Abstract

Over the past few years, the development of the economy has been characterized by the trend globalization, including the modern metallurgical industry. To develop successfully in such conditions, companies need to have competitive advantages that ensure their attractiveness in the international arena. The transition to sustainable, competitive development of metallurgical companies in the context of the fourth industrial revolution is not possible without the digital transformation of their activities. In the world's largest industrial and manufacturing companies, a large-scale digital transformation is already underway, and the steel industry is not the exception. It is important to understand that the process of digital transformation is more than just introducing new technologies, investing in new tools, or upgrading existing systems. The article discusses the aspects of digital transformation of metallurgical companies, which is becoming more and more relevant in connection with the transition to a new stage of development of society. A major focus is laid on the concept of the digital economy and the importance of digital transformation for the competitive development of metallurgical companies, the need to assess the "digital maturity" of companies in order to develop an effective strategy for digital transformation is made a case. The authors provided the main criteria for the readiness of metallurgical companies to digital transformation, as well as the existing problems that slow down the transformation process. The article also presents the results of a study of the successful experience of Russian companies in the metallurgical industry in the field of digital transformation.

Keywords: Industry 40, digitalization, digital transformation, metallurgical industry, economic development

Introduction

The leading trend in the modern development of industrial enterprises is the mass introduction of cyberphysical systems into production, which is characterized by the term "industry 4.0". While describing the changes in companies, this term implies a revolution, namely, the merging of information and operational technologies. The typical features of such changes are the development of information and communication technologies, automation and robotization of production processes.

Digital transformation, regarded as an approach by which businesses change their business models, processes, and business systems using digital technologies and competencies, is inevitable. As a result of their efforts to digital transformation, companies are improving their business performance and consider advanced technologies and high-performance information technologies as significant competitive advantages and drivers of growth.

In recent years, Russian metallurgical companies have also been actively involved in the digital transformation process. At the end of 2019, according to the results of a study based on a survey of financial directors of leading companies in Russia, the metallurgical industry is the second most digitalized industry in Russia after high-tech, telecommunications, entertainment and media: the level of innovation in the metallurgical industry, considered as a weighted average of technology complexity assessment is 0.24, while the level of innovation in Russia is 0.17 on average. The leading Russian metallurgical companies, as well as world leaders in metallurgical production, expect a significant increase in efficiency from the digitalization of production and business processes.

In regard to the above, it is highly relevant to study the concept of the digital economy in general and the importance of digital transformation for the companies ' development of metallurgical industry in particular, as well as criteria for their readiness to change; barriers to the rapid development of the transformation process; positive experience of realisation of projects of digitalization of metallurgical production.

Problem Statement

At the present stage of development of society and the formation of new social relations, humanity has entered the next phase of its development, which is called the era of digitalization or the fourth industrial revolution. Currently, large, leading companies around the world are in the process of digital transformation.

At the moment, there is no clear, generally accepted definition of digital transformation, but this term is used to mean the transformation of a business by revising its business strategy, models, operations, products, marketing approach, goals, etc. through the use of digital technologies. It is important to understand that digital transformation is not just an evolution of information technology, but a complete business change that affects the entire organization.

The transition to "digital production" and technological development on digital technologies is the basis for global competitiveness of enterprises, including metallurgical companies. Therefore, the focus of this research is a new stage of industrialization and qualitative improvement in production efficiency based on digital technologies, current trends and challenges of digital transformation of production as the basis for the competitiveness of metallurgical enterprises.

Research Questions

The conditions for the development of the modern digital economy require companies to improve not only their production processes, but also their business processes, which can be achieved by introducing various types of innovations and adapting business models to modern realities. This approach, through which companies change their business models, processes, and business systems using digital technologies, is called digital transformation.

The activities of the world's largest industrial companies are already fully characterized by a large-scale digital transformation. Companies in the steel industry are no exception. Digitalization has become for them a mandatory and integral component of competitive and breakthrough development.

