Abstract

The development management ideology of Voronezh region is based on the strategy of advanced development, built upon the modernization of the diversified economy, new quality of the social sphere and the formation of an active social environment. The article is devoted to the analysis of the feed industry of the Voronezh region and Russia as a whole. The main directions of the promotion of agro-industrial enterprises specializing in the production of animal products and potential consumers are analyzed. Increasing zootechnical and veterinary requirements encourage the industry to increase the number of products, expand the range and constantly improve the quality of feed, protein-vitamin-mineral concentrates and premixes. One of the indicators that characterize the level of development of animal husbandry and the consumption of animal products of the population is the volume of production of compound feeds. In order to increase the consumer properties and nutritional value of feed for farm animals and poultry, it is necessary to conduct the research on the development of recipes for biologically valuable compound feeds using new types of additives. The role of energy-saving and low-waste technologies is great.

Keywords: Development, feed industry, food production

Introduction

The development management ideology of Voronezh region is based on the strategy of advanced development, built upon the modernization of the diversified economy, new quality of the social sphere and the formation of an active social environment. The strategy is a system of goals, tasks and activities aimed at developing the economy and social sphere, taking into account the state policy in the field of strategic planning implemented by the Russian Federation and the government of the Voronezh region. The priority development chosen as the main goal would ensure the leading position of the region among the regions of the Russian Federation since it is based on an innovative socially-oriented scenario related to investment in high-tech projects, which allows for the transformation of innovative factors into a leading source of economic growth (Litvinova et al., 2016).

One of the main strategic conditions for the economic stability of the region is the creation of favorable conditions for the successful development of agricultural enterprises. Despite this, in recent years, the growth rate of regional agricultural production in Voronezh region has significantly exceeded the national average. In terms of gross agricultural output, the region is traditionally one of the five largest agricultural regions of the Russian Federation (Rosstat, 2019).

Problem Statement

One of the main strategic conditions for the economic stability of the region is the creation of favorable conditions for the successful development of agricultural enterprises. Despite this, in recent years, the growth rate of regional agricultural production in Voronezh region has significantly exceeded the national average. In terms of gross agricultural output, the region is traditionally one of the five largest agricultural regions of the Russian Federation (Rosstat, 2019).

Research Questions

To achieve sustainable innovative development of the agro-industrial complex (KAP) of the region it is required to increase production competitiveness as well as agriculture stability; ensure the production of environmentally friendly products by applying "green thinking" and "healthy diet" policies; create conditions for the development of basic and perspective branches of agriculture in the long term; create prerequisites for the formation of "growth points" and the agricultural cluster; further develop vertically integrated structures, agro holding companies and agglomerations; use agricultural land efficiently as a basic production resource; create conditions for the development of processing industry; consolidate organizations in the compound feed and food industries of the region on the interregional markets; develop regional marketing in order to increase investment attractiveness of the agro-industrial complex (KAP) of the region; form personnel potential of agro-industrial complex, possessing innovative thinking and being able to ensure the effective functioning of the industry in market conditions; form and develop regional infrastructure to ensure innovative development of agricultural industries (Rising prices for raw materials negatively…, 2018).

Purpose of the Study

The aim of the article is to analyse the feed industry of the Voronezh region and Russia as a whole an the main directions of the promotion of agro-industrial enterprises specializing in the production of animal products and potential consumers.

Research Methods

In the process of working on the study the systemic, and structural-functional approaches, as well as the method of analysis of relevant state of feed industry were used.

Findings

The level of investment in the agro-industrial complex (KAP) in 2019 amounted to 42 billion rubles or 24% of the total investment in the Voronezh region. The investment portfolio of the agro-industrial complex (KAP) includes 57 investment projects with total funding of 124 billion rubles, the implementation is scheduled to be due by 2021.

