Abstract

In recent years, the monitoring reports on economic, social and ecologic trends of various governmental and non-governmental organizations have become more frequent warning that the existing business models are "pushing" our world towards “future ruin-world”. So, looking for suitable alternative economic and social governing models, which on the one hand lead to "economical use" of resources, and on the other - do not limit the opportunities for growth and development of the economy. Following the common trends, the transition from the existing (linear) model to the sustainable (circular) model of business, although it seems to have no alternative, still faces misunderstanding and resistance in business and civilian society. In accordance with the above, this paper focuses on one of the main priorities of the transition to a circular economy, namely innovation in highly intelligent systems. Without entering into discussions about the pros and cons of the widespread entry of technologies into social and economic life, the authors perceive that intelligent information systems should support the smooth (or not so smooth) transition to a circular economy. In order to justify the given theses, the paper is structured as follows: first, an introduction to (the need to) use the circular economy model; second, identifying the possible smart systems applied in the circular economy; and third, evaluating the impact of the measures to introduce modern intelligent systems in practice. The examples used are from practice in Bulgaria.

Keywords: Circular Economy, Digital Transformation, Intelligent Information Systems

Introduction to the Circular Economy Model

The dynamics of the environment show that the current unsustainable and ecological production and consumption patterns must be transformed as soon as possible. Significant improvement in resource efficiency and productivity (Rajput & Singh, 2019) and transformation to a rational circular economy is needed. Striving to achieve it would guarantee environmental sustainability, including in restorative and regenerative aspects, as well as solving a number of economic problems (Rajput & Singh, 2019).

Without overstating the importance of the circular economy, researches indicate that it is precisely through circular economy (CE) mechanisms that progress is made in improving resource efficiency and environmental performance at all levels of the supply chain (Sarc et al., 2019). Its complex impact, and especially on resource conservation, that makes it a global strategic priority and (for the time being) an alternative solution to replace the existing linear economy (LE) model (Chauhan et al., 2022), operating on the principles of full recovery of materials and zero waste and pollution.

The common understanding of the “circular economy” is that it is not an opposite economic approach to the existing "linear economy" approach, but rather a turning of the eye to problems that are essential for the future of human society, but have until now been "neglected" as:

continuous reduction of use cycles and increasing demand for new product solutions;

frequent change of supply chains, incl. and increasing the segments of these chains in order to achieve maximum profit at the expense of other objectives;

establishment of regional competition, which increases the intensity of wear and tear of natural resources, which leads to more costs and an increase in waste in nature.

The need for the adoption of a circular economy approach can be demonstrated by the definition of Kirchherr et al. (2017, p. 225) according to which the Circular Economy is based on business models that, by increasing alternative reuse, recycling and recovery of materials in production/distribution and consumption processes, lead to the creation of green products, companies, consumers and in ultimately, sustainable development, economic prosperity and social justice are achieved.

And despite the promised benefit for common and future generations, the imposition of the circular economy model has many opponents. Regardless of the resistance to the wider penetration of sustainability and circular economy technologies in business practice, CE is attracting the attention of business organizations as a way to achieve sustainable growth and increased efficiency. Its implementation, however, requires a change in the current business model of LE (Pagoropoulos et al., 2017). The main challenge to making the transition from a linear to a circular economy is that companies need increasingly innovative product and process solutions.

One of the indisputable ways to reach an appropriate level of innovation is the digitization of processes (Ajwani-Ramchandani et al., 2021) by the use of big data, introduction of: block-chain; artificial intelligence (AI) technologies and the Internet of Things (IoT) as well as by using other smart tools and technologies (Ghoreishi & Happonen, 2020). In this way, companies will be able to develop "individualized" business models, which will facilitate the predictive analysis of the results of their activity, and allow appropriate monitoring throughout the life cycle of the organizations (Chauhan et al., 2021).

In order to be able to successfully implement modern innovation (information) technologies, it is necessary for customer-adapted systems to be coordinated with industrial companies (the restoration industry and their suppliers) (Sarc et al., 2019). The use of intelligent systems to achieve the objectives of CE has been realized and studied by many scholars. For example, according to Wilts et al. (2021), smart technologies provide the necessary support to implement the principles of CE, and according to Awan et al. (2021) there is a growing interest in the potential of smart systems in production and consumption. Rocca et al. (2020) consider that digital transformation is a successful means of eliminating barriers to CE, while according to Stock and Seliger (2016) it can be achieved in this way by increasing the efficiency and motivation of workers, building intelligent production-based of resource efficiency, closed-loop production processes. According to the Ellen MacArthur Foundation (2019), intelligent systems contribute to the circulation of products, intelligent management and predictive maintenance.

