Abstract

The priority of industrial innovations and high technologies introduction is caused by the significance of new competitive products development, and the influence it has on the world economy. A competitive and sustainable industry can play a critical role in boosting economic growth. The aim of the study is to explore new opportunities for industrial cooperation in the context of digitalization to improve the performance efficiency in industry. Target, integrative and organizational approaches to building industrial cooperation have provided methodological background for modeling network activities in industry. The network of collaborative activities organization is considered as the most relevant, favorable and effective form of achieving goals in the industrial development. Networking assumes relationship between participants based on mutual interest, collaborative decision-making and ensures performance efficiency in achieving innovative goals. A platform-based network model of interaction has been proposed to optimize the production processes management, efficient distribution and use of resources of cooperating partners in the production of competitive industrial products. Digital platforms in such a model are used as the basis for the creation of a customized and specialized system of digital interaction between independent participants, united in a single information environment, leading to cost savings due to the use of digital technologies and changes in the division of labor. Ensuring the network effects of cooperation is carried out in terms of social, environmental and economic components. Management of complex business relationships and interaction processes in the implementation of network platforms is becoming more relevant and ensures efficiency in high-tech industries.

Keywords: Industry, digital platforms, network effects

Introduction

Innovation’s advancement ensures high indicators of industrial production, which are the basis of developed economies. The priorities of innovation in industry are steadily shifting from the intellectual component of the innovation process towards its practical, implementation stages.

Industrial production in the world largest countries has developed rapidly in the last decade with the introduction of advanced technologies. However, as a result of the introduction of firm constraints in the economy due to COVID-19, the volume of global industry fell sharply: at the peak of the "first wave" of the pandemic - by 12.2% in April and by11.5% in May. Although as the world industry was adapting to the new conditions, the recovery began (Global economy news, 2020). The crisis severely hit manufacturing and transport, resulting in disruptions to global value chains and product supply, as well as declining jobs and working hours in these sectors.

According to the UN Under-Secretary-General, countries remain firm in their commitment to the goals and principles of the UN and the 2030 Agenda, a “do better than it was” recovery.

Advanced digital production technologies are changing manufacturing and have implications for future industrial development. A 2020 UN report notes that “fostering inclusive and sustainable industry and further investment in physical infrastructure, innovation and research are fundamental to long-term economic development” (On the Sustainable Development Goals, 2020). In such conditions manufacturers are using the advantages of digitalization, actively mastering new technologies for organizing cooperation and interaction.

Problem Statement

The study of network effects of interaction between digital platform users in industry involves the following tasks:

- Studying the directions of digital transformation in the industry.

- Determination of principles of digital platforms application in the organization of industrial cooperation and network interaction.

- Highlighting the network-type effects on digital platforms users in industry, determination of structural elements.

Research Questions

While performing the research the following issues were considered:

- What new opportunities in industrial cooperation arise during digital transformations in industry?

- What are the extra benefits of platform-based networking for industrial companies?

- What constituents form the structure of network effects of interaction between digital platforms users in industry?

Purpose of the Study

Explore the advantages of creating a platform-based networking organization of industrial cooperation and determine the structure of the effects of participation in digital projects.

Research Methods

Digitalization provides new opportunities for industrial cooperation ensuring increased flexibility and productivity, speed of response to market changes. Modern digitalization is being implemented together with new technological breakthrough in the Industry 4.0 format, providing intense transformation of industrial production. Industry 4.0 refers to a complex evolution of the entire industrial sector, which includes technological advances in manufacturing equipment (e.g., additive manufacturing), intelligent off-the-shelf products (IoT), data processing tools and analytics involving various activities and stakeholders at all levels (Savastano et al., 2019). The digital connection of machines over the Internet accompanies the Fourth Industrial Revolution; smart machines are transforming a wide variety of industries (Trapote et al., 2018). There is a growing interest in Industry 4.0 as it integrates cutting edge manufacturing and technology that seems to be changing the way businesses operate. These changes are applied to improve existing production systems with new technologies, offering a better way to organize and manage all processes within production and services including their logistics and supply chains (Ejsmont et al., 2020).

Networking design acts as a technology for innovative development and through an open developing space allows new content production. The methodological background of this work includes several approaches to simulating network activity in industry.

Target approach

The target approach lies in the fact that an industrial company selects partners with similar or alike goals - high-tech products development. Coordinating goals when combining organizations potentials gives the synergy effect - a much greater efficiency in comparison with their autonomous existence.

Integrative approach

The integrative approach implements the principle of management process integration, ensures integrity in the design systems and the effective allocation of cooperating partners’ resources, launching competitive industrial products. Integrative processes are processes of qualitative transformation of individual elements of system interaction which provide companies with competitive advantages through more efficient use of resources and cost cuts.

