Abstract

The innovative development of domestic enterprises continues to be a priority in the Russian economy. Particularly relevant is the activity of mechanical engineering sector which serves as a diffusion source of innovative transformations into other industries through the development of basic means of production. Among the factors which have a positive impact on the efficiency of the innovation processes in this industry, we may highlight a digital transformation of production processes which is implemented by recently introduced concept of Industry 4.0. This concept targets building a unified automated information system that allows one to level out the appeared bottlenecks in the product creation chain. As a practice shows, the implementation of measures within the framework of the Industry 4.0 concept can significantly advance the efficiency of the business processes in the production sector due to innovative activities. However, because the domestic enterprises have only recently initiated the processes of digital transformation there are a number of infancy-related issues that impede achieving the targets, one of which is upgrading the management for more efficient administration. Herein, the authors consider a solution to this concern, which could create favorable conditions for the industry’s transition to "digital" processes of innovation in order to advance their efficiency.

Keywords: Innovation, industry 40, digitalization, machine-building enterprises, management

Introduction

The mechanical engineering is the most important industry in the Russia to be in a core development of the national economy under modern conditions. To be developed, it gives an impetus to further significant changes in other industries, which are necessary to meet not only the current challenges in the modern economy but also to follow the priority directions of development adopted at the national state level in order to advance the country to the level of top-developed countries.

First of all, such a direction means an innovative activation of domestic enterprises which has been already supported for a long time by substantial state resources. Undoubtedly, having a key role in the structure of industrial production, the mechanical engineering here acts as a flagship entailing positive trends in innovative transformations into all the sectors of the Russian economy, because this industry sets up the level, pace and directions of scientific and technological progress. As analysts from McKinsey point out, the current lag in the innovative development of mechanical engineering enterprises in our country when compared to some foreign ones in the top-developed countries is significant, and the gap still constantly grows.

The processes of innovative transformations in industry are still not intensive enough despite a certain positive trend in increasing the innovative activity of industrial enterprises. The aggregate level of innovative activity in industrial organizations is 15.1 percent only. Therefore, this casts a doubt on the possibility to overcome an “innovative breakthrough” in the development of the domestic economy.

In this context, the key factor, which could dramatically contribute to the achievement of the ambitious goals of our state and to positively impact on the results of the innovative activity of mechanical engineering enterprises, is the implementation of measures within the concept of the 4th Industrial Revolution or Industry 4.0. This concept aims at the transition to an automated digital mode of the production systems of enterprises with the purpose of improving the efficiency of their management and functioning.

The development of industry in any country defines both its general economic position in the global distribution of labour and the wealth of a given society. Therefore, many economists and statesmen often pay attention, first of all, to the technical and/or technology capabilities of a given industrial sector, which results in a success of the digital economy. Regarding the mechanical engineering, a production base is laid for the creation of various types of products in the country and the level of labour productivity in other industries through the building complex high-automated equipment. Therefore, a success in the development of mechanical engineering often determines the economic situation of the state. As a result, many countries introduce new methods to facilitate the development of automated equipment through a digitalization.

Problem Statement

The 4th industrial revolution in mechanical engineering

Accounting for the current trends, the future of mechanical engineering is considered to follow the technologies of the 4th Industrial Revolution. The Industry 4.0 concept was formulated in Germany in 2011 by academics and businessmen as a means to increase the competitiveness of the engineering industry through the integration of “cyber-physical systems”, or CPS, into factory production processes. In 2016, Klaus Schwab introduced the term Industry 4.0 into a widespread use. As Schwab noted, “Unlike the previous ones, this industrial revolution goes not linearly, but rather exponentially” (Schwab, 2018, p. 285).

In the field of mechanical engineering, the term "Industry 4.0" means the technology of "smart" factories, including mass-scale processes for robotization, 3D printing, virtual and augmented reality, and neuro-technology. In other words, all devices, processes and information data are united through the Internet and innovative technologies of virtual reality and programming. The essence of the Industry 4.0 concept in mechanical engineering is determined by the following provisions: 1. Digitalization and integration of vertical and horizontal product value chains; 2. Digitalization of products and services, which involves the creation of new digital products or the modernization of products, to be supplemented with intelligent sensors and communication devices; 3. Digitalization of the business model and the access to customers, namely a comprehensive personalized service based on data and integrated platforms. New digital business models aim to generate additional revenue employing digital solutions (Industry 4.0: creating a digital enterprise, 2016).

