those with weak cost management practices (Gligor & Esmark, 2016; Manuj & Mentzer, 2008). The use of information technology, such as advanced analytics and supply chain visibility systems, further supports cost control and improves logistics performance outcomes (Gunasekaran et al., 2017; Sundram, Chhetri, et al., 2020). Emphasizing cost control, optimizing operations, and leveraging technology contribute to enhanced logistics performance, including cost reductions, improved customer service, and increased profitability.

H3: There is a relationship between effective cost management towards manufacturing performance.

Relationships between SBM and LP

Supply base management has a significant impact on logistics performance. The literature emphasizes that well-managed supplier relationships, collaborative partnerships, and supplier development initiatives positively influence logistics performance outcomes (Li et al., 2006; Monczka et al., 2015). Effective supply base management practices, including supplier integration, information sharing, and performance measurement, enhance supply chain responsiveness and agility, leading to improved logistics performance (Liu et al., 2016; Mentzer et al., 2001). Monitoring supplier performance metrics and implementing proactive supplier management strategies are crucial for ensuring timely corrective actions and enhancing logistics performance (Kannan & Tan, 2002; Narasimhan & Das, 2001). In summary, effective supply base management practices contribute to enhanced logistics performance in terms of cost efficiency, delivery reliability, and overall supply chain effectiveness.

H4: There is a relationship between supply base management towards manufacturing performance.

Research Methods

To collect data on the influence of purchasing strategies on logistics performance, fieldwork was conducted using a questionnaire survey (Seuring & Müller, 2008). The questionnaire was designed based on the type of questions that can effectively measure the influence of purchasing strategies on logistics performance (Bhatti & Sundram, 2015). All items in the questionnaire described the main content of the constructs and were measured using Likert-type scales with response options ranging from 1 (strongly disagree) to 5 (strongly agree). Before the main survey, a pilot study was conducted to assess the validity of the constructs. Sample questionnaires were distributed to 30 selected respondents from different areas of logistics management, who acted as judges to evaluate the items and provide feedback on their understanding of the questionnaire (Sundram et al., 2013). All items, except for those in the demographic profile section, were assessed in the pilot study. The responses were then analyzed using SPSS to perform reliability analysis tests. Scores greater than 0.5 were considered acceptable, indicating a high level of agreement among the respondents (Bhatti et al., 2012).

In terms of sampling, a proportionate stratified sampling method was adopted. This approach ensures that the members represented in the sample from each stratum are proportionate to the total number of elements in the respective strata (Sundram et al., 2012). The population consisted of logistics companies operating in Malaysia. The sample size included 100 completed surveys collected in two rounds, resulting in a response rate of 45 percent. The questionnaires were distributed to the respondents through self-administered questionnaires via email. This method offered several benefits, including lower distribution and processing costs, faster turnaround time, increased flexibility, and reduced paper usage (Sundram, Atikah, et al., 2016; Sundram, Chandran, Atikah, Rohani, et al., 2016). To ensure survey completion, phone calls, and email reminders were sent exactly one week after the initial contact. Additionally, a token of appreciation in the form of a prize worth RM20 was arranged to encourage participation. By employing this methodology, the study aimed to gather data from a representative sample of logistics companies in Malaysia to explore the relationship between purchasing strategies and logistics performance effectively. The questionnaire design, pilot study, sampling approach, and distribution method were carefully chosen to ensure the quality and reliability of the collected data.

