Abstract

The article defines the directions of transition of the glass industry from the traditional concept of building business models based on the resource approach to the new concept of digital production and substantiates its importance, relevance and efficiency. The authors review the methodical support of glass industry transition to digital production. The systematic benefits are proved by digital transformation of all business processes and business models in the glass industry. At the industry level, the transformation of the glass industry is characterized by the minimization of human participation in the production process and the transition to effective data-based management. In addition to the wide implementation of ERP solutions, the technology contributing to the transformation of traditional manufacturing in the digital and characterized by full digital integration of production and logistic chains and supply chains include: - digital design and modeling as a set of technologies of computer designing, computer engineering and supercomputing, mathematical modeling, optimization, and technological preparation of production, focused on additive manufacturing, and developing smart models and smart digital doubles; - use of new synthetic materials, especially composite materials, silicates, metamaterials and metal powders for additive manufacturing.. Moreover, they are likely to be accompanied by a large-scale transformation of common technological operations known as "smart", that makes it possible to develop an innovative digital glass factory and transfer from "Glass Industry 4.0" to "Glass Industry 5.0", providing the corresponding shift to new technological instructions.

Keywords: Digital economydigital platformbusiness processesinformation technologydigital transformation of the glass industry

Introduction

The concept of Industry 4.0 is considered as a set of technologies (working with big data (predictive Analytics, etc.), the Internet of things / industrial Internet of things, agile approaches to managing the development of new products, "smart" production systems (smart factories), augmented and virtual reality technologies, etc.), which significantly transform business processes and business models in terms of decentralization of "production" systems (production systems means not only the production of goods, but also the provision of services), profitability from "production of piece products" and "production" can be profitable for each specific consumer increases, there is a focus on life cycle contracts (that is, the added value is calculated for the entire period from production to disposal of the product/service) (Ukolov, 2019).

The technique of research fronts indentification

The concept of Industry 4.0 is considered as a set of technologies (working with big data (predictive Analytics, etc.), the Internet of things / industrial Internet of things, agile approaches to managing the development of new products, "smart" production systems (smart factories), augmented and virtual reality technologies, etc.), which significantly transform business processes and business models in terms of decentralization of "production" systems (production systems means not only the production of goods, but also the provision of services), profitability from "production of piece products" and "production" can be profitable for each specific consumer increases, there is a focus on life cycle contracts (that is, the added value is calculated for the entire period from production to disposal of the product/service) (Ukolov, 2019).

Presently, we are likely to witness a transformation boost towards the digital economy. In fact, the report “Prospects for Digital Economy, 2017” made up by the Organization for Economic Cooperation and Development, points out the following concept: “Data-based innovations come out as the key driver for the 21st century growth. Both the interrelation of tendencies, providing a greater shift of socio-economic activities to the streaming platforms and a dropping cost for data collection, its storage and processing, have made it possible to generate and process a great number of data, called “big data” (OECD, 2017). It is viewed as the main contribution into economy regarding the development of new industrial sectors, processes, and products, with the key competitive advantages included. In fact, the benefits of business data have led to a wide range of business processes, aimed at global value optimization, labor efficiency, and customer-focused relationships.” Many OECD member states are noted to have initiated special projects aimed at developing research and professional skills regarding the digital economy, with Russia as no exception. In July 2017, the project “Digital Economy of the Russian Federation” came into force clarifying that “the ecosystem of the digital economy of the Russian Federation is due to have digital data viewed as a key factor of production in all areas of socio-economic activity that provides effective cross-border and business interaction, scientific and educational interplay, relations between the state and its citizens” (Medvedev, 2017). The key digital technologies are highlighted both as big data and neurotechnological artificial intelligence. The program is aimed at five main aspects, including the development of research skills and technological benefits. Apart from the government institutions, the academic community seems to be focused on the new phenomenon and future development of digital economy. Thus, in 2013, the Massachusetts Institute of Technology worked out a project turning digital economy into a large-scale project that involves policymakers, leading scientists, and experts, unites them into a team. It aims at “considering how individuals and businesses interact and benefit into digital transformations” (Neogronte, 1995). The key research initiative is called “Social Analytics and Digital Experiments”. It makes it possible to host an annual Conference on Digital Experiments, bring leading scientists together, and highlight interdisciplinary significance of this new approach, both theoretically and practically. In 2017, Moscow State University established the National Center for Digital Economy (Oreshkin, 2017). It is focused on “promoting the development of digital economy in Russia. Moreover, it aims at bringing all the departments of Moscow State University together with other leading scientific and educational centers, public authorities and companies involved in research and scientific activity, international cooperation, educational and methodical guidance, innovative expertise in order to contribute to the development of digital economy in Russia”. These two centers are likely to make the research of digital economy relevant in general. When figuring out scientific priorities in the glass field, one can focus on the list of issues made up by the Center of Glass Technologies Zentrum Handwerk (Samarin, 2019), State Association of Flat Glass Manufacturers (BF-Bundesverband Flachglas, Germany) (Klaus Bauer, Trumpf Werkzeugmaschinen GmbH & Co. KG, 2017), Rosenheim GmbH, German Trade Association of Professional Independent Experts, Augsburg Academy, Dortmund Academy, Darmstadt Technical University, as well as German Professional Association of Manufacturers of Laminated Insulating Glass. These issues are considered by leading academic journals to highlight the key aspects of publications. It helps turn attention to the perspectives of the glass industry in the nearest future. The project under study is aimed at working out methods to analyze and process big data that will help set up patterns and models of digital shift in the glass field.

