Abstract

Rice husk from paddy is an example of agricultural waste that can be potentially applied for microwave absorber fabrication. Rice husks as an abundant of agricultural waste in Malaysia which bears huge potential as beneficial invention for various applications, e.g., an alternative microwave absorber have been explored in this paper. Thus, the effect of different grain sizes of rice husks (45µm, 1mm, 2 mm and 3 mm) used as the microwave absorber have been investigated. The microwave absorber has been fabricated at microwave x-bands in the frequency range of 8.2 GHz to 12.4 GHz which will be used primarily for radar applications. Two types of resin (polyester resin and MEKP) were used as a binder of rice husk composites. The dielectric and S parameters have been measured using rectangular waveguide and Professional Network Analyzer (PNA). The highest value of microwave absorption has been obtained by 3 mm grain size of rice husks which can be use fabricate the microwave absorber.

Keywords: Grain sizesrice huskdielectricmicrowave absorberrice huskspolyester composites

Introduction

Nowadays, there a various type of electronic devices that we used in our daily lives. All the devices emit electromagnetic interference that can affect human body systems. Electromagnetic interference also can cause malfunction to high sensitivity electronic equipment and in military facilities. Thus, microwave absorbers are one of the main materials overcome the issues. The microwave absorbers will absorb the electromagnetic interference and will dissipate it as heat. An efficient microwave absorber needs to have high absorptivity, high environmental resistance, high mechanical strength, and the most important thing is it needs to be lightweight. Recently, composites consisting of the polymer matrix and electromagnetic filler have gained the attention of many researchers for use in developing microwave absorption due to their good properties.

Agricultural waste is gaining attention in development of microwave absorber due to its high carbon content that can be used as the filler in the polymer matrix ( Iqbal, Malek, Lee, Zahid, & Mezan, 2014). Rice husk from paddy is an example of agricultural waste that can be potentially applied for microwave absorber fabrication. Paddy sector is one of the major contributors to the Malaysian economy. Thus, rice husk is the most prolific agricultural waste which is only 27.0 % is used as renewable energy to produce electricity and for the manufacture of products such as particleboard and fibreboard ( Yoon, Son, Kim, & Lee, 2012). The high presence of carbon (35 – 37 %) in rice husk makes it a valuable material for use in industrial application. Recently, several researchers have stated that carbon has an important role in microwave absorption or shielding ( Thomassin et al., 2013) which due to the ability of carbon to absorb the microwave radiation. A good microwave absorbance can be generally obtained through adjusting the filler content and the sample thickness ( Feng et al., 2008; Nornikman, Soh, Azremi, Wee, & Malek, 2009). This work will focus on investigating the effect of microwave absorption for a various grain sizes of rice husk, which include method in determining the material’s dielectric constant through the experimental method.

Problem Statement

Microwave radiation coming from electromagnetic interference (EMI) that are emitted from electronic devices such as mobile phones, laptops and ovens. The development of microwave absorbing materials continues to attract much attention from researchers because of the increasing environmental pollution from electromagnetic interference (EMI) produced by electronic devices. The application of rice husk as the filler in the polymer matrix-based composite is a rising issue in microwave absorber development due to its cost-effective and high carbon content.

Research Questions

What is the role of the grain sizes of rice husk on the dielectric and microwave properties of rice husk/polyester resin (RH/PE) composites?

Purpose of the Study

The purpose of this study is to study the role of the grain sizes of rice husk on the dielectric and microwave properties of rice husk/polyester resin (RH/PE) composites.

Research Methods

Fabrication of rice husk/polyester resin composites

Rice husk was acquired from the paddy and rice industry, BERNAS, Sungai Limau Dalam, Yan, Kedah, Malaysia. The rice husk was washed by distilled water to remove some impurities and dusts. After that, it was dried in the oven at temperature 100 0C for one hour. After the rice husks were taken out from the oven. The dried rice husk was kept until at room temperature (25 0C), grinded and were sieved into 45µm, 1mm, 2mm and 3 mm grain sizes, respectively.