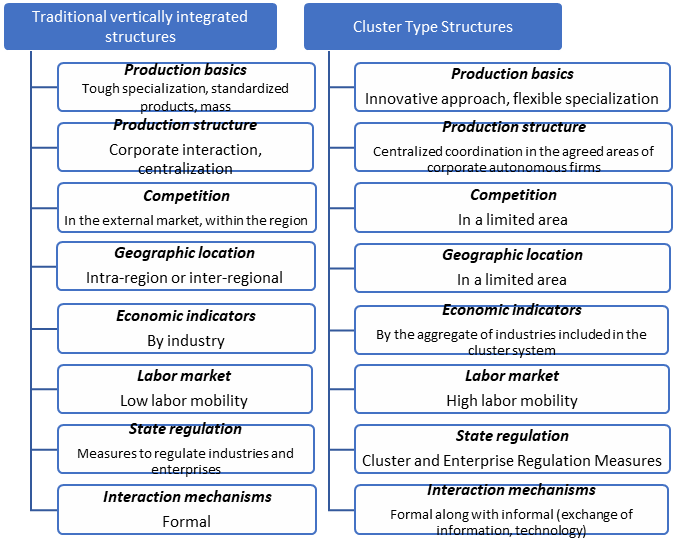

The need to improve the economic efficiency of the agro-industrial complex (KAP) of Voronezh region requires the formation of a new model of agro economics that allows you to take maximum advantage of the available potential (Skopintseva, 2017). An agro-industrial cluster is an innovation-oriented, geographically localized integrated structure with elements of a network organization that includes various areas of an agro-industrial complex (KAP) that differs from traditional vertically integrated structures (Figure 1).

The formation of agro-industrial clusters in a region is quite a complex process, they are formed slowly, and visible results are achieved no earlier than in several years (Rosstat, 2019). However, such associations have a positive impact not only on individual enterprises in the cluster structure but also on the economy of the region as a whole, as there is the interaction between three sectors: business (commercial organizations, lending institutions), institutions (universities and research centres, public organizations, chambers of Commerce) as well as authorities (local authorities, tax administrations, regulatory structures).

The solution to the problem of regional clusters forming is based not on attracting additional budget funds, but on coordinating activities implemented within the framework of other tasks (Rating of the largest producers of compound feeds in Russia according to the results of 2018, 2019). Rural areas development takes place in those municipal areas where investors - agricultural holding companies come and where "growth points" are formed (Shakhov et al., 2016). Therefore, this is the place where agro-industrial clusters should be created

Structure of feed production in Russia

The formation of conditions for the production development and technological bases for the production of compound feed industry is one of the main tasks of the highly efficient agriculture in order to provide animals with high-quality compound feed and feed additives (Chernozemye: harvesting data for grains and oilseeds, 2018; Lytkina et al., 2016; Orlova, 2019).

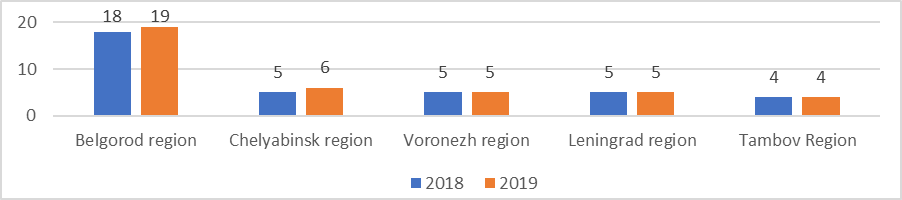

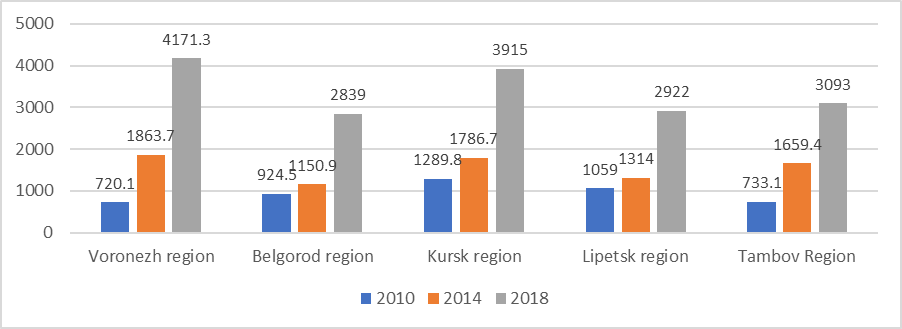

Voronezh region is traditionally included in the TOP-5 largest compound feed producing regions (Figure 2).