Companies are digitizing the most important functions of production, supply and sales, and other activities. The introduction of data analysis and process automation technologies is the key to more flexible and efficient production. Currently, metallurgical companies are seeking to increase productivity through the use of special technologies and algorithms that make it possible to track the relationship between the properties of raw materials and production costs, and production constraints. In addition, there is a widespread integration of disparate production processes, which in turn has a positive effect on losses and volumes of heat and energy consumption, on optimization of production times, etc.

Thus, the world's leading metallurgical companies, including Russian ones, expect a significant increase in the efficiency of their operations from the digitalization of production and business processes.

Purpose of the Study

In regard to the above, the purpose of this research is to determine the essence of digital transformation and its place in the formation of a flexible and effective management system for a modern industrial enterprise. To achieve this goal, it is necessary to identify what is meant by the digital economy and digital transformation, determine the criteria for evaluating the level of digitalization of the metallurgical industry and readiness of the Russian metallurgical enterprises for digital transformation, what factors slow down the process of digital transformation, and find out the social and financial advantages of this process. To illustrate the results of a successful implementation of digital transformation, we should consider the experience of Russian metallurgical giants.

Research Methods

In the study of theoretical and practical aspects of the digital transformation of metallurgical enterprises in the framework of the development of the digital economy, general logical and empirical methods that form the basis of general scientific methods are used.

Findings

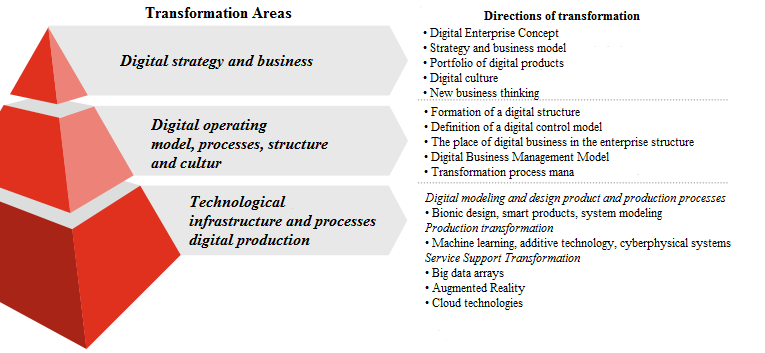

In recent years, digital transformation has been an important phenomenon in company research. Despite this fact, there is still no unified and harmonized definition of the digital economy in Russia, as well as in international practice. "Strategy for the development of the information society in the Russian Federation for the period 2017–2030" has the following definition of the digital economy: "The digital economy is an economic activity in which the key factor of production is data in digital form, processing large volumes and using the results of analysis of which, in comparison with traditional forms of management, can significantly improve the efficiency of various types of production, technologies, equipment, storage, sale, delivery of goods and services". Improving efficiency and optimization as a goal of the digital economy requires building conceptually new business models (Vasilenko, 2018). Fundamentally different approaches to managing enterprises and organizations are an important aspect of digital transformation. Digital transformation can be understood as the process of integrating digital technologies into all aspects of business activities, requiring fundamental changes in technology, culture, operations, and the principles of creating new products and services (Min et al., 2019). The main areas and directions of transformation of industrial companies are shown in Figure 1.

Changes in these areas can create both new business models and reconstruct old ones, and, consequently, digital transformation becomes the most important strategy for all industries.

The metallurgical industry is no exception. Russian metallurgical companies are traditionally one of the main suppliers of steel products in the world market. However, in order to maintain a leading global position in the context of Industry 4.0, Russian metallurgical companies need to maintain their competitiveness. This will be facilitated by the constant development of the company, flexibility, readiness to continuously adapt to changing conditions through the use of advanced technologies and the organization of decision-making processes using high-quality data, i.e. active movement towards digital transformation.