Intelligent systems applied in the circular economy

Intelligent systems are based on the functionality of various artificial intelligence tools. AI provides the ability of computers to perform tasks inherent to humans. It is applied in the construction of systems by working with intellectual processes, imitating thinking abilities (Kunnathur, 2020), performing complex analyses and drawing rational conclusions. The intelligence of systems is expressed in their ability to perceive, process and transform data into information from which knowledge is extracted for purposeful behaviour. Among its core functions is the ability to selectively combine multiple processes, including environmental perception, problem-solving, reasoning, learning, memory, and action to achieve goals. (Paschen et al., 2019)

Categorizing the role of intelligent systems in CE, three main directions of action can be distinguished:

Improvement of processes at the company level, through an intelligent logistics infrastructure, minimizing production defects and utilization of resources;

Expanding innovative circular business models by combining real-time and historical data from consumer behaviour and product implementation. Improves pricing and demand forecasting mechanisms, and predictive maintenance;

Facilitates the development of circular products, components and materials through rapid prototyping and testing. (Ghoreishi & Happonen, 2020)

Systematically, some of the main functionalities of some of the tools with which the intelligent systems work in CE are summarized in Table 1.

Impact of project financing on the circularity of the Bulgarian economy

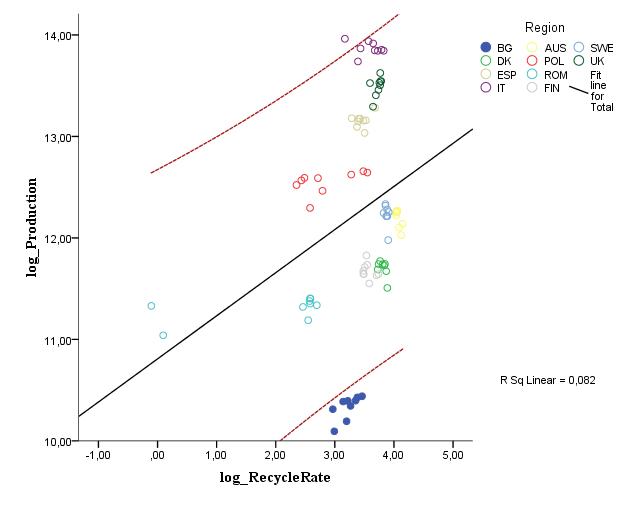

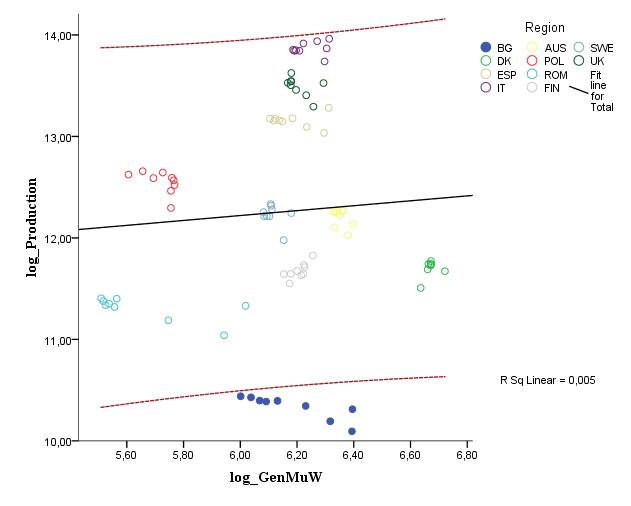

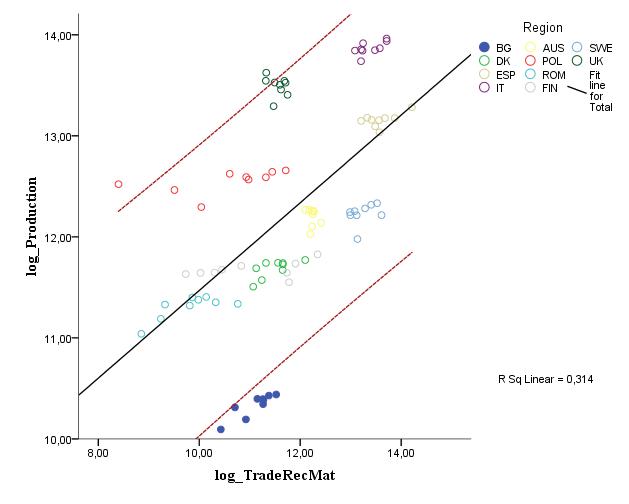

Following Ivanova (2019, 2020), as well as Sterew and Ivanova (2019), the Bulgarian economy is significantly lagging behind in terms of applying the circular economy approach in practice. This determines the unenviable last place within the EU of the Bulgarian economy (as indicated in Figure 1; Figure 2 and Figure 3).

However, in the last 4 years, regardless of the pandemic situation 2020-2022, BGN 1,212 million (620 million euro) has been invested in 1,024 projects (Table 2) in the real Bulgarian economy under the

