Abstract

Today, the provision of the population with high-quality products is an important challenge for any economic entity. The growth rate of production, as well as a significant increase in its quality, sufficiently affects not only the costs, but also the economic entity profit and cost-effectiveness. It is mandatory for organizations to carry out the production process in accordance with the developed plan, as well as the assortment features, quantity and quality. At the same time, considerable attention is paid to aspects of the output growth, improvement of its quality, and the spoilage absence based on the studied market demands. In this regard, issues of product quality control, in order to prevent spoilage, are quite relevant and significant in the organization's management system. The article reveals the concept of product quality control, suggests a system for controlling the manufactured products quality, identifies factors leading to the spoilage occurrence, and develops a system for spoilage prevention at an enterprise in order to maximize profits.

Keywords: Quality controlmanufactured productsenterpriseindustryspoilage prevention

Introduction

The economic entities heads responsibility for various managerial decisions made by them, including in the product quality area, increases significantly in the process of manufactured goods production and sale, various production programs development, development plans, and business strategies in the field of pricing policy. Control measures are an integral part of the heads of the organization for managing the manufactured products quality. The implementation of the production plan has an impact on the uninterrupted fulfillment of obligations to supply products to all consumers based on contracts and orders for the products manufacture. Hence, product quality control is an essential function in the management of any organization. In world practice, the permissible level of manufactured products rejection is within 2-3% and is subject to strict control in order to reduce its share in the organization’s manufactured products. That is why the importance of the process of manufactured products quality control in an industrial organization with the spoilage preventing is increasing.

Problem Statement

The products quality control considered as an obligatory element of the organization’s production process management, allowing to establish the products compliance with the current legal requirements or to identify permissible deviations in order to correct them before the delivery of products to the customer. The products quality control makes it possible to carry out measurements, examinations, tests or evaluations of various product characteristics and compare the results obtained with the established requirements to determine the required characteristics.

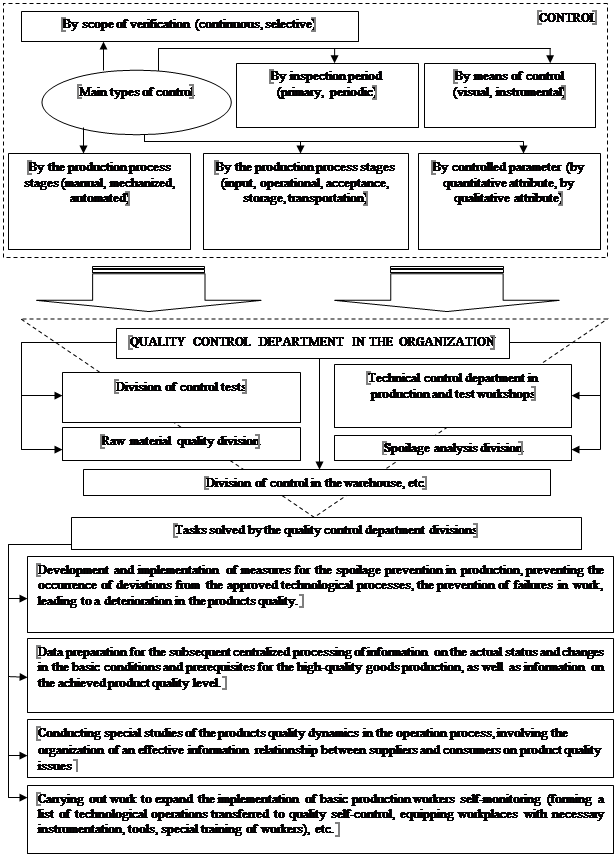

However, the money savings made some industrial organizations to give insufficient attention to monitoring the manufactured products quality, which leads to a systematic product quality violation and complaints from potential customers. In this regard, in industrial organizations it is advisable to allocate a special department in the organizational structure that will control the process of manufactured product quality and solve the following tasks:

- to prevent various kinds of disagreements in the process of manufacturing products and the occurrence of various deviations from legal requirements confirming directly the quality of products;

- to carry out preventive measures, referral to prompt spoilage prevention;

- to stop and promptly eliminate the detected spoilage at the lowest cost;

- to optimize activity and increase the competence of specialists of industrial enterprises, etc.