Organizational approach

The organizational approach forms a platform-based network model of interaction for optimizing production management, ensures functioning of a single information space, based on large amounts of data transfer at all stages of digital design of industrial production life cycle. A new modification of organizational blocks is associated with collaborative decision-making and partners’ mutual interest, ensuring the collaborative activities efficiency.

Findings

The Russian Federation ranks 58 in the IMS-9 Industrial Index. Digitalization offers a number of new opportunities for inclusive and sustainable development. Digital transformation is the main trend of technological development in Russia and is being implemented in almost all industries. The basis for digital transformation is computer technology and digital measuring tools, which are used by modern industrial production in all areas of companies' activities.

Digital innovations around the world are driving the emergence of new technologies, organizational models and industrial collaboration. According to Walther (2018), due to customizable and easy-to-understand information in real time “more informed and effective decisions are made regarding their resources, assets, their employees, their suppliers and customers” (p. 4).

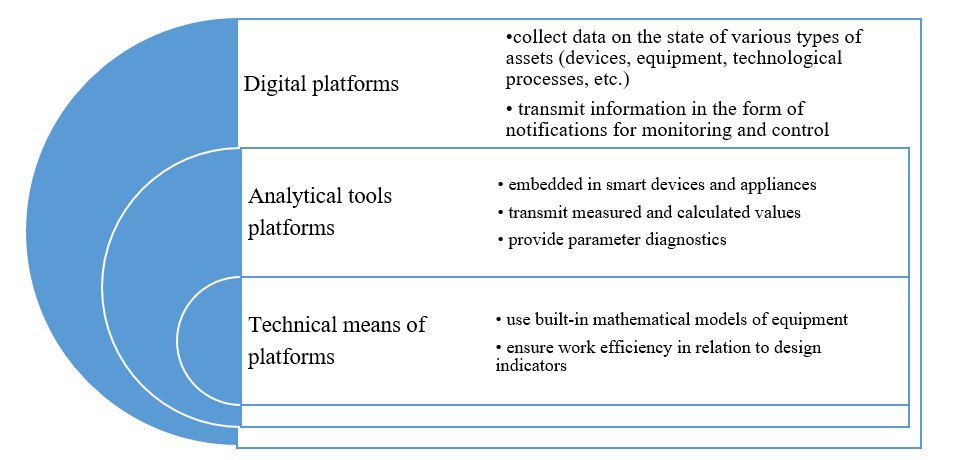

Platform base of digital transformation

Carrying out digital transformation applying a variety of modern technologies is based on an appropriate digital platform. A digital platform should be understood as a set of digital data, models and tools, informationally and technologically integrated into a single automated control system for the target subject area.

Companies use digital platforms as a large-scale system for working with big data in general, which allows analyzing equipment and technological process operation, as well as optimizing management to increase productivity. Around each digital platform, a system of participants in the supply, production, service and operation with additional benefits is formed (Figure 1).

Currently, Russian economy is going through a further stage of digital transformation. Specific types of projects and digital platforms used by Russian industrial companies are presented in Table 1.

However, the degree of digital technologies adaptation in terms of realizing their business potential, as shown by a study by the McKinsey Global Institute, in industry is lower than in the economy as a whole (Twenty-five years of digitization, 2019). Leading industrial enterprises, the so-called "top quartile" companies, significantly outperform competing companies that have average values of metric indices used to assess the state of the enterprise. This can be traced across all indices, both in terms of production efficiency and in terms of reliability and safety. Thus, in oil refining companies of the "upper quartile" show 4% higher operational readiness and 10% higher equipment efficiency, 20% lower operating costs and three times fewer incidents compared to the average values. Likewise in oil and gas production: companies of the "first quartile" have 8% higher operational availability, 40% lower operating costs and half the number of incidents.

To a large extent, these results are due to automation, introduction of digital technologies and related business processes.

Formation of digital platforms in Russia is based on the "Digital Economy of the Russian Federation" programme, implementation of which is aimed at a breakthrough in all sectors of economy, and "effective development of markets and industries (spheres of activity) in digital economy is possible only if there are developed platforms, technologies, institutional and infrastructure environment” (Departmental project "Digital Industry", 2018).

The departmental project "Digital Industry" is aimed at platforms that have a significant impact on the industrial enterprises development:

- A platform for effective investment in industry,

- A platform for creation and development of enterprise production,

- A platform for a set of state support measures selection, their provision and control over the achievement of project performance indicators,

- A platform for ensuring production and promotion of industrial products in the domestic market,

- A platform for promoting products in the foreign market, increasing export volumes,

- A platform for analyzing and forecasting the development of production based on objective statistical data.

The INCONA platform for the digitalization of industry, sectorial and national adaptation of digital technologies has been launched in Russia. According to the estimates of the Union of Domestic Producers, the introduction of the INCONA platform can give an annual growth of 3.7%, only to the GDP of the industrial sector, which corresponds to an increase in the country's GDP at the level of up to 0.9%.

