Abstract

Timely assessment of all components of the production potential of the enterprise allows to identify not only those problems that at this particular moment impede the achievement of maximum efficiency of the enterprise, but also those that may arise in the near and medium term, to choose the right tools to neutralize these threats and ensure, thereby, a reliable prospect for the sustainable development of an economic entity. The paper provides an assessment of the production potential of a furniture industry enterprise in the Krasnoyarsk Territory using the method of A. Gorina, which includes an assessment of individual elements of production potential, namely: fixed assets, working capital and labor resources, then a general assessment of production potential is performed. The dominant position in the structure of production potential is occupied by labor resources, and this is a historically established pattern that does not lose its relevance in the modern world. The knowledge, skills and abilities possessed by employees determine the volume and quality of the goods produced. An important factor is the fact that the analysed elements of production potential are interconnected. Based on this fact, it can be said that the measures proposed to increase the level of use of one of the elements of production potential will, to a greater or lesser extent, affect the other elements, which will have a positive effect on the efficiency of the entire enterprise.

Keywords: Production potential, timber industry, furniture industry

Introduction

In modern conditions of a market economy, each enterprise faces the task of choosing ways to ensure financial stability and competitiveness in the market in its segment, because the market can rightfully be considered a self-organizing system, in which there is only a place for those players who are able to withstand the pressure of competition and many different factors. influencing the development of the market. These issues are especially relevant for enterprises, whose competitive environment, by definition, is multi-subject, and the volume of supply for potential consumers often exceeds demand. These include furniture manufacturers (Antonova & Alhmadeeva, 2014).

The main reason for this state of affairs lies, in our opinion, in excessive concentration on the issues of neutralizing the negative impact of external factors and the formation of consumer loyalty, to the detriment of research and optimization of enterprise processes. There is certainly such interest, but most often it concentrates on certain aspects - personnel motivation, technical support of production, etc. (Kononenko, 2017).

By identifying and point-by-point solving problematic issues, it is possible to achieve only a temporary solution to them. To achieve a long-term positive effect, it is necessary to approach the issue of improving the internal environment of the enterprise in an integrated manner - through a comprehensive assessment of the production potential (Shnayder & Fedulova, 2017). Enterprise development trends depend on the mobilization of the main elements of production potential, namely production management resources and organization of the production process. Production potential is the basis for the development of an enterprise, and increasing the efficiency of its use and increasing it is one of the main tools for increasing the efficiency of activities and competitiveness.

Problem Statement

To determine the key areas for the development of the enterprise, it is necessary to be guided by the priorities aimed at solving the main problems while maximizing the benefits. Based on the analysis of the experience of industrialized countries, it can be said that enterprises that maintain a high level of production potential are the most stable in conditions of instability in the external environment by obtaining timely information about the state of the production system and prompt response to ongoing changes.

The effective functioning of an industrial enterprise consists of many factors, but the resources of the enterprise were and remain the key ones. Knowledge of the level of production potential makes it possible to make timely and economically viable decisions in the management of production and the enterprise as a whole, affecting its current and future state.

A qualitative and detailed analysis of the production potential allows you to form a complete picture of the state of the research object, which in the future will allow the management to influence not only the final results of the enterprise, but also to determine the directions of economic growth and structural development of the entire enterprise as a whole.

Research Questions

In the course of assessing the production potential of a furniture industry enterprise, it is necessary to solve the following tasks:

- Analyze theoretical and methodological approaches to assessing the production potential of an enterprise;

- Determine the structure of the manufacturing enterprise of the furniture industry;

- Assess the elements of the production potential of the research object;

- Develop recommendations for increasing the indicators of the use of the production potential of the enterprise.

Purpose of the Study

The purpose of the study is to assess the production potential of a furniture industry enterprise, as well as to identify problem areas of the research object in order to develop recommendations for increasing the rate of using the production potential of the enterprise.

Research Methods

Theoretical and methodological approaches to the analysis of the production potential of an enterprise

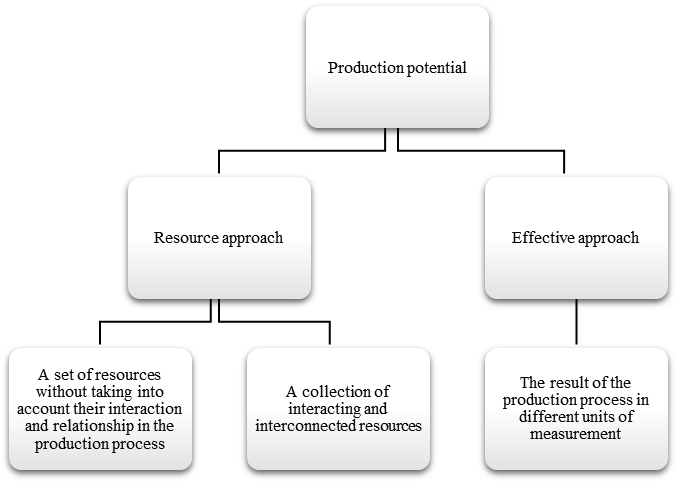

Currently, in economic science there is no single, generally accepted definition of the concept of "production potential", however, there are two main approaches to considering its essence, which are displayed in Figure 1.

