Abstract

A variety of constructions and technologies, different classes/grades of concrete and specified properties of ready mixed concrete and background/raw materials requires the composition calculation of the concrete in each particular case. It is necessary to design a concrete mixture, that is, select the included parts of the concrete mix and their quantity to solve this problem and obtain concrete with specified characteristics. However, the preliminary proportioning / design of mixture is not a simple task. The variety of qualitative sorts of cement, fine and coarse aggregates make calculating considerably complicated. Obtaining the required strength of concrete is dependent on various properties of its base components. The diversity of factors affects the concrete composition so that there is a need for the conceptual design of the concrete composition. In other words, it requires holding a simulation experiment. It results in designing a software solution that notes the proportioning of concrete when characteristics of materials and concrete mix changes are made. It enables to design a heavy-weight concrete guided by economic aspects and depending on the operating conditions of structures as soon as possible. The paper deals with a variety of composite materials and difficulties in designing composite media for specified characteristics. Reinforced concrete is used as an example of composite material for marine structures. A code snippet and a flowchart consisting of the main procedures for designing the production bill of concrete are presented. The authors describe instructions for inserts in concrete for joint operation of the concrete and reinforcing environment.

Keywords: Composite; algorithm, flowchart; engineering, strength, reinforcing environment

Introduction

The production technology and goods thereof are one of the most promising areas of modern science development. Products made of these materials are widely used in construction, current automotive and aviation industries, and in the marine structure building. The composite material is a structural (metal or non-metallic) material that combines reinforcing elements in the shape of threads, fibres yarns, or flakes of higher strength materials. Examples of composite materials are plastic reinforced with boron, carbon, glass fibres, tows/bundles or fabrics made of them; aluminium reinforced with steel threads, beryllium. By combining the volumetric content of components, it is possible to obtain composite materials with the required values of strength, high-temperature strength, shear modulus, and abrasion resistance. One can also manufacture composites with the necessary magnetic, dielectric, radio-absorbing and other precisely the right material characteristics to satisfy a particular application. Many surveys are devoted to calculations of structures made of composite materials (Kozin et al., 2019; Taranukha & Vasilyev, 2015; Zemlyak et al., 2019).

This article comments on procedures and models for designing the specified characteristics of reinforced concrete and composite material that combines the joint functioning of concrete and steel reinforcement. Concrete is a pure composite and consists of gravel and sand, which are bound together with a neat cement paste made of cement and water. Moreover, metal fitting is usually added to reinforce concrete strength. Concrete acts perfectly at compression loads, but it becomes brittle and fragile when it is stretched. The concrete tensile strength is 10-20 times less than the compressive strength. Tensile stresses, as well as the shrinkage of concrete throughout curing/hardening, causes cracks where the water reaches. This is, in turn, resulted in corrosion of metal reinforcement, its destruction and substantial loss of concrete integrity. The variety of designs and technologies, different classes of concrete and characteristics of the concrete mix and raw materials demand constant developments on its composition, to make the concrete more resistant to various external effects and loads, which will ensure its sustained operations.

To solve this problem and obtain the concrete with specified characteristics, it is necessary to design the concrete composition, i.e., proportion the components of the concrete mix and their quantity. These studies are observed in the studies of L. I. Dvorkin, Yu. M. Bazhenov, V. P. Sizov and other authors (Bazhenov, 1975; Dvorkin, 1981; Sizov, 1979). However, the preliminary design of the composition has a certain difficulty that related to the variety of cement types, fine and coarse aggregates, as well as concrete admixture.

Concrete mixes are often optionally reinforced with basalt nano-fibre (Perfilov & Gabova, 2017; Perfilov & Lepilov, 2019). Studies of the rheological/flow properties of concrete mixtures were performed in a number of surveys (Ali Yazdi et al., 2020; Aruova et al., 2020; de Andrade et al., 2020).

Problem Statement

The following goals have been set out during the research:

- To study and review the approaches of proportioning the concrete mix and choose the best one, ensuring the most user-friendly and detailed calculation algorithm.

