Abstract

The analysis of factors influencing the cost of logging is carried out. The modelling of the costs for the maintenance and operation of equipment in the context of three systems of machines: when using chainsaws on felling, delimbing and crosscutting; with the use of machine felling and delimbing with a chainsaw, as well as with the use of multi-operational complexes - harvesters and forwarders. An economic and mathematical model of the formation of costs for the maintenance and operation of equipment is presented, the total costs for timber harvesting are calculated. The dependence of the level of costs for timber harvesting on the average volume of the log and the distance of skidding was revealed, the construction of an economic and mathematical model was carried out using various harvesting technologies. The necessity of economic assessment and economic modelling of costs is substantiated, factors influencing the cost of production are established, which is important in the subsequent economic assessment of effective conditions for logging. The optimal technology of timber harvesting with a combination of factors influencing the efficiency of timber harvesting has been revealed.

Keywords: Economic assessment, efficiency, logging, economic and mathematical model

Introduction

The profit of an enterprise shows its success in the market. However, this indicator does not give an unambiguous assessment, since with a decrease in sales volume, it is necessary to find out the reason. To do this, an assessment of efficiency is carried out, this allows you to determine ways to improve performance and identify which processes can slow down the development of the enterprise.

In the context of the global economic crisis caused by the pandemic, the problem of minimizing costs and increasing the efficiency of using fixed assets is becoming one of the main issues for enterprises in all industries. This problem is especially acute for logging enterprises, the profitability of production of which, even in a stable economy, is low.

To date, the global demand for roundwood and sawn timber has fallen sharply, which has led to a decrease in the price of logging products. This presented the logging enterprises with a choice: either to stop their activities, or to look for reserves to reduce costs and increase the economic efficiency of the enterprise. One of the main such reserves is the optimization of the use of fixed assets of the enterprise, which include machinery and equipment for logging (Bespalova et al., 2018).

Thus, loggers face the problem of choosing between three harvesting technologies (whip, assortment and mixed), as well as numerous brands and models of equipment. Which equipment to choose for a particular harvesting technology, different natural and climatic conditions, in order to avoid downtime?

The answer to this question will solve the problem of assessing the economic feasibility of acquiring one or another equipment, will allow timber industry to avoid mistakes in the choice of equipment, and, therefore, minimize or eliminate the risk of losses due to its underutilization or breakdowns.

The choice of the harvesting method and the corresponding system of machines depends on various factors, including the natural production conditions, the qualifications of the personnel, the level of labor organization, environmental protection requirements, but to a decisive extent - on the productivity of the machine systems and the level of production costs. As a rule, the use of mechanized harvesting technology gives high output, but requires large capital costs (Posmetev & Nikonov, 2020; Tikhomirov & Bykovskiy, 2019).

Among the natural production factors influencing the choice of the logging method and the system of logging machines, it should be noted the seasonality of logging operations, the distance of skidding, the operational characteristics of the logging areas and soil and soil conditions. In particular, the operational characteristics of felling areas include the species and age composition of cut plantations, commercial timber yield, timber stock per hectare, average log volume and average cutting area (Bezpalko, 2018; Tikhomirov & Bykovskiy, 2019).

Therefore, the calculation of the costs of operating forestry equipment, taking into account the influence of various factors, is one of the key elements of the methods for comparing the efficiency of use, different harvesting technologies and machine systems.

The development of a simple and understandable, covering all technical, economic and natural and climatic factors, methods for assessing the costs of operating machines and determining economic efficiency, will allow forest users to determine the choice of exactly the set of equipment that will most fully satisfy their needs and requirements. This, in turn, will allow to reduce costs and achieve a higher level of profitability of logging activities, which is currently a priority for the forest industry.

Problem Statement

Russia contains over a quarter of the world's timber resources. The total timber stock in Russia is 82 billion m3. In addition to the fact that the forest performs important environmental functions, it is also a source of raw materials. This explains the significant role of the timber industry in the country's economy (Maslodudov, 2018).

