Abstract

Fast pace of development of ICT over last decades led to enormous transformations in many spheres of economic and social life. Impossible has become possible, dreams have become reality. The proof for this is the concept of Industry 4.0. It’s not only a buzzword now. It has become a business practice and a well-established research area with a rapidly growing body of knowledge. Its size can be defined by Google Scholar that returns over 32000 search results when asked about Industry 4.0. Logistics is also the beneficiary of these changes. It has become digital and is becoming smart. As such, it becomes a process that, to the greatest extent, shifts supply chains from the inside to make them fully supportive to the concept of Industry 4.0. On the basis of a simple transcription we can call such structures Supply Chains 4.0. The purpose of the paper is to deliberate on the Supply Chain 4.0 concept, its delimitation, drivers and barriers, and to define its capabilities to create value under conditions of Industry 4.0 in order to give the discussion a strategic management perspective. Major recent developments in ICT as well as seminal theoretical advances will be taken into account to cope with the operationalization of Supply Chains 4.0 while providing a theoretical point of view on supply chain design, its operational performance and process maturity. The paper aims to designate new paths of scientific cognition, to open new avenues of detailed research, and to fine-tune scientific discussion in the field.

Keywords: ICT in logisticsdigital logisticssmart logistics; Industry 40Supply Chain 40

Introduction

The development of industry - like many other branches of the economy - is characterized by clear breakthroughs that are associated with the introduction and dissemination of new technologies. Currently there’s a lot of talk around the fourth industrial revolution (4IR) which is based on the use of cyber-physical systems.

It comes after the third industrial revolution, which was associated with the automation of production as a result of the use of ICT, which in turn followed the second industrial revolution related to the division of labour and the development of mass production. The first industrial revolution, in turn, meant the use of steam powered machines. So we can say that we have been through the way from Industry 1.0 to Industry 4.0 (Crandall, 2017). Hence the idea of just such a term, which is defined by the current development phase of the industry. Each of these revolutions meant new possibilities and led to the next one. Each of the breakthroughs changed the way businesses operate, left its mark on all spheres of their activity. This also applies to logistics.

The 4IR is the result of the Internet technology breakthrough, which leads to the automation of very complex tasks, blurs the line between the sphere of physical processes and the sphere of the digital world. It can certainly be said that the 4IR will have an impact on socio-economic life on an unprecedented scale. That means that it will significantly affect customer behaviour, the way customers satisfy their needs. Thus, the impact of the 4IR on logistics can be much greater. It can therefore be expected that it will also significantly change the way supply chains operate. Therefore, the purpose of the paper is to deliberate on the Supply Chain 4.0 concept, its delimitation, drivers and barriers, and to define its capabilities to create value under conditions of Industry 4.0 in order to give the discussion a strategic management perspective.

The paper briefly presents the idea of Industry 4.0. This forms the basis on which conditions for logistics and supply chain management will be derived, including the development of Supply Chains 4.0. Next, selected technologies that contribute to digital transformation and to the revolution in the functioning of these cooperative structures will be presented.

The emergence of Industry 4.0

Changes that have taken place in industry in recent decades after the third industrial revolution related to process automation that started – as it is assumed – from the development and production of programmable logic controller (PLC) MODICON 084 in 1969 by Bedford Associates (Laughton & Warne, 2003) according to project framework from Hydramatic – a branch of General Motors responsible for the production of automatic transmissions (Bryan, Bryan, 1997). Since then, computerized numerical control (CNC) machine-based processes, microcomputer systems, client-server architecture, computer aided design (CAD), computer aided manufacturing (CAM), computer integrated manufacturing (CIM) and real time computing (RTC) were introduced. These and many other solutions, as well as the recent popularization of the Internet, have made huge changes in the functioning of industry, have led to the integration of all production areas from product design, through the control of physical manufacturing processes to the quality control of final products, have made a vision of the industrial Internet of Things (IoT) a real thing. This is the largest phenomenon of the IoT in vertical terms, which encompasses a vast amount of disciplines such as energy production, manufacturing, agriculture, health care, retail, transportation, logistics, aviation, space travel and many more (Gilchrist, 2016). At present, one can already speak about an almost instantaneous mapping of physical processes in an information system, about a close connection of real processes with a layer of numerical calculations carried out in a computer system, which gives completely new possibilities in automating complicated tasks. This happens in the so-called cyber-physical systems. Cyber-Physical Systems (CPS) is defined as a new generation of systems with integrated computational and physical capabilities that can interact with humans through many new modalities, transformative technologies for managing interconnected systems between its physical assets and computational capabilities (Baheti & Gill, 2011). So we can talk about another industrial revolution. The concept of Industry 4.0 was introduced in the high-tech strategy project of the German government, promoting the computerization of manufacturing processes, and was first used at the Hannover trade fair in 2011 (Kagermann, Lukas, & Wahlster, 2011).

The changes that take place in industry in the age of the 4IR are being translated into other areas of economic activity. In this case the transmission belt is supply chains, including logistics as one of the processes conducted within the system. Therefore, in a similar convention – as version 4.0 – many different areas and initiatives are named right now. The turn of the 20th and 21st centuries is a significant shift in the practice of management due to information technology adoption. Researchers describe the significance of this situation in the context of a strategic inflection point (Puffer, 1999). Methods of production have changed and production management has changed as well. Logistics must also adapt to the requirements of industry and the guidelines of current ICT (Timm & Lorig, 2015). The scale and significance of these changes make us think differently about competitiveness. “This calls for more future theoretical research which will model the 4IR into the competitiveness framework and empirical works to examine the impact of the 4IR. This could be achieved either through adding extreme automation and connectivity as new factors and sources to current competitiveness frameworks or by examining how technology and new business model impact the effect of current factors” (Liu, 2017).

Certainly, however, Logistics 4.0 should not be treated as a scientific paradigm, but only as a phenomenon and a set of specific solutions (Szymańska, Adamczak, & Cyplik, 2017). The concepts of Industry 4.0 and Logistics 4.0 are based on the same premises related to ICT and are complementary in both theoretical and managerial aspects.

Industry 4.0 implications in logistics

Industry 4.0 imposes a technology driven approach to its processes. On the one hand, it imposes action in the environment of big data sets, and on the other hand it enables embedding intelligence into devices (Silverio-Fernández, Renukappa, & Suresh, 2018), products (Mühlhäuser, 2008) and services (Kagermann, 2014), and consequently factories (Lucke, Constantinescu, & Westkämper, 2008) and entire industry sectors (Haverkort & Zimmermann, 2017). The widely used adjective in this area is “smart”. This intelligence – and hence the automation of operation – is conditioned by the availability of big data sets and appropriate methods of data processing. Then we can talk about intelligent behaviour of inanimate objects that can perform tasks that normally are performed by people. In this way logistics can also be intelligent as the process of planning, implementing, and controlling procedures for the efficient and effective transportation and storage (including inbound, outbound, internal, and external movements) of goods including services, and related information from the point of origin to the point of consumption for the purpose of conforming to customer requirements (CSCMP, 2013). “Smart logistics is a logistics system, which can enhance the flexibility, the adjustment to the market changes and will make the company be closer to the customer needs. This will make possible to improve the level of customer service, the optimization of production and make lower the prices of storage and production” (Barreto, Amaral, & Pereira, 2017). According to Uckelmann (2008) the following criteria shall be used to define smart logistics:

smart logistics embraces smart service as well as smart products within logistics;

smart logistics is derived from a technology driven approach, and thereby subject to change;

smart logistics frees humans from (control) activities that can be delegated to smart products and services;

smart logistics are invisible and calm and can therefore be described as transparent;

smart logistics are connected, thus communicating and possibly interacting with their environment;

smart logistics facilitate state-of-the-art data processing (which may include, but do not require software agents);

smart logistics integrates existing logistic technologies, such as material handling systems, and enable these to react and act in a correspondingly smart manner;

smart logistics include state-of-the-art billing, payment or licensing as integral component.

Logistics as a transformation of resources in space-time continuum generates large amounts of data, which are currently acquired and then saved in a variety of computer systems. Every operation, such as receiving of goods, release of goods, cross-docking, storing, picking, attaching labels (with barcodes and RFID tags), sorting, packing, forming and un-forming of loading units, staffing and stripping of containers, loading, unloading, moving, etc. generates data. Taking into account real-time tracking of resources and controlling (sensing) the conditions in which they remain – that gives the currently desired end-to-end visibility – logistics generates still more structured (EDI messages), semistructured (log files) and unstructured (text files) data sets, and their sizes are growing. We call it Big Data. The same applies to all resources that are subject to logistic operations in procurement, production, distribution or related to the reuse of products and materials (reverse logistics), and thus affects billions of goods moved daily in logistics systems worldwide. So you can say that logistics activities are data-driven and logistics itself is prone to Big Data. But first of all we have to be aware that Big Data means new data processing methods to extract meaningful information from these large data sets. We need to be able to do big data processing and big data mining to unlock useful information we can then use in order to achieve particular goals.

The intelligence of logistics as a process (its being smart) will change over time, as this feature is technically conditioned and the technology will certainly change with the presentation of new generation devices in the field of data processing, networking, automatic identification and data capture, positioning and sensing. More and more data will also be available. It is already known today that new challenges arise in process modelling and simulation in Logistics 4.0 due to a need of representing both: material flow and automation systems as well as autonomous software systems and human actors (Timm & Lorig, 2015). By undertaking these challenges businesses can change the logistics sector. It is already today that we can observe the effects of this in the form of:

the rise of cloud-based analytics platforms (beyond ERPs, CRMs and BIs),

broadening and improving field service operations,

optimisation of processes mostly in inventory management and transportation,

omnipresent automation which can be most visible in manufacturing and warehousing,

an improved forecasting and increased knowledge about customers through machine learning,

the emergence of new services.

Developing Supply Chains 4.0

In the era of Industry 4.0 logistics becomes digital and smart. The question worth investigating is how it contributes to supply chain performance and what components of Industry 4.0 should be embraced when developing Supply Chains 4.0. The above mentioned logistics features supported by appropriate Industry 4.0 components and the nature of the supply chain which starts with unprocessed raw materials and ends with finished goods delivered to the end user, and which links many companies together (CSCMP, 2013), can be leveraged to a brand new level. This is not only due to new ways of performing tasks but a whole new variety of coordination and collaboration with channel partners and a streamlined integration of supply and demand management and other business functions within and across companies.

The IoT, cloud computing and all devices present in the two such as mobile devices, smart devices, are just a starting point towards the development of a new supply chain. Social networks should be added to this setup, as the concept of the supply chain must take into account the human being as the final recipient of goods that are delivered, but also as an internal resource in the form of employees. That is why it is increasingly said about cyber-physical social systems (CPSS) and the Internet of People (IoP), which emphasizes that they are not seen merely as end users of applications, but they are active elements of the Internet (Conti, Passarella, & Das, 2017).