- To develop the most optimal software environment for data visualization and calculations and automate the accounting process of the high-density concrete composition, including concerning concentrated solutions of additives and aggregate moisture

Research Questions

The study covers the following issues:

Design of the specified characteristics of the composite environment for reinforced concrete

As had already been pointed out, reinforced concrete was used as an example for designing the specified characteristics of the composite environment. The most developed and implemented in practice are two-parameter problems when the normalized property of concrete is its compressive strength Rсж, and the concrete mixture is the value of workability (flowability or stiffness factor) (Dvorkin, 1981).

Compressive strength determines the concrete class. The concrete classes, according to tensile and bending strength, are determined by the compressive strength. According to Bazhenov (1975), the strength of concrete within a certain period when hardening under normal conditions depends on the water-cement ratio. When solving two-parameter problems for heavy concretes, the values of the cement-water ratio, water consumption considering the required flowability or stiffness of the concrete mix, and the consumption of cement and aggregates are consistently determined. In this case, it is assumed that the concrete mixture consists of the absolute volumes of all its components.

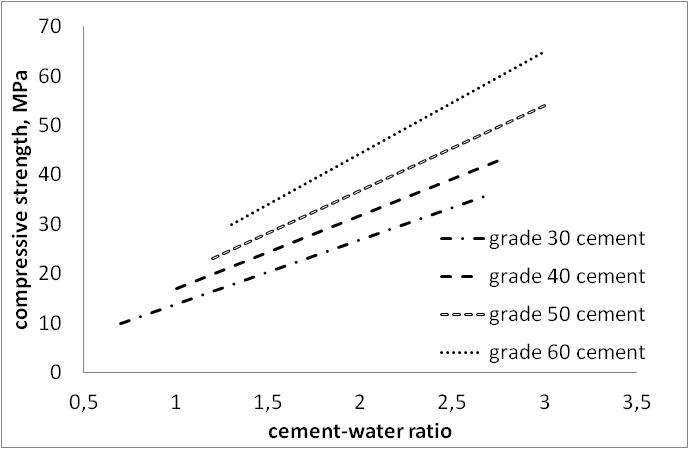

Dependence of the material strength on the cement grade

Figure 1 presents the dependence of the concrete strength at 28 days on the ratio of C / W and the cement grade. The graphs 1,2, 3 and 4 correspond to the cement grades 300, 400, 500, 600.

Purpose of the Study

The purpose of the study is to decide on an algorithm and develop a software product for carrying out a computational experiment and preliminary calculation of the composite material mix by the example of concrete.

Research Methods

Borland Delphi 7 compiler based on the Object Pascal programming language was used for procedures and functions in designing the heavy concrete mix. Bazhenov’s method was used as the basis for calculating without considering chemical additives.

The software product will contain algorithms for calculating the nominal composition of concrete, accounting for the field composition taking into consideration the moisture content of aggregates, and accounting for the amount of the additive substance in a liquid and dry form. The software will also contain a database of additives of various types, calculate the amount of the additive substance according to the amount of cement.