The volume of harvested wood in Russia in 2019 amounted to 218.5 million m3, which is less than in 2018 by 20 million m3. This is due to the surplus of raw materials on the market, as well as weather conditions, as a result of which logging enterprises were forced to reduce the volume of wood raw materials. The Strategy for the Development of the Timber Industry until 2030 was also approved, which, in turn, had an impact on the timber industry in Russia (Order of the Government of the Russian Federation No. 312-r, 2021).

In 2020, there were changes in the export of timber, the requirements for phytosanitary control were tightened, and there were restrictions on the supply of wood raw materials from Russia.

In the context of the pandemic, there was a decrease in demand and a decrease in prices, which affected the decrease in the efficiency conditions. Therefore, these changes make it necessary to optimize the costs of timber harvesting by constructing an economic and mathematical model that makes it possible to conduct an economic assessment of the effective conditions of timber harvesting, depending on the selected technology.

Research Questions

In the course of constructing an economic and mathematical model for the formation of costs and determining effective conditions for logging, it is necessary to solve the following problems:

- Identify and analyze the factors that determine the efficiency of logging;

- Build an economic and mathematical model of the formation of costs for the maintenance and operation of equipment to calculate the total costs of timber harvesting.

On the basis of the research carried out, to reveal the dependence of the level of costs for timber harvesting on the average volume of the log and the distance of skidding, to build an economic and mathematical model.

Purpose of the Study

The purpose of the study is to develop an economic and mathematical model, covering the formation of costs and the determination of effective conditions for logging, including all technical, economic and natural and climatic factors, methods for assessing the cost of operating machines and determining economic efficiency.

Research Methods

Justification for the choice of timber harvesting technology

To date, the choice of the logging technology that is most acceptable for the conditions of Russia is an important task, since logging enterprises, planning the economic efficiency of timber harvesting, consider the criteria "result - costs" as the main criterion, focusing on minimizing the cost part, which affects profits as the basis of efficiency. Depending on the type of timber removed from the forest and its skidding, three technologies are mainly used in logging (Bezpalko, 2018):

- mechanized (timber harvesting and skidding);

- machine (harvesting and skidding of whips);

- assortment (harvesting and skidding of assortments).

In general, the logging technology includes: a complex of logging operations, logging (at the intermediate logging site, upper warehouse), transportation of timber (Pozdnyakova et al., 2019).

The work performed calculations for three systems of machines (Table 1).

Reducing timber stocks in industrialized areas and the presence of difficulties in the development of wild forests in new sparsely populated areas that do not have wide road networks and a system of processing enterprises, as well as an increase in public attention to the environmental consequences of forest development leads to the need to revise forest policy in the direction of increasing the volume of selective cuttings and thinnings of forest maintenance. In this regard, there is growing interest in the assortment technology of logging, which allows the most efficient mechanization of these types of felling, taking into account modern environmental requirements.