The polyester resin (PE) was used as the bonding agent to bind the rice husk into a solid form while methyl ethyl ketone peroxide (MEKP) as a hardener agent was used to harden the mixtures and to facilitate fabrication process. There was 30 % of MEKP over polyester resin is used for fabrication. Rectangular mold was used to fabricate the rice husk into planar microwave absorber. The mold is custom made at the thickness dimension of 5 mm, 15.8 mm in length and 7.9 mm in width. This is due to fix the waveguide adapter for X-band frequency which is the range of 8.2 to 12.4 GHz. Rice husk/polyester composites were compressed in the mould using G clamp.

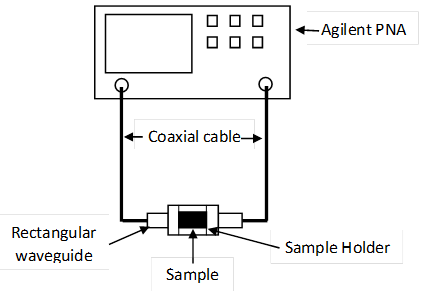

Dielectric and microwave properties measurements

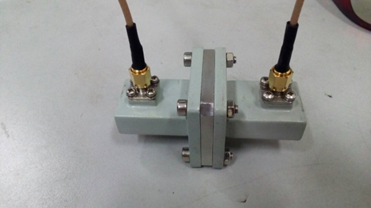

Dielectric and microwave properties were measured using Agilent network analyser. Dielectric constant and reflection loss were measured using rectangular waveguide. The frequency range between 8.2 and 12.4 GHz is used for measurement. The images of waveguide used are shown in Figure

Findings

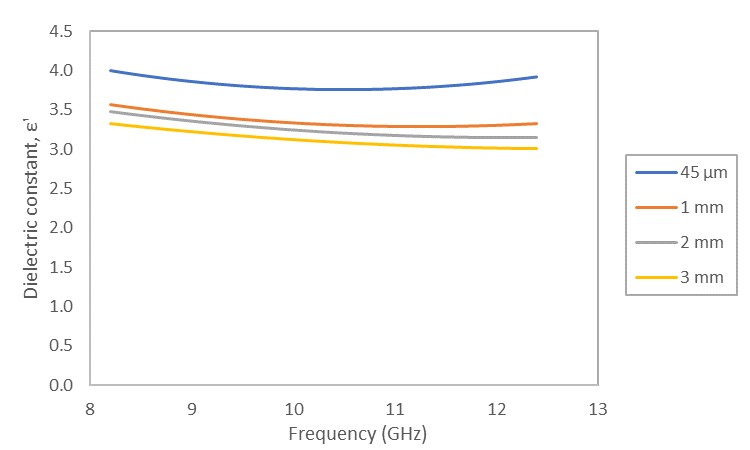

Dielectric Constant and Loss Factor

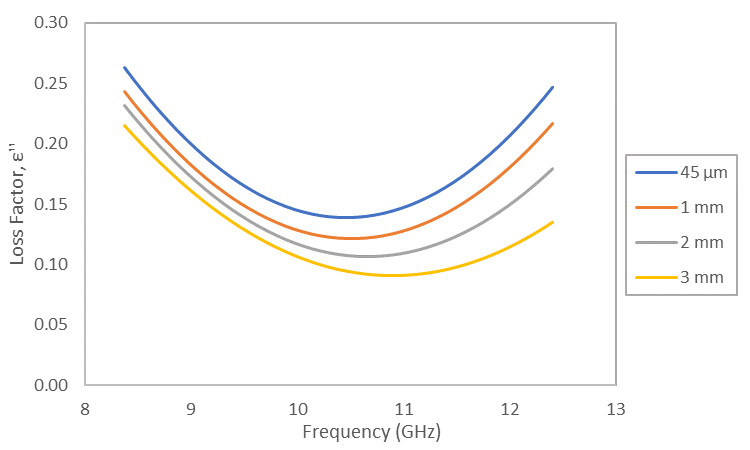

Real part, ε’ and imaginary part, ε” of dielectric properties can be define as dielectric constant, ε’ and loss factor, ε”, respectively. The dielectric properties of the rice husk composites are very important in developing the microwave absorber. This is because the dielectric properties can be used to define the ability of the material used to store EM energy, convert it to heat, then dissipate the heat ( Liu et al., 2012).

