Abstract

Gold nanoparticle are scattered in solution and become stable by adding citrate ions that cause the AuNP becomes negative charge, which may then complicate the deposition process of AuNP as we know that mica also produce a negative charge. It is predicted that the AuNP was not tending to keep a firm hold on the bare mica surface and was taken off during the wash off process. Mica has been functionalized or modified using distinct molecular weight (MW) of Poly-L-Lysine (PLL) to make the surface positively charged for effective attachment of negatively charged gold nanoparticle (AuNP). Poly-L-Lysine surface functionalization was designed to improve particle attachment as well as to obtained smooth surface (lower roughness or rms values) for high topographical resolution images. 0.01% PLL of 70-150 kDa as well as 150-300 kDa MW give the surface roughness lower than 1. However, PLL of 150-300 kDa MW acquired excessive count of AuNP attachment on modified mica compared to 70-150 kDa of PLL Lower rms is essential to attain even, smooth and dirt-free surface for effective attachment of AuNP.

Keywords: Atomic force microscopy (AFM)Gold Nanoparticle (AuNP)Poly-L-Lysine (PLL)surface functionalizationsurface roughness

Introduction

Mica are frequently make use as a substrate due to the atomically even, smooth and dirt-free surface after cleaved. Mica is hydrophilic and promote a negative charge surface which is a good choice for solid electrostatic adsorption of desired nanoparticle ( Ebner et al., 2008).

Nanoparticle samples are normally needed to be scattered on even and horizontal surface for high resolution topography image. Gold nanoparticle (AuNP) are scattered in solution and become stable by adding citrate ions that cause the AuNP becomes negative charge, which causes difficulties when mapping the AuNP for AFM scanning. To resolve this difficulty, mica has been modified with Poly-L-Lysine (PLL) to stimulate positive charge that electrostatically stick the AuNP to the modified area ( Grobelny et al., 2009). Therefore, negatively charged AuNP can stay immobilized against lateral forces strived by AFM tips all along scanning ( Colville, Tompkins, Rutenberg, & Jericho, 2010).

The function of PLL molecular weight (MW) is substantial in its distribution use on mica. The smaller MW PLL (30-70 kDa) is handy to use due to its lower viscosity while the larger MW PLL (>300 kDa) contributes higher area for molecules attachment. The largest MW of PLL surge the “positivity” of the mica and contribute to strongest attraction ( Huang, Gibson, Facer, Gu, & Polak 1983).

In this study, mica surface modified with distinct molecular weight of PLL are observed using AFM to characterize the surface roughness to acquire high topographical imaging resolution. Then, the particle attachments of AuNP are determined using ImageJ analysis to count the number of particle adhered on the functionalized mica surface.

Problem Statement

Gold nanoparticle are scattered in solution and become stable by adding citrate ions that cause the AuNP becomes negative charge, which may then complicate the deposition process of AuNP as we know that mica also produce a negative charge. It is predicted that the AuNP was not tending to keep a firm hold on the bare mica surface and was taken off during the wash off process. To resolve this difficulty, mica has been modified with Poly-L-Lysine (PLL) to stimulate positive charge that electrostatically stick the AuNP to the mica ( Grobelny et al., 2009). Therefore, negatively charged AuNP can even stay immobilized against lateral forces strived by AFM tips all along scanning ( Colville et al., 2010). As such, there seems to be degree of compromise between substrate surface flatness and nanoparticle attachment efficiencies related to the molecular weight of PLL used. However, according to author knowledge, none of the work described has properly characterized this relationship.

Research Questions

What is the number of AuNP attachment related to the molecular weight of PLL on the modified mica surface?

Purpose of the Study

To determine the number of AuNP attachment related to the molecular weight of PLL on the modified mica surface.

Research Methods

The mica substrate is stimulating to have a positive charge that stick the particle to the mica surface using different molecular weight of PLL solution (MW 70-150 kD and MW 150-300 kDa of 0.01% PLL). All the chemicals were obtained from Sigma Aldrich. The solutions were all prepared shortly before experiments. The PLL solution is prepared by ratio dilution of 1:10 with deionized water ( Grobelny et al., 2009). The 40 nm of AuNP was synthesized using citrate reduction method ( Makhsin, Razak, Aziz, & Noordin 2011). 25 µl of 40 nm AuNP was applied on functionalized mica using micropipette. Then, the substrate was air dried for 2 hours at room temperature. The mica was then rinsed gently with deionized water to remove loosely attached particles. Finally, the mica was air dried under room temperature and ready for AFM imaging. The topography images of the functionalized mica was carried out using XE-BIO AFM (ParkSystems) in the AFM noncontact (NC) mode of operation in air ( Zakaria, Siti, Aziz, & Razak, 2013). Silicon nitride tips with a specification of nominal 2 nm radius, 125 μm of length, force constant of 42 N/m and a resonance frequency of about 330 Hz were used. The approach-retract cycle were carried out at typical z-scan rate of 0.3 Hz. The scan size has an X-Y scale of 5 x 5 μm. Image processes and analysis was measured by XEI software.