Operational Program Innovations and Competitiveness 2014-2020/OPIC/ efficient use of materials. Regardless of the fact that a large part of them are aimed at implementing energy-efficient equipment and technologies, they are largely a fulfilment of the country's commitments to creating a sustainable and circular economy.

Energy and resource efficiency program

Procedures: BG16RFOP002-3.001 "Energy Efficiency for Small and Medium Enterprises", BG16RFOP002-3.002 "Improving Energy Efficiency in Large Enterprises" and BG16RFOP002-3.004 "Support for Resource Efficiency Pilot and Demonstration Initiatives".

The purpose of the procedures is: providing focused support to small and medium / large enterprises in Bulgaria for the implementation of energy efficiency measures with the aim of achieving sustainable growth and competitiveness of the economy, as well as increasing the resource efficiency of enterprises through the implementation of new solutions, techniques and methods

Among the additional indicators of the procedures, based on the circular economy approach, there are also:

Reduction of the amount of raw materials used in the production of a unit of production before/after the implementation of the project in percentages;

Reduction of the amount of waste intended for disposal - amounts of generated waste on an annual basis before/after the implementation of the project in t/year;

Amount of emissions before/after project implementation

Technological Development and Innovation Program

Over 10 different procedures to support the creation and implementation of innovations in enterprises.

The purpose of the procedures is: Providing focused support to Bulgarian enterprises to increase innovation activity in the thematic areas of Innovation Strategy for Intelligent Specialization /ISIS/.

Additional indicators of the procedures, based on the circular economy approach, include:

Implementation of eco-innovation projects.

By accepting the hypothesis that the economic growth at the national level (respectively, the growth of the manufactured product) depends entirely on the change of the CE activities: waste collection (GenMuW), recycling rate (RR) and trade in recycled raw materials (TrRecMat) (Sterev, 2019).