Data Analysis

Respondents’ Profile

Table 1 presents the profile of the survey respondents, indicating their distribution across various industries. The majority of respondents were from the consumer products sector, highlighting its prominence within the study sample. Table 2 provides insights into the employee count of the organizations represented in the survey. The data reveals that a significant proportion of respondents belonged to organizations with 100-200 employees, indicating a range of medium-sized companies participating in the study. Tables 3 and 4 offer an overview of the surveyed organizations' profiles. Table 4 specifically showcases the market reputation of the product for the majority of manufacturing industry players, with most of them falling within the top 7 rankings. This suggests that the surveyed organizations have established a strong market presence and a favourable perception of their products. Tables 5 and 6 delve into the profile of organizational resources. Table 5 highlights the number of suppliers used in the manufacturing industry, with the data indicating that a significant proportion of organizations utilize 25-50 suppliers. This suggests that these organizations have diverse supplier networks to meet their manufacturing needs. Table 6 sheds light on the percentage of purchases made from sources outside of Malaysia in the manufacturing industry. The data reveals that a substantial portion of the organizations surveyed, approximately 20-40%, engage in purchasing activities from international sources. This demonstrates the global sourcing practices prevalent in the manufacturing industry, enabling organizations to access a wider range of inputs and expand their market reach. Overall, these tables provide a comprehensive profile of the surveyed respondents and their organizations, offering valuable insights into the industry, market reputation, organizational resources, and global sourcing practices within the manufacturing sector.

Descriptive Analysis and Reliability Analysis

Tables 7 and 8 provide information on various variables measured in the study, along with their means, standard deviations (SD), number of items, and Cronbach's alpha reliability coefficients.

Logistics Performance (LP): The mean score for logistics performance is 4.5780, indicating a relatively high level of performance. The standard deviation (SD) of 0.47863 suggests moderate variability in responses. This variable is measured using four items, and Cronbach's alpha coefficient of 0.788 indicates good internal consistency (Sundram et al., 2013).

Effective Negotiation (NG): The mean score for effective negotiation is 4.4500, indicating a positive perception of negotiation effectiveness. The standard deviation (SD) of 0.33459 suggests low variability in responses. This variable is measured using four items, and Cronbach's alpha coefficient of 0.638 indicates acceptable internal consistency.

Collaborative Relationship and Interaction (RI): The mean score for collaborative relationship and interaction is 4.4540, indicating a positive perception of collaboration and interaction. The standard deviation (SD) of 0.49190 suggests moderate variability in responses. This variable is measured using five items, and Cronbach's alpha coefficient of 0.621 indicates acceptable internal consistency (Sundram, Atikah, et al., 2016).

Effective Cost Management (CM): The mean score for effective cost management is 4.1986, indicating a relatively high level of perceived cost management effectiveness. The standard deviation (SD) of 0.41815 suggests moderate variability in responses. This variable is measured using four items, and Cronbach's alpha coefficient of 0.885 indicates excellent internal consistency (Sundram et al., 2012).

Supply Base Management (SBM): The mean score for supply base management is 4.5367, indicating a positive perception of supply base management practices. The standard deviation (SD) of 0.51753 suggests moderate variability in responses. This variable is measured using five items, and Cronbach's alpha coefficient of 0.708 indicates good internal consistency (Bhatti et al., 2012).

Overall, the results suggest that respondents perceive favourable levels of logistics performance, effective negotiation, collaborative relationship and interaction, effective cost management, and supply base management. The variables show varying levels of internal consistency, with effective cost management demonstrating the highest reliability coefficient.

Table 8 reveals the correlation matrix of the conceptual variables. A two-tail test at a 0.05 significance level indicates that there are positive relationships between a dependent variable and the independent variables.

Regression Analysis

The results from Table 9 provide important information about the relationship between the predictors (effective negotiation, collaborative relationship and interaction, effective cost management, and supply base management) and the dependent variable (logistics performance). The coefficient of determination (R2) value of 0.745 indicates that approximately 74.5% of the variation in logistics performance can be explained by the combined influence of these four predictors.

The maximum Mahalanobis Distance value of 13.235 suggests that there may be outliers or extreme values in the data. Consequently, data points with high Mahalanobis Distance values may be removed from the analysis to ensure the validity of the results. The Cook's Distance value of 0.100 indicates that the data points are within an acceptable range and do not exert excessive influence on the regression model. This suggests that the data is valid and suitable for further analysis.

Examining the estimated coefficients in Table 9 and Figure 2, the constant (b) is 0.13, and the coefficients for effective negotiation (bNG), collaborative relationship and interaction (bRI), effective cost management (bCM), and supply base management (bSBM) are 0.346, 0.478, 0.422, and 0.229, respectively. All of these coefficients are statistically significant at a significance level of 0.05, indicating that there is a significant linear relationship between the predictors and logistics performance (Sundram & Chandran, 2010).