The main positive effects of the introduction of digitalization processes in domestic enterprises, regardless of the industry and field of activity can be: increase the profitability of the enterprise due to the efficiency of production; increase control over the production process and its results; increase the volume of output by increasing the load of current production capacity; improving the quality of products and reducing the number of marriage and waste; improving control over the work of personnel and increasing productivity; acceleration of turnover of production materials and in General of current assets; increase in the volume of exports outside the Russian Federation (Orlova, 2017).

Testing of the technique and analysis of results

Digital shift in the glass field is viewed as the key factor of digital economy development that makes it possible to get digital dividends since reasonable economic outcomes are true to measure with implemented digital techniques and tools. Digital shift in the glass field has several features, including minimal human involvement into production and maximum efficiency of data management. “Glass Industry 4.0” considers the whole production cycle from monitoring and planning to digital designing, testing, and making experimental samples. “Glass Industry 4.0” uses “smart” big data to make “smart” models of future products (cars, constructions, aggregate units, appliances, and devices) (Schäfer, 2016). All of them are designed due to the new paradigm of digital modelling experimenting with “smart” digital copies. Digital development of all aspects of the glass field is the main feature of different stages of production, from exploration of sand deposits to raw material processing and product marketing. Digital shift makes it possible for the glass field to move forward implementing technologies of artificial intelligence, neural networks, and big data. They are indispensable elements of “Glass Industry 4.0” which make innovations come true.

The main objective of “Glass Industry 4.0” is to slow down the rapid growth of integration expenditures and transaction costs.

To assess the effectiveness of digitization of the glass field, it is obvious to apply to an expert assessment using the factors of efficient digitalization. Evaluation is based on a 5-point scale.

The evaluation model includes seven factors, represented as follows:

K1 means regulation norms and formal factors of digitalization,

K2 includes qualified personnel and specific training courses,

K3 stands for research skills and technological outcomes,

K4 defines information infrastructure,

K5 controls information safety,

K6 foresees financial and economic efficiency of digitalization,

K7 marks social effectiveness of digitalization.

The expert opinion seems to be reliable and consistent if based on evaluation and analysis of the coefficient of concordance W, calculated using the formula:

where:

12 is the constant value in Kendall’s formula to calculate the concordance coefficient;

N is the number of experts;

n is the number of evaluation criteria;

ri is the sum of ranks of the i-index;

r is the average sum of all scores.

The coefficient W variates from 0 to 1. If it is equal to one, it shows the complete consistency of experts’ views. If it is equal to zero, it indicates the absence of connection between experts’ evaluations. In case when 0.2 ≤ W ≤0.4, it shows weak ties of experts’ opinion. If W ≥ 0.6, it shows strong ties of experts’ opinion.