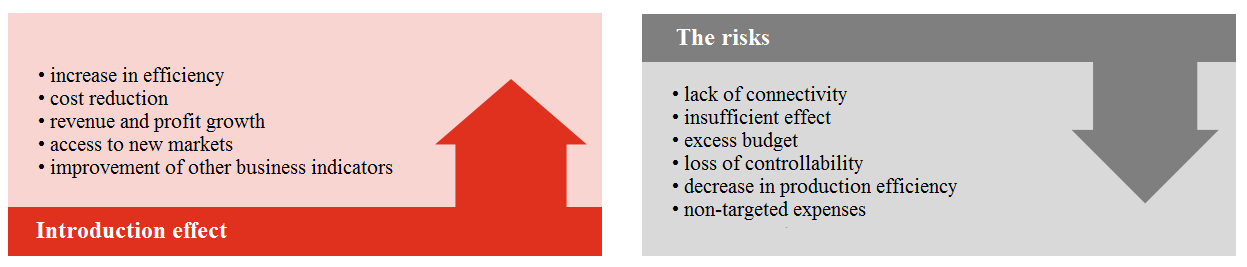

To form a successful strategy for digital business transformation, it is necessary to rely on the existing digital potential and the level of readiness for its implementation (Albukhitan, 2020). The stage of assessing the digital maturity of metallurgical companies is necessary to allow you to make informed decisions about investments in digital transformation projects and minimize risks (see Fig. 02).

To assess the level of digital readiness of enterprises at the quantitative and qualitative levels, it is necessary to take into account the indicators that most fully reflect the target indicators of the state program and global trends (Gileva, 2019). These include: the availability and level of development of infrastructure for digital technologies; the level of development of communication services, storage and transfer of information; the level of development of human capital; the level of "digitalization" of business, including the level of automation of internal processes; the level of information security; the presence of regulatory environment and barriers to the development of digital technologies (Klau, 2016).

Various barriers to digital transformation may arise at all stages of its implementation. The most significant and widespread are the insufficient level of digitalization of the company, the lack of necessary competencies, inefficient business processes, high risks and costs. In addition, people and culture, which are essentially the driving force of transformation, slow down the digital transformation of industrial companies. In this area, the main problems are in the existing corporate culture, management style and economic justification for changes. For steel companies, until recently, a significant problem was the lack of a clear understanding of the economic benefits of investing in digital development, the lack of a digital culture, and the lack of a clear program for developing digital activities. Here again, we come to the conclusion that in order to correctly form an effective strategy for digital transformation of a company, it is necessary to first assess the readiness of its elements for such changes.

At the moment, it is an undeniable fact that the world's leading metallurgical companies, including Russian ones, expect a significant increase in efficiency from the digitalization of production and business processes. According to the World Economic Forum, the metallurgical and mining industries could benefit from digitalization in excess of $320 billion by 2025. There are already successful examples of digital transformation projects implemented by major players in the global market of metallurgical products. Some of them have already reduced costs by several tens of millions of dollars due to the introduction of large-scale solutions and have shown a 5–20 % increase in production. According to a study by Accenture, only 20–22 % of global industrial companies currently receive the expected return on digital investment. Such companies encourage the "top-down" way of digitalization and introduce cloud and platform technologies. These methods provide an advantage, helping to scale digital ideas to the entire business and create a modern flexible agile culture.

