Abstract

The article is devoted to the analysis and study of human resource management for the enterprise engaged in the technological assembly of products. The target of research in this article is employees of the enterprise engaged in the production of technological products. The subject of the study is labor supplies dealing with the technological process of an enterprise. It implies series assembly of a product as well as packaging in small batches. The purpose of the study is the theoretical and methodological justification of simulation modeling methods use for workforce optimization at an enterprise engaged in the technological assembly of products. The main points of development and testing of the simulation model Any Logic are characterized. A discrete event approach will be used for the problem analysis. A workforce optimization algorithm based on the example of the technology product assembly process, has been proposed. The proposed approach includes production management both with the help of employees and robots, capable of balancing the conduct of processes in production. Experiments will be carried out on the model, proving the effectiveness of the developed simulation model.

Keywords: Any Logic, discrete event approach, human resource management, simulation model, workforce optimization

Introduction

Human resource management within an organization is an activity aimed at the effective use of the potential of employees in achieving the goals of the enterprise. At the same time, management is based not only on the beneficial corporate interests, but includes safeguarding interests of employees. Human resource management is designed to solve the main tasks of the enterprise: recruitment needs, staff development and their rank advancement (Chernyaeva & Denisenko, 2016).

In any organization, labor force is often at the top of the mind, requiring heavy expenses. The financial performance of the organization's activities depends on their level. An important indicator characterizing the work of any enterprise is its workforce productivity and the efficiency of labor supplies use. Sticking points in the effective use of labor supplies are interconnected with all production processes, which imply a thorough study of them. The solution of the problem connected with inefficient workforce in the study lies in using simulation modeling methods (Filippov et al., 2016).

At the moment, simulation modeling methods are some of the most powerful and effective methods in studying production processes at the enterprise. The simulation model gives a large number of parameters making possible to track the logic and patterns of the simulated object conduct. After the simulation, it is possible to describe the behavior of the system, evaluate the impact of various system parameters and select the optimal number of equipment and workers to perform all operations of the production process. It is also promising to find out the size of shippable quantity within product transfer among different workplaces (Leonov et al., 2017).

The main problem of modern enterprises is inefficient human resources management. As a result, the company loses profit, staff resources and potential for development. Analyzing workforce, the task of the manager is to assess the number of employees necessary for performing a particular process, as well as to develop a work schedule so that the production can be optimized without excessive load on human resources. To improve labor force efficiency is possible due to:

- study and assessment of labor supplies endow by trade at the enterprise and its business units;

- identification of labor supplies with more complete and effective use of them;

- study of labor-consuming of products;

- determining of product generation per unit time by one employee;

- increased supply of necessary tools for faster production;

- timing of working hours and staggering of schedules;

- time limit for the execution of any given action point in the employee's task.

Working schedule formation is the most obvious method for effictivization of work processes. To increase the process of assembling products consisting of several parts, it is necessary to stagger a sound work schedule and set up the delivery of parts with good frequency (Leonov et al., 2019).

The program Any Logic was used to build the simulation. The system Any Logic developed by XJTechnologies is a general–purpose machine modeling environment. This development covers the main areas of modeling for the time being, such as discrete event, system dynamics and agent-based simulation (Efromeeva & Efromeev, 2020).

Problem Statement

Simulation modeling makes it possible to play different behavior scenarios of consumers, suppliers, employees, competitors, helping to determine largely the development of the organization in the future. In any study related to the use of simulation modeling, there are the following stages:

- designing an abstract model;

- implementation of the model using a software product;

- model analysis;

- conducting experiments with a working model;

- evaluation of results.

Production processes simulation offers means for (Padushin et al., 2021):

- detecting and eliminating problems in advance that appear at the start-up stage and would require time or financial costs;

- reducing investment in production, having the same performance parameters at the same time;

- optimizing production and choosing the most rational solution from a variety of options;

- making tradeoffs on the distribution of labor force in the employment sector.

The simulation model of production processes can be presented in the form of a "black box" model. Such a model is used at the sheduling stage and for implementing numerical experiments with the model (Kuzmenko et al., 2020). Then we get data-out on the number of manufactured products and the number of batches received. The simulation method makes simulating the production process in reality possible as if it were going on in very deed, but in accelerated time mode. In any production process, delays may occur due to the priority of tasks or staff workload, when performing a particular task, as well as a shortage of materials necessary for task execution (Lozbinev et al., 2017).