Interaction of digital platform participants

Digital transformation affects all indicators of industrial companies: economic efficiency of production (productivity, operating costs), reliability (availability), safety (number of incidents), compliance with environmental legislation, etc. However, there is also a need for horizontal integration that goes far beyond one organization and encompasses a company and its partners, suppliers and customers.

With digital transformation, a higher level of cooperation and collaboration is achieved; digital platforms are able to organize the interaction of stakeholders.

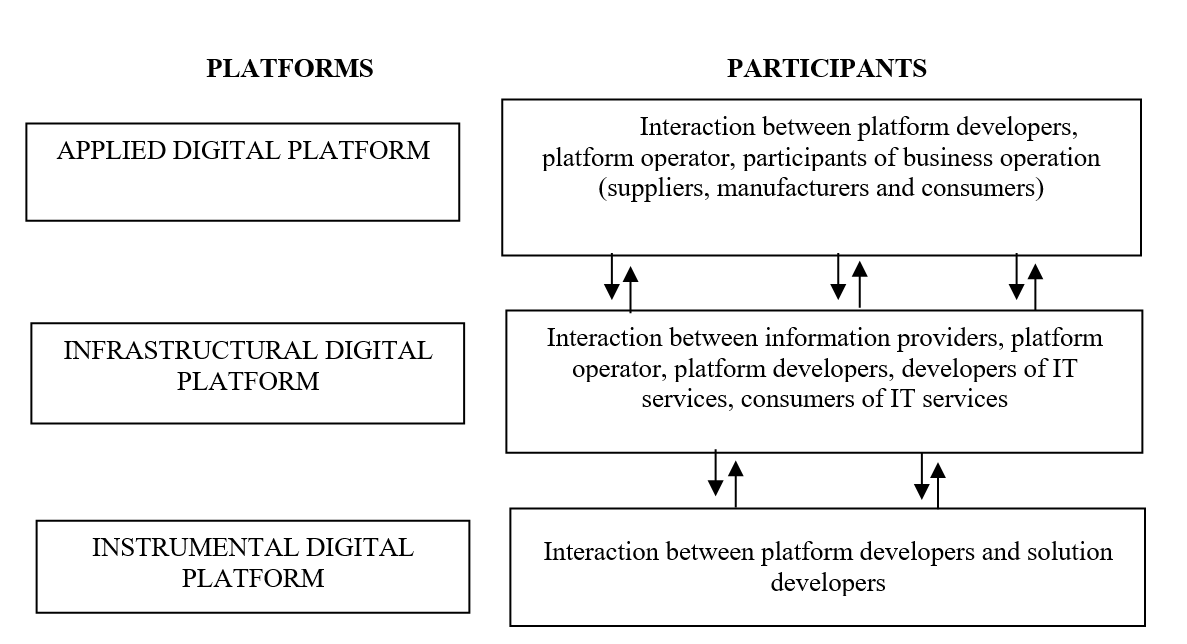

Among the main types there are instrumental, infrastructural, applied digital platforms with corresponding participants and operations, as well as specific results of interaction.

The instrumental digital platform is based on information processing services, tools for setting up software products and standard software solutions for interaction between platform developers and developers of such solutions.

Information providers, platform operator, platform developer, developers of IT services and consumers of IT services are participants in infrastructural digital platforms that provide access to data sources and services for their processing in the automation of business activities.

Applied digital platforms provide opportunities for algorithmic exchange of information between participants for solving problems of technological management in industrial facilities. "Software platforms that collect, analyze and display data from various sources either from within an individual plant or across several plants" (Walther, 2018, p. 6).

The interaction of participants in digital platforms is based on mutually beneficial conditions that ensure effective development of activities and additional economic effect of cooperation (Figure 2).

Networking initiatives can focus on collaborative development and involve the use of different types of resources: knowledge, technology, human resources, infrastructure, etc. Through platforms networking helps participants to access information, improve its use, create and share the necessary data, while providing partners with certain advantages and benefits.

Conclusion

Almost all processes from direct control and management of the technological process to business planning and workflow are currently carried out using digital data and digital infrastructure. Computer technologies make it possible to create corporate networks with access control and information security tools. Integrating digital information from platforms and then networking between platforms enables intelligent manufacturing, complementing capabilities and improving efficiency in resource aggregation, dynamic allocation, etc. Networking platforms provide robust digital support and complete transparency, fast internal and external communication and interconnection. Through the network companies collaborate to make decisions and allocate resources efficiently. A networking business model through a digital platform is effective in the digital economy and provides participating companies with a competitive advantage, effectively connects the device and network layers, and helps to collect, transfer and integrate fragmented industrial system knowledge into the platform (Vrabic et al., 2018). Experts also believe this could have an additional advantage over a longer period of time in the form of risk reduction and ensure resilience (Choi & Wang, 2009), open up additional opportunities to meet new needs, diversify and co-create value, increase efficiency (Porter & Kramer, 2011).

