Abstract

The paper discusses the current issues and problems in the management decision-making process in terms of processing information, the uncertainty of information about material quality and the role of the expert-technologist in the decision-making process. Description of the concept of the decision support system in the process of production control in conditions of uncertainty of information on material quality.For the selected class treatment processes proposed two-intelligent control system of industrial enterprise on the basis of agent-based decision support systems and fuzzy controllers. The generalized network technology as a way of presenting the conversion process as a directed graph in which the nodes are arranged agents. A model of agent interaction within the technological network has been developed. Proposed fuzzy system for assessing the quality of the material and developed a model of a database and knowledge base for the management of the recycling process on the basis of fuzzy controllers.

Keywords: Uncertainty of information about material qualitydecision-making processagent-based decision support systemsfuzzy controllersexpert-technologist

Introduction

A common factor of uncertainty in production for a wide range of industries (agricultural, food, construction, mining, chemical, transport, etc.) is the uncertainty of the material quality (feedstock, intermediate product and final product) in the recycling process (hereinafter — RP). This uncertainty affects the efficiency of the industrial enterprise and the quality of the final product (Novikov et al., 2010). Decision-making difficulties for the management of the RP arise due to incomplete information about the material quality; the complexity of building models and control algorithms based on precise mathematical methods; it also includes the problems of applying the methodology and tools accounting the human factor in unforeseen emergency situations (Oberkampf et al., 2004).

World experience shows that in such conditions the most effective way to improve the quality and reduce the cost of production is a comprehensive management of RP using modern methods of processing information with intelligent, optimal and adaptive control of the recycling process (Bagnoli & Smith, 1998; Del Giudice et al., 2017; Dubois & Prade, 1990; McNeill & Thro, 1994; O'Hagan & O'Hagan, 1993; Zadeh, 1983).

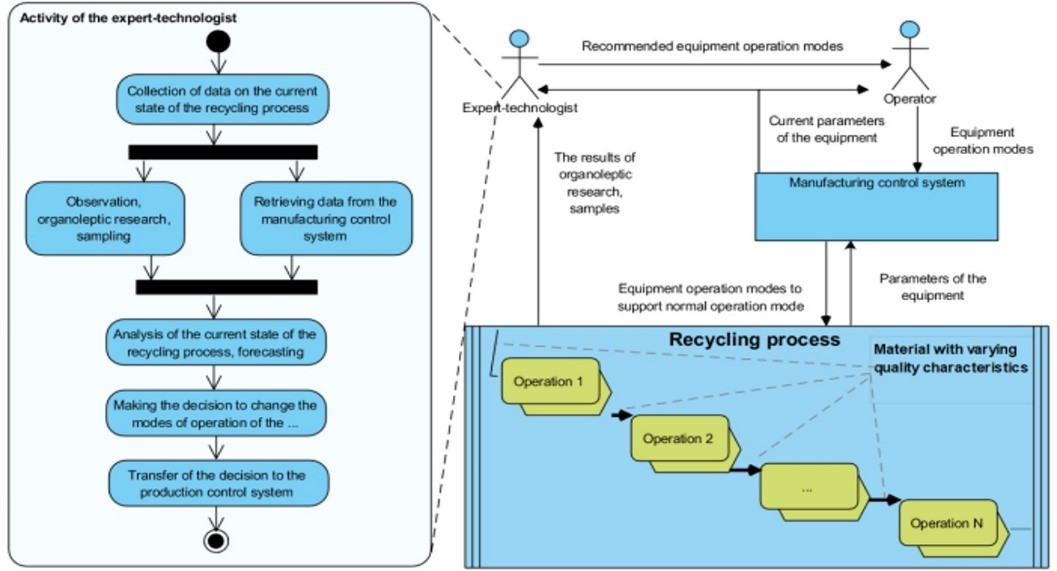

An expert technologist plays an important role in the management of RP in modern industry (figure

Due to the fact that the recycling process is characterized by unsteadiness, inertia, delay, random disturbances, fuzzy and incomplete information, problems in the management of a large processing enterprise appear (Aydogan & Gokalp, 2014; Benavides & Diwekar, 2013; Cosenza & Galluzzo, 2012; Escaco et al., 2009).

Modern methods of digital production, data processing and modeling allow using software tools for extraction, representation, processing and formation of objective knowledge bases, and creating simulation models. The use of intelligent control systems will exclude the expert technologist from direct participation in the management by providing him the opportunity to develop and adapt the system.