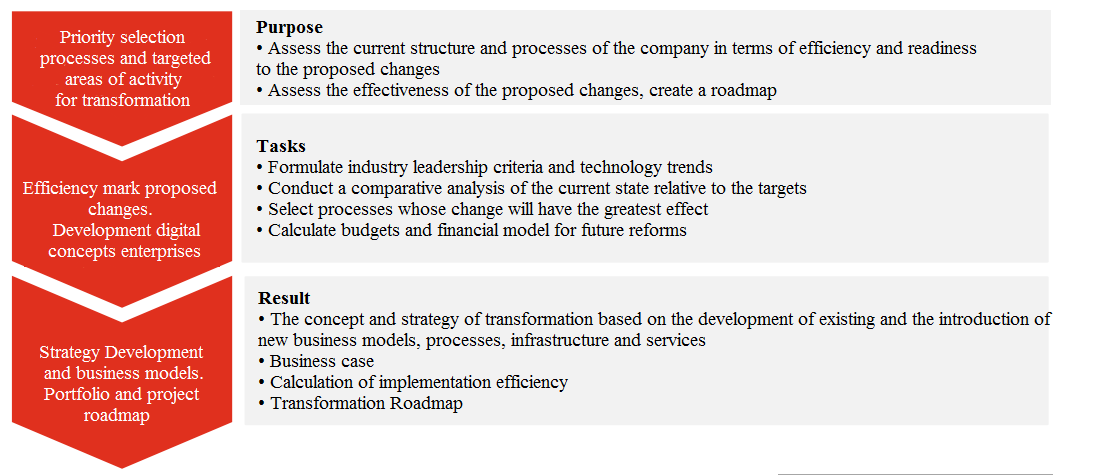

In general, the metallurgical industry should be classified as a conservative type of business (Skvortsova & Achkasov, 2019). According to the analysis of the Organization for Economic Cooperation and Development, this industry has a medium-low digitalization index (Digital Intensity). In Russia and around the world, steel companies are outpacing the banking sector, telecommunications, and retail in terms of scale and speed of digital transformation. Comparative analysis within the metallurgical industry shows that Russian companies are not lagging behind international competitors. In 2018–2019, most large enterprises implemented a number of pilot projects and formed digital transformation programs. According to the above-mentioned research by Accenture, Russian steel companies are not far behind and even in some cases are ahead of the industry in terms of creating ideas and prototypes for digital transformation. However, the Russian steel industry is lagging behind at the stage of transition from research to implementation of viable solutions in the production environment and subsequent scaling up to obtain financial benefits. The reasons for this are, as a rule, the lack of a comprehensive approach to creating a digital enterprise, as well as differences between traditional and modern agile approaches and the slow introduction of cloud and platform technologies in the production environment. If we analyze the experience of starting digitalization process, the absolute majority of metallurgical companies begin it with the implementation of disparate digital initiatives aimed at improving separate functional areas. In the process of their implementation, synchronization of changes, comparison of their timeliness and effectiveness, one is inevitably led to the conclusion that there is a need for a strategic coherence of such projects and a digitalization strategy. The algorithm for developing a digital transformation strategy for a metallurgical enterprise can be described in the diagram shown in Figure 3.

Despite the mentioned barriers that prevent full-scale digital transformation of Russian steel companies, the process has already been launched and the industry analysts Deloitte noted the implemented digital projects of domestic steelmakers. For example, introduction of a personnel positioning system that allows you to increase the level of work safety by timely responding to emergencies through monitoring, and analysis of personnel actions and equipment performance. The system detects the location of employees in real time, automatically issues shift tasks and monitors the results. It also warns the dispatcher about the presence or approach of employees to dangerous areas and equipment operation failures. Thus, digitalization helps companies achieve virtually zero levels of workplace injuries and deaths through the use of tracking, video Analytics, accident prevention algorithms, drones, and robots.

Another significant result of the digital transformation of Russian metallurgical companies can be considered a popular direction today, the robotization of routine operations in administrative processes. More than 80 % of the companies surveyed by KPMG pilot or implement RPA-based solutions. Magnitogorsk iron and steel works (MMK), one of the world's largest steel companies, is a pioneer of this direction. It has launched a robot for collecting and systematizing quotations for raw materials. Also, a robot responsible for interacting with scrap metal suppliers successfully operates in the company's commercial Directorate. It processes e-mail, independently searches Russian Railways databases, and generates reports for the company's specialized services. The automation of production processes allows freedom employees to deal with more complex, intellectual tasks, which improves the company's efficiency. Another example is the recommendation service "Sniper", which operates on the principles of AI (artificial intelligence), which allows MMK to optimize the consumption of ferroalloys and additional materials in steelmaking. Every year, "Sniper" saves the company about 4 million dollars. Another project is aimed at reducing the cost of pig iron and involves the creation of an optimization model of blast furnace production; the economic effect is 14.3 million dollars annually. Other projects of the company in the field of digitalization are optimization of power plant boilers (the effect is almost 2 million dollars per year) and the creation of digital twin turbo units (1.2 million dollars per year).