Findings

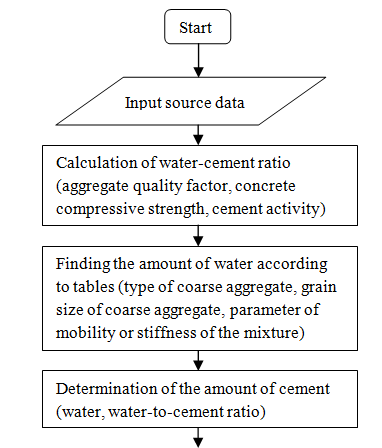

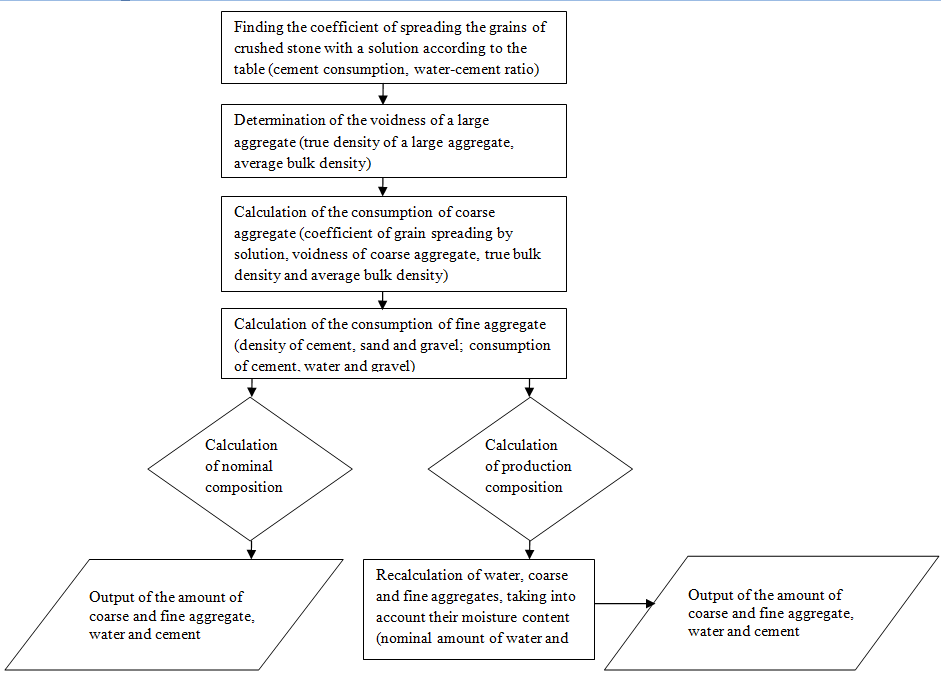

The algorithm for calculating the concrete composition is presented as a flowchart in Figures 2,3,4. function arguments are given in brackets, and the required function is shown with no use of brackets.

Furthermore, based on inputs gathered, the remaining components of the concrete mix, as well as the nominal and production composition are found here

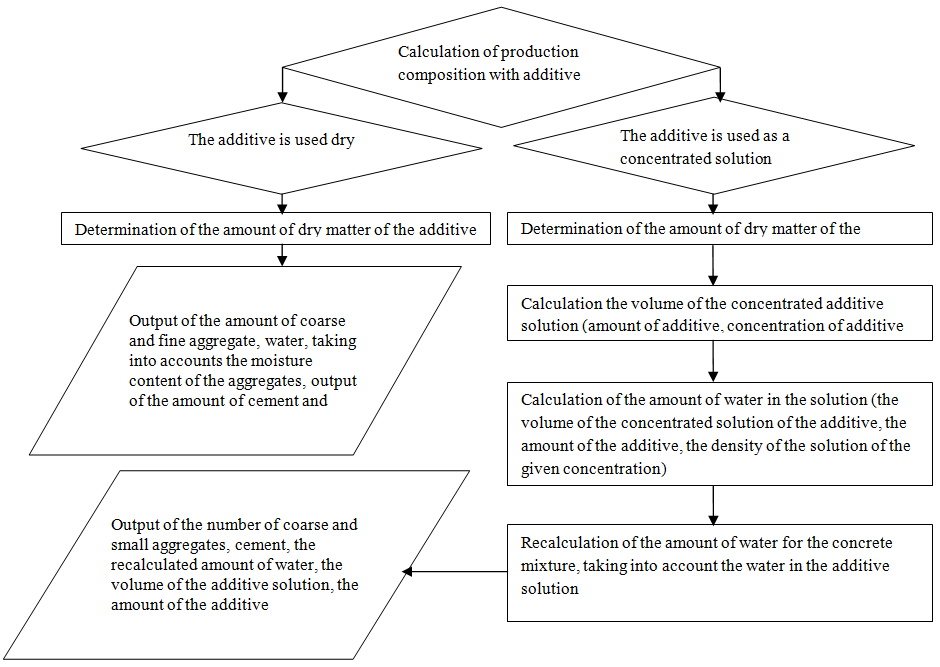

Figure 4 shows a flowchart for calculating the concentrated solution of the additive

For correct dosing and uniform distribution, the additives are introduced into the concrete mixture in the form of an aqueous solution of working concentration, that is, a solution that closes the mixture without additional water injection.