The resource-based approach is the most popular and widespread among economists, which is most likely due to the breadth of the spectrum of resources used in the production of material goods, which makes it possible to find an opportunity to assess the potential of an enterprise from different angles, using each of the types of resources as a criterion and evaluation parameter. There are two directions within the resource approach. According to the first approach, the production potential is a generalized characteristic of all available resources separately, the summation of which ultimately gives an economic result (Azovskaya & Syardova, 2016). Within the framework of the second direction, not only the volumes of resources are taken into account, but also their technical level, quality, structure. It is the interrelationships between different resources that lead to the achievement of an economic result in the form of a certain amount of material goods (goods, services) produced (Ivanova, 2015; Ivanova & Zorina, 2016).

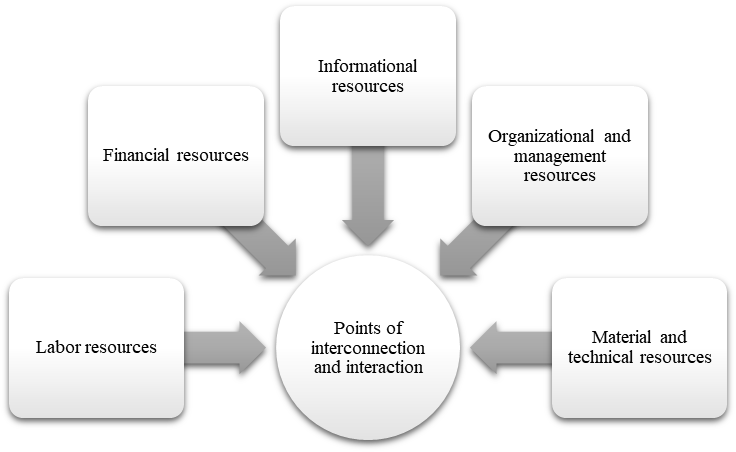

The production potential of an enterprise is not just a set of interrelated material, technical, labor, organizational and managerial resources, but a set that corresponds to the current state of scientific and technological progress in this particular area of production (Borodkina et al., 2015). In the modern information society, science has ceased to perform an accompanying function in relation to production, it itself has become a direct productive force, labor has been intellectualized, and in this regard, it is necessary to include information resources in the structure of production potential (Kifa & Kryuchkova, 2016; Lashmanova, 2017). As a result, the totality of all resources that make up the production potential of a modern enterprise is shown in Figure 2.

In the theory of determining the value of production potential, there is currently no unity in view of the wide variety of approaches to assessment, as well as the diversity of the specifics of the scope of activities of industrial enterprises (Plakitkin et al., 2021). Table 1 shows the main approaches to assessing the production potential of an industrial enterprise. Thus, the most reliable and suitable for calculations in accordance with the set goal and objectives of the study are the methods for the valuation of production potential.

To assess the production potential of a furniture enterprise, it was necessary to select a methodological toolkit that allows you to demonstrate not just a general picture of the state of the production potential of the studied enterprise, but specific data for each of the elements.

The main provisions of the assessment of the production potential of the enterprise according to the method of A.A. Gorina

In order to comply with the principle of objectivity and for maximum data accuracy, it was decided to use Gorina (2016). Gorina (leading researcher at the National Research Mordovian State University named after N.P. Ogarev).

The assessment is based on a system of indicators covering all elements of production potential. The application of the methodology makes it possible to identify the existing problems and shortcomings that have arisen in the process of realizing the potential of the enterprise, and to make a managerial decision on the development of production potential.