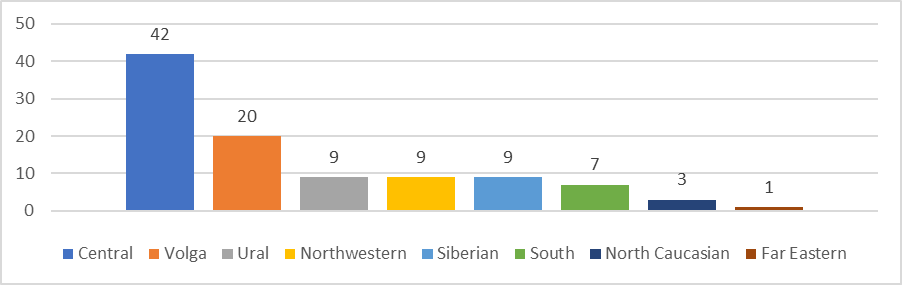

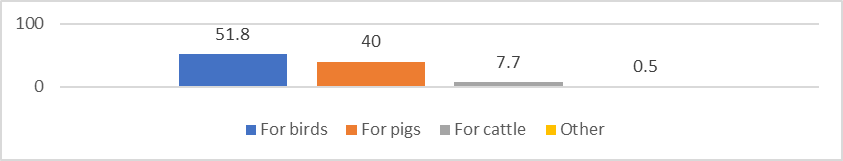

By 2025, according to the forecast of the compound feeders Union, the production of compound feed will reach 40 million tons in the Russian Federation. The Structure of compound feed production in Russia classified by Federal districts and animal species for the year 2019 is shown in figures 3,4 (Shentsova et al., 2016).

In general, the capacity of Russian compound feed mills is estimated at 36 million tons, and by 2025 they will amount to 45 million tons (Emelyanov et al., 2020). At the same time, the country's need for compound feed is 42 million tons, and it will grow to 60 million tons by 2025. In the meantime, the development of compound feed mills and their investment plans are negatively affected by rising prices for raw materials, primarily grain. The rise in the price for raw materials has a significant impact on the work of compound feed consumers, especially small poultry and pig farms. Businesses are under pressure from rising prices for grain and compound feed, which they cannot produce themselves, so some of them are leaving the market. As a result, the profitability of compound feed production falls, because consumers are not ready to pay for very high-quality compound feed, so many businesses are sacrificing their margin (Pechenevsky & Snegirev, 2020). The price situation forced compound feed producers to develop new products. Thus, against the background of rising wheat prices, producers are increasing the use of rye.

In the cost structure, the cost of compound feed occupies a fairly significant part and is up to 70%. The condition for the successful development of these industries is to provide them with high- quality and balanced biologically full-value compound feed. The main producers of livestock products are the Central Federal district (more than 10 million tons), the Volga region (more than 5 million tons) and the Ural region (2.5 million tons).

Industrial production of compound feeds in Russia is represented by large stable enterprises located in the Central Federal district. The main production of compound feed is concentrated in the hands of agricultural holdings, which include compound feed production as well as poultry farms, pig farms and marbled beef producers. The main producers of compound feed are agricultural holdings and large integrated structures, their market share is about 45%, while about 40% of them are independent feed producers, i.e. specialized companies and factories, and the rest are large farms that have their own feed mills and workshops. About 17 or 20 million tons of unbalanced compound feed are used in private farmsteads and small multi-industry agricultural enterprises (Rating of the largest producers of compound feeds in Russia according to the results of 2018).