As a result, when calculating the composition of concrete with additives, it is necessary to recalculate the amount of water, since part of the water must enter the mixture in the form of an aqueous solution of the additive, which complicates the design of the composition.

Conclusion

While doing this research, the authors solved the following tasks:

They studied and analyzed methods of designing the concrete composition, and decided on the best one, containing the most user-friendly and detailed calculation algorithm.

The researchers developed the most optimal software environment for data visualization and calculations and automation of a designing process of heavy concrete composition considering concentrated solutions antifrost additives and moisture content of aggregates.

References

Ali Yazdi, M., Dejager, E., Gruyaert, E., Tittelboom, K. V., & Belie, N. D. (2020). Bond strength between concrete and repair mortar and its relation with concrete removal techniques and substrate composition. Construction and Building Materials, 230, 116900. DOI:

Aruova, L. B., Ospanova, Z. N., Gordienko, B. S., Alibekova, N. T., Kalieva, Zh. E., Urkinbaeva, Zh. I., & Nurbaeva, M. N. (2020). Properties of Fine-Grained Concrete Mixtures during the Construction of Monolithic Structures. IOP Conference Series: Materials Science and Engineering, 829, 012018. DOI:

Bazhenov, Yu. M. (1975). Sposoby opredeleniya sostava betona razlichnykh vidov [Methods for determining the composition of concrete of various types]. Stroyizdat. [in Russ.]

de Andrade, G. P., de Castro Polisseni, G., Pepe, M., & Toledo Filho, R. D. (2020). Design of structural concrete mixtures containing fine recycled concrete aggregate using packing model. Construction and Building Materials, 252, 119091. DOI:

Dvorkin, L. I. (1981). Optimalnoye Proyektirovaniye Sostavov Betona [Optimal design of concrete mixes]. Vishcha shkola. [in Russ.]

Kozin, V. M., Vasil'ev, A. S., Zemlyak, V. L., & Ipatov, K. I. (2019). Investigation of the limit state of ice cover under conditions of pure bending when using reinforcing elements. Vestnik Tomskogo Gosudarstvennogo Universiteta. Matematika I Mekhanika, 61, 61-69.

Perfilov, V. A., & Gabova, V. V. (2017). Nanomodified constructional fiber-reinforced concrete. MATEC Web of Conferences, 129, 05021.

Perfilov, V. A., & Lepilov, V. I. (2019). Method for Manufacturing of Fiber-Concrete Mixture for Fencing Structure Blocks. Materials Science Forum, 974, 201-205. DOI:

Sizov, V. P. (1979). Proyektirovaniye sostava tyazhologo betona [Design of heavy concrete formulations]. Stroyizdat. [in Russ.]

Taranukha, N. A., & Vasilyev, A. (2015). Numerical investigation problems limit carrying capacity of composite structures, Marine intellectual technologies, 2(3), 27-32.

Zemlyak, V. L., Kozin, V. M., Vasil'ev, A. S., & Ipatov, K. I. (2019). Experimental and Numerical Investigations of the Influence of Reinforcement on the Load-Carrying Capacity of Ice Crossings. Soil Mechanics and Foundation Engineering, 56, 37-43. https://doi.org/10.1007/S11204-019-09566-X

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

21 June 2021

Article Doi

eBook ISBN

978-1-80296-110-2

Publisher

European Publisher

Volume

111

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1168

Subjects

Social sciences, education and psychology, technology and education, economics and law, interdisciplinary sciences

Cite this article as:

Vasilyev, A. S., Radionov, S. V., & Shtepa, E. V. (2021). Algorithms And Models In Numerical Projection Of Composite Environment On Specified Characteristics. In N. G. Bogachenko (Ed.), Amurcon 2020: International Scientific Conference, vol 111. European Proceedings of Social and Behavioural Sciences (pp. 1073-1079). European Publisher. https://doi.org/10.15405/epsbs.2021.06.03.142