Abstract

In this paper, an investigation of zinc oxide (ZnO) material, and about the role of it for window layer purpose in CIGS Solar Cell has been addressed. It was performed by varying the window layer (ZnO) thickness and changed the band gap values. The simulation was carried out using numerical simulation tool, Solar Cell Capacitance Simulator (Scaps-1D) software. The ranges of window layers (ZnO) thickness were varied from 100 nm to 500 nm, and the band gap were set from 3.1 to 3.4 eV. In order to study the effect varying of those parameters on the performance of CIGS solar cell devices, there are such as fill factor (FF), open circuit voltage (Voc), short circuit current density (Jsc) and efficiency (η) were determined from the current density-voltage (I-V) characteristics. As overall, for all those characteristics were found that the cell performances increased the thickness were decreased even very slightly, but the short circuit current density (Jsc) were increased significantly.

Keywords: Zinc OxideCIGS Solar CellSCAPSband gapwindow layer

Introduction

In solar cell structure the window layer usually consists of three thin, which is transparent layers with different electrical/optical properties, and they are such as a front contact and a buffer layer. Generally, the window layer material is often made from some metal oxides since these both can be made transparent and the most important is that it can be fit into the solar cell’s band structure. Here, the property or the good material that determines if the oxide is transparent and possible to lets the light reach the absorber layer is that the difference between its energy levels for electrons, which is its known or called its band gap, is much larger than the energy in the light with energies that is used to produces current and finally to generate of electricity. In this case, its means that the oxide cannot absorb that light ideally. Sometime a front contact may however limit the power from the solar cell due to a trade-off between the conductivity and the transparency. This is happens caused a higher part of free charge carriers in the oxide will increase its conductivity and thereby decrease the material use, but however in the same time this will impair its transparency which will decrease the amount of light reaching the absorber layer. Since over last decades, more research have been done in order to explore new materials and new methods to deposit front contacts/window layer, which is the research mainly aims to decrease the current losses.

Zinc Oxide As Material Challenges For Solar Cells Industry

Zinc oxide has been well recognized as one of the most promising oxide semi-conductor materials owing to its excellent optical, electrical, and acoustic properties. Moreover, ZnO has a direct band gap of 3.37 eV and a large exciton binding energy of 60 meV. Its binding energy is much larger than that of GaN (24 meV) and the thermal energy at room temperature (26 meV), which results in an efficient excitonic lasing even at room temperature under low threshold voltage ( Tang et al., 1998). The advantages of zinc oxide (ZnO) comparing to other materials are its low price, non-toxicity, and easy manufacturability, thus it has become highly potential material for industrial applications. A great revolution by Zinc Oxide (ZnO) material in the field of semiconductors has been started since many years ago. The number of Zinc Oxide (ZnO) articles that published has been increasing each year, and in 2007 ZnO becomes the second most popular semiconductor materials after Silicon (Si) ( Yang, 2010). Zinc Oxide (ZnO) is an attractive material for many applications, particularly in electronic field or electronic devices, and the most popular one applications there are; solar cell, conductive film, light emission display (LED) and thin film transistors ( Kimura et al., 2011). Zinc oxide (ZnO) have been used as transparent Conducting Oxide (TCO) or called it as window layer, which is in CIGS solar cells this materials has been applied since years ago, its due to this material more comparative absorption losses, and also leads to the reduction of the quantum efficiency of TFSCs in the infrared (IR) regions.

CIGS Solar Cells and ZnO Window Layer Material

Copper-indium-gallium-diselenide (CIGS) solar cells are presently considered to be the best thin film absorbing material in terms of their excellent light-to-power conversion efficiencies. As reported in the previous research, 17.4% efficiency were obtained for CIGS thin-film sub-module as a new certified world record. Meanwhile, the other report said that the CIGS thin film solar cell lately has achieved the highest conversion efficiency reach to 20.4%. However, in our model device structure we use undope zinc oxide as window layer, and the cadmium as buffer. In this paper, the focus study will be highlight on the investigate the band gap energy, and thickness layer of ZnO window layer for CIGS thin film solar purpose, which is in effort to improve the performances of the CIGS solar cells by applied those parameters. The effects of the thinning layer, and the optimization study of the band gap energy of the window layer (ZnO) were investigated by numerical analysis Solar Cell using numerical simulation tool (SCAPS).