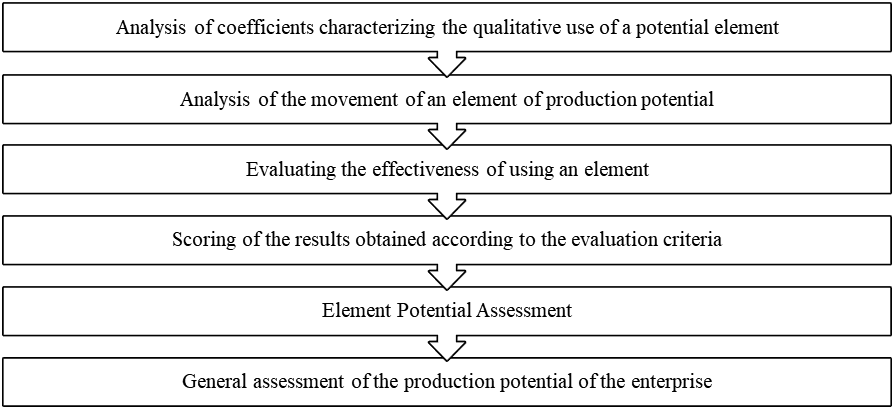

Gorina (2016) consists of the following items for assessing the elements of production potential: assessment of fixed assets; assessment of working capital; assessment of labor resources. The assessment of the elements of production potential is carried out according to the algorithm presented in Figure 3.

When assessing the production potential of the element "Fixed production assets" at the stage of assessing the indicators characterizing the high-quality use of the element, the wear and tear rates of fixed production assets are calculated. The movement of the item "Fixed Production Assets" is analysed by calculating the renewal and retirement rates. To assess the efficiency of using the element, the main indicators are adopted that characterize the efficiency of using the basic production assets of the enterprise.

Assessment of the potential of the element "Working capital" includes an analysis of the coefficients of the value of the working capital of the enterprise, the availability of material resources (actual and planned). To assess the effectiveness of the use of the element, the main indicators are adopted that characterize the efficiency of using the working capital of the enterprise.

When assessing the potential of the element "Labor resources", coefficients are calculated that characterize the movement of personnel, as well as the change in average earnings at the enterprise.

For each element of the assessment of production potential, criteria are provided that determine the ranking of the indicator by a five-point system.

Assessment of the elements of production potential by the method of A.A. Gorina on the example of an operating enterprise of the furniture industry

The object of research in this article is an operating enterprise of the furniture industry in Krasnoyarsk. To comply with the logic of calculations according to the methodology, we will conduct a sequential assessment of each of the elements of production potential according to the methodology of A.A. Gorina (Tables 2-4). The calculation is carried out for the period from 2018 to 2020 in order to analyse the dynamics of changes in indicators that form the production potential of the enterprise.

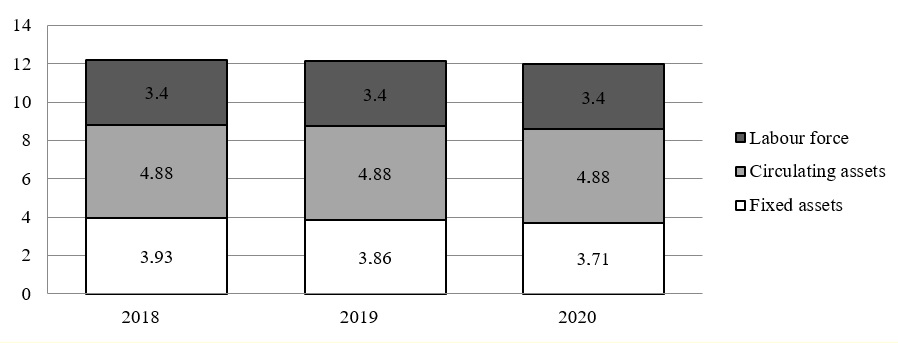

The constituent elements of fixed assets were ineffectively exploited by the enterprise. The average assessment of potential for 3 years does not exceed 3.93 points. There is a negative dynamics of the indicator of using the potential of the element under study (from 3.93 points to 3.71). The decrease in the indicator is due to the high depreciation of fixed assets with their slow renewal. The ineffective use of the available production space should also be noted.

The next step in the assessment of production potential is the assessment of the element "Working capital". The average assessment of working capital was 4.88 points, which is a very high indicator of the use of the potential of this element, but it is worth noting that the working capital turnover ratio tends to decrease.

Next, let's move on to assessing the potential of the third element of the production potential of the enterprise "Labor resources". The overall assessment of the use of the potential of this element is at the level of 3.4 points.

Analysis of the data in the Table 4 shows that in 2019, production increased, compared to 2018, by 34 thousand rubles, and in 2019 it decreased again and showed a result lower than 2018 by 8 thousand rubles. or 2%. The average annual earnings of employees increased slightly, also by 2%. The decrease in the growth of labor productivity during the study period deserves special attention of the enterprise management; this negative trend is enhanced by the growth of average annual wages. The positive factor is the low staff turnover at the enterprise and the growth of wages.