These findings suggest that effective negotiation, collaborative relationship and interaction, effective cost management, and supply base management all play significant roles in influencing logistics performance in the manufacturing industry. Managers should pay attention to these factors and incorporate them into their decision-making processes to improve overall logistics performance.

This paper contributes significant insights and discussions regarding the relationship between effective negotiations, collaborative relationship and interaction, effective cost management, and supply base management with logistics performance in the manufacturing sector. The findings provide theoretical support for the concurrent deployment of these purchasing strategies to enhance logistics performance in the industry. The results indicate a positive relationship between effective negotiation and logistics performance, supporting hypothesis H2. Effective negotiation plays a crucial role in securing favourable pricing and terms with suppliers, which directly impacts logistics performance. Negotiating for the lowest prices and favourable deals is essential for achieving cost savings and efficient procurement in the logistics process.

Furthermore, the results support hypothesis H3, which suggests that effective cost management directly affects logistics performance. Effective cost management strategies enable manufacturers to optimize their resource allocation, reduce expenses, and improve overall logistics efficiency. This leads to enhanced logistics performance and operational effectiveness. Effective cost management also enhances the relationship between purchasing strategies and logistics performance. By effectively managing costs, manufacturers gain greater flexibility in cost-reduction efforts and a better understanding of supplier capabilities. This allows for improved communication and collaboration with suppliers, ultimately contributing to enhanced logistics performance.

Overall, the findings of this study highlight the importance of effective negotiation and cost management in driving logistics performance in the manufacturing sector. By implementing these strategies, manufacturers can achieve cost savings, improve supplier relationships, and enhance overall logistics efficiency. This research provides valuable insights for practitioners in the manufacturing industry, emphasizing the significance of these purchasing strategies for achieving optimal logistics performance in the context of Malaysia.

Discussion and Conclusion

The findings of this study provide valuable insights into the relationship between effective negotiation, collaborative relationship, effective cost management, supply base management, and logistics performance in the manufacturing sector in Malaysia. The discussion will elaborate on these key variables and their implications for the manufacturing industry in the Malaysian context.

Effective negotiation plays a crucial role in enhancing logistics performance in the Malaysian manufacturing sector. By engaging in successful negotiations with suppliers and other stakeholders, manufacturers can secure favourable terms, pricing, and delivery arrangements, ultimately leading to improved logistics performance. Negotiation skills and strategies enable manufacturers to establish mutually beneficial agreements, optimize procurement processes, and ensure the timely availability of materials and resources. Effective negotiation in the Malaysian manufacturing sector can result in cost savings, improved supplier relationships, and enhanced logistics efficiency (Sundram, Atikah, et al., 2016).

Building collaborative relationships with suppliers and downstream retailers is vital for achieving optimal logistics performance in the Malaysian manufacturing sector (Sundram, Rajagopal, et al., 2018; Sundram, Bahrin, et al., 2018). Collaboration facilitates information sharing, joint decision-making, and resource pooling, leading to improved coordination and integration across the supply chain. By working closely with suppliers and downstream partners, manufacturers in Malaysia can enhance supply chain visibility, streamline processes, and respond swiftly to market demands. Collaborative relationships enable manufacturers to address challenges collectively, enhance customer satisfaction, and achieve overall logistics performance excellence (Sundram, Akmal, et al., 2017; Sundram, Atikah, et al., 2017),

Effective cost management practices have a significant impact on logistics performance in the Malaysian manufacturing sector. By implementing robust cost management strategies, manufacturers can optimize their operations, minimize expenses, and improve resource allocation. Cost management efforts, such as value analysis, supplier rationalization, and cost reduction initiatives, contribute to overall logistics performance improvement. By efficiently managing costs in areas such as transportation, inventory, and warehousing, Malaysian manufacturers can achieve cost savings, enhance profitability, and allocate resources more effectively to meet customer demands.