Analysis of factors affecting the cost of logging products

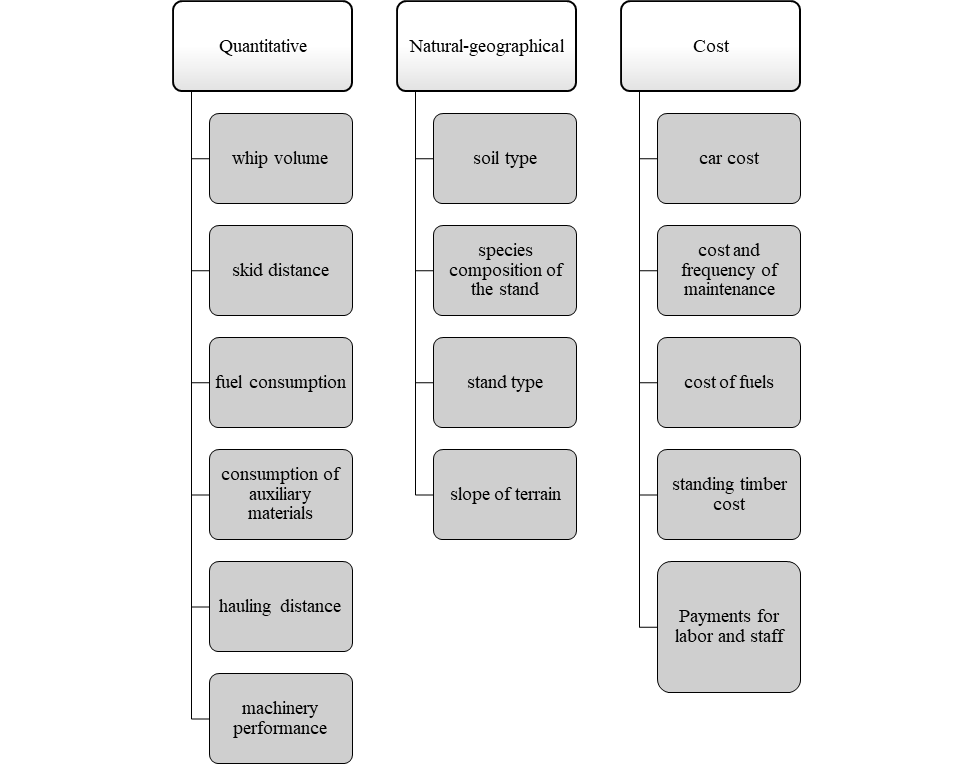

Factors and indicators affecting the final amount of production costs can be divided into 3 groups: quantitative, natural-geographical and cost (Figure 1). This list of factors is not exhaustive. In the course of the analysis, two factors were identified that directly or indirectly affect all the variables of the developed economic and mathematical model: the average volume of the whip and the distance of skidding.

The costs included in the economic and mathematical model include all the costs of maintaining and maintaining equipment. These include: depreciation of machinery and equipment; fuels and lubricants; on-site equipment maintenance; carrying out maintenance; the cost of purchasing spare parts, auxiliary and consumables; remuneration of the main workers. Thus, all of the above cost items change under the influence of such factors as the volume of the whip and the distance of the skid (Mohirev et al., 2019).

The average log volume affects the shift performance of machines and mechanisms at all logging operations. The higher the volume of the log of the cut trees, the higher the shift capacity, expressed in cubic meters. Thus, for the same amount of time, the same mechanism with different volumes of the tree-length can be used to harvest a different amount of m3 of wood. It follows from this that the amount of depreciation charged on a machine or mechanism will be transferred to a different amount of m3 of finished products, therefore, the larger the average volume of the whip, the lower the specific depreciation deductions.

Modeling the costs of maintaining and operating machines and mechanisms

The criterion for choosing the optimal system of logging equipment for enterprises (from an economic point of view) is, as a rule, the lowest costs for its acquisition and maintenance with high productivity (Ryabukhin, 2018). The economic benefits of loggers can be expressed as follows:

Иfix+ Иvar+ Кspmin

where: Иfix – fixed costs in the cost of maintaining and operating equipment; Иvar– variable costs in the cost of maintaining and operating equipment; Кsp– specific capital investments.

In the study, the rates of consumption of material resources, labor standards and standards were used to calculate the unit operating costs for various types of machinery and equipment during clear felling, depending on the change in the average volume of the tree-length and the distance of skidding (Figure 2).

The condition for a correct comparison was the uniformity of the manufactured products - assortments, 4 and 6 m long. The basic cost value was taken as the cost of harvesting 1 m3 of timber with a minimum log volume (up to 0.29 m3) and a minimum average skidding distance (up to 150 m).

