Abstract

In the article, the current methodology for minimizing the logistical costs of a trade and procurement enterprise in conditions of demand instability was developed. It was based on a reliable prediction of a real situation during the pandemic. A multi-product transport model was built which provided the possibility of interchangeability of goods. The optimization of the order quantity and delivery date for the merchandise group was carried out and suppliers were selected based on bulk discounts. The joint optimization of transport and warehouse costs was analyzed, the absolute values of orders were calculated and a delivery calendar was made up taking into consideration the reduction of risks of a shortage of goods in the warehouse by introducing the reserve stock value for each group of goods into the optimization model. Based on the results of the study, practical recommendations were given to the head of the trade and procurement enterprise on optimizing its functioning, on the procurement, transportation and storage of goods, which provided significant savings in financial flows without additional costs and investments. The management of the enterprise successfully tested the recommendations received. It led to a significant decrease in costs, to an increase of the competitiveness in the market, to an improvement of consumer service and to the increase of salary fund without reducing staff and additional loans.

Keywords: Logistics, cost minimization, optimization, predicting

Introduction

The past year has been a year of severe economic and geopolitical shocks for the whole world, the current year tends to maintain instability in the pandemic. In small and medium businesses, there is an urgent need to find additional opportunities to reduce costs, to reduce the cost value of products, to improve the quality of service of consumers, to reorganize and to restructure enterprises. In this situation, the successful solution of logistical issues can become a new vector of business development in general, increasing its efficiency and competitiveness as well. To this date, there are significant unused reserves for improving the efficiency of supply chains, for optimizing the level of the logistical costs of the enterprise. The relevance of developing the methodology for minimizing the logistical costs of trade and procurement enterprises is beyond doubt. It is necessary to optimize transport and procurement costs as well as formation and storage costs. Optimizing the costs and expenses of an enterprise is the search and implementation of a more effective way to manage finances. The expenses should be useful: an enterprise is profitable when each spent ruble leads to a minimal profit. The optimization of accompany costs will help increase profitability, avoid economic problems and save the enterprise in crisis.

Problem Statement

The research is aimed at developing the methodology for minimizing the logistical costs of a specific trade and procurement enterprise that trades specific goods in conditions of demand instability for a given product. The research also considers the issues of building a multi-product transport model, of optimizing the order quantity and delivery date, of making the right choice of suppliers of goods, of organizing a delivery calendar and of ensuring the effective functioning of the enterprise in the period of instability of the economic situation. It is necessary to identify the main components of logistical costs, optimize the order quantity and the delivery calendar, minimizing the risk of a shortage in the warehouse, taking into account random variations in the real demand for the goods. The following problem directions were stated:

- Prediction of variable purchasing demand for the group of goods of this enterprise in the conditions, of instability of the sales market.

- Minimization of transport costs of the enterprise, selection of suppliers, organization of a current delivery calendar.

- Optimization of warehouse costs for groups of goods, taking into account bulk discounts.

- Realization of joint optimization of transport and warehouse costs, specification of the value of the optimal quantity order and delivery calendar.

Research Questions

The following questions must be answered in the course of the research.

- How to minimize transportation and warehouse costs without additional investment?

- How to organize a purchase plan so that inventory level in the warehouse does not fall below the acceptable level while the total costs are minimum?

- How can the ratio of transport and warehouse costs affect the planning of the logistical activities of the enterprise?

Purpose of the Study

The purpose of the study is to develop an express methodology for optimizing the logistical costs of a trade enterprise, in particular, transport and procurement costs and inventory formation and storage costs in conditions of demand instability for goods.

Research Methods

The research was carried out on the basis of a trade and procurement enterprise located in Kurgan, which has a branch in Shadrinsk. It consisted of several stages. At the first stage, the demand for goods purchased by the enterprise was carefully studied and analyzed. At the second stage of the research ways to optimize transport costs were sought. To find a more efficient logistical solution, a multi-product model was built that took into account the features of balancing the task with the indication of banned routes. At the third stage, an inventory optimization calculation was made. A mathematical model of the economical quantity order for multi-product supplies was built, taking into account bulk discounts. At the final stage, a joint optimization of logistical costs (transport and warehouse) was carried out. Reserve stock was entered for all merchandise groups to minimize the probability of stock shortages in the warehouse due to prediction errors (Albekov et al., 2017; Montlevich & Borodinova, 2008; Sterligova; 2019).