Process simulation for series assembling of 10 pieces per package will be viewed in the article.

Research Questions

A feature of modeling systems with discrete events is the construction of a model with transactions that display dynamic modelled entities (applications), and blocks, which are objects, capable of processing these applications. Parts act as such applications in the designed system. Services use resources for their work. Resources can be understood as employees, including premises in case of its being viewed as a model. This method is ideal for a product assembly shop simulation. A discrete-event approach will be applied for the projected model. In this approach, an agent-application that is serviced on various operations will be taken up. Parts and the product itself will be treated as an agent- application for this task. Manufacturing process within a workshop aimed at parts production is considered to be the service of the agent- application, made through various services. Let's develop a model that will have the following parameters. In product assembly, the first part is subjected to two technological operations before assembly, the second and third parts are subjected to one technological operation before assembly.

The first technological operation with the first part lasts from 3 to 5 minutes and is performed by one robot. The second technological operation with the first part lasts from 4 to 8 minutes and is performed by one employee according to the work time schedule (from 9 to 18 on weekdays with a lunch break from 13 to 14) (Kuz'menko & Kondrashin, 2019). The technological operation for part process with the second part lasts from 6 to 10 minutes and is performed by a worker. The technological operation for part process with the third part lasts from 5 to 8 minutes and is performed by a worker. The product assembly, performed by a robot, lasts from 5 to 10 minutes. Then product is packed in 10 pieces per package. It takes a worker from 10 to 16 minutes to make parcels. The first part for assembly is delivered from warehouse 1 with a rate 1 piece per hour. The second part for assembly is delivered from warehouse 2 with a rate 2 pieces per hour. The third part is delivered from warehouse 3 with a rate 1 piece per hour. This model does not imply a workload for manual workers. The process of product assembling runs measuredly and sequentially, not impeding technological operations, just on employees' working days. Either outside working time or on weekends, there are some problems, reflected in the model in yellow or red (Lozbinev et al., 2017).

Purpose of the Study

This is a model algorithm for WFO (workforce optimization) at the enterprise engaged in the technology product assembly for optimizing them and improving the efficiency. A comprehensive approach for reducing labor resources workload is recommended (Text book on modelling in AnyLogic TM, 2005):

- each technological operation is performed separately by one worker in the shop, no employee performs 2 operations simultaneously;

- a robot is introduced to perform certain types of technological operations;

- a controlled simulation model is created in AnyLogic to describe the main agents and operations involved in the assembly process at the enterprise;

- the study of real production processes and fixing the time to perform a particular technological operation.

Research Methods

To build a simulation model within studies, the following elements were used to write the article (Efromeeva & Efromeev, 2020):

Source. Creating agents. It is usually used as the initial block of the process diagram. So that the block can create agents with certain animations and attributes, an agent type is in the making and the name of this type is specified into the property of the block "New Agent".

Service. Captures a specified amount of resources for the agent, delays the agent for a specified time, and then releases the captured resources. Implemented as a sequence of blocks Seize, Delay, Release and it should be used in cases where all that is required is to delay the captured resources for a certain time, and then release.

Resource Pool. Specifies a set of a certain type. Resources are objects required by agents to perform their tasks. Resources can be captured and released by their agents using blocks Seize, Release, Assembler and Service. There are three types of resources: moving, static and portable. Static resources are tied to a specific complex (rooms, machines); moving resources can move by themselves (personnel, transport); portable resources can be moved by agents or moving resources (Text book on modelling in AnyLogic TM, 2005).

Assembler. Builds one new agent from a certain number of agents coming from various sources (up to 5). The type of the new object, as well as its initialization, is determined by the user. The number of agents that is to arrive at each individual port for one new agent being created is set using the block parameters (number 1, number 2, etc.). The assembly begins when all the agents necessary for the assembly are received (in case of availability of all necessary resources, if specified). The assembly time is set in the Delay Time parameter.