Findings

The final stage of assessing the production potential of the enterprise is a general assessment of the production potential - Table 5. For the study period from 2018 to 2020. indicators characterizing the production potential of the enterprise, subject to assessment by the method of Gorina (2016), received a little over 4 points.

The lowest indicators of potential use are noted for the element "Fixed production assets" and "Labor resources". There are no significant fluctuations in the indicators of the efficiency of using production potential. The calculation results are presented more clearly in the form of Figure 4.

Thus, we can say that the production potential of the enterprise is not fully realized, which allows us to talk about the existing reserves of its effective use.

Conclusion

The purpose of assessing the use of the production potential of the enterprise is to identify bottlenecks and develop recommendations for increasing the level of use of the production potential of the enterprise. When analyzing the elements of the production potential of the enterprise, it was revealed that an insufficiently high level of use of production potential occurs due to the ineffective use of existing fixed assets, as well as insufficient elaboration of the personnel policy of the enterprise.

In order to reduce the negative impact of the identified factors, the following measures are proposed in the context of the elements of production potential:

Element "Fixed production assets":

- A high rate of wear of fixed assets and a low coefficient of serviceability of fixed assets - to update the equipment park, introduce periodic maintenance and current repairs of equipment.

- Low utilization rate of production area - it is recommended to analyze the current production processes, identify a reserve of unused usable space for rent or for the acquisition of new production lines in order to expand the range of products.

These proposals will have a positive impact on the rates of retirement and renewal of fixed assets, as well as on the indicators of the efficiency of their use.

The item "Working capital" has the highest score. The proportion of material costs is quite high, but with a decrease in the share of fixed costs in the structure of the cost of manufactured products due to economies of scale, this indicator can be increased.

For the element "Labor resources", two problems are noted - indicators of changes in the average earnings of workers and changes in average annual output. The positive dynamics of these indicators is possible in combination with measures aimed at increasing the use of the potential of the element "Fixed production assets".

Thus, a detailed analysis of the production potential of a furniture enterprise made it possible to identify unused reserves for increasing the efficiency of the enterprise.

References

Antonova, I. I., & Alhmadeeva, G. Ch. (2014). Development of the personnel management system in the context of the introduction of the lean production methodology. Baltic Humanitarian Journal, 2(7), 51-53.

Azovskaya, O. N., & Syardova, O. M. (2016). Methodology for evaluating the efficiency of the functioning of the production processes of the enterprise. Azimuth of scientific research: economics and management, 2(15), 14-16.

Borodkina, V. V., Ryzhkova, O. V., & Ulas, Yu. V. (2015). Production potential of the Northern territories of the Krasnoyarsk Territory: problems and opportunities for development. Russian entrepreneurship, 22, 4053-4074.

Gorina, A. A. (2016). Assessment of the production potential of the enterprise. Economic research and development, 5, 70-83.

Ivanova, T. N., & Zorina, K. H. (2016). Changes in the practice of personnel management in modern organizations. Karelian Scientific Journal, 3(16), 125-128.

Ivanova, T. N. (2015). The system of principles of the modern social and labor space. Azimuth of scientific research: pedagogy and psychology, 2(11), 137-140.

Kanapukhin, P. A., & Maslennikov, O. V. (2012). Production potential in a market economy: the essence, structure and properties. Modern economy: problems and solutions, 7(31), 9-13.

Kifa, L. L., & Kryuchkova, I. V. (2016). On the issue of trends in personnel development. Azimuth of scientific research: economics and management, 4(17), 175-177.

Kononenko, K. G. (2017). Ways to improve the efficiency of using the labor potential of the enterprise. Young science, 4, 69-70.

Lashmanova, Yu. Yu. (2017). The system of indicators for evaluating the production unit of the production potential of the enterprise. Russian entrepreneurship, 7, 1105-1126.

Plakitkin, Yu. A., Plakitkina, L. S., & Dyuchenko, K. A. (2021). Assessment of the production potential of domestic machine-building enterprises for the implementation of the import substitution program in the coal industry. «Coal» Journal, 1, 126-134.

Shnayder, O. V., & Fedulova, N. N. (2017). The main ways to improve the efficiency of using the production potential of the enterprise. https://cyberleninka.ru/article/n/osnovnye-puti-povysheniya-effektivnosti-ispolzovaniya-proizvodstvennogo-potentsiala-predpriyatiya

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Moiseeva, E. E., Rubinskaya, A. V., & Shishmareva, A. V. (2021). Assessment Of The Prodaction Potentional Of The Furniture Industry Enterprise. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 2215-2224). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.248