Assessment of real demand for product and analysis of enterprise mode of operation

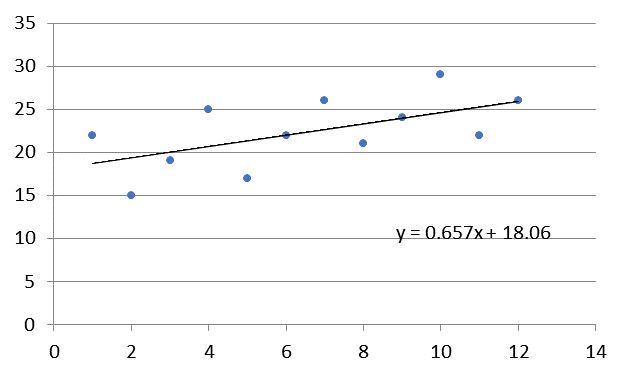

At the initial stage of the research, the demand for specific products purchased by the enterprise was carefully studied and analyzed. Since the prediction accuracy for the merchandise group is higher, a significant assortment of items requires the systematization of multi-product material flows and the grouping of multi-product stocks. The criteria for combining the goods into groups were the price of goods and functional characteristics. Goods of three categories are considered: independent goods, complimentary goods, substitutional goods. In order to make the prediction, based on the construction of the additive model of time series, the theoretical curve of purchases over the past period was calculated and its comparative analysis with real data on sales of goods was carried out. Thus, a reliable prediction of the demand for all groups of goods was made for the next period. At this stage, regression analysis, least squares method, and reliability of estimate of the resulting trend equation acted as research methods. For each group of goods, a different trend line was built, more often there was a linear dependence, in several cases there was a quadratic one. Figure 1 shows the theoretical dependence of sales of the first group of goods for 12 months of the previous year.

Thus, the increasing need for goods of this group is obvious, the regression coefficient is 0.6573, therefore, we leave this product for the next period. At the first stage of the research, only four of the five merchandise groups were left (Popov et al.; 2018; Trifuntov, 2018; Zaitsev, 2017).

5.2. Analysis of enterprise transport costs and optimization plan

The second stage of the research included the work on ways to optimize transport costs. To find a more efficient logistical solution, a multi-product model was built. It took into account the features of balancing the task with the indication of banned routes. The arguments in favor of combining different goods into one order are the following requirements

- supplier requirement for total value of each order, being not lower than limit value;

- implementation of full loading of used vehicles;

- limitation of quantity of goods shipment and its frequency to each customer;

- reduction of costs for organization, formation of schedule orders.

Let there be m points of production, n points of consumption, k types of product. We believe that each point produces (consumes) all types of products. We introduce vectors of production volume 𝑎𝑖=(𝑎𝑖1,𝑎𝑖2,…,𝑎𝑖m),consumption volume 𝑏𝑗=(𝑏𝑗1,𝑏𝑗2,…,𝑏𝑗n),cost of transportation of a unit of products from i point of production to j point of consumption 𝑐𝑖𝑗=(𝑐𝑖𝑗1,𝑐𝑖𝑗2,…,𝑐𝑖𝑗𝑘),and volume of transportation 𝑥𝑖𝑗=(𝑥𝑖𝑗1,𝑥𝑖𝑗2,…,𝑥𝑖𝑗𝑘). In the case of interchangeable goods, the need for one product can be met by some volume of other goods, we take this requirement into account in a separate matrix. As a result, solving the obtained transport problem of linear programming by classical methods, an optimal transportation plan for all groups of goods was revealed. In the course of solution, the following conclusions were made: one supplier was replaced, namely, a supplier from Yekaterinburg was included in the transportation plan, while deliveries from Tyumen were completely abandoned, which made it possible to transport the goods to the branch of the enterprise on the itinerary from Yekaterinburg to Kurgan. The optimization of such a plan has an economic effect within 18%, which is achieved only by changing the order plan and does not require additional costs (Kryanev, 2017; Kundysheva, 2020).

5.3. Joint optimization of enterprise transport and warehouse costs

At the last stages of the research, a calculation was made to optimize inventory in warehouses. A mathematical model of the economical order quantity for multi-product deliveries was built taking into account bulk discounts. The joint optimization of logistical costs (transport and warehouse) was carried out as well.