Batch. Converts the specified number of incoming agents to one new agent. The block contains a succession inside where arriving agents are stored. When the number of agents accumulates equal to the specified batch size, a new batch agent is created. The batch can be permanent or temporary. When creating a permanent batch, the agents stored in the succession are destroyed, while when creating a temporary batch, all these agents are added to the contents of the batch and can be retrieved later by the block. Unbatch.

Sink. Destroys entered agents. It is usually used as the final block of the process diagram.

Based on these types of blocks, a simulation model was developed.

Development of a Simulation Model of the Assembly Shop in the Any Logic Environment

The discrete-event approach assumes the presence of an application (agent) and blocks for processing these applications. To build the model, the elements specified in the paragraph 2.1. will be used.

Modeling of Agents-Parts and Products

The parts, which are going to be assembled and the product itself, will be presented in the model as a Type of agents. We assign the name of a new type of agents - Detal_1 – for the first part, Detal_2 – for the second part, Detal_3 – for the third part. Separately, it should be noted that for the product, the name of the new type of agents is Isdelie. After carrying out all operations, there is a list of 5 agents on the Projects tab.

Parts Supply Simulation

The parts, which are going to be assembled and the product itself, will be presented in the model as a Type of agents. We assign the name of a new type of agents - Detal_1 – for the first part, Detal_2 – for the second part, Detal_3 – for the third part. Separately, it should be noted that for the product, the name of the new type of agents is Isdelie. After carrying out all operations, there is a list of 5 agents on the Projects tab.

A Parts Process Simulation

The first part undergoes two technological operations. Each operation is treated as a provided service of the agent Detal_1. The Service block is used to provide agent service.

This block consists of a service queue and a block simulating the delay of a part during service. The block has one input and three outputs: out, outTimeout, outPreempted. If the service of the parts has been completed, they are introduced to the out. If waiting time for the service in the queue is up, the parts are introduced to the Timeout. The output of outPreempted has the parts displaced by the parts with a higher priority for part process. In this task, all parts must be serviced, so only the out output will be used.

The task for the first technological operation. In the block properties, set its name (Operaciya_1), queue capacity — The maximum capacity, the duration of the operation. The duration of the operation is set by a triangular distribution, in which the first parameter means the minimum operation time (3 minutes), the second parameter — the average duration of the operation (4 minutes), the third — the maximum duration of the operation (5 minutes).

As mentioned in the paragraph formulating the task, the first technological operation with part 1 is performed by a robot. To simulate an operation task for a robot, you need to specify a Set of resources in the Service block performing the operation. To specify a Set of resources the creation of resources in the model in advance is quite urgent. The resources in the model are set by the ResourcePool block. In its Resource Pool properties, we set the name of the resource Robot_1, the number and type — Portable. In general, the resources in the model can be of three types: moving, portable and static. When choosing a moving type, the robot can serve several operations, moving from one to another.

The task for the second technological operation. Drag the Service block so that the out of the Operaciya_1 block output and the input of the new block are connected. In the block properties, we set its name Operaciya_2, the queue capacity is 10 and the service time is 4, 6 and 8 minutes.

The second technological operation is performed by an employee according to prescribed schedule. To set the work schedule, the Schedule block is used.

In the Schedule block properties, set two schedules — from 9 to 13 and from 14 to 18. Add a schedule using the + button to the right of the Schedule table. We set a yes/no schedule type.