Thus, it is suggested to use an intelligent control system of an industrial enterprise, the recycling process of which has the following characteristics:

•discrete-continuous flow of the material recycling;

•the uncertainty of information about the material properties;

•the time variation of material properties in different nodes of RP;

•the distribution in the space of local RP control of devices systems;

•absence (full or partial) of the rate of flow measurement of material properties in the RP system;

•undefined dependency of the local system management from data about the recyclable material properties.

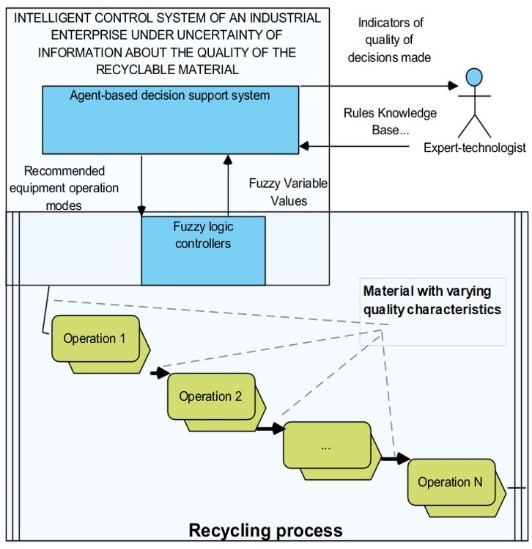

Such an intelligent system (figure

•agent decision support system, which includes:

•technological network;

•chronomodel RP;

•algorithm for evaluating the adequacy of the model in relation to the research object;

•model and algorithm of agent-based decision-making system in the RP management;

•fuzzy evaluation system for measuring material properties, evaluation of RP quality and agents’ decision-making

•fuzzy system the algorithm for determining the type and parameters of membership function of fuzzy for the expert table;

•databases and knowledge bases models of the decision making system for the RP management;

•fuzzy logic controllers.

Technological network

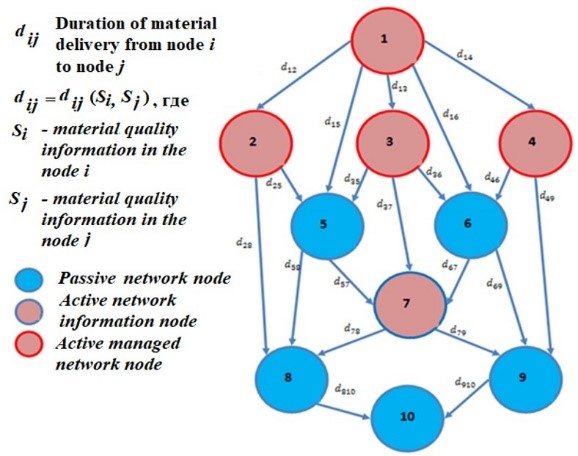

Form of a technological network. The technological network (hereinafter — TN) is the directed graph, nodes of which are a group of process devices. Nodes are divided into 2 types: active and passive (Figure

Active nodes are characterized by the fact that they change the material properties, passive are characterized by the immutability of the material properties. Active and passive nodes are divided into managed and unmanaged. Managed nodes are characterized by the presence of local equipment control systems. Unmanaged nodes are characterized by the absence of local control systems. As a rule, the transfer of recyclable material in such nodes is carried out from one active node to another. The task of the local management decision-making system is to support the operation of the TN equipment at the required level depending on the incoming data on the properties of the recyclable material.

Agency decision model

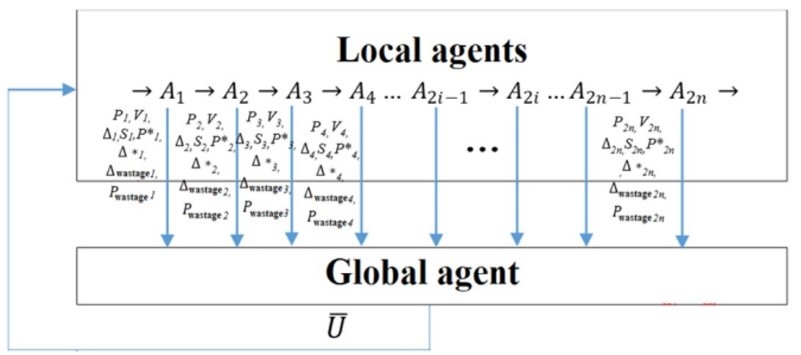

Each node of the TN is put in accordance with the agent Aij. The node to which the agent is bound is called the agent responsibility node. Thus, the set of TN nodes corresponds to the set of agents — , where i is the agent’s number, j is the number of the responsibility node