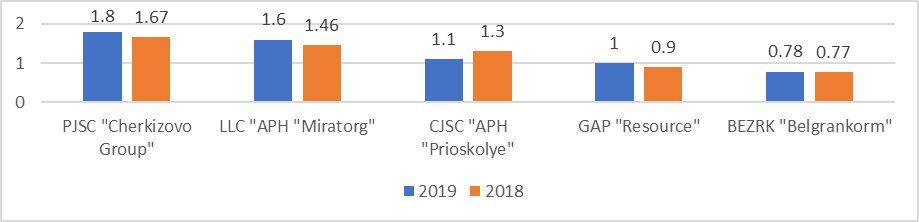

According to the forecasts of the compound feeders Union, the volume of production of compound feed enterprises that will remain on the market is estimated at a maximum of 250,000-300,000 tons per year, and organizations are able to expand the range of products by adding, for example, recipes for aquaculture or livestock. The largest compound feed producers are shown in figure 5.

The leading positions in the rating are occupied by the largest meat producers: “Cherkizovo” group, “Miratorg” holding, “Resurs” group and “Prioskolye” holding. Over the past year, all of them have increased their indicators, which is due to the increase in meat production, primarily poultry (+6.9%) and pig farming (5.5%). The “Resurs” group showed the most significant growth rate among the leaders, increasing production by 200 thousand tons to 1.1 million tons, which allowed it to rise from fourth to third place.

New participants in the rating were “Agroeco” holding, which increased the volume of output from 30 thousand tons to 410 thousand tons, “Damate” company (288 thousand tons) and agro-industrial complex “Don” (279 thousand tons). In addition, “KoPitania” holding returned to the list of leaders (400 thousand tons, 16th place).

"Prioskolie" company reduced compound feed production by 270 thousand tons, which amounted to more than 1 million ton. This result was influenced by the sale process of Inzhavinskaya poultry farm, as well as selling "Altai broiler" poultry farm purchased PJSC “Cherkizovo Group”. In 2018, Russia produced 28.9 million tons of compound feed, which is 5% more than in 2017. The Industry continues to develop, the total volume of feed production in comparison with 2018 increased by 3% in 2019. At the same time, the production of premixes for livestock shows the best dynamics: for two years in a row, this sector continues to grow steadily, which in 2019 amounted to 27%.

The main competitive criteria for evaluating feed on the market are quality and cost. Currently, the most popular are energy- saving, low-waste and environmentally friendly technologies for the production of full-value compound feed and feed additives.

Grain production

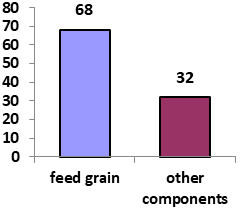

In 2019, along with compound feed projects, the construction of large grain processing plants continues, which is no less significant for compound feed production, since the content of grain in compound feed remains high and reaches up to 70%.

Grain production in the Centralno-Chernozyomny region forms the basis of gross agricultural output, and employment of all categories of farms in grain production and its processing products creates an objective need for the development of the compound feed industry. Market conditions characterize a relatively constant demand for grain and its processed products both within the district and abroad.

The agro-industrial complex in Voronezh region accounts for 18% of the gross regional product. The share of the agricultural sector in the Centralno-Chernozyomny region in the gross public product is almost 25%. According to the average long-term yield of grain crops, the district is slightly inferior to the North Caucasus, and in terms of gross output per 100 hectares of agricultural land, it ranks first in the Russian Federation (Rosstat, 2019).

Grain production remains one of the main components of agricultural production. The data on production dynamics are shown in figure 6.

The volume of grain production in Voronezh region during the period under review is increasing, thus in 2018, 4171.3 thousand tons of grain were produced according to the grain portal of the Central Chernozyomy region, whereas in 2010 this figure was 720.1 thousand tons ( figure 6). In 2019 Voronezh region collected 5.2 million tons of grain and ranked fourth in the country.