Digital platforms facilitate transactions, networking and information exchange; act as mechanisms to enable participants to interact online and become their benefit.

Formation of network effects of cooperation is accompanied by the benefits in a structure which includes social, environmental and economic components:

- The social component is characterized by increased labor safety and efficiency, flexibility and more comfortable working conditions; ensures social development and includes new working standards.

- Environmental benefits include economical energy consumption and resource management through accurate manufacturing design, prevention of man-made hazards which helps to reduce the negative impact of industrial production on the environment and improve the efficiency of resource utilization.

- The economic component is accompanied by savings on operating costs, decrease in the cost of products created, and reduction in production time, ensuring the profit of the activity and the return on investment.

Thus, network cooperation acts as a technology for innovative development and, through an open developing space, allows production of new content. The main task of networking is cooperation, integration of forces, resources, assistance and support of participants. Building a networking organization means integrating unique experiences, capabilities, knowledge and resources of the participants united by a new project. At the same time, formation of a network by various participants ensures mutual compensation for resource shortages and strengthening of advantages. The use of network platform cooperation in industrial companies contributes to the expansion of technical and economic opportunities, boundaries of interaction when creating various organizational models and obtaining network effects.

Acknowledgments

The reported study was funded by RFBR according to the research project № 19-010-00346.

References

Choi, J., & Wang, H. (2009). Stakeholder relations and the persistence of corporate financial performance. Strategic Management Journal, 30(8), 895-907.

Departmental project "Digital Industry". (2018). Minpromtorg Russia, 14. https://digital.gov.ru/uploaded/files/vedomstvennyij-proekt-tsifrovaya-promyishlennost.pdf

Ejsmont, K., Gladysz, B., & Kluczek, A. (2020). Impact of Industry 4.0 on Sustainability. Sustainability, 12(14), 5650.

Global economy news. (2020). Results of 2020 and expectations. Moscow: Center for Macroeconomic Research. https://www.sberbank.com/common/img/uploaded/analytics/2020/itog2020.pdf

On the Sustainable Development Goals. (2020). United Nations report. https://unstats.un.org/sdgs/report/2020/The-Sustainable-Development-Goals-Report-2020_Russian.pdf

Porter, M. E., & Kramer, M. R. (2011). The big idea: Creating shared value. Harvard Business Review, 89, 2-17.

Savastano, M., Amendola, C., Bellini, F., & D’Ascenzo, F. (2019). Contextual Impacts on Industrial Processes Brought by the Digital Transformation of Manufacturing: A Systematic Review. Sustainability, 11, 891.

Trapote, J. G., Rio Belver, R. M., Carrasco, E. C., & Andara, A. R. (2018). Visualization of The Digital Transformation of The Machine Tool Sector. Towards an Industry 4.0. DYNA, 93(6), 587-591.

Twenty-five years of digitization. (2019). Ten insights into how to play it right McKinsey Global Institute.https://www.mckinsey.com/~/media/mckinsey/business%20functions/mckinsey%20digital/our%20insights/twenty-five%20years%20of%20digitization%20ten%20insights%20into%20how%20to%20play%20it%20right/mgi-briefing-note-twenty-five-years-of-digitization-may-2019.ashx

Vrabic, R., Erkoyuncu, J., Butala, P., & Roy, R. (2018). Digital twins: Understanding the added value of integrated models for through-life engineering services. Procedia Manufacturing, 16, 139-146.

Walther, T. (2018). Digital transformation of the global cement industry. Proc. of the IEEE-IAS/PCA Cement Industry Conference (IAS/PCA ‘18), 1-8. Business https://www.semanticscholar.org/paper/Digital-transformation-of-the-global-cement-Walther/4ebed65575b8c98c20e362bcfc505b95ee291e3a

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

25 September 2021

Article Doi

eBook ISBN

978-1-80296-115-7

Publisher

European Publisher

Volume

116

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2895

Subjects

Economics, social trends, sustainability, modern society, behavioural sciences, education

Cite this article as:

Tsohla, S. Y., Simchenko, N. A., & Oborin, M. S. (2021). The Structure Of Interaction Network Effects Between Digital Platforms’ Users In Industry. In I. V. Kovalev, A. A. Voroshilova, & A. S. Budagov (Eds.), Economic and Social Trends for Sustainability of Modern Society (ICEST-II 2021), vol 116. European Proceedings of Social and Behavioural Sciences (pp. 102-110). European Publisher. https://doi.org/10.15405/epsbs.2021.09.02.11