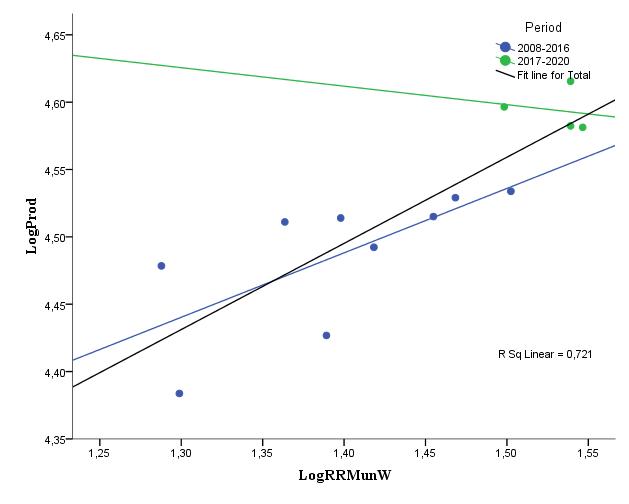

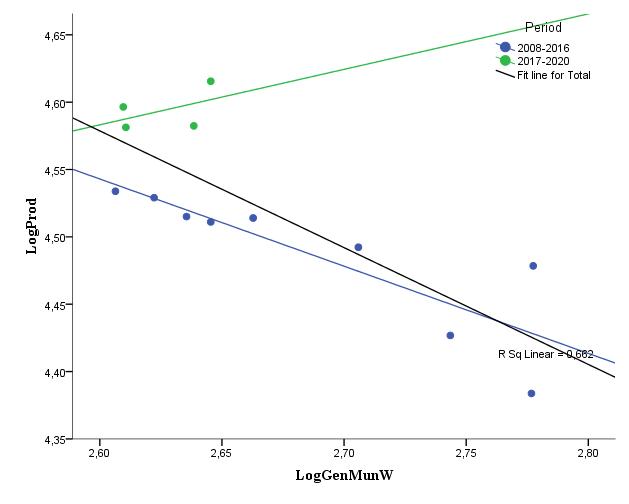

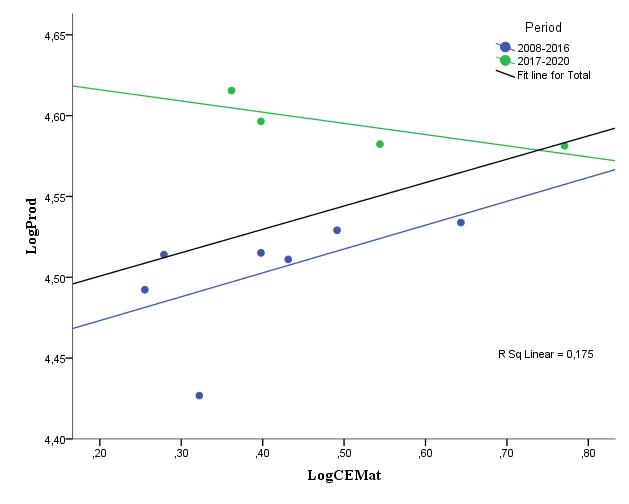

At the same time, there has been a change in the dependencies for the last 4 years (respectively 2017 – 2020 inclusive), which can be explained by the investments, respectively public and private, in applying innovations in the circular economy, as well as in the application of Intelligent Systems in them (Figure 4, Figure 5 and Figure 6).

The specific differences are observed in the following Table 3.

The data (from Figure 2 and Table 3) show that with the introduction of resource-saving technologies, the impact of generated waste on manufactured products increases by 34%. The same relative share (34%) is the observed positive effect of the degree of waste recycling on the growth of production in the industry.

All this has a positive effect and with an increase in the trade in recycled raw materials by 42%, there is a growth in the produced output.

Conclusion

Undoubtedly, the future industrial policy both in Bulgaria and in the European Union will be based on the principles of the circular economy. Although the transition from a linear to a circular economy requires a significant change not only in the business model but also in the replacement of machines, technologies and people, this transition can be accelerated by using incentive measures from the state to ensure it.

Data from the last program period show that the funds invested by the state in the introduction of new technologies, resource-saving machines and equipment, and especially in the introduction of the technologies of Industry 4.0: intelligent production systems, are returned and they contribute to a significant increase in the output from Industry with reduced waste values and a significant increase in trade in recycled raw materials. All this should be taken into account for the new program period, as it can be recommended:

Development of a Stress Test of the companies/projects financed under the programs of the National Plan for Recovery and Sustainability or financed through the cohesion funds of the EU / as a necessary condition for participation in project competitions.

Introduction of a target criterion in financing projects to improve the stress test values before and after the project.

Planning a national training campaign for SMEs on the transition to the circular economy when creating a Platform /National Register/ of companies /and their good practices/ related to the circular economy.

Planning an advertising campaign among consumers to reduce waste and increase willingness to reuse "waste" from household and production.

Development of mechanisms to stimulate the entry and use of smart tools in SMEs.

Acknowledgements

The publication contains the results of a study financed with funds from a targeted subsidy for the UNWE Research Fund under contract No. NID NI 5/2023/А

References

Ajwani-Ramchandani, R., Figueira, S., Torres de Oliveira, R., Jha, S., Ramchandani, A., & Schuricht, L. (2021). Towards a circular economy for packaging waste by using new technologies: The case of large multinationals in emerging economies. Journal of Cleaner Production, 281, 125139.

Awan, U., Sroufe, R., & Shahbaz, M. (2021). Industry 4.0 and the circular economy: A literature review and recommendations for future research. Business Strategy and the Environment, 30(4), 2038-2060.

