Abstract

With the increasingly fierce market competition, the manufacturing industry has realized the importance of modern digitization, and has spent huge sums of money to strengthen enterprise informatization, hoping to go further on the basis of the original technology and digital service level. Based on some of the current problems in the manufacturing industry, this paper mainly proposes mobile digital solutions. At the same time it clarifies the advantages of mobile digital solutions to develop the potential of manufacturing company. In the current environment of economic globalization and the booming of mobile information technology, companies in various industries are actively responding to the drastically changing business environment and the challenges faced in economic development, and the manufacturing industry is no exception. This article analyzes a series of problems encountered by manufacturing companies on the road of digital development, puts forward some relatively feasible measures, and demonstrates the overall mobile digital solutions of mobile information technology in the manufacturing industry and the significance of its implementation.

Keywords: Mobile informatization, digital solutions, manufacturing, development potential

Introduction

With the rapid development of information technology, mobile digital solution has played an increasingly important role in modern people's lives and manufacturing. It can improve the efficiency of the enterprise, and make the enterprise tend to be digital and mobile. In the information age today, it is more related to the survival of the enterprise (Jiyi et al., 2015; Okazaki, 2006; Okaxaki & Roinero, 2010). Mobile digital solutions have been widely used in the fields of finance, medical treatment, telecommunications, e-commerce, etc. The applications in the manufacturing industry are also emerging and becoming more widespread (Dong & Wu, 2017; Li & Guangming, 2014; Zhenyu et al., 2016).

The problems encountered in the development of the manufacturing industry are broad and specific: obtaining orders - the entire process of distributing goods takes a long time and is inefficient; errors occur at the superior level, and good sales opportunities are most likely to be missed. This article analyzes some of the problems encountered in the digital construction of manufacturing enterprises: production and marketing, office management, customer service, and on-site management, and proposes mobile digital solutions, in order to improve the development potential of manufacturing enterprises.

Problem Statement

In the current environment of economic globalization and the booming of mobile information technology, companies in various industries are actively responding to the drastically changing business environment and the challenges faced in economic development, and the manufacturing industry is no exception.

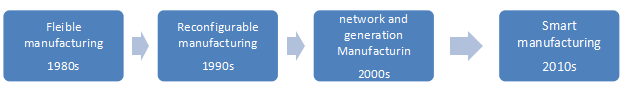

Figure 1 shows the history of the manufacturing revolution.

In the development of the manufacturing industry, information technology plays a very important role, especially in terms of efficiency and productivity. Changes in information technology have penetrated into all aspects of manufacturing. It has transformed the traditional industrial model and moved towards intelligent manufacturing (Qu, 2013).

In 2015, the Chinese government formulated the “Internet +” action plan to promote the integration of mobile Internet, cloud computing, big data, and the Internet of Things with modern manufacturing to promote the generation of new business models including modern manufacturing and innovative manufacturing (Moote, 2007).

Information technology has created opportunities for the development of new digital services. Since 1997, China's Huawei has been cooperating with Russia. In the future years, Huawei will help Russian operators launch 5G networks in Russia. In 2018, the President of the Russian Federation established the national and strategic goals for the development of the Russian Federation by 2024. The main goal is to implement groundbreaking scientific, information technology and socio-economic development in the Russian Federation (Mrngyuan, 2020). The government of the Russian Federation has set a number of goals for the "Russian Federation Digital Economy" national plan. It is expected that the introduction of 5G networks will simplify the implementation of information and communication technologies in traditional industries and the national economy.

This will promote the development of mobile information solutions in Russia.

Japan publishes the "Manufacturing White Paper" every year, sorting out the current situation of the manufacturing industry that year, and summarizing the future development direction. The 2015 "Manufacturing White Paper" pointed out that Japan needs to actively use information technology and use big data to promote the upgrading and transformation of the manufacturing industry. It requires further promotion of the integration of manufacturing and informatization, and the degree of digitization of the manufacturing industry will be increased from 30% to more than 50%.

The United States proposes to build a manufacturing innovation network and vigorously promote the research and development and innovation of production technology. From August 2012 to February 2015, a total of 5 information network technology innovation institutes, such as the "Advanced Composite Materials Innovation Institute", were established. The United States also promulgated the "Manufacturing Promotion Act" to protect the competitiveness of the manufacturing industry.