Problem Statement

The photovoltaic/solar industry panel growing rapidly and its due to the increasing of awareness of the versatility, reliability, and economy of solar photovoltaic systems for ever widening applications. Since over last decades until nowadays the major investments and on hand manufacturing facilities are mainly for silicon based technologies, with over a 93% market share, due mainly to its maturity and huge government subsidies in particular in Europe countries, they are the world’s biggest user of solar energy. However, the cost of photovoltaic is three times higher compare to the conventional source, which is one of the main constraints

Therefore, some steps should be taken to reduce the amount of materials and energy used to manufacture solar cells in order to minimize the price of photovoltaic energy. The first generation of solar cells or well known as silicon generation, it were not able to provide energy with lower cost due to the manufacturing processes that are used to produce them are inherently expensive. In order to reduce the production cost of solar cells, the research moved on to the second generation of solar cells, which has been under concentrated development in the 1990s and early 2000s, which is the low-cost were achieved but the issue is the cells efficiency is low. The goals of the thin film solar cells; designs that used minimal materials, cheap manufacturing processes, and environment friendly. Another goal target of thin film solar cells in future is to create a novel approaches to obtain efficiencies in the range of 30% - 60%.

Research Questions

As well known, the window layers/TCO mostly used in photovoltaic solar cell structures, where it normally were covered by an anti-reflection layer, which leads to increase the absorption number of photons.

Why the window layer need to be applied in thin film solar cell (TFSC) structure

Due to the high absorption in the solar cell material, then the photons gets absorb too near to the surface the where the recombination might be changed significantly. In order to overcome this issue a window layer were used in TFSC structure to avoid front surface recombination, and normally the materials with large band gap were applied between buffer layer and grid contact. The growth of the photons number for the thin film solar cell (TFSC), automatically it will be increase the chances of high performance and reliability.

The Contribution of Window Layer on Solar Cells Structure

In solar cell structure the window layer usually consists of three thin, which is transparent layers with different electrical/optical properties, and they are such as a front contact and a buffer layer. Generally, the material that used here is often made from some metal oxides since these both can be made transparent and the most important is that it can be fit into the solar cell’s band structure. All-oxide solar cells are promising candidates for future sustainable energy production and of them is zinc oxide (ZnO) material. Oxide semiconductors span a wide range of electronic properties, with many of them being abundant, low cost chemically stable and non-toxic. They are widely implemented in the fields of photovoltaics, optoelectronics (e.g., in thin-film displays and light-emitting diodes) and functional coatings (e.g., in solar control windows. Commercialized and emerging thin-film photovoltaic (TFPV) technologies use metal oxides as transparent electrodes, buffer/window layers.

Purpose of the Study

In this paper, the purpose of this research will be described as details, in order to attain the best window layer material which possible to applied in CIGS solar cells structure. The numerical modelling were used for the efficiency improvement of thin film solar cell, and there are some of research objectives / the purpose of study were presented as mention bellows;

To propose a different structure and a promising window layers to improve the efficiency of solar cells.

To propose the alternate of window layer materials, in order to reach the high output voltage and the high efficiency of thin film photovoltaic devices

To discover/to learn the different solutions for the cost reduction of thin film solar cells and the cost factor of photovoltaic devices

Research Methods

The numerical simulation have an abundant prominence for the understanding and design or modelling of solar cells ( Wang, Cui, & Su, 2015). A Solar Cell Capacitance Simulator or known as SCAPS is one of the computer simulation software for set simulating alternating current and direct current electrical characteristics of thin film hetero-junction solar cell ( Burgelman, Nollet, & Degrave, 2000).

Numerical Analysis (Scaps-1D)

Some researchers also have contributed to develop its such as Alex Niemegeers, Marc Burgelman, Koen Decock, Stefaan Degrave, Johan Verschraegen. 𝑆𝐶𝐴𝑃𝑆 − 1𝐷 is the one-dimensional simulation software program for the modelling of PV devices. As general 𝑆𝐶𝐴𝑃𝑆 − 1𝐷 tool is freely available for the photovoltaic research community and its can be freely downloaded from its web link. It normally may runs on a window operating system environment. Currently SCAPS is widely used to investigate and replicate the characteristics of all types of solar, due to the all devices and material parameters are well controlled, and therefore have possibility the evaluation of trends and quantified changes in PV performances. Its mean that this software is designed to simulate and helps us to analyse some performances such as the 𝐽 − 𝑉 characteristics curve, ac characteristics (𝐶 − 𝑉 and 𝐶 − 𝑓), spectral response (𝑄𝐸) of a device, power conversion efficiency (𝑃𝐶𝐸), fill factor (𝐹𝐹), short-circuit current (𝐽𝑠 ), open circuit voltage (𝑉𝑜𝑐), energy bands of materials used in solar cell and concentration of different material used by solving the semiconductor basic equations ( Simya, Mahaboobbatcha, & Balachander, 2015).