Effective supply base management is critical for enhancing logistics performance in the Malaysian manufacturing sector. By strategically managing relationships with suppliers, manufacturers can ensure a reliable supply of quality materials and components. Through supplier selection, evaluation, and development, manufacturers can build a robust supply base that meets their specific requirements. Effective supply-base management practices, including supplier collaboration, risk management, and performance measurement, contribute to improved logistics performance. By nurturing long-term partnerships and managing supplier relationships effectively, Malaysian manufacturers can enhance supply chain responsiveness, reduce lead times, and ensure consistent product availability.

The findings of this study have significant implications for the Malaysian manufacturing sector. Manufacturers in Malaysia can leverage effective negotiation skills to secure favourable terms and improve their logistics performance. Collaborative relationships with suppliers and downstream partners can foster innovation, agility, and competitiveness in the supply chain. Implementing effective cost management practices enables manufacturers to optimize resources and achieve cost savings, enhancing overall logistics performance. Furthermore, supply base management practices help manufacturers build resilient supply chains and ensure a reliable flow of materials. By adopting these strategies, Malaysian manufacturers can improve their operational efficiency, reduce costs, enhance customer satisfaction, and gain a competitive edge in the global market.

In conclusion, this study highlights the importance of effective negotiation, collaborative relationships, effective cost management, and supply base management in driving logistics performance in the manufacturing sector in Malaysia. By focusing on these key variables and implementing appropriate strategies, manufacturers in Malaysia can enhance their competitiveness, improve supply chain efficiency, and achieve sustained success in the dynamic business environment.

Implications for Theory and Practice

From a theoretical standpoint, this research contributes to the existing body of knowledge by providing empirical evidence on the relationship between purchasing strategies and logistics performance. It fills a gap in the literature by offering insights into how purchasing strategies can be effectively utilized to enhance logistics performance. The study highlights the importance of considering not only cost management but also collaborative relationships with suppliers to leverage resources and gain competitive advantages that are difficult for competitors to imitate.

Practically, the findings have important implications for purchasing managers. The study emphasizes the need for managers to focus not only on cost reduction and waste elimination through effective cost management but also on building deep supplier relationships. Developing positive partnerships with selected suppliers can lead to enhanced collaboration, resource sharing, and improved performance outcomes. The research underscores the significance of involving suppliers and downstream retailers in the decision-making process and fostering mutual trust and cooperation.

Suggestions for Future Research

While this study provides valuable insights, certain limitations warrant caution in interpreting the findings. Future research could address these limitations and further contribute to the field. One suggestion is to expand the study by involving multiple respondents from each organization, allowing for a more comprehensive understanding of purchasing strategies within the firm. Additionally, investigating contingent factors such as demand uncertainty or industry type could provide further insights into the optimal alignment of purchasing strategies. Research focusing on different industries or service sectors, considering their unique characteristics and requirements, would also enrich the understanding of purchasing strategies' effectiveness. Furthermore, exploring the fit between specific purchasing strategies and logistics performance would contribute to the generalizability and extension of the findings.

Overall, this study contributes to both theory and practice by highlighting the importance of effective purchasing strategies in enhancing logistics performance. It underscores the significance of collaborative relationships, cost management, and supply base management in achieving operational excellence and gaining sustainable competitive advantages in the manufacturing industry. Future research endeavours can build upon these findings and explore additional dimensions to enrich our understanding of the complex interplay between purchasing strategies and logistics performance.

References

Akmal, A. O., Sundram, V. K., Sayuti, N. M., & Atikah, S. B. (2016). The relationship between supply chain integration, just-in-time and logistics performance: A supplier’s perspective on the automotive industry in Malaysia. International Journal of Supply Chain Management, 5(1), 44-51.

Ali, S. N. R., Rajagopal, P., Sundram, V. P. K., Saihani, S. B., & Noranee, S. (2020). ERP system implementation in a leading LED manufacturing in Malaysia: A supply chain perspective. International Journal of Supply Chain Management, 9(2), 104.

Arntzen, B. C., Brown, G. G., Harrison, T. P., & Trafton, L. L. (2015). The practice of supply chain management: Where theory and application converge. Springer.