However, with the increased need for the construction of factories, reconstruction of existing cereal workshops as part of agricultural holdings imported equipment is being installed. In the future, the production of animal feed will continue to grow, although, at a slower pace than previously, this is due to an increase in demand for livestock products. At the same time, the high grain content in the diets of farm animals and poultry makes Russian producers dependent on the grain market.

According to the SoyaNews Agency data (media registration certificate No. FS77-42837), by 2035, grain consumption in Russia will amount to 86.6 million tons, including 52.3 million tons that will be used in the production of feed and compound feed.

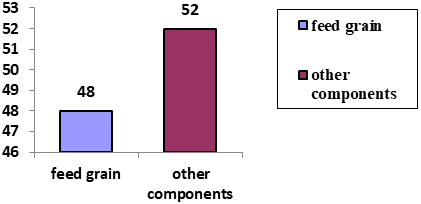

Currently, the share of grain components in the total volume of compound feed is more than 70%. The production of livestock products in our country spends twice as much feed compared to the standards of developed countries, and the main reason for that is the imbalance of feed composition for farm animals, poultry and fish in protein as well as amino acids. Obtaining high-quality compound feed requires first of all the availability of a good recipe that provides an optimal content of nutrients and biologically active substances (Figure 7).

In the composition of domestic feed, as a rule, a high proportion of grain raw materials prevails, in the European Union (EU) it is 45-50%, in Russia, this figure goes up to 70%. In the EU, the main components of compound feed are legumes, bagasse as well as flakes, by-products of the food and processing industry.

As a rule, for the production of compound feeds, feed grain is used, which has special requirements, and it should be used rationally. According to the research of agricultural analysts, it could be said that the country produces more than 24-25 million tons of full-value compound feed. The main difference between feed grain and food grain is its quality. Feed crops undergo a less demanding certification process before entering an agricultural market. The price of such raw material is much lower than the high class grain. Depending on the compliance with such indicators as appearance, the mass fraction of gluten and its quality, glassiness, cultures are divided into several classes.

National and international standards differ from each other therefore there are 5 kinds for durum wheat and 6 kinds of soft wheat, which are combined into 3 groups. Group “A” includes 1-3 class grain (high-quality wheat used in food production, which is exported to the foreign market), group “B” includes class 4 wheat, rich in strong varieties, which is used in the production of pasta. Feed wheat includes a grain of 5-6 class.

Feed grain is used in livestock, poultry and fish farming, the rate of feed wheat in the main diet is the following: small livestock and pigs - up to 40 %; cattle - up to 35 %; horses - up to 30 %; small pets from 20 to 40 %; poultry - up to 60 %. The quality and grade of wheat affect the way the grain is used and processed: with an increased cellulose content, it is suitable for feeding livestock, small cattle, horses, and with less cellulose content to feed it to pigs, poultry and fish. For better assimilation by animals, it is important not only to include feed grains in the compound feed composition but also to use them as the basis of recipes.

Along with the scientifically based feed balancing by nutrients, there are significant reserves for reducing the cost per unit of body weight gain due to the introduction of biologically active substances, which primarily include enzyme formulations. The introduction of enzyme formulations into diets can increase the digestibility of feed nutrients and release some of the metabolic energy.

Quality assessment and rational use of food raw materials is carried out on the basis of the research of the composition as well as physical and chemical properties using modern organoleptic and instrumental methods of analysis. The calculation of ration optimization considered in the article was carried out using the “KormOptima” programme, taking into account the introduction of lickers into the feed. A special place in the technology of lick-briquettes belongs to the process of mixing components as the most energy-intensive, which positively affects the quality of the finished product and increases its shelf life. The imperfection of mixing technology affects the quality of products, creates additional difficulties in achieving high quality, providing the necessary animal weights and prevention of diseases. Modern trends in the development of mixing theory have prepared the conditions for a scientific approach to the creation of new energy-efficient technologies for feed briquettes using essential principles of energy conservation at all production stages.

The process of licking is an important factor that determines the utility of the use of licks compared to loose mixtures. There is a reliable relationship between the duration of block licking, milk productivity, and even the level of immunoglobulin in blood.