The Modeling of Device Structure

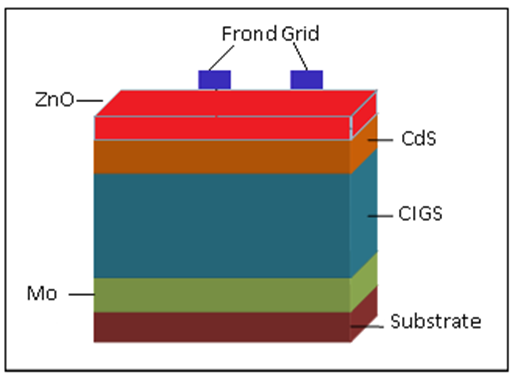

Here, the propose model structure of CIGS thin film solar cell (TFSC) has been conduct under an AM 1.5 light spectrum with 1000 W/m2 light intensity, which is the hetero-junction structure of CIGS cells is a formed of different semiconductor materials. The details of our CIGS solar cell structure as illustrated in fig.

The Modeling of Device Structure

In this study, SCAPS software was employed by specifying the input values, such as the semiconductor parameters in each layer on the CIGS solar cell structure device. Should be note, regarding to study a CIGS solar cell device structure, which is all about material optical parameters info. The description of the material parameters used in our simulation model were summarized as show in table

Findings

In this section, the influence of variation of energy band gap, and the thickness values of window layer (ZnO) on the performance of CIGS solar cell were discussed. The details discussion of the simulation results/research findings were presented in this section.

Effect Of Thickness Variation Of Zno Window Layer On Cigs Solar Cell Performance

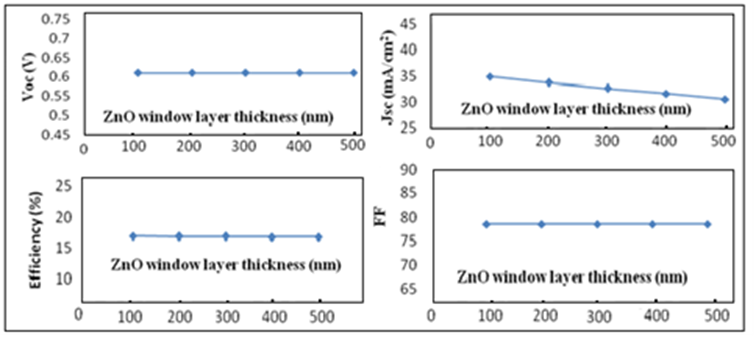

In this simulation study, the thickness of CIGS solar cell window layer was varied from 0.1 to 0.5 mikron (100-500 nm), while the other of input parameters are were kept unchanged. The effect of the varying thickness of window layer is shown in Fig 2. It is found that there is no significant effect on Voc, Fill Factor (FF) or even in efficiency with the change of window layer. The Open circuit voltage (Voc), fill factor (FF), and short circuit voltage (Jsc) of CIGS solar cell were increased by reducing the ZnO window layer thickness. This is simply because of the less absorption caused of ZnO window layer of the solar cell, as more absorption and electron-hole pair generation should occur in the CIGS absorption layer.

Here, we also observed that JSC increases with decreasing of the window layer thickness, this may happened is due to the increased of the band-gap energy. Moreover, we note that JSC decreased when the thickness increased. It is also assumed that both Voc and Jsc values will be reduced when the thickness of the window layer is were increased, and it’s due to the recombination process at the back contact of the solar cell.

The Effect of Band Gap Variation on the CIGS Cell Performance

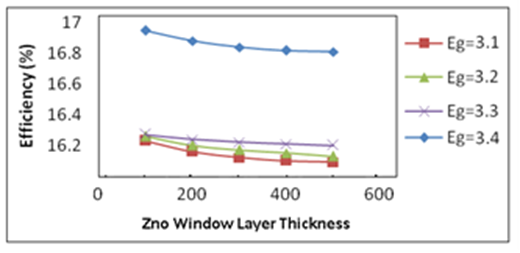

Figure

The curve shows the best efficiency of solar cell performance with band gap values of 3.1 eV and at 100 nm ZnO layer thickness. Usually the lower edge of the conduction band it may changes with the difference of band gap, and its caused to the material grading in the window layer of CIGS solar cells, which is the change between the maximum and minimum of the conduction band edges is represented by energy gap (Eg). According to the simulation results, the highest an efficiency of CIGS solar cell were achieved at 17% while the ZnO band gap were at 3.1 eV, and the thickness of window layer (ZnO) were set at 100 nm.