It can be seen that manufacturing informatization and mobile digitization play a very important role in the industry 4.0. There are many theoretical and practical problems in the application of mobile information technology in the manufacturing industry. The application of mobile digital solutions in manufacturing enterprises has not been fully studied. This article mainly introduces 4 types of mobile digital solutions in China: production and marketing, mobile office, customer service, and on-site management.

Problems in production and operation: Improper placement or even loss of production equipment is an important problem for manufacturing company in terms of production and operation. In addition, market research is time-consuming and costly. The traditional ordering mode consumes a long time and low efficiency is also a common problem in manufacturing enterprises.

Problems in mobile office: The management and sales staff of manufacturing company cannot log in to the system in time, which affects the production and operation of the company. In addition, the company's sales staff missed important meetings due to going out, which is also an important issue that needs to be resolved.

Corporate customer service issues: How to improve the corporate image is a problem that manufacturing company has been thinking about; the easy confusion of customer service numbers is also one of the problems that have plagued manufacturing company for a long time.

Problems in site management: At present, for manufacturing company, production efficiency is still the focus of attention, and insufficient attention is paid to the use of production resources, resulting in waste of various resources, such as excessive finished products, waste of working hours, repeated handling, waste of material storage, etc. However, the on-site production process is relatively non-standard, which makes the on-site production workers produce according to their own experience during the work process, which causes confusion in the production order and difficulty in management.

The application of mobile digital solutions is to solve the above problems. Through the application of mobile solutions, mobile digital is becoming more and more important in the development of manufacturing companies, and it will continue to develop the potential of manufacturing company.

Research Questions

In course of the study the following questions were raised:

- What is the role of mobile digital solutions in manufacturing?

- What problems do mobile digital solutions mainly solve in the manufacturing industry?

- The opportunity of mobile digital solutions to develop manufacturing company’s potential.

Purpose of the Study

Analyze the value of mobile information technology to manufacturing enterprises, and explore the feasibility of digital solutions in manufacturing.

Looking for mobile information solutions to solve the main problems of the manufacturing company and increase the development potential of the manufacturing industry.

Research Methods

The paper used the universal scientific research methods (analysis and synthesis, observation, case study) as well as statistical methods.

Mobile digital solutions are the modern trend of manufacturing management.

Mobile digital solutions are a set of measures related to the introduction of mobile information technology, digital mobile communications and so on in the era of digital economy to solve the problems existing in industrial company.

It is safe to say that mobile digital solutions are an effective way to solve the problems of Chinese manufacturing companies, which not only can meet the mobile office needs of manufacturing company, it also improve the information management level of the manufacturing industry (Lucian Fogoros, 2014; Nv'er, 2015).

With the promotion of information systems, manufacturing companies need to collect more and more data, such as processing data, quality data, inspection data, etc.; there are more places to collect data, such as warehouses, processing workshops, test workshops, and inspections. However, due to the special requirements of certain workplaces, some places are not suitable for collecting data using traditional PCs or touch screens, such as gunpowder workshops, where dust-proof, explosion-proof and anti-static requirements are extremely high, and PC terminals cannot be used; such as airplanes maintenance flight test is carried out on the flight test tower, and it is impossible to install a PC on the tower. Therefore, the demand for mobile terminals by manufacturing companies is increasing, and the information system is required to support the mobile terminal method to collect data (Moote, 2007; The 4th China Mobile Phone Design and Application Innovation Competition, Mobile Phone Design Monitoring and Analysis Project Team, Communications Industry News, Editor Department, 2016), which improve the innovative- technological potential of manufacturing company.

The application of mobile digital solutions enables the manufacturing industry to meet the industry’s requirements for timely response to the market and logistics management; it also improves the company’s understanding and grasp of itself, and makes it clear about the problems in its development and the needs for improvement. At the same time, it verifies the importance of information technology in the development of the manufacturing industry, enabling it to strengthen the management and application of this aspect, and also increases the network potential of manufacturing company.

On-site management can not only help manufacturing companies implement commercial policies, but also ensure the stability of company assets. Improper on-site management will affect the normal production and operation of manufacturing enterprises. Haiyan (2021) pointed out that most enterprise managers have low awareness of the importance of on-site management informatization, and do not believe that on-site informatization has an important impact on the development of enterprises. Manufacturing is the foundation of national development, and the mode and efficiency of on-site management of the entire enterprise are of great significance to manufacturing companies.