To determine the weight coefficients for each factor, the Fishborn method is used and represented in the formula:

where:

ai is the weight coefficient of the i-criterion,

n is the number of evaluation criteria,

ri is the rank of the i-indicator.

The value of the coefficient close to one indicates a higher degree of the multifactor model that shows a high chance of the glass field to adopt digital transformation. Digital transformation (digitalization) in the glass industry is a primary creation of a new business model and a new market based on benefits of digital economy. The characteristic feature of the “Glass Industry 4.0” is the creation of new business models, combining the physical and digital worlds. Such cooperation is possible when smart machines begin to form and use digital models of the physical world. This is what ensures the independence of decision-making machines close to real time. Sometimes it seems that new business models of “Glass Industry 4.0” are the information tools of a person overseeing a decision-making process. But experimental projects have shown that people stop being interested in new behaviors that make them face challenges. It is necessary for the initiative to be intercepted by cyber-physical systems. Moreover, machines should be focused on goals and digital models set up by people as a part of the real world rather than by rigid standards and algorithms. To ensure a high degree of competitiveness of the modern glass enterprise it is necessary to implement the components of modern digital production technologies in the following areas:

Use of approaches to the creation and development of project management teams for their effective collaboration in different geographical locations and countries;

Creation and implementation of the technique of coordination of technical characteristics of the equipment delivered for the Russian glass enterprises;

The management of the production lifecycle glass company;

Quality control of the delivered production at manufacturing plants;

Ensuring the integration of equipment supplied by foreign partners with the equipment of domestic producers;

The formation of logistic routes in the conditions of tough climatic conditions and remoteness of the places of delivery;

Provision of installation and commissioning works in harsh conditions;

Providing service support and fulfillment of extended warranty terms.

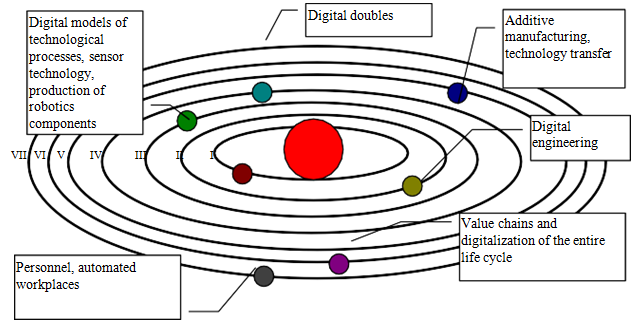

Digital transformation is currently viewed as a systematic upgrade of all business processes and models in the glass industry worldwide. It brings a large-scale transformation of common technologies into “smart” and affects the development of the innovative digital glass factory (Figure

Factories of the Future make up a set of business processes in the glass field, implemented into the business environment (business system) of the company, which has the following characteristics:

1.Development of advanced digital glass platforms capable of combining geographically distributed economic agents (suppliers, contractors, end users of glass products), to decompose the business processes of manufacturing glass products, to visualize the stages of technological processes, in order to involve consumers in open innovation in the glass industry;

2.Implementation of the glass platform should contribute to the formation of a variety of digital models of the existing design of glass products, and new glass products that have no analogues. The digital model involves not only a total digital transformation of the glass industry, but also taking into account the triad of the requirements of the modern global market: reducing the time of decision-making (Time-to- Decision, T2D), their execution (Time-to-Execution, T2E) and output to the market (Time-to-Market, T2M), where the market, of course, refers to the global market. Digital models should have a high level of display of real glass products and real technological processes (digital production);

3.The principles of digital production should correspond with the terms of the production life cycle of glass products (from the concept idea, design, production, operation).

At the stage of formation of Factories of the Future there is also the formation of new key competencies, for example:

-potential, which is opened due to all-pervasive communications, inter-machine interactions, digital modeling;

-capacity to manage change throughout the life cycle of glass products.

Conclusion

“Knowledge economy” has come into use as a term since the 60s of the 20th century. Suggested by the American economist F. Machlup, it indicated the economic sector that produces knowledge (Machlup, 2018).

According to the World Bank, the competitiveness of countries has gradually stopped being dependent on the availability of natural resources and cheap labor. Nowadays, it is intensively highlighted by economic innovation and know-how. It provides the export of scientific knowledge, high-tech products, intellectual and educational services and indicates its highest degree of efficiency (Soumitra, 2019).