The company always carried out one delivery per month. It was about the same volume of goods, which led to low transport costs, but in turn increased the amount of inventory and, as a result, the cost of storage of goods. The total logistical costs were quite significant. To solve this problem, it was proposed to increase the number of deliveries per month. Based on the calculations, the most optimal number of deliveries is three. In this case, of course, transport costs increase, but warehouse costs decrease by several times, since it is not necessary to keep the goods in stock for a long time. The developed model of economical order quantity for the group of goods under study contains a delivery calendar. For deliveries of less volume you can do with vehicles of lower capacity. New order quantity has been obtained and an up-to-date delivery calendar has been drawn up, which reduces the risk of shortage of goods in the warehouse by introducing the reserve stock for each group of goods into the optimization model. Despite an increase of almost 1.5 times in transport costs, total costs (sum of transport and warehousing) decrease by about 33%. The economic impact on transport and ware house costs is shown in Table 1.

Based on the received results, recommendations were made to change the work of the enterprise in the procurement, transportation and storage of goods. This method of enterprise planning is optimal, leading to small savings, which is achieved only by changing the order and transportation plan without additional costs (Garmash, 2018; Parkhomenko et al., 2017).

Findings

As a result of the research, detailed recommendations were made to the management of the enterprise on changing the work plan, procurement, transportation and storage of goods, based on the theoretical provisions of the research and confirmed by practical calculations. The logistical costs of the trade and procurement enterprise were optimized based on the prediction of variable demand for goods. The current order quantity was obtained and a new delivery calendar was drawn up, allowing the enterprise to reduce the risk of a shortage of goods in the warehouse by introducing the reserve stock for each group of goods into the optimization model. The synergistic effect is 33%. This method of enterprise planning is relevant because it results in savings that are achieved only by changing the order and transportation plan without additional costs. It will significantly increase the competitiveness of the enterprise in the market and improve the level of service of consumers by timely meeting variable demand (Gavrilchik et al., 2020; Mikhashchenko et al., 2019).

Conclusion

The conducted research has allowed solving the following problems. An express methodology has been developed to optimize the logistical costs of a trade enterprise. In particular, transport and procurement costs and expenses for the formation and storage of stocks in conditions of instability of demand for the corresponding goods. A procurement plan has been organized, in which the goods are always in stock. The costs of transporting and storing the goods in stock are minimized and the logistical activities of the enterprise are clearly planned. The management of the enterprise has successfully tested the recommendations received, which has led to a significant reduction in costs, an increase in the level of service of consumers and in the wage fund without reduction of staff and additional loans.

References

Albekov, A., Romanova, T., Vovchenko, N., & Epifanova, T. (2017). Study of factors which facilitate increase of effectiveness of university education. The International Journal of Educational Management, 31(1), 12-20.

Garmash, А. N. (2018). Mathematical methods in control. NIC Infra-M.

Gavrilchik, M. V., Mikhaschenko, T. N., Safronov, V. V., & Sidorov, P. V. (2020). Mathematical and computer modeling of a planar mechanism with a certain number of links. IOP Conference Series: Materials Science and Engineering, 32083-32090.

Kryanev, А. V. (2017). Econometrics (advanced level). COURSE, NIC INFRA-M.

Kundysheva, Е. S. (2020). Mathematical methods and models in economics. Moscow: “Dashkov& K” Publishing and Trading Corporation.

Mikhashchenko, T. N., Gavrilchik, M. V., & Bogolyubov, D. A. (2019). The determination of the optimal profile line of stator arc in the double-acting wing pumps. IOP Conference Series: Materials Science and Engineering, 32061-32069.

Montlevich, V. М., & Borodinova, I. А. (2008). About some organizations of multi-product transport. Bulletin of Saratov State University. Humanitarian series, 86-93.

Parkhomenko, T. V., Bondarenko, V. A., Erokhina, T. B., & Guzenko, N. V. (2017). Marketing and logistic instrumentarium of activation of inter-country cooperation of Russia and solving the issue of import substitution. European Research Studies Journal, 20(1), 105-116.

Popov, P. V., Miretskiy, I. Yu., Ivut, R. B., & Khartovskiy, V. Е. (2018). Logistics: models and methods. INFRA-M.

Sterligova, А. N. (2019). Inventory management in supply chains. INFRA-M.

Trifuntov, А. I. (2018). Supply chain management. The higher school.

Zaitsev, М. G. (2017). Management and decision optimization methods: examples, tasks, cases. Publishing house Delo RANEPA.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Mikhashchenko, Т. N., Lupashko, S. G., Gavrilchik, М. V., Lukerianova, Е. А., & Korosteleva, S. М. (2021). Optimization Of Enterprise Logistical Costs In Conditions Of Instability. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 2342-2347). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.261