Findings

AFM rms surface roughness values taken at multiple places on the mica surface with the scan size of 5x5 μm. Figure

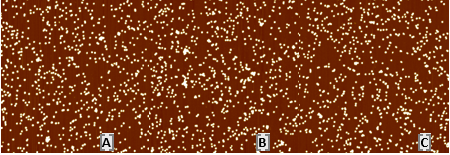

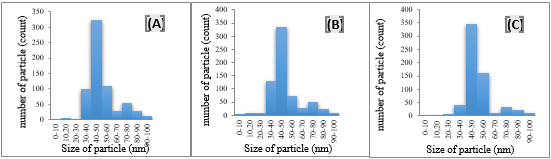

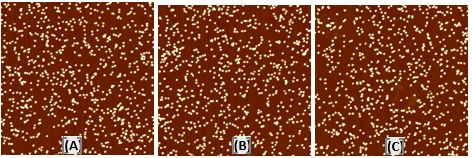

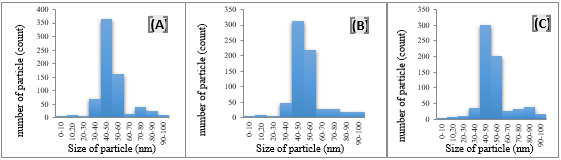

Scanning in larger scan size (Fig 1 and 3) is essential to discover the area with the consistent distribution of AuNP along with the count of gold nanoparticles adhered on the mica surface. Particular AuNP on modified mica were recognized as white dots with average size of 40 nm-50 nm and size range of 0 to 100 nm determined by ImageJ analysis demonstrated by the histogram distribution (Figures

Table

Conclusion

Effective attachment of AuNP on mica functionalized with distinct molecular weight of PLL indicating the circular shape nanoparticle with average size of 40 nm. The surface roughness (rms value) is increase with increasing the number of particle attachments on mica substrate. The increasing on attachment of AuNP was also shown to be directly proportional to MW of PLL.

Acknowledgments

This study was supported by the Universiti Sains Malaysia through Research University Grant (RUPRGS) (1001/PFIZIK/845010).

References

- Colville, K., Tompkins, N., Rutenberg, A. D., & Jericho, M. H. (2010). Effects of poly(L-lysine) substrates on attached Escherichia coli bacteria. Langmuir : The ACS Journal of Surfaces and Colloids, 26(4), 2639–2644.

- Ebner, A., Wildling, L., Zhu, R., Rankl, C., Haselgrübler, T., Hinterdorfer, P., & Gruber, H. J. (2008). Functionalization of probe tips and supports for single-molecule recognition force microscopy. Topics in Current Chemistry, 285, 29–76.

- Grobelny, J., DelRio, F. W., Pradeep, N., Kim, D.-I., Hackley, V. A., & Cook, R. F. (2009). NIST - NCL Joint Assay Protocol , PCC-6 Size Measurement of Nanoparticles Using Atomic Force Microscopy. National Institute of Standards and Technology.

- Huang, W. M., Gibson, S. J., Facer, P., Gu, J., & Polak, J. M. (1983). Improved section adhesion for immunocytochemistry using high molecular weight polymers of L-lysine as a slide coating. Histochemistry, 77(2), 275–279.

- Makhsin, S. R., Razak, K. A., Aziz, A. A., & Noordin, R. (2011). Study on Controlled Size, Shape and Dispersity of Gold Nanoparticles (AuNPs) Synthesized via Seeded-Growth Technique for Immunoassay Labeling. Advanced Materials Research, 364, 504–509.

- Zakaria, N. S, Siti, R., Aziz, A., & Razak, K. (2013). Imaging of Colloidal Gold Nanoparticle Using Atomic Force Microscope. Nano Hybrids, 4, 47–60.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 March 2020

Article Doi

eBook ISBN

978-1-80296-080-8

Publisher

European Publisher

Volume

81

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-839

Subjects

Business, innovation, sustainability, development studies

Cite this article as:

Nurul Sabihah, Z., Azlan, A. A., & Nor Dyana, Z. (2020). Functionalization Of Mica Surface Using Poly-L-Lysine (Pll). In N. Baba Rahim (Ed.), Multidisciplinary Research as Agent of Change for Industrial Revolution 4.0, vol 81. European Proceedings of Social and Behavioural Sciences (pp. 677-682). European Publisher. https://doi.org/10.15405/epsbs.2020.03.03.79