The dielectric properties of the microwave absorber can be changed by varies the thickness of the materials used. The distribution of the filler will alter the electrical properties of the material ( Hourouebie, Blondel, & Dhume, 1997). However, only the effect of the grain sizes of rice husk on dielectric properties of microwave absorber were studied in this work. The loss factor, ε” is the most important properties in considering microwave absorption. This is because it has a direct relation with dissipation of microwave energy within the material.

It can be clearly seen from Figure

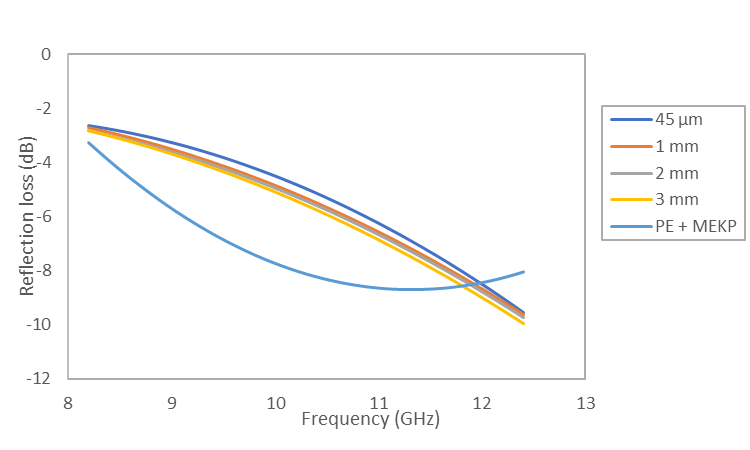

Reflective loss and microwave absorption

Reflectivity and absorption performances of the RH/PE composites and Polyester resin+ MEKP were investigated in this work. Similar with dielectric properties results, all RH composites with differences of grain sizes samples were also slightly followed the profile of Polyester resin+ MEKP. The higher value of dielectric properties of samples indicated that higher values of reflectivity.

The reflectivity values of samples are above -10 dB in the frequency range of 8.2 to 12.2 GHz for S11 shown in Figure