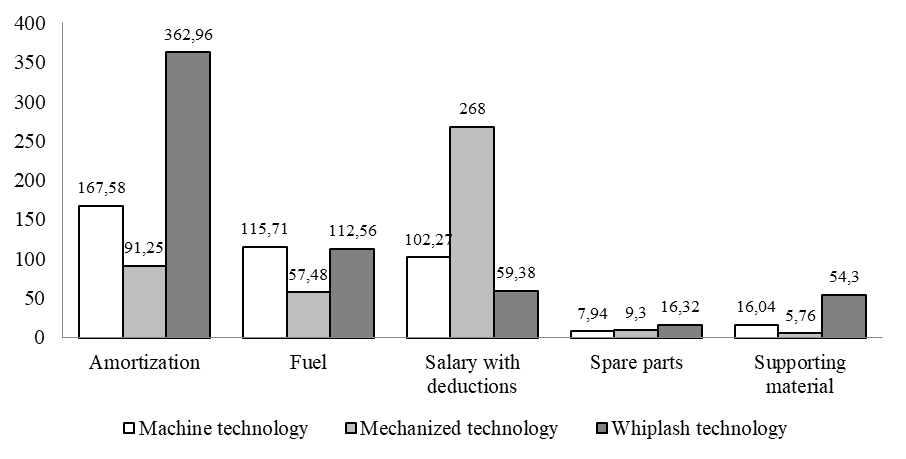

Timber harvesting is more expensive in terms of depreciation due to the high cost of timber harvesting machines. For the mechanized technology of timber harvesting, high values are noted under the item “wages” due to the presence of manual labor. Tables 2 and 3 show the calculation of the cost of harvesting 1 m3 of wood with different volumes of the tree-length and the distance of skidding.

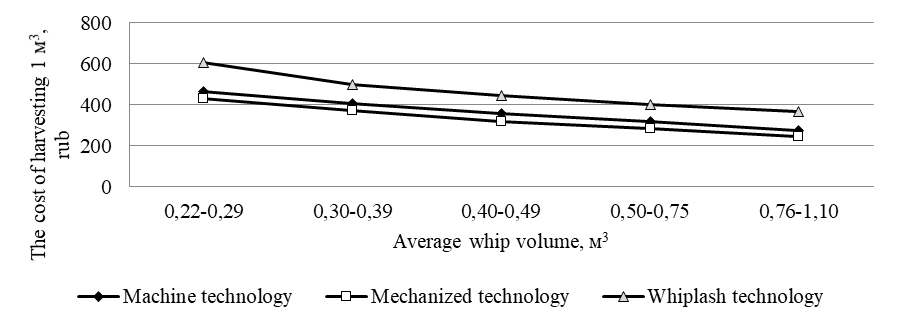

Based on the schedule of unit costs for the production of 1m3 of wood, it can be concluded that, under the accepted conditions, the use of mechanized technology is preferable based on the criterion of minimizing costs (Figure 3).

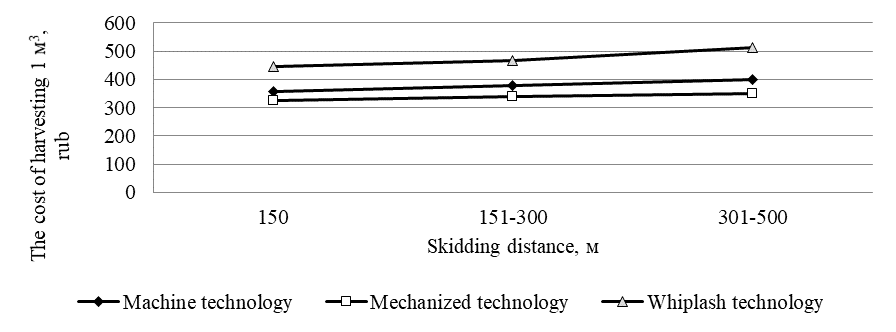

With an increase in the skidding distance, the unit costs for three sets of machines increase. With an average log volume of 0.40-0.49 m3, the costs for using domestic and imported machines differ, and mechanized timber harvesting technology is also preferable (Figure 4).

Findings

With an increase in the volume of the whip, a decrease in the cost of harvesting 1 m3 of wood is observed within the limits of the invariability of such a factor as the distance of skidding. At the same time, with a change in the skidding distance, an increase in the cost of harvesting 1 m3 of timber is observed, while the factor "log volume" remains unchanged.