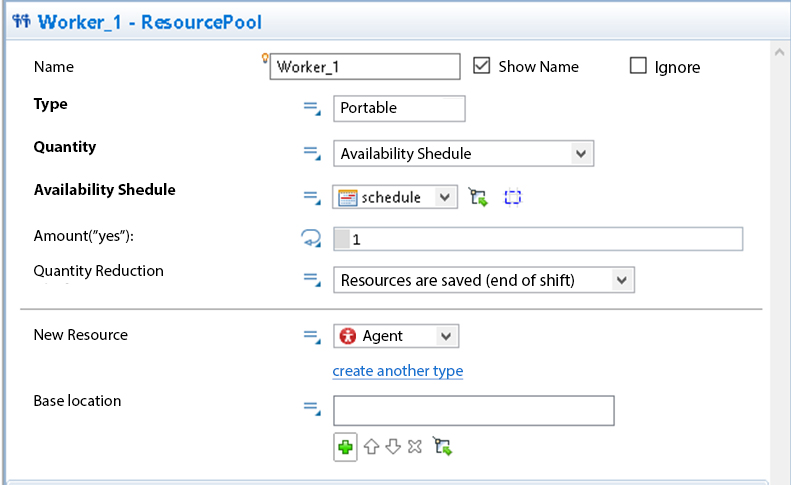

Then set the resource using the ResourcePool block. Since the work of the employee is set by a schedule, in the properties of the Resource Pool block, in the sub-clause Quantity Specified, select the Availability Schedule item. In case of selecting just Schedule item, the number of workers employed at the specified hours should be set in the Schedule block itself. Since the Schedule type is selected in the Schedule block yes/no, i.e. the resource can be available or not, this type of schedule is called an Availability Schedule. In the Availability Schedule item a newly created schedule is selected. As a result, the properties of the ResourcePool block should look like in Figure 1.

Let's simulate the execution of an operation using the Service block. In the block properties, specify its name (Operaciya_3), queue capacity (Maximum) and operation execution time.

The technological operation is performed by a worker. Moreover, this is not that employee, who processes the first part. Therefore, creating a new resource is essential. He will work according to the same schedule as the worker processing the first part, so there is no need to create a new schedule. Thus, it is necessary to create a new resource working in concordance with the existing schedule.

Setting the assembly operation. To simulate the assembly process in the AnyLogic environment, an Assembler block is used, which has 5 inputs and one output. The parts from which the product is assembled are input at the entrance, at the exit of the block, a new application agent is created, namely the assembled product. In the properties of the Assembler block, we set the assembly runtime and the type of agent at the output in the New Agent section.

The assembly is performed by a robot designed specifically for this operation. Therefore, it is necessary to use the ResourcePool block for creation of another type of RobotAssembler resources.

Setting packing operation. The assembly operation is also set by the Service block, while the worker performing it is specified by the ResourcePool block. Since he works on the same schedule as all other employees, the prescribed availability schedule is used.

Packing operation produces boxes containing 10 items each. For the simulation of boxes, we will introduce a new agent into the model — Box. The packaging of products will be simulated using the Batch block. This unit accepts a specified number of products as input and releases their batch. Setting a permanent batch makes its disassembly into individual products impossible.

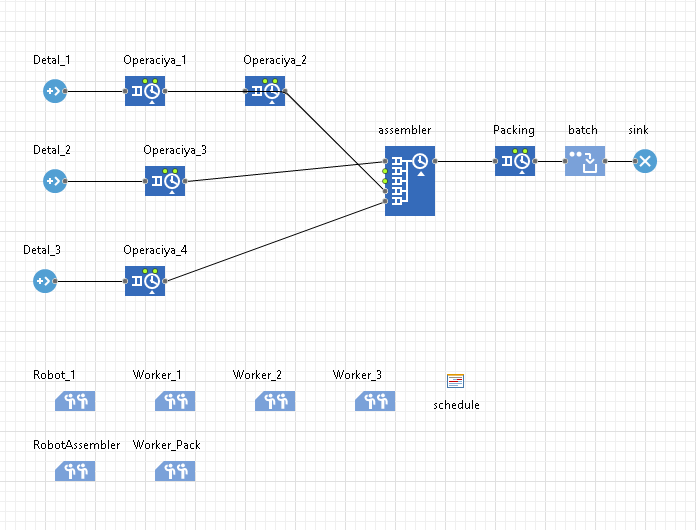

Packed boxes are taken away from the workshop. The block Sink is used to simulate the departure of boxes from the model. It has one input and just cancels forming applications. The finished simulation model is shown in Figure 2.

Findings

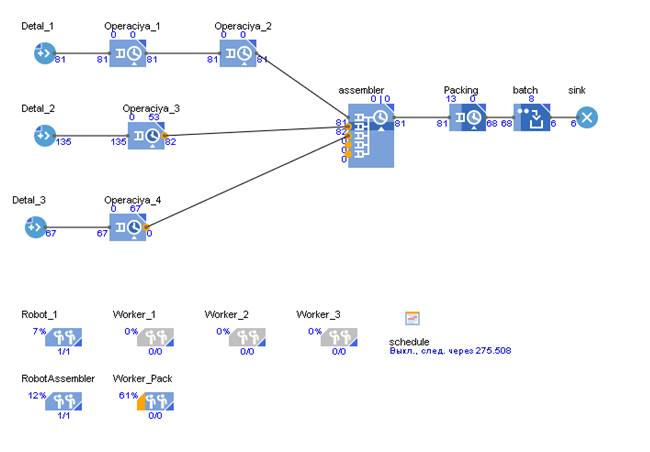

Fire up the acquired model by clicking on the button on the toolpallete in the top menu. The working model is shown in Figure 3.