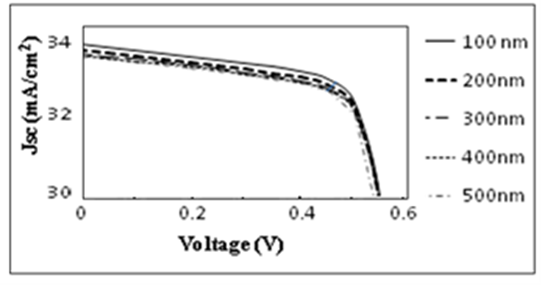

The Variation Effect of ZnO Window Layer Thickness on the J-V Characteristics Performances of Solar Cell

Figure

The Effect of Thickness Variation of ZnO Window Layer On The J-V Characteristics Performances of Solar Cell

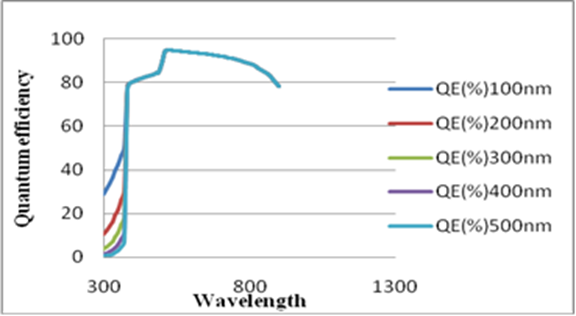

The quantum efficiency spectrum is illustrated in figure

Conclusion

In conclusion, the simulation studies of the band-gaps, and the thickness of window layers in CIGS solar cell structure were conduct, in order to achieve the optimal performance through reducing the carrier recombination and increasing the carrier collection by assumed the material parameters and device structure. The result in an efficient carrier collection in the CIGS cells were show both of the Voc, and Jsc are enhanced. The highest efficiency of 17% were achieved while the ZnO window layer thickness were set at the lowest value thickness, and the band gap were at 3.4.eV. Means the thickness of window layer in this work is considered to be 100 nm, which is found as optimum from the simulation results. In conclusion, based on the performance cell from the simulation results we note that ZnO is one of the suitable materials, and also the promising window layer of CIGS solar cells, with options open in its fabrication process.

Acknowledgments

The authors would like to acknowledge to Prof Marc Burgelman and his colleagues for providing the SCAPS-1D software, which is the SCAPS version of 2.8.02 program were developed at University of Gent, Belgium.

References

- Burgelman, M., Nollet, P., & Degrave, S. (2000). Modelling polycrystalline semiconductor solar cells. Thin Solid Films, 361–362, 527–532.

- Kimura, M., Furuta, M., Kamada, Y., Hiramatsu, T., Matsuda, T. Furuta, H., … & Hirao, T. (2011). Zno Thin-Film Transistors with Sinx/Siox Stacked Gate Insulators: Trap Densities and N2o Flow Rate Dependence. Electrochemical and Solid-State Letters, 14(9), 365-367.

- Simya, O. K., Mahaboobbatcha, A., & Balachander, K. (2015). A comparative study on the performance of Kesterite based thin film solar cells using SCAPS simulation program. Superlattices Microstruct, 82, 248–261.

- Tang, Z., Wong, G. K., Yu, P., Kawasaki, M., Ohtomo, A., Koinuma, H., & Segawa, Y. (1998). Room-Temperature Ultraviolet Laser Emission from Self-Assembled ZnO Microcrystallite Thin Films. Applied Physics Letters, 72(25), 3270-3273.

- Wang, D. L., Cui, H. J., & Su, G. (2015). Modeling method to enhance the conversion efficiency by optimizing light trapping structure in thin-film solar cells. Sol Energi, 120, 505-513. https://10.1016/j.solener.2015.07.051

- Yang, L, (2010). Synthesis and Characterization of Zno Nanostructures (Doctoral Dissertation). Linköping University.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 March 2020

Article Doi

eBook ISBN

978-1-80296-080-8

Publisher

European Publisher

Volume

81

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-839

Subjects

Business, innovation, sustainability, development studies

Cite this article as:

Husna, J., Sibuea, S. R., Sulaiman, O. K., Muhammad Rafiq, Y., Suhardi, N., Nasution, A. H., Haramaini, T., Nasution, M. K., Ambri, M., & Ahmad Rifqi, M. Z. (2020). The Prospects Of Zinc Oxide (ZnO) For Window Layer Cigs Solar Cells. In N. Baba Rahim (Ed.), Multidisciplinary Research as Agent of Change for Industrial Revolution 4.0, vol 81. European Proceedings of Social and Behavioural Sciences (pp. 730-738). European Publisher. https://doi.org/10.15405/epsbs.2020.03.03.85