Digital glass factories (Digital Factory) – a system of integrated technological, production and management solutions to ensure the development of a set of production, economic relations in the industry on the basis of digital approaches and tools that enable the shortest possible time to produce competitive products from glass for any purpose, and to save on the rising costs of integration and market transactions and

"Smart" glass factories (Smart Factory) – business systems based on the widespread introduction of cyber-physical systems, a combination of local and cloud, distributed artificial intelligence, as well as the use of people, robots and IoT as sources of big data for total optimization of processes and solutions. As a rule, the business model "Smart glass factory" uses the results of digital glass factories as one of the inputs. "Smart" glass factories implies the availability of technological equipment for the production of glass (CNC machines), industrial robotics and a variety of automated control systems.

Virtual glass factories (Virtual Factory) – is the result of combining digital and smart glass factories into a single distributed network of information management, Enterprise Information Management: EIM = PLM+MES+ERP, providing the formation of easy logistics routes from the stage of preparation of the charge, cooking glass and the development and packaging of glassware, as well as providing after-sales support.

References

- Klaus Bauer, Trumpf Werkzeugmaschinen GmbH & Co. KG. (2017). Industry associations in Germany reflect attacks on large Windows. http://www.steklosouz.ru/sfriend?id=5232

- Machlup, F. (2018). Stages of formation and development trends of the knowledge economy. https://helpiks.org; https://helpiks.org/9-45297.html

- Medvedev, D. (2017). Digital economy of the Russian Federation, On approval of the program. Order of the Government of the Russian Federation, 1632-R. (2017, 28 July). http://static.government.ru/media/files/9gFM4FHj4PsB79I5v7yLVuPgu 4bvR7M0.pdf

- Neogronte, N. (1995). Being Digital Knopf. (Ed.). Vintage Books.

- OECD. (2017). Report of the Organization for economic cooperation and development. OECD Digital Economy Outlook 2017, OECD Publishing, Paris. http://www.oecd.org/sti/oecd-digital-economy-outlook-2017-9789264276284-en.htm

- Oreshkin, M. (2017). MSU has established a digital economy centre. https://ruspekh.ru/events/item/v-mgu-sozdan-tsentr- tsifrovoj-ekonomiki

- Orlova, S. (2017). The discovery of the Velikodvorsk processing plant is an important step in the development of the glass industry in the Vladimir region. https://avo.ru/novosti/-/asset_publisher/E2PryKmsVruz/content/svetlana-orlova-otkrytie-velikodvorskogo-pererabatyvausego-kombinata-eto-vaznyj-sag-v-razvitii-stekol-noj-otrasli- vladimirskoj-oblasti-

- Orlova, S. (2017). The results of the socio-economic development of the Vladimir region in 2018. https://avo.ru/web/guest/promyslennoe-proizvodstvo

- Samarin, N. (2019). Glass processing technology. https://www.stanki.ru/techno/stekloobrabotka/obrabotka_stekla

- Schäfer, J. (2016). Glasstec 2016: Glass is the material of the future. http://www.glassnews.info/?p=7809

- Soumitra, D. (2019). Global Innovation Index. http://www.tadviser.ru/index.php/%D0%A1%D1%82%D0%B0%D1%82%D1%8C%D1%8F:Global_Innovation_Index

- Ukolov, V. F. (2019). The importance of digitalization for economic sectors. http://russiaonline.info/story/digitalization-impact

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

08 March 2021

Article Doi

eBook ISBN

978-1-80296-102-7

Publisher

European Publisher

Volume

103

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-644

Subjects

Digital economy, cybersecurity, entrepreneurship, business models, organizational behavior, entrepreneurial behavior, behavioral finance, personnel competencies

Cite this article as:

Gubernatorov, A., Aleksandrova, I., Khripunova, M., & Shuvalova, O. (2021). Efficient Digital Platforms In Manufacturing Industries. In N. Lomakin (Ed.), Finance, Entrepreneurship and Technologies in Digital Economy, vol 103. European Proceedings of Social and Behavioural Sciences (pp. 337-343). European Publisher. https://doi.org/10.15405/epsbs.2021.03.42