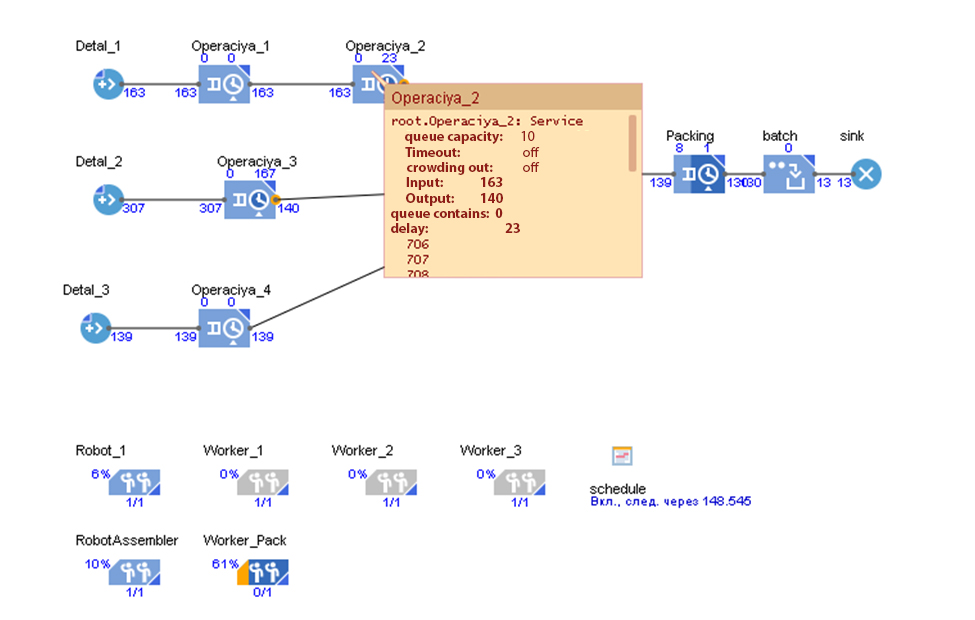

As can be seen in Figure 3, there are problems you can face in three places: at the exit of the technological operation, performed on the second and third parts. Accordingly, problems arise during the assembly of parts. This is due to the time of the experiment. For three workers –Worker_1, Worker_2 and Worker_3 at the moment, non-working hours, namely, they are busy with these technological processes. Also, the program itself gives an error: the agent left the block in the second operation due to the empty set of resources. It should be noted that the optimization of working time includes not only a demonstration of the acceleration of manufacturing, but also the optimization of employees' working time with time management providing workers with sufficient time for rest. Problematic situations are remeditated over time. This can be clearly seen in Figure 4.

Based on Figure 4, there are problems with the system arising within the technological operation for the first and second parts. It is connected with the delay of agents in the second technological operation for the first part and in the third operation for the second part. This is evidently due to the lack of time when workers process arrived parts and they queue up. At the same time, it can be noted, there is no overtime working and the workflow is comfortable.

Conclusion

A simulation model of the technological process for products assembly in production has been analyzed in the article. Thus, it can be concluded that with the help of simulation modeling, an unlimited number of experiments with changing system parameters can be performed. With the help of simulation modeling, it is possible to describe the structure of the system and its processes as it is, not using various mathematical formulas and constructions. To eliminate problems related to the optimization of labor resources, simulation modeling is the most appropriate.