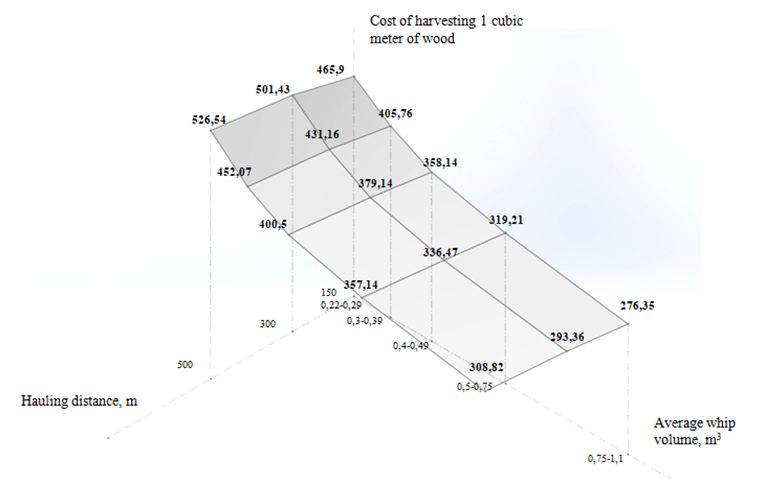

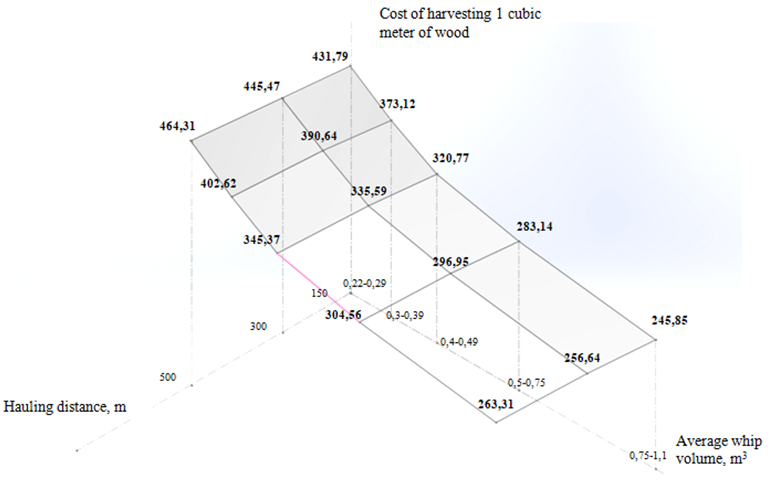

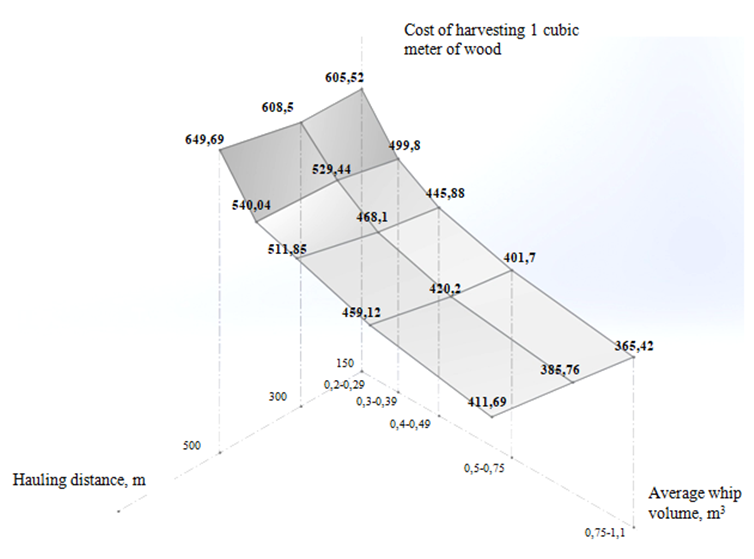

To determine the dependence of the cost level on the above factors, the graphs of the dependence were plotted in the context of the analysed logging technologies - machine, mechanized and assortment (Figures 5-7).

The resulting graphs make it possible to determine and predict the level of costs for timber harvesting with a combination of the identified factors (the volume of the log and the distance of skidding).

Analysing the visualized research results, we can say that the graphs clearly demonstrate a decrease in the cost of harvesting 1m3 of wood. The highest value of costs for all technologies is noted under the condition of timber harvesting with a volume of 0.2-0.29 m3 with a skidding distance of more than 500 km. The smallest results are provided on the condition of harvesting whips with a volume of 0.75-1.1 m3 at a skidding distance of 150 m.