Chauhan, C., Dhir, A., Akram, M. U., & Salo, J. (2021). Food loss and waste in food supply chains. A systematic literature review and framework development approach. Journal of Cleaner Production, 295, 126438.

Chauhan, C., Parida, V., & Dhir, A. (2022). Linking circular economy and digitalisation technologies: A systematic literature review of past achievements and future promises. Technological Forecasting and Social Change, 177, 121508.

Ellen MacArthur Foundation. (2019). Artificial intelligence and the circular economy: AI as a tool to accelerate the transition. http://www.ellenmacarthurfoundation.org/publications

Ghoreishi, M., & Happonen, A. (2020). New promises AI brings into circular economy accelerated product design: a review on supporting literature. E3S Web of Conferences, 158, 06002.

Gupta, S., Chen, H., Hazen, B. T., Kaur, S., & Santibañez Gonzalez, E. D. R. (2019). Circular economy and big data analytics: A stakeholder perspective. Technological Forecasting and Social Change, 144, 466-474.

Ivanova, V. (2019). Circular Economy in Bulgaria–Perspectives and Challenges. Nauchni trudove, (5), 203-215.

Ivanova, V. (2020). Development of Circular Economy: Opportunities and Impediments. Mednarodno inovativno poslovanje = Journal of Innovative Business and Management, 12(1), 9-17.

Kirchherr, J., Reike, D., & Hekkert, M. (2017). Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling, 127, 221-232.

Kunnathur, М. (2020). Applying Artificial Intelligence techniques in Project Management. Masters in Engineering and Management.

Lee, J., Davari, H., Singh, J., & Pandhare, V. (2018). Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manufacturing Letters, 18, 20-23.

Liu, Q., Trevisan, A. H., Yang, M., & Mascarenhas, J. (2022). A framework of digital technologies for the circular economy: Digital functions and mechanisms. Business Strategy and the Environment, 31(5), 2171-2192.

Orozova, D., & Georgieva, M. (2014). Applications of "Big Data". Computer Sciences and Communications, 3(4). Burgas.

Pagoropoulos, A., Pigosso, D. C. A., & McAloone, T. C. (2017). The Emergent Role of Digital Technologies in the Circular Economy: A Review. Procedia CIRP, 64, 19-24.

Paschen, J., Kietzmann, J., & Kietzmann, T. C. (2019). Artificial intelligence (AI) and its implications for market knowledge in B2B marketing. Journal of Business & Industrial Marketing, 34(7), 1410-1419.

Rajput, S., & Singh, S. P. (2019). Connecting circular economy and industry 4.0. International Journal of Information Management, 49, 98-113.

Rocca, R., Rosa, P., Sassanelli, C., Fumagalli, L., & Terzi, S. (2020). Industry 4.0 solutions supporting Circular Economy. 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC).

Sarc, R., Curtis, A., Kandlbauer, L., Khodier, K., Lorber, K. E., & Pomberger, R. (2019). Digitalisation and intelligent robotics in value chain of circular economy oriented waste management - A review. Waste Management, 95, 476-492.

Sterev, N. (2019). New Industrial Business Models: From Linear To Circular Economy Approach. Trakia Journal of Sciences, 17(Suppl.1), 511-523.

Sterew, N., & Ivanova, V. (2019). From sustainability to a model of circular economy: The example of Bulgaria. In Proceedings of INTCESS 2019- 6th International Conference on Education and Social Sciences (pp. 757-766). U.A.E.

Stock, T., & Seliger, G. (2016). Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP, 40, 536-541.

Wilts, H., Garcia, B. R., Garlito, R. G., Gómez, L. S., & Prieto, E. G. (2021). Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources, 10(4), 28.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

15 November 2023

Article Doi

eBook ISBN

978-1-80296-130-0

Publisher

European Publisher

Volume

131

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1281

Subjects

Technology advancement, humanities, management, sustainability, business

Cite this article as:

Biocheva, P., Sterev, N., Zakaria, N. B., & Musa, K. (2023). Intelligent Systems in the Circular Economy. In J. Said, D. Daud, N. Erum, N. B. Zakaria, S. Zolkaflil, & N. Yahya (Eds.), Building a Sustainable Future: Fostering Synergy Between Technology, Business and Humanity, vol 131. European Proceedings of Social and Behavioural Sciences (pp. 907-917). European Publisher. https://doi.org/10.15405/epsbs.2023.11.74