Bakar, N. A., Peszynski, K., Azizan, N., & Sundram, V. P. K. (2016). Abridgment of Traditional Procurement and E-Procurement: Definitions, Tools and Benefits. Journal of Emerging Economies and Islamic Research, 4(1), 74. DOI:

Bhatti, M. A., & Sundram, V. P. K. (2015). Business research: Quantitative and qualitative methods. Effect of transformational leadership on job satisfaction and patient safety outcomes, 66, 180-189.

Bhatti, M. A., Hoe, C. H., & Sundram, V. P. K. (2012). A guide for beginners data analysis using SPSS and AMOS. Pearson Malaysia.

Bowersox, D. J., & Closs, D. J. (1996). Logistical management: The integrated supply chain process. McGraw-Hill.

Choy, K. L., Lee, W. B., & Lo, V. H. Y. (2012). The relationship between purchasing management and logistics performance in Hong Kong. International Journal of Logistics Management, 23(2), 195-213.

Christopher, M., Lowson, R., & Peck, H. (2004). Creating agile supply chains in the fashion industry. International Journal of Retail & Distribution Management, 32(8), 367-376. DOI:

Ellinger, A. E., Daugherty, P. J., & Keller, S. B. (2002). The relationship between marketing/logistics interdepartmental integration and performance in US manufacturing firms: an empirical study. Journal of Business Logistics, 23(1), 1-22.

Fawcett, S. E., Waller, M. A., & Allred, C. (2008). Supply chain information sharing: The role of trust and relationship length. Journal of Business Logistics, 29(1), 193-210.

Flynn, B. B., Huo, B., & Zhao, X. (2010). The impact of supply chain integration on performance: A contingency and configuration approach. Journal of Operations Management, 28(1), 58-71. DOI:

Gligor, D. M., & Esmark, C. L. (2016). Supply chain operational capability, logistics performance, and firm performance in the oil and gas industry. International Journal of Physical Distribution & Logistics Management, 46(6/7), 671-694.

Gunasekaran, A., & Ngai, E. W. T. (2009). Modeling and analysis of build-to-order supply chains. European Journal of Operational Research, 195(2), 319-334. DOI:

Gunasekaran, A., Subramanian, N., & Papadopoulos, T. (2017). Information technology for competitive advantage within logistics and supply chains: A review. Transportation Research Part E: Logistics and Transportation Review, 99, 14-33. DOI:

Kannan, V. R., & Tan, K. C. (2002). Supplier selection and assessment: Their impact on business performance. Journal of supply chain management, 38(3), 11-21.

Li, S., Ragu-Nathan, B., Ragu-Nathan, T. S., & Subba Rao, S. (2006). The impact of supply chain management practices on competitive advantage and organizational performance. Omega, 34(2), 107-124. DOI:

Liu, F., Leung, S. W., & Chan, H. K. (2016). Supplier integration and logistics performance: The moderating role of demand uncertainty. International Journal of Production Economics, 177, 93-101.

Manuj, I., & Mentzer, J. T. (2008). Global supply chain risk management strategies. International Journal of Physical Distribution & Logistics Management, 38(3), 192-223. DOI:

Mentzer, J. T., DeWitt, W., Keebler, J. S., Min, S., Nix, N. W., Smith, C. D., & Zacharia, Z. G. (2001). Defining Supply Chain Management. Journal of Business Logistics, 22(2), 1-25. DOI:

Mkumbo, F. A. E., Ibrahim, A. R., Salleh, A. L., Sundram, V. P. K., & Atikah, S. B. (2019). The influence of supply chain practices and performance measurement practices towards firm performance. International Journal of Supply Chain Management, 8(3), 809-819.

Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2015). Purchasing and supply chain management. Cengage Learning.

Narasimhan, R., & Das, A. (2001). The impact of purchasing integration and practices on manufacturing performance. Journal of Operations Management, 19(5), 593-609. DOI:

Selvaraju, M., Beleya, P., & Sundram, V. P. K. (2017). Supply chain cost reduction using mitigation & resilient strategies in the hypermarket retail business. International Journal of Supply Chain Management, 6(2), 116-121.