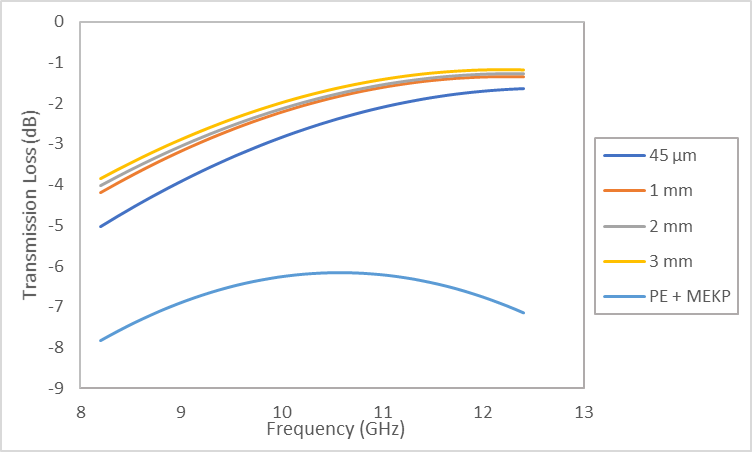

From figure

Conclusion

Rice husks with various grain sizes were used as the filler which is bond in Polyester resin+ MEKP to fabricate rice husk/polyester resin-based composites. These materials were investigated to determine their dielectric properties and microwave absorptivity. The waveguide-measurement technique was used to measure the reflected, transmitted, and absorbed fractions of the microwaves by the composites . In addition, rice husk/polyester resin-based composites with different grain sizes were investigated to determine their microwave absorption performances. The results of this study proved that the rice husk/polyester resin-based composites have greater potential microwave absorber which both reflectivity and transmission are below than -30 dB. Furthermore, the maximum % absorption is in range 10 to 30 %. However, unfortunately the values of % absorption is slightly difference for differences of grain sizes of rice husk/polyester resin-based composites. Generally, carbon is the main element that contributes to the electromagnetic absorption. Thus, the Carbon nanotubes, CNTs or graphene are suggested to deposited into rice husk/polyester resin-based composites to enhance the microwave absorption.

Acknowledgments

This research was funded under Research University (Individual) Grant, Universiti Sains Malaysia (1001/PJJAUH/8011058) and MOHE FRGS (203.PJJAUH.6711489).

References

- Feng, X., Liao, G., Du, J., Dong, L., Jin, K., & Jian, X. (2008). Electrical conductivity and microwave absorbing properties of nickel-coated multiwalled carbon nanotubes/poly(phthalazinone ether sulfone ketone)s composites. Polymer Engineering & Science, 48(5), 1007–1014. https://doi.org/10.1002/pen.21028

- Hourouebie, P., Blondel, B., & Dhume, S. (1997). Microwave and optical properties of soluble conducting polymers. Synthetic Metals, 85(1–3), 1437–1438. https://doi.org/10.1016/S0379-6779(97)80308-6

- Iqbal, M. N., Malek, M. F., Lee, Y. S., Zahid, L., & Mezan, M. S. (2014). A Study of the Anechoic Performance of Rice Husk-Based, Geometrically Tapered, Hollow Absorbers. International Journal of Antennas and Propagation, 2014, 1–9. https://doi.org/10.1155/2014/498767

- Liu, G., Wang, L., Chen, G., Hua, S., Ge, C., Zhang, H., & Wu, R. (2012). Enhanced electromagnetic absorption properties of carbon nanotubes and zinc oxide whisker microwave absorber. Journal of Alloys and Compounds, 514, 183–188. https://doi.org/10.1016/j.jallcom.2011.11.060

- Nornikman, H., Soh, P., Azremi, H., Wee, F. H., & Malek, M. F. (2009). Investigation of an Agricultural Waste as an Alternative Material for Microwave Absorbers. Piers Online, 5, 506–510.

- Thomassin, J.-M., Jérôme, C., Pardoen, T., Bailly, C., Huynen, I., & Detrembleur, C. (2013). Polymer/carbon-based composites as electromagnetic interference (EMI) shielding materials. Materials Science and Engineering: R: Reports, 74(7), 211–232. https://doi.org/10.1016/j.mser.2013.06.001

- Yoon, S. J., Son, Y.-I., Kim, Y.-K., & Lee, J.-G. (2012). Gasification and power generation characteristics of rice husk and rice husk pellet using a downdraft fixed-bed gasifier. Renewable Energy, 42, 163–167. https://doi.org/10.1016/j.renene.2011.08.028

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 March 2020

Article Doi

eBook ISBN

978-1-80296-080-8

Publisher

European Publisher

Volume

81

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-839

Subjects

Business, innovation, sustainability, development studies

Cite this article as:

Nur Syuhada, A., Ramzun, M. R., Ahmad Shafawi, M. K., Nurul Sabihah, Z., Nusaibah, S. B. A., & Nor Zakiah, Y. (2020). Rice Husk As An Alternative Material For Microwave Absorber. In N. Baba Rahim (Ed.), Multidisciplinary Research as Agent of Change for Industrial Revolution 4.0, vol 81. European Proceedings of Social and Behavioural Sciences (pp. 803-809). European Publisher. https://doi.org/10.15405/epsbs.2020.03.03.93