Manufacturing companies will produce large amounts of inventory if they produce and operate improperly. Excessive inventory scale and excessive capital occupation will affect the economic benefits of manufacturing company (Youqin, 2020). Production and operation problems are typical problems of manufacturing companies. Good production and operation help organize the production of products, reduce the operating costs of manufacturing companies, and improve the competitiveness and influence of manufacturing companies in the market.

With the changes in the consumer market, the requirements of customers for products have shifted from ownership to use rights, that is, from product-oriented logic to service-oriented logic (Resta et al., 2017), and the role of manufacturing companies has also changed from "product producer" to "service provider" "to meet the diverse needs of customers.

At present, the office mode in the production workshop of some large companies is still manual office, that is, manually fill in paper data and then carry out the electronic operation process. This office mode has low production efficiency, high labour intensity and is prone to human factors. Errors are only applicable to cases where the amount of data is relatively small, and cannot cope with the huge data generated by manufacturing company (Qu, 2013).

Due to some problems in manufacturing companies, mobile digital solutions have emerged to solve such problems.

Advantages of mobile digital solutions:

Work anywhere – mobile terminal equipment is very easy to use. It is the most natural substitute for paper and the best tool. No matter when you need to go to the list (for example, production order, inventory picking list, bill of materials, etc.), or no matter where the operator needs to manually collect data, information or fill in forms (such as quality control lists). Mobile devices are the most effective.

The production environment faced by employees in the manufacturing industry today is more complex and more responsible than ever. With mobile devices, users can easily see the operating status and production status of each machine, whether in the office, at home, or on the road. You can also insert notes, and other colleagues can also be able to see wherever they are. You can share immediately.

Respond immediately – mobile equipment is especially important for production departments that consist of multiple scattered or independent machines or when the production line is too long. It can avoid setting up many fixed monitoring sites in the factory (which can save a lot of money in terms of equipment and infrastructure). It can still ensure that the operator can receive or enter the necessary information for production. From the perspective of the amount of equipment required, it not only has an economic impact, but it can also accurately collect and negotiate the required information, which reduces the waste of time and the occurrence of errors.

The data shows that if factory managers can carry mobile devices and obtain real-time information, productivity can be increased by 5-10%; if business managers can access real-time sales information, they can improve forecast accuracy in time, which can reduce an average of 5% Overproduction and waste; asset maintenance and management through mobile platforms will increase equipment utilization by an average of 5% (Gang, 2014). Therefore, this will greatly enhance the economic potential of manufacturing companies.

Dedicated – the many subdivisions of the manufacturing industry directly lead to the obvious characteristics of the corresponding product solutions, and the delivery of products and services needs to be tailored to the specific production process of the enterprise to generate value, and the workload of customized development is large. The manufacturing industry can improve production efficiency and quality, reduce energy consumption based on mobile information technology, provide users with personalized customized products, and promote the healthy and stable development of manufacturing information technology.

Findings

Mobile digital solutions for Chinese manufacturing companies

Solutions to production and operation problems--Improper placement of production equipment: Design a mobile informatization solution for production equipment management, using 4G/4G+ wireless transmission network and mobile dedicated terminals to realize machine-to-machine data transmission. Enterprises can use this design to effectively manage remote equipment and position.

Market research is time-consuming and costly: Design an information mobile solution, connect this information server with the company’s ERP system, market investigators can enter the company market survey interface through SMS and WAP ports and fill in directly And upload, the company can learn the latest situation of the market as quickly as possible.

The traditional ordering mode is time-consuming and inefficient: design SMS ERP mobile digital solutions, which can be connected to the SMS platforms of China Unicom, China Mobile at the same time. Customers can express their willingness to purchase through SMS. Success or failure will be guaranteed. As notified, after the order is generated, the delivery system will assign tasks and deliver them according to the prescribed route. The whole process is automated, which greatly improves work efficiency and also takes advantage of mobile network communications.

Mobile office problem solutions--The management and sales staff of manufacturing company cannot log in to the system in time for office work. For this, they can propose a mobile office solution for the "Group E Network". China Unicom launched the "Wo yun" office platform in the mobile Internet era. With the help of virtual mirroring technology and secure access technology, it can instantly, seamlessly and securely extend the information systems such as the collaborative office system and business management system of manufacturing company. On the smart phone terminal, office efficiency has been greatly improved, and the production and operation of the enterprise has been improved.