Comparing the results obtained, we can conclude that the optimal technology of timber harvesting with a combination of factors affecting the efficiency of timber harvesting is mechanized timber harvesting technology. This is due to the low level of maintenance costs of the mechanisms.

The results of the study are applicable to the implementation of forestry enterprises in the activities of enterprises to determine the level of procurement costs and identify the most promising and suitable options for orders. The results obtained also allow us to plan the prices for timber sales and predict the expected profit.

Conclusion

One of the main directions of increasing the efficiency of logging production is to reduce operating costs, as well as to use it as efficiently as possible, which is possible with the correct selection of machinery and equipment.

The level of costs for the maintenance and operation of machines and mechanisms determines the economic efficiency of logging production as a whole. These costs account for about 30% of the cost of one harvested cubic meter of wood.

To calculate the costs of maintaining and operating the equipment, an economic and mathematical model was compiled, taking into account the influence of the main factors on the level of costs for cutting operations - the average volume of the log and the distance of skidding.

It has been used to calculate costs for three machine systems:

- using machine technology of workpieces;

- using mechanized procurement technology;

- using cut-to-length procurement technology.

Also, for each calculation, an illustration of the dependence of costs on the factors that determine their level is presented.

In the process of cost modelling, it was concluded that the use of imported equipment is highly costly, although it is characterized by maximum productivity. Under the accepted conditions, the use of mechanized technology is preferable based on the criterion of minimizing costs. With an increase in the skidding distance, the unit costs for three sets of machines increase.

Comparing the results obtained, we can conclude that the optimal technology of timber harvesting with a combination of factors affecting the efficiency of timber harvesting is mechanized timber harvesting technology. This is due to the low level of maintenance costs of the mechanisms.

The results of the study are applicable to the implementation of forestry enterprises in the activities of enterprises to determine the level of procurement costs and identify the most promising and suitable options for orders. The results obtained also allow us to plan the prices for timber sales and predict the expected profit.

References

Bespalova, V. V., Polyanskaya, O. A., & Sokolova, V. A. (2018). The assessment of forest resources is one of the economic problems of Russia. Problems of socio-economic development of Siberia, 1(31), 9-16.

Bezpalko, A. R. (2018). Factors affecting the efficiency of logging enterprises. Effective economic management: problems and prospects. «ARIAL», 172-176.

Maslodudov, D. A. (2018). New projects and management approaches will be an impetus for the development of the forest industry of the Krasnoyarsk Territory of the Siberian Forestry Complex, 1(5), 8-12.

Mohirev, A. P., Davydenko, A. N., & Medvedev, S. O. (2019). Determination of the impact of the average crop volume and wood stock on the direct costs of logging. Forest and chemical complexes-problems and solutions, 481-484.

Order of the Government of the Russian Federation of February 11, 2021, №312-р. (2021). Strategy for the development of the forest complex of the Russian Federation until 2030. http://static.government.ru/media/files/pFdqtWFH8y9SfQjDE0Xnwd8eXWoJJMYB

Posmetev, V. I., & Nikonov, V. O. (2020). Analysis of the effectiveness of technologies for harvesting and exporting timber used in the modern conditions of Russia's development. Voronezh Scientific and Technical Bulletin, 3(33), 36-56. DOI:

Pozdnyakova, M. O., Mohirev, A. P., & Medvedev, S. O. (2019). Factor analysis of the economic efficiency of enterprises of the timber industry. Basic research, 5, 94-98.

Ryabukhin, P. B. (2018). Economic and mathematical modelling of the evaluation of the efficiency of the enterprises of the timber industry. The system. Methods. Technologies, 4(48), 139-144. DOI:

Tikhomirov, E. A., & Bykovskiy, M. A. (2019). Approaches to the formation of the cost of logging. View of young researchers: forest complex, economy and management, 497-502.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Voronina, E. A., Ivanova, T. O., Moiseeva, E. E., Rubinskaya, A. V., & Shishmareva, A. V. (2021). Economic Assessment Of Effective Logging Conditions. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 2225-2235). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.249