In the responsibility node, each agent

transmits the following current information on its node at time

(figure

1. The operation mode of the equipment

2. Volume

3. Time remaining for material recycling .

4. Compliance of the regime with the quality of the material S.

5. Operation mode corresponding to the quality P*.

6. The time remaining for recycling the material in the mode corresponding to the quality Δ*.

7. The losses linked with a mismatch between mode and material quality .

Each agent sends an information about the state of its node to the global agent, which performs:

1. Calculation of the minimum time through which there will be a change of the material quality in one of the RP nodes.

2. Calculation of time and productivity losses throughout the entire current recycling process chain at the time

3. Calculation of time and productivity losses along the entire recycling process chain planned at the time

4. Selecting the operating mode

5. The transfer of recommended operating modes of the equipment and switching time to the needed mode taking into account transients in nodes to agents .

In fact, technological network due to the activity of global agents allows the agent to generate the event model that reflects the digital portrait of the material flow and their properties and represents chronomodel of the recycling process.

This database and knowledge model of system includes entities that are intended to be stored:

values of parameters of function of accessory of indistinct variables;

interrelations of rules and indistinct variables;

methods of a defazifikation of indistinct variables;

indistinct variables;

rules;

parameters of functions of accessories;

storages of functions of accessory;

the sizes measured by sensors;

values of the operated parameters;

communications between agents and the equipment in knot of their responsibility;

data on software equipment;

communications between sensors and the measured sizes;

information on agents;

messages which agents exchange;

communications between agents and agents of influence;

data on sensors;

measurement stories sensors;

stories of change of the operating equipment operation parameters.

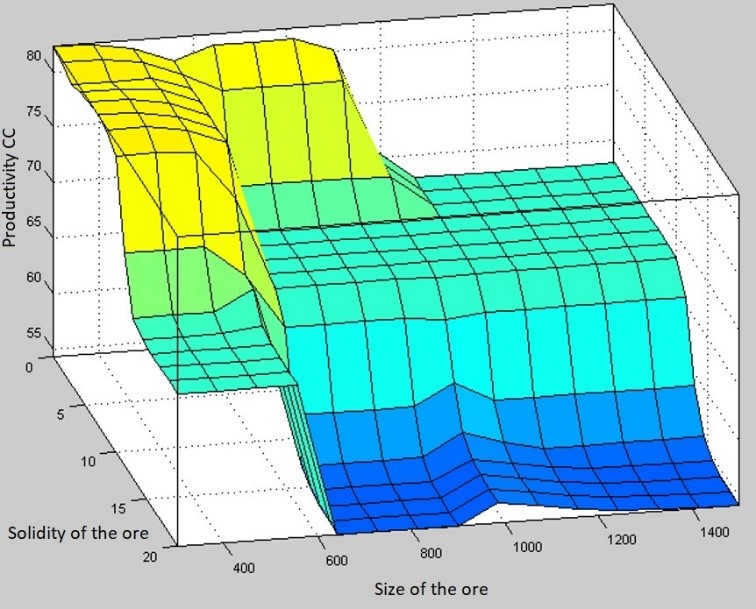

As an example, let’s consider the fuzzy function of determining the operation mode of an equipment unit, which establishes a fuzzy relationship between performance and fuzzy variables that characterize the material property. Productivity of coarse crushing (CC) = Productivity CC

,

,

,

, where M is the domain of

(figure

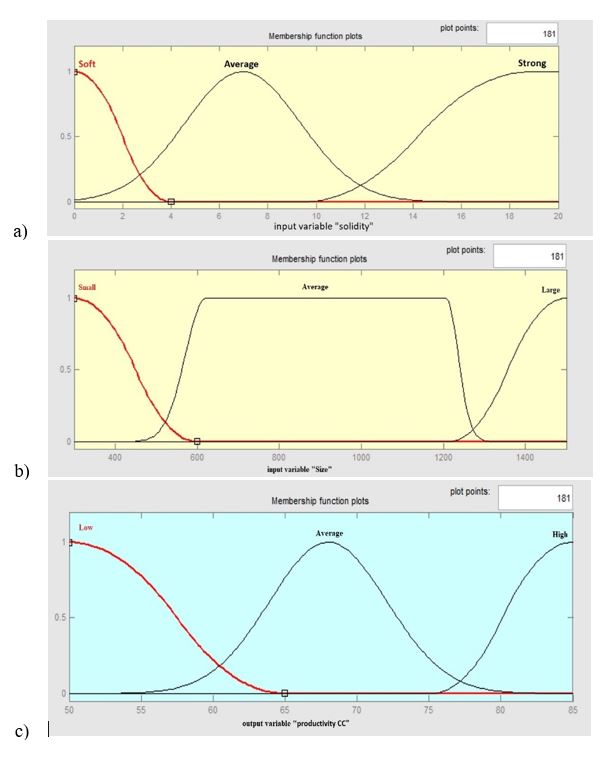

Fuzzy input variables:

Fortress (x1). Values x1 are soft, medium, hard (figure

Size (x2). Values x2 are small, medium, large (figure

Output: Productivity CC values are low, medium, high (figure

Conclusions

As a result of this work is presented the concept of a support system of decision-making in the management of the processing process. For the selected class treatment processes proposed two-intelligent control system of industrial enterprise on the basis of agent-based decision support systems and fuzzy controllers.

The generalized network technology as a way of presenting the conversion process as a directed graph in which the nodes are arranged agents. A model of agent interaction within the technological network has been developed. Proposed fuzzy system for assessing the quality of the material and developed a model of a database and knowledge base for the management of the recycling process on the basis of fuzzy controllers.

A decision support system under uncertainty of information about recyclable materials for the enrichment process was developed based on the tools. As a result of the conducted experiments on the enrichment process model, there was obtained the following outcome: the volume of recyclable material was increased by at least 4% and the amount of useful material at losses was decreased by at least 1.5%.

References

- Aydogan, S., & Gokalp, K. (2014). A fuzzy model based adaptive PID controller design for nonlinear and uncertain processes. ISA Transactions, 53, 280-288.

- Bagnoli, C., & Smith, H. C. (1998). The Theory of Fuzzy Logic and its Application to Real Estate Valuation. Journal of Real Estate Research, American Real Estate Society, 16(2), 169-200.

- Benavides, P. T., & Diwekar, U. (2013). Studying various optimal control problems in biodiesel production in a batch reactor under uncertainty. Fuel, 103, 585-592.

- Cosenza, B., & Galluzzo, M. (2012). Nolinear fuzzy control of a fed-batch reactor for penicillin production. Computers and Chemical Engineering, 36, 273-281.

- Del Giudice, V., De Paola, P., & Cantisani, G. B. (2017). Valuation of real estate investments through Fuzzy Logic. Buildings, 7(1), 26.

- Dubois, D., & Prade, H. (1990). Resolution principles in possibilistic logic. International Journal of Approximate Reasoning, 4(1), 1-21.

- Escaco, J. M., Bordons, C., Vilas, C., Garcia, M. R., & Alonso, A. A. (2009). Neurofuzzy model based predictive control for thermal batch processes. Journal of Process Control, 19, 1566-1575.

- McNeill, M. F., & Thro, E. (1994). Fuzzy Logic A Practical Approach. AP Professional Boston.

- Novikov, S. I., Shahnovich, V. R., & Safronov, A. V. (2010). Metody nechetkoj logiki v zadachah avtomatizacii teplovyh processov jelektrostancij. Vestnik IGJeU, 4, 1-4.1.

- Oberkampf, W. L., Helton, J. C., Joslyn, C. A., Wojtkiewicz, S. F., & Ferson, S. (2004). Challenge problems: uncertainty in system response given uncertain parameters. Reliability Engineering & System Safety, 85(1-3), 11-19.

- O'Hagan, N. K., & O'Hagan, M. (1993, September). Decision Making with a Fuzzy Logic Inference Engine. Proc. Applications of Fuzzy Logic Technology, Soc. of Photo-Optical Instrumentation Engineers, 320.

- Zadeh, L. A. (1983). The role of fuzzy logic in the management of uncertainty in expert systems. Fuzzy sets and systems, 11(13), 197-198.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

08 March 2021

Article Doi

eBook ISBN

978-1-80296-102-7

Publisher

European Publisher

Volume

103

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-644

Subjects

Digital economy, cybersecurity, entrepreneurship, business models, organizational behavior, entrepreneurial behavior, behavioral finance, personnel competencies

Cite this article as:

Milovidova, A., Cheremisina, E., & Dobrynin, V. (2021). Intelligent Control System Of An Industrial Enterprise Under Uncertainty Of Information. In N. Lomakin (Ed.), Finance, Entrepreneurship and Technologies in Digital Economy, vol 103. European Proceedings of Social and Behavioural Sciences (pp. 357-364). European Publisher. https://doi.org/10.15405/epsbs.2021.03.45