According to the results of the PricewaterhouseCoopers study, which was attended by more than 2,000 respondents from 9 industry sectors and 26 countries, the digitalization contributes to, (i) a sharp enhancing a labor productivity, (ii) the development of relations with consumers through digital channels, (iii) accelerating a globalization while maintaining regional specificity, (iv) creating more effective administering structures that ensure the use of data analysts (Industry 4.0: creating a digital enterprise, 2016). As a practice shows, the implementation of the Industry 4.0 concept in mechanical engineering makes it possible to provide: connectivity of all equipment in an integral information field which does not require a human control; flexibility and transparency of the production base, high adaptability of processes to environmental conditions; efficiency of planning of production processes to manufacture products or their parts and assembly units; fast readjusting equipment according to the requirements of individual customers; constant and fast modernization of products.

Considering the advantages, which Industry 4.0 technologies provide, the top-economically developed countries have actively been engaged in the digital transformation process. These states support installing favorable conditions for the “digitization” of their industrial enterprises, which, in their turn, also take a direct initiative to introduce digital technologies into production. Thus, according to the noted research by PricewaterhouseCoopers, 131 foreign companies, of 278 in total surveyed, employ Industry 4.0 technologies. These companies include such German ones as Wittenstein, Bosch and BASF SE. Also, the digital technologies are actively developed in the enterprises of Great Britain, France, Italy, Belgium (Avilova & Ulmaskulov, 2018).

Russia has also began to be active in this direction. In 2017, the Strategy for the Development of the Information Society in the Russian Federation for the period of 2017-2030 years was developed. This strategy formulates the tasks how to introduce digital technologies into the day-to-day activities of industrial enterprises, and a number of large enterprises, such as OJSC KAMAZ, "Electropribor" (Kazan), JSC "SOFTLINE TRADE" are already implementing certain elements of Industry 4.0.

Research Questions

Within the framework of this study, the following questions were raised: to determine the main trends in the digitalization of machine-building enterprises; to identify the directions of transition to the digitalization of Russian enterprises; to identify the "bottlenecks" that prevent effective digitalization; to find a solution to the existing problem.

Purpose of the Study

The purpose of this study is to find a solution aimed at improving the efficiency of the digitalization processes of domestic machine-building enterprises, which will have a positive impact on their innovative activities.

Research Methods

The authors used universal scientific research methods, primarily statistical methods.

Digital transformation of mechanical engineering enterprises in Russia

The Russian domestic enterprises, primarily in the mechanical engineering industry, were long-time out of support from the state and the most of them exhausted their production potential. This makes challenges to ensure the pace of digitalization when compared to one which the foreign enterprises exhibit. There is still a huge number of manufacturing enterprises in the country which require even a primary automation to be integrated. The time lag behind the world leaders in this industry is 5-8 years according to experts (Avilova & Ulmaskulov, 2018). The authors of the study summarize that “despite a number of encouraging trends, in general, we have to state increasing the gap between Russia and the leading countries in terms of two key manifestations of the new technological revolution - digitalization and platformization” (New technological revolution: challenges and opportunities for Russia, 2017). Currently, labor productivity in Russia is 2.5 times lower than, for example, one in the United States, and its stable growth has not yet been observed. Obviously, it can be achieved only by raising the technical level of production. At the same time, the degree of depreciation of basic assets, as given by national statistics, is quite high: 2008 (45.6 %), 2016 (50.2 %), 2017 (47.3 %), 2018 (46.6 %), 2019 (37.8 %). The share of investments into basic assets in the Russ. GDP is consistently low and amounted to be 21.4% in 2017, 20.0 % in 2018, and 20.6 % in 2019.

The expenses on research and development (R&D) which industry enterprises invested in 2015 were 0.3 % of GDP against 1.54 % in China, 1.79% in the United States and 2.72 % in Japan. In absolute values, the R&D costs of industrial enterprises in China and the United States are almost 30 times higher than those in Russian industry. The report "New Technological Revolution: Challenges and Opportunities for Russia" published in October 2017 by the Center for Strategic Research (CSR) has been dedicated to readiness of Russia to the 4th industrial revolution (New technological revolution: challenges and opportunities for Russia, 2017). According to the authors, the peak of the new industrial revolution related to scaling of breakthrough technologies and a change in the architecture of markets in our country will take a place in the 2020s – 2030s. Currently, Russia has a national project tilted as "Digital Economy of the Russian Federation" for the 2019-2024 period and the TechNet roadmap of the National Technology Initiative (NTI), based on the global Industry 4.0 program. These programs provide a support for the significant introduction of digital technologies, robotization and integration of technological, production and business processes throughout the enterprise as a whole, from development and procurement to a production, logistics and service during an operation (Naumov et al., 2020).