Overall, in 20019, MMK, in partnership with Deloitte International, create a portfolio of digital transformation projects. The implementation of projects will improve the efficiency of business processes at MMK and will bring the company an additional economic benefit of 4.5 % of EBITDA until 2025. Integrated corporate information system, mobile access to key business applications, use of artificial intelligence technologies to solve problems of modeling and forecasting of technological and business processes, end-to-end production planning and operational management of orders, solving problems of protecting the life and health of the plant's employees at work are among the priority areas. Within the framework of the "industry 4.0" concept implemented at the company, MMK is conducting a comprehensive digitalization of business processes, which so far has been successful. Only in 2019, the implementation of projects from this pool brought the company more than $ 25 million, and according to the forecast, their contribution to EBITDA should be $ 160 million by 2025.

To sum up, we would like to note that today the digital transformation affects all areas of MMK's activities, starting with sinter production, where mathematical models help to analyze the quality of purchased coal and optimize the process of iron smelting, and ending with communication with customers, who, using a specially created application for them, "MMK Client", can track the progress of their orders online. The successful implementation of IT projects within the framework of digital transformation at MMK was possible due to the digital "maturity" of the company, which has long been distinguished by a high level of industrial automation and extensive use of information systems. Thus, the use of digital technologies in all areas of activity will be the main driving force of the development of companies in the metallurgical industry in the near future.

Conclusion

Summarizing up the results of this study, we can draw the following conclusions:

The digital transformation of the company is the main factor in increasing the competitiveness of metallurgical companies in the context of ongoing globalization and the transition to the fourth industrial revolution.

Effective digital transformation does not involve the implementation of separate pilot projects to digitalize production; the company must have a clearly formed digital transformation strategy.

To effectively determine the vector of digital transformation of the company, it is necessary for the management to understand the level of its readiness for digital transformation. Therefore, the assessment of "digital maturity" is an integral part of an integrated approach to developing an effective company transformation strategy, which makes it possible to see a complete picture of the integration of strategy, technology, business processes and data to obtain significant results in improving business efficiency.

The digital transformation of metallurgical enterprises is under way, as illustrated by the positive experience of implementing digital technologies, at the same time, there are some barriers to a faster and full-scale development.

References

Albukhitan, S. (2020). Developing Digital Transformation Strategy for Manufacturing. Proc. Computer Sci., 170, 664–671.

Gileva, T. A. (2019). Digital maturity of the enterprise: methods of assessment and management. Bull. USPTU. Sci., еd., econ.. Ser. Econ., 1(27), 38–52.

Klau, T. (2016). Deloitte how to thrive in the digital economy. http://deloitte.wsj.com/cio/2016/06/21/how-to-thrive-in-the-digital-economy

Min, J., Kim, Y., & Lee, S. (2019). The Fourth Industrial Revolution and Its Impact on Occupational Health and Safety, Worker's Compensation and Labor Conditions. Safety and Health at Work, 10, 400–408.

Skvortsova, N. V., & Achkasov, D. V. (2019). Modern trends and problems of the development of the metallurgical industry in the economy of Russia. Actual issues of the modern econ., 973–984.

Vasilenko, N. V. (2018). Digital economy: concepts and reality. In Innovation Clusters in the Digital Economy: Theory and Practice (pp. 147–151). Publ. House of the Polytech. University.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

17 May 2021

Article Doi

eBook ISBN

978-1-80296-106-5

Publisher

European Publisher

Volume

107

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2896

Subjects

Science, philosophy, academic community, scientific progress, education, methodology of science, academic communication

Cite this article as:

Skvortsova, N. V., & Kuznetsova, M. V. (2021). Digital Transformation As A Driver Of Economic Development For Metallurgical Companies. In D. K. Bataev, S. A. Gapurov, A. D. Osmaev, V. K. Akaev, L. M. Idigova, M. R. Ovhadov, A. R. Salgiriev, & M. M. Betilmerzaeva (Eds.), Knowledge, Man and Civilization - ISCKMC 2020, vol 107. European Proceedings of Social and Behavioural Sciences (pp. 1507-1514). European Publisher. https://doi.org/10.15405/epsbs.2021.05.199