The components of cattle licks are selected in an optimal ratio and provide the animal's body's need for essential vitamins, macronutrients and micronutrients, as well as carbohydrates. The use of lick-salt bricks increases appetite regulates water-salt balance as well as calcium and phosphorus metabolism. In addition, it improves the process of hematogenesis as well as reinforces the immune system.

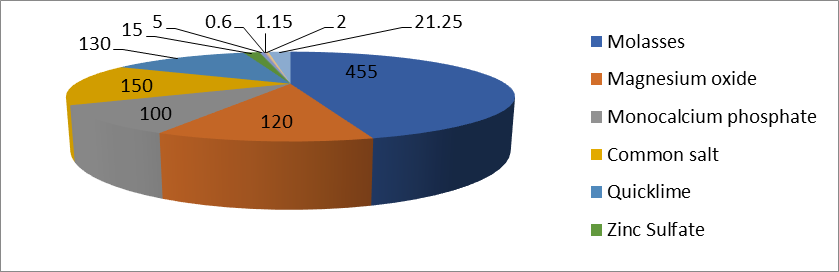

To determine the content of vitamins, trace elements and other indicators, high-performance liquid chromatography, atomic absorption spectroscopy, spectrophotometric and rheological methods were used. Measurement errors did not exceed the values established in the current standards for quantitative analysis methods of the raw materials quality and finished products. The recipe for feed bricks was obtained by optimizing the mixing process. The recipe is shown in figure 8.

Detecting a rational area for changing the mixing characteristics was carried out using experimental planning methods. The selection of ranges of changes in input information factors was carried out using a central rotatable uniform planning, which allowed 56 experiments to obtain regression equations in 3-fold repetition that adequately describe the real process of mixing ingredients when creating compound feed briquettes.

The mixing process of components is the most energy-intensive, which positively affects the quality of the finished product and increases its shelf life. When developing a mathematical model of the mixing process, an informal method was used: modification of mathematical descriptions of the mixing process for a specific type of mixing apparatus.

The mathematical model of the mixing process of a binary composition in a mixer is based on a mathematical description:

; (1)

,(2)

where k = (NAa+ NBb)/b – coefficient; сА, сВ are the relative concentrations of components A and B; mА, mВ – the mathematical expectation of the concentrations of components A and B, corresponding to the prescription value of the component concentration in the mixture; – coefficient of proportionality; NA, NB – number of groups of particles A and B; a = aA VA; b = bB VB; a and b are the number of particles included in the integration of A and B; VA и VB are the volumes of particles of types A and B; A and B – material density of particles A and B; DA and DB are the variance characterizing the completeness of the mixing process.

In the course of the research, we obtained lick-salt bricks, which determined the content of moisture and vitamins, it was found that during 14 months of storage in the warehouse, the content of vitamins gradually decreases. Storage in the laboratory led to a significant destruction of vitamins after 6 months.

The preservation of vitamins A, E, and D in bricks after 12 months of storage in the warehouse was high and amounted to 90.5%, 91.4%, 90.7% respectively in the control of 81.8%, 71.4%, and 70.3% of the original.

However, the technological properties of the products have not changed, and there are no signs of damage associated with increased humidity in the environment. There were no signs of bacterial flora development on the surface of the bricks. Microbiological quality indicators were within acceptable limits. As a result, the optimal shelf life of products in warehouse conditions is 12 months, whereas in unfavorable conditions it is only 6 months.

Currently, the main criteria for evaluating compound feeds that can withstand competition in a market economy is not only quality but also the optimal cost (Emelyanov et al., 2020).

The increase in the cost of commercial products is associated with increased resistance to the storage, increased growth in live weight, and improved quality indicators. The analysis shows that the technology for obtaining feed briquettes according to the proposed recipe is economically feasible. In a year, the increase in sales profit will be 1758.1 thousand rubles with an increase in the product profitability from 10 to 11.9 %, the return on sales will grow from 9.1 to 10.7 %, and the payback period of capital investments in the amount of 759.2 thousand rubles will be up to 1 year.