It is worth noting that the development of industrial technologies is a key factor in the positive business growing (Götz & Jankowska, 2020). Therefore, the introduction and development of digitalization in the industrial sector has a great potential for the domestic economy, primarily for the tasks of innovative development.

The concept of Industry 4.0 for the purposes of innovative development of mechanical engineering enterprises and the problems of its implementation

Industry 4.0 makes possible improving and modernizing products and processes in order to advance the efficiency of mechanical engineering as a whole via employing new technologies (Plakitkin & Plakitkina, 2018). At present, the following major positive impacts to utilize Industry 4.0 technologies at the innovative development of mechanical engineering enterprises can be distinguished from a practice viewpoint.

The type of manufactured products which can be determined by software including various modules is being improved. The external shape of the product becomes simpler and more suitable for new methods like an additive manufacturing. The renewal of the equipment fleet does not take place within the framework of discrete replacements, which require a single-time large investment, but follows a model of constant modification, primarily by updating the software part of the products.

Approaches to product development are being improved, as a result of which the influence of the human factor is significantly reduced, the production time and the amount of resources are reduced not only at the production stage through, for example, robotization and the introduction of automatic control, but also under the operation of the product through, for example, an automatic monitoring of modes by the manufacturer.

Approaches to the production of products are being improved, as a result of which it is possible to implement a shop-floor model of production within the framework of an effective "hybrid" model of operating production facilities. By introducing such a model, the enterprise forwards the available means of production not only for the production of the final product itself, but also carries out a part of some operations within a framework of a distributed production chain, which is automatically managed by a single center. As a result, the utilization of production facilities can reach 100 % efficiency (Prospects for Industry 4.0 and digitalization of industry in Russia and the world, 2018).

Despite the obvious advantages of the transition of industrial enterprises to the principles of organizing their activities in accordance with the "Industry 4.0" concept, such a transition, in modern conditions, is not available for many industrial enterprises in Russia due to the fact that the real state of the production and information basis of enterprises does not have opportunities for the introduction of modern digital tools. For example, if the previous changes in the industrial sector were based on the "Industry 3.0" concept, which assumes the automation of only individual production processes, then the present concept of "Industry 4.0" involves the transition of all processes of the product life cycle to end-to-end digitalization, as well as their integration into the digital ecosystem (Alami & Maraghy, 2021). Of course, such global transformation processes will be accompanied by many side issues, which, in turn, are associated with the specifics of the development and functioning of domestic industrial production. Based on the data of the analytical report of "Digital Transformation in Russia - 2020" by KMDA, the following factors are highlighted that impede the digital transformation of enterprises: lack of relevant competencies and knowledge, the need for a large volume of financial resources from industrial enterprises; lack of readiness of the labor market of industrial enterprises in Russia to significant modifications; risks in the field of information security; lack of readiness of enterprise management to innovate in the field of digital technologies.

Despite the fact that many Russian business leaders understand the benefits of digital organization of activities, the level of those who prefer conservative methods is still high.

As one can see, the selected factors appear both outside and inside the enterprises themselves that directly affects the adjusting a range of search for solutions aimed at reducing a negative impact of these factors. Of course, one can indicate the need for a state support to solve the existing problems, however, enterprises themselves should show an initiative and make efforts in this direction. In particular, they could train a personnel, find a funding to form sources of transformation. But, first of all, according to the authors, it is necessary to form a management system that will provide an appropriate basis for the digital transformation of innovative processes.

Findings

Implementation of the Industry 4.0 concept into the innovative activity of mechanical engineering enterprises

One way or another, the introduction of Industry 4.0 technologies is a change that, together with the need to carry out innovative activities, significantly destabilizes the current functioning and advances entropy. To reduce the negative impulses caused by such a state, the management must ensure making clear borders to frame the transformations.

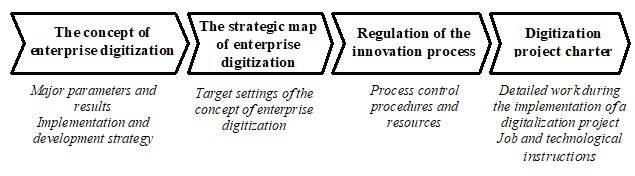

One of these areas, according to the authors, is the defining a standard for digital transformation of enterprise innovation processes to target a goal and sequence of changes and to prepare employees and the enterprise as a whole to the changes, and to provide an understanding of the digitalization process. The major components of such a standard are proposed as following.