Seuring, S., & Müller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production, 16(15), 1699-1710. DOI:

Sivan, S., Ghadiri, S. M., Rajagopal, P., Atikah, S. B., & Sundram, V. P. K. (2022). Adoption and Benefit of Industrial Revolution 4.0 in Logistics Industry: A Conceptual Paper. Journal of Entrepreneurship, Business and Economics, 10(2S1), 79-94.

Sundram, V. P. K., & Chandran, V. G. R. (2010). Research methods. UPENA-University Technology MARA, Shah Alam, Selangor.

Sundram, V. P. K., Akmal, A. O., Atikah, S. B., & Munir, Z. A. (2017). Green supply chain management practices in Malaysia manufacturing industry. International Journal of Supply Chain Management, 6(2), 89-95.

Sundram, V. P. K., Atikah, S. B., & Chandran, V. G. R. (2016). Supply chain management: Principles, measurement, and practice. University of Malaya Press, Kuala Lumpur.

Sundram, V. P. K., Atikah, S. B., Hafiz, M. Z., Azimah, D., Shahrin, N., & Thirunavukkarasu, K. (2017). Supply chain logistics: A Malaysian perspective. Petaling Jaya, Selangor Malaysian Logistics and Supply Chain Association.

Sundram, V. P. K., Chandran, V. G. R., & Bhatti, M. A. (2012). Research methods: A workbook for business undergraduates. Universiti Teknologi MARA.

Sundram, V. P. K., Chandran, V. G. R., Atikah, S. B., Rohani, M., Nazura, M. S., Akmal, A. O., & Krishnasamy, T. (2016). Research methodology: Tools, methods, and techniques. MLSCA, Selangor.

Sundram, V. P. K., Chhetri, P., & Bahrin, A. S. (2020). The Consequences of Information Technology, Information Sharing and Supply Chain Integration, towards Supply Chain Performance and Firm Performance. Journal of International Logistics and Trade, 18(1), 15-31. DOI:

Sundram, V. P. K., Rajagopal, P., & Bhatti, M. A. (2013). Social science research methods: A quantitative approach. Petaling Jaya, Selangor: Malaysian Association of Productivity.

Sundram, V. P. K., Rajagopal, P., Atikah, S. B., & Subramaniam, G. (2018). The role of supply chain integration on green practices and performance in a supply chain context. A conceptual approach to future research. International Journal of Supply Chain Management, 7(1), 95-104.

Sundram, V. P. K., Bahrin, A. S., Abdul Munir, Z. B., & Zolait, A. H. (2018). The effect of supply chain information management and information system infrastructure: The mediating role of supply chain integration towards manufacturing performance in Malaysia. Journal of Enterprise Information Management, 31(5), 751-770. DOI:

Syakirah, N., Rajagopal, P., Sundram, V. P. K., Zuraidah, R. R., Ratna, M. N., & Zamry, G. (2020). Achieving supply chain excellence through effective supplier management: A case study of a marine organisation. International Journal of Supply Chain Management, 9(4), 11-23.

Tan, K. C. (2001). A framework of supply chain management literature. European Journal of Purchasing & Supply Management, 7(1), 39-48. DOI:

Wagner, S. M., & Bode, C. (2008). An empirical examination of supply chain performance along several dimensions of risk. Journal of Business Logistics, 29(1), 307-325. DOI:

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

06 May 2024

Article Doi

eBook ISBN

978-1-80296-132-4

Publisher

European Publisher

Volume

133

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1110

Subjects

Marketing, retaining, entrepreneurship, management, digital marketing, social entrepreneurship

Cite this article as:

Chandran, S., Krishnasamy, T., Sundram, V. P. K., & Othman, A. K. (2024). The Relationship Between Purchasing Strategies and Logistics Performance in Malaysian Manufacturing. In A. K. Othman, M. K. B. A. Rahman, S. Noranee, N. A. R. Demong, & A. Mat (Eds.), Industry-Academia Linkages for Business Sustainability, vol 133. European Proceedings of Social and Behavioural Sciences (pp. 893-906). European Publisher. https://doi.org/10.15405/epsbs.2024.05.73