In experiments on livestock, the use of lick-salt bricks produced using the proposed technology for feeding allowed to increase the average daily growth of animals by 8.1 %, and the net profit – by 7.8% compared to products developed using the existing technology.

The implementation of these sets of measures will help to solve the issues of creating highly efficient agriculture and providing the population with a full-value and balanced diet.

Conclusion

Global trends of agriculture development are designing new socio-economic environment related to the technological situation in the region, the transition to a new development model, diversification of economy and creation of innovative technologies, science and technology national projects, providing Russia’s sustainable dynamic and balanced development in the long term. The purpose of the state policy in the field of formation and development of the national innovation system is the creation of economic conditions for bringing to market competitive, innovative products to implement strategic national priorities of the country, improving the life quality of the population, economic growth, developing fundamental science, education, culture as well as defence and security of the country by pooling efforts of the state and business sector on the basis of mutually beneficial partnership.

References

Chernozemye: harvesting data for grains and oilseeds (2018). Retrieved from http://www.zerno.avs.ru/

Emelyanov, A. B., Kopylov, M. V., Kazartsev, D. A., Abrahamyan, M. K., & Nechaev, M. V. (2020). Optimization of the process of mixing liquid-phase heterogeneous products by mathematical modeling. Proceedings of the Voronezh State University of Engineering Technologies, 82(1), 47-52. https://doi.org/10.20914/2310-1202-2020-1-47-52

Litvinova, T. N., Khmeleva, G. A., Alferova, T. V., Ermolina, L. V., & Cheryomushkina, I. V. (2016). Scenarios of business development in the agricultural machinery market under conditions of international trade integration. Contemporary Economics, 10(4), 323-332.

Lytkina, L. I., Shevtsov, A. A., Shentsova, E. S., & Apalikhina, O. A. (2016). A probabilistic model of the process of mixing feed ingredients in a continuous mixer. Bulletin of the Voronezh State University of Engineering Technologies, 2, 16-21.

Orlova, N. (2019). Features of the development of the feed industry. AGROINVESTOR magazine, January.

Pechenevsky, V. F., & Snegirev, O. I. (2020). The main conceptual directions of the formation and development of the agrarian structure in the Central Black Earth macro-region. Proceedings of the Voronezh State University of Engineering Technologies, 82(1), 283-290.

Rating of the largest producers of compound feeds in Russia according to the results of 2018. Retrieved from DairyNews.ru

Rising prices for raw materials negatively affects the investment plans of enterprises (2018). Retrieved from https://www.agroinvestor.ru/

Rosstat (2019). Agriculture in Russia 2019.

Shakhov, A. G., Cheremushkina, I. V., & Chernitskiy, A. E. (2016). Feed additive for increase of productivity and natural resistance of young agricultural animals. International Journal of Pharmacy and Technology, 8(4), 26876-26881.

Shentsova, E. S., Lytkina, L. I., Apalikhina, O. A., & Muravyov, A. S. (2016). The selection of rational parameters of the technological conditions of the mixing process upon receipt of feed briquettes. Bulletin of the Voronezh State University of Engineering Technologies, 3, 61 – 67.

Skopintseva, E. (2017). Domestic feed is not enough components. Economics and life, 15, 9681.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

01 February 2022

Article Doi

eBook ISBN

978-1-80296-123-2

Publisher

European Publisher

Volume

124

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-886

Subjects

Land economy, land planning, rural development, resource management, real estates, agricultural policies

Cite this article as:

Cheremushkina, I. V., Oseneva, О. V., & Apalihina, О. А. (2022). Prospects For The Innovative Development Of The Feed Industry. In D. S. Nardin, O. V. Stepanova, & E. V. Demchuk (Eds.), Land Economy and Rural Studies Essentials, vol 124. European Proceedings of Social and Behavioural Sciences (pp. 236-247). European Publisher. https://doi.org/10.15405/epsbs.2022.02.29