1. The concept of enterprise digitalization is a document composing the goals, objectives and principles of the development and implementation of the digital transformation of the enterprise. The structure of this document can be presented in the form of two head sections:

Section I which describes a digital transformation in the form of development goals, characteristics of the direction of innovative development, the charter of digitalization projects, the regulation of business processes for innovative development; and Section II which describes the digitalization management loop and include forms of management reporting which indicate the process of digital transformation, the achievement of intermediate and final development goals, which provide an information for making management decisions; information monitoring system underlying the management reporting forms; regulations for the procedures to exchange by information and the designing management reporting forms; regulations for the procedures to make and to implement the management decisions by responsible persons employing the existing information.

2. A strategic map of enterprise digitalization as a document to implement the Enterprise Digitalization Concept and to identify the development goals through a balanced system of key indicators in relation to digitalization projects.

The sequence to design the major regulations of the standard for digital transformation of an enterprise is shown in Figure 1.

In our opinion, the implementation of the proposed standard in a mechanical engineering enterprise will allow:

- to ensure the transparency of the digital transformation of the innovative activity of the enterprise and, accordingly, its controllability;

- to systematize and to regulate information flows within the framework of ongoing transformations, both in the context of digitalization and innovation;

- to control and to manage financial flows in the process of changes;

- to track and to effectively manage the costs of digital transformation and innovation;

- to evaluate the effectiveness of digital transformation in the framework of enterprise development.

Conclusion

Thus, on the basis of the study carried out, it seems possible according to the authors to draw the following conclusions:

- the strengthening an innovative activities in mechanical engineering enterprises is one of the priority directions in the strategy of development of the domestic economy;

- a digital transformation of innovative processes in mechanical engineering enterprises is a favorable factor to advance their productivity and to reduce a production cost;

- one of the most important factors hindering the speed and efficiency of digitalization processes is the unpreparedness of enterprise management systems for transformation;

- the implementation of the standard for digital transformation of the enterprise would allow one to form the necessary management basis and to contribute to the achievement of the set development goals.

The implementation of the proposed solution would create the necessary favourable conditions for the initiated transformations in the enterprises and would contribute to appearance of necessary background to implement an innovative development.

References

Alami, D., & Maraghy, W. (2021). A cost benefit analysis for industry 4.0 in a job shop environment using a mixed integer linear programming model. Journal of Manugacturing System, 59, 81-97.

Avilova, V. V., Ulmaskulov, T. F. (2018). Prospects for the application of the technology "Industry 4.0" in the Russian industry. Basis, 1(3), 13-15.

Götz, M., Jankowska, B. (2020). Adoption of Industry 4.0 Technologies and Company Competitiveness: Case Studies from a Post-Transition Economy. Foresight and STI Governance, 14(4), 61-78.

Industry 4.0: creating a digital enterprise. (2016). https://www.pwc.ru/ru/technology/assets/global_industry 2016_rus.pdf

Naumov, I. V., Dubrovskaya, J. V., Kozonogova, E. V. (2020). Digitalisation of Industrial Production in the Russian Regions: Spatial Relationships. Economy of region, 16(3), 896-910.

New technological revolution: challenges and opportunities for Russia. (2017). https://strategy.csr.ru/user/pages/researches/novaya-tehnologicheskaya-revolutsiya-2017-10-13.pdf

Plakitkin, Yu. A., Plakitkina, L. S. (2018). Industry 4.0 and Digital Economy of the Russian Federation Programs - Opportunities and Prospects in the Coal Industry. Mining Industry, 1(137), 22-28.

Prospects for Industry 4.0 and digitalization of industry in Russia and the world. (2017). https://json.tv/ict_telecom_analytics_view/perspektivy-industrii-40-i-tsifrovizatsii-promyshlennosti-v-rossii-i-mire-20180312123158

Schwab, K. (2018). The Fourth Industrial Revolution. Eksmo-Press.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Pchelintseva, I., Kiseleva, O., Vasina, A., & Sysoeva, O. (2021). The Features Of Innovative Development Of Russian Enterprises In "Industry 4.0" Concept. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 1773-1780). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.198