Optimization of either working time or technological process of product assembly dealing with three parts should be performed using the capabilities of simulation modeling. Thus, the results can be clearly seen. The following solutions are proposed:

It is possible to optimize the working hours of employees and hire workers who will work over the lat night shift. If employees usually work 8 hours a day, then hiring extra workers divided into 2 groups of 3 people, working two shift, will make it possible to increase the volume of manufactured parts three times, with neither discomfort nor overworking for other employees. It is possible to burden with works the employees dealing with arriving parts: once every 1 hour, and the assembly takes no more than 15 minutes. That is, if we increase the supply of parts by 4 times, then the employee will be optimally busy during working hours, and the productivity of the workshop will increase by 4 times.

In the process of work, a simulation model of the production process for the products assembly was developed.

References

Chernyaeva, S. N., & Denisenko V. V. (2016). Imitacionnoe modelirovanie sistem: uchebnoe posobie [Simulation modeling of systems]. Voronezh State University of Engineering Technologies. Text: electronic // IPR SMART: https://www.iprbookshop.ru/50630.html

Efromeeva, E. V., & Efromeev N. M. (2020 Imitacionnoe modelirovanie: osnovy prakticheskogo primeneniya v srede [Simulation modeling: fundamentals of practical application in AnyLogic]. Saratov: Vuzovskoe obrazovanie. DOI:

Filippov, R. A., Filippova, L. B., & Sazonova, A. S. (2016). Internet veshchej: osnovnye ponyatiya i opredeleniya [Internet of things: basic concepts and definitions]. BSTU Publishing House. https://search.rsl.ru/ru/record/01008894495

Kuzmenko A. A., Filippova L. B., Sazonova A. S., & Filippov R. A. (2020). Intelligent System of Classification and Clusterization of Environmental Media for Economic Systems. Proceedings of the International Conference on Economics, Management and Technologies 2020 (ICEMT 2020). Advances in Economics, Business and Management Research, 139, 583-586. DOI:

Kuz'menko, A., & Kondrashin, D. (2019). Metody i podhody k razrabotke avtomatizirovannoj sistemy analiza dinamiki izmenenij ploshchadi lesnyh nasazhdenij na osnove metodov avtomaticheskogo raspoznavaniya obrazov [Methods and approaches to the development of a automated analysis’s system of the changes’ dynamics in the area of forest plantations based on the methods of automatic pattern recognition]. Ergodesign, 4(6), 230-240. DOI:

Leonov, E. A., Leonov, Y. A., Kazakov, Y. M., & Filippova L. B. (2017). Intellectual Subsystems for Collecting Information from the Internet to Create Knowledge Bases for Self-Learning Systems. Proceedings of the Second International Scientific Conference “Intelligent Information Technologies for Industry” (IITI’17), 94-103. Advances in Intelligent Systems and Computing book series. DOI:

Leonov, Y. A., Leonov, E. A., Kuzmenko, A. A., Martynenko, A. A., Averchenkova, E. E., & Filippov, R. A. (2019). Selection of rational schemes automation based on working synthesis instruments for technological processes. Science Book Publishing House LLC.

Lozbinev, F. Y., Sazonova, A. S., & Filippova, L. B. (2017). Prognozirovanie zhivuchesti korporativnoj seti svyazi na osnove nejro-nechetkogo podhoda [Prediction of the resistance of a corporate communication network based on the neuro-fuzzy approach]. Virtual simulation, prototyping and industrial design, Materials of the IV International Scientific and Practical Conference. Publisher: Tambov State Technical University. https://www.elibrary.ru/item.asp?id=31888207

Padushin, D. G., Leonov, Y. A., Kuzmenko, A. A., & Filippovd, R. A. (2021). Analysis of road traffic accidents using an information and analytical system. AIP Conference Proceedings 2402, 050045. DOI: 10.1063/5.0072742

Uchebnoe posobie po modelirovaniyu в AnyLogic [Text book on modelling in AnyLogic TM]. (2005). XJ Technologies Company Ltd. https://clck.ru/s9bTr

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

29 August 2022

Article Doi

eBook ISBN

978-1-80296-126-3

Publisher

European Publisher

Volume

127

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-496

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Sazonova, A. S., Leonov, Y. A., & Filippov, R. A. (2022). Human Resource Management Of The Enterprise Using Simulation Modelling. In I. Kovalev, & A. Voroshilova (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-III 2022), vol 127. European Proceedings of Social and Behavioural Sciences (pp. 468-478). European Publisher. https://doi.org/10.15405/epsbs.2022.08.51