Research Questions

An analysis of current research on the identified problem has shown that this issue is sufficiently discussed within the framework of the terminological apparatus, elements and tools of quality control. However, more detailed specification of manufactured products assurance activities are required in order to prevent spoilage

Domestic and foreign scientists research different quality management aspects; in particular, works of Feigenbaum (2015), the founder of the quality management theory, connect with the methods and types of work on quality control systematization, cost analysis for its implementation. The scientist emphasized the human factor importance in the quality control process at all phases of the production process.

The significance and role of quality management in the production system of manufactured products were studied by domestic scientists, such as Basovskii and Protasev (2008), Burchakova and Mizintseva (2004), Sukhova and Zaikina (2016).

Lyamin (2016) pointed the problems and directions for improving the system of quality control of raw materials in the manufactured products production.

Analytical tools for products quality control are described in the works of Gudkov and Gudkova (2013), Eskerova (2012), Petukhova and Goncharova (2017) and others.

The issues of management accounting and manufactured product, improvement its quality as the basis for making management decisions were studied by Osipov, Gorbunkova, and Chekaldaeva (2015), Popova (2007), Rozhdestvenskaia (2016).

Available theoretical and methodological developments in the field of product quality control further demonstrates the need of research on forming of a complex control system that provides proactive and preventive measures to reduce the share of defects in manufactured products.

Purpose of the Study

The purpose of this study is to establish a quality control system for manufactured products in order to prevent spoilage based on available theoretical and methodological developments studying and summarizing.

Research Methods

Such scientific research methods, such as analyzing theoretical sources on the research problem; comparison; generalization; specification; description, and special research methods (collection of scientific sources, collection of information and other) were used during the study

Findings

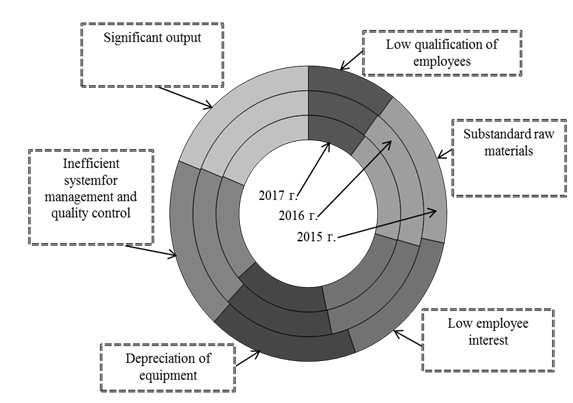

Every operation for manufactured products quality control is an important part of the technological production process, further packaging, transportation, storage and shipment to consumers. Analysis of the manufactured products production process in the industrial enterprise allows identifying the main factors leading to the appearance of spoilage (Figure

- forecasting and analytical: development of reporting and planning forms for the current and future control, containing integrative indicators of the main elements of the manufactured product and the quality of its components, and used for making management decisions in the field of improving product quality;

- preventive or prophylactic, aimed at taking preventive measures on minimizing defects and ensuring the business processes prevention, which result in deviations from the requirements of standards, various technical conditions, etc.;

- control, connected with the prompt implementation of various control procedures and activities aimed at eliminating adverse events in the manufactured goods production, timely delivery to counterparties

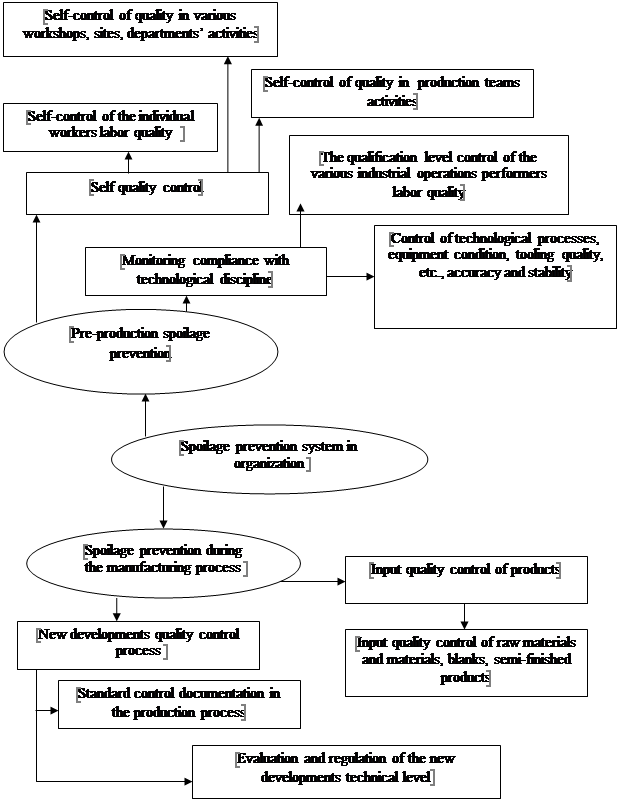

The presence of a manufactured products spoilage prevention system is an important element of quality control in the economic entity activity, as it allows maximizing profits at the lowest cost.