Sales staff missed important meetings when they went out: Mobile conference phone office solution--The conference convener can use the mobile conference phone platform to convene multiple company personnel for a conference call at the same time, which breaks the boundary between space and time and can deliver important information to relevant parties at any time personnel. In addition, it can also develop mobile phone mail solutions for the needs of the company's superiors and subordinates to receive mail.

Solutions to customer service problems--China Unicom provides a corporate CRBT program to help companies promote their own culture and create a good corporate image. Unicom uniformly customized a set of exclusive corporate ring back tones for group customers, and showed the corporate products and corporate style to customers in less than one minute. Because the customer service number is easy to be confused, a mobile switchboard information solution was proposed. Set up an 11-digit mobile switchboard number, and program other numbers such as mobile phones and fixed phones to form multiple extension numbers. In this way, customers are easy to understand during operation and the error rate is greatly reduced; companies can unify external voice portals and improve customer service levels.

On-site management problems--First of all, the mobile information management platform that produces the product can record the production quantity, type, and yield of the product in time. If there is a problem with the product, the corresponding information can be obtained from the mobile information management platform in time. Secondly, various manufacturing standards, processes, drawings, parameters and technologies have corresponding requirements. It can also be stored on the mobile information platform. If there are modifications or changes, they can be completed in time through the mobile information platform.

The application of mobile digital solutions enabled manufacturing company to improve its understanding and grasp of itself, and made it clear about its own development problems and the levels that need to be improved. Through the implementation of this program, the managers of manufacturing company can understand market information in time, so that the company's ability to respond can be further improved.

Mobile digital solutions in Russia

In Russia, 5G networks are still in the research stage. In addition to serving the consumer market, 5G networks have the potential to support a series of solutions for manufacturing company [10]. However, technological breakthroughs such as the uncertainty of 5G spectrum acquisition and deployment conditions are also key issues affecting the introduction of 5G. This paragraph will consider key issues that will be during 5G implementation and mobile digital solutions to solve these problems. The problems are as follows:

- Frequency spectrum for 5G (coordination with the Russian government approval for frequency allocation is needed);

- Technical problem (deployment procedures and conditions);

- Information Security of 5G

For 5G frequency spectrum, the implementation of the socio-economic potential of 5G:

Network in Russia will largely depend on access to the spectrum of millimeter waves (mm wave). Assignment to each frequency operator of about 1 GHz will play a key role in meeting the demand for many advanced mobile data services due to ultra-high speed and low response time.

Government can maximize the social benefits of using national resources by developing a transparent and comprehensive spectrum roadmap, which is the product of an effective dialogue between relevant stakeholders. It is also important to ensure that there are enough frequencies to meet the needs of changing technology and demand. The business plans of mobile operators are inextricably linked with the availability of spectrum and the conditions for its provision, while the complexity and cost of spectrum acquisition decisions means that they should be notified as soon as possible about the upcoming frequency distribution, especially in case of updates.

For technical problem, Policy makers should identify mechanisms for streamlining administrative procedures governing the construction and deployment of 5G networks, including non-discriminatory and simplified access to federal and municipal infrastructure; connection to municipal or transport energy infrastructure; and simplifying the process of obtaining permits and standard operating procedures. The transition from authorization based on permits to notification procedures for certain infrastructure, such as small cells, can provide operators with the right conditions to accelerate the development of 5G, which will provide a good start in terms of the overall competitiveness and potential of the economy.

For 5G information Security problem, personal data or Internet of things data should be balanced and take into account the need to protect confidential information, as well as promote the development of entrepreneurship and industry and the emergence of new innovative services based on the use of mobile data. For example, the movement of subscribers around the company, recorded using mobile network can be a decisive factor in the design of intelligent transport systems. In addition, Governments, individuals and mobile operators throughout the region need to develop a single legal framework that protects confidentiality and information security to gain the trust of citizens and ensures that data flows and cross-border trade are protected from violations and compromises. By implementing appropriate protection measures, operators in Russia will be able to navigate the changing landscape of security threats and support the development of the region’s digital economy as it enters the 5G era.

Conclusion

The application and promotion of mobile digital solutions and the use of mobile informatization play a very important role in the development of the industry and promote the development and progress of social informatization. In addition, there is another aspect that cannot be underestimated, that is, the application of mobile solutions also plays a "social" role. Even if you are not face-to-face, you can also discuss and discuss with colleagues, which plays an important role in enhancing the development potential of the manufacturing company.

Despite all enumerated positive aspects, there are also some challenges of applying mobile information technology in manufacturing. The application of mobile digital solutions requires mobile terminals, and mobile terminals will distract attention during use, which may be a dangerous existence for the manufacturing site environment. Especially when using information technology for on-site management, it is necessary to recognize the surrounding production environment to avoid accidents. At the same time, mobile digital solutions require network support, and network information failures may occur in the complex production and operation environment of the manufacturing industry. If information is not sent or received in time during the informatization solution process, it will affect the company's management performance. Therefore, optimizing the network operating environment and preventing accidents will be the challenges faced by the application of information technology in the manufacturing industry. At the same time, through the application of mobile digitalization, it is necessary to break through the traditional informatization model based on computer terminals, innovative information input and output modes continuously.

To sum up, informatization has become a focus of social research, and the application and promotion of mobile digital plays an important role in enterprises, manufacturing industries, communication operators and social informatization. This article analyzes a series of problems encountered by manufacturing companies on the road of digital development, puts forward some relatively feasible measures, and demonstrates the overall mobile digital solutions of mobile information technology in the manufacturing industry and the significance of its implementation.

References

Dong, L., & Wu, H. (2017). Mobile Internet and regional development in China. Environment and Planning A, 49(4), 725-727.

Fogoros, L. (2014). 5 reasons why the manufacturing industry tends to be mobile. Journal of Automation Technology and Application, 1.

Gang, H. (2014). Modern manufacturing concept based on cloud computing. Journal of Electronic Technology and Software Engineering, 15, 179.

Haiyan, Ch. (2021). Problems and Countermeasures of Management Informationization of Manufacturing Enterprises. J. Chinese Market, 3.

Helo, P., Suorsa, M., Hao, Y., & Anussornnitisarn, P. (2014). Toward a cloud-based manufacturing execution system for distributed manufacturing. Computers in Industry, 65(4), 646-656.

Jiyi, W., Wenjuan, L., Jianping, H., Jianlin, Zh. & Deren, Ch. (2015). Overview of mobile Internet research. J. Science in China: Information Science, 1, 45-69.

Li, P., & Guangming, L. (2014). Analysis on the application of mobile office business in the industry. J. Office Automation, 5, 57-59.

Moote, S. (2007). The advantages of distributed server nodes in large system. J. Modern Television Technology, 8, 30-33.

Mrngyuan, Y. (2020). Cooperate with China's Huawei to promote 5G in Russia (Technology). J. Economic Potential Research, 6.

Nv'er, R. (2015). Research on the Application Mode of Mobile Applications in Discrete Manufacturing. Hebei University of Technology.

Okaxaki, S., & Roinero, J. (2010). Online media rivalry: a latent class model for mobile and pc internet users. J. Online Information Review, 34(1), 98-124.

Okazaki, S. (2006). What do we know about Mobile Internet Adopters? A Cluster Analysis. Inf Manage J. Information & Management, 43(2), 127-141.

Qu, Ch. (2013). The transformation of manufacturing mobile informatization is imminent. China Computer Education News, 16.

Resta, B., Gaiardelli, P., Cavalieri, S., & Dotti, S. (2017). Enhancing the design and management of the product-service system supply chain: an application to the automotive sector. Service Science, 9(4), 302-314.

The 4th China Mobile Phone Design and Application Innovation Competition, Mobile Phone Design Monitoring and Analysis Project Team, Communications Industry News, Editor Department. (2016). China Mobile Phone Design Monitoring Report [N]. Communications Industry News, 2017-01-16 (013).

Youqin, H. (2020). Research on Inventory Management of Manufacturing Enterprises. J. Research on Chinese Township and Village Enterprises, 10.

Zhenyu, L., Huawei, D., Feiyun, L., & Chengtao, L. (2016). Discussion on the development of mobile office applications. J. Science and Technology Vision, 4, 93.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Can, W. (2021). Mobile Digital Solutions In Manufacturing: Advantages And Challenges Of Application. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 1850-1859). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.206