Spoilage prevention should be implemented at the pre-production stage, which includes elements of monitoring compliance with technological discipline and quality self-control, and in the production process, which includes elements of product quality control and new developments.

Figure

An effective system of products quality control will allow pre-production, current and subsequent monitoring, timely detect adverse changes in the framework of exceeding the permissible spoilage level, quickly identify and prevent the circumstances leading to a decrease in product quality both in the current period and in the future.

Conclusion

Thus, the manufactured products quality control system in industrial enterprise is a prerequisite for an effective management system of production process, it increases the products and enterprise competitiveness, maximizing financial results, reducing production costs and manufactured products spoilage, which favorably affects the financial condition of the enterprise. The spoilage prevention system includes control elements at each stage of the production and ensures timely detection and suppression of deviations from the established regulatory requirements. The quality control department in the organization’s management system has the functional role: to implement forecast-analytical, preventive (proactive), and control functions that help eliminate failures in the process of manufactured goods production and provide the proper quality.

References

- Basovskii, L. E. (2008). Quality management: Tutorial. Moscow: INFRA.

- Burchakova, M. A., & Mizintseva, M. F. (2004). Quality management: studies. allowance. Moscow: Publishing House Ros. un-that friendship of nations.

- Eskerova, Z. A. (2012). The main tools in the arsenal of statistical methods of product quality control. Bulletin of KarSU, 90.

- Feigenbaum, A. (2015). Product quality control: Translation from English. Moscow: Economy.

- Gudkov, K. V., & Gudkova, E. A. (2013). Analysis of the structure of the information system of manufactured product quality control. Modern information technology, 18, 68–74.

- Lyamin, B. M. (2016). The need to improve the quality control system of raw materials in the production of manufactured products. Food technology and product expertise. In Collection of scientific articles, materials of the 2nd International Scientific Practical Conference (pp. 54–58).

- Osipov, V. I., Gorbunkova, A. O., & Chekaldaeva, Iu. A. (2015). Management accounting and control of manufactured products. In Problems of modern economics Materials of the IV International Scientific Conference (pp. 65–69).

- Petukhova, I. A., & Goncharova, E. V. (2017). Analysis of the product quality control system. Scientific and methodical electronic journal "Concept", 2, 655–661.

- Popova, L.V. (2007). Cost accounting, calculation and budgeting in selected industries. Teaching manual. Moscow: Business and Service.

- Rozhdestvenskaia, E. S. (2016). Management accounting of income and expenses of an industrial enterprise. Management accounting in the global economic space: intercountry dialogue: a collection of articles of the international scientific-practical conference. Moscow: Polytech.

- Sukhova, N. A., & Zaikina, A. N. (2016). Features management of quality control of the enterprise. Economics of quality control management products of the enterprise. Collection of scientific papers. Publisher, GOU VPO "Ufa State Aviation Technical University".

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

28 December 2019

Article Doi

eBook ISBN

978-1-80296-075-4

Publisher

Future Academy

Volume

76

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-3763

Subjects

Sociolinguistics, linguistics, semantics, discourse analysis, science, technology, society

Cite this article as:

Sрakhgiraev*, I., Varaksa, N., Maslov, B., Rozhdestvenskaia, E., & Poshuev, N. (2019). Manufactured Product Quality Control In Organization As The Spoilage Prevention Mean. In D. Karim-Sultanovich Bataev, S. Aidievich Gapurov, A. Dogievich Osmaev, V. Khumaidovich Akaev, L. Musaevna Idigova, M. Rukmanovich Ovhadov, A. Ruslanovich Salgiriev, & M. Muslamovna Betilmerzaeva (Eds.), Social and Cultural Transformations in the Context of Modern Globalism, vol 76. European Proceedings of Social and Behavioural Sciences (pp. 2830-2836). Future Academy. https://doi.org/10.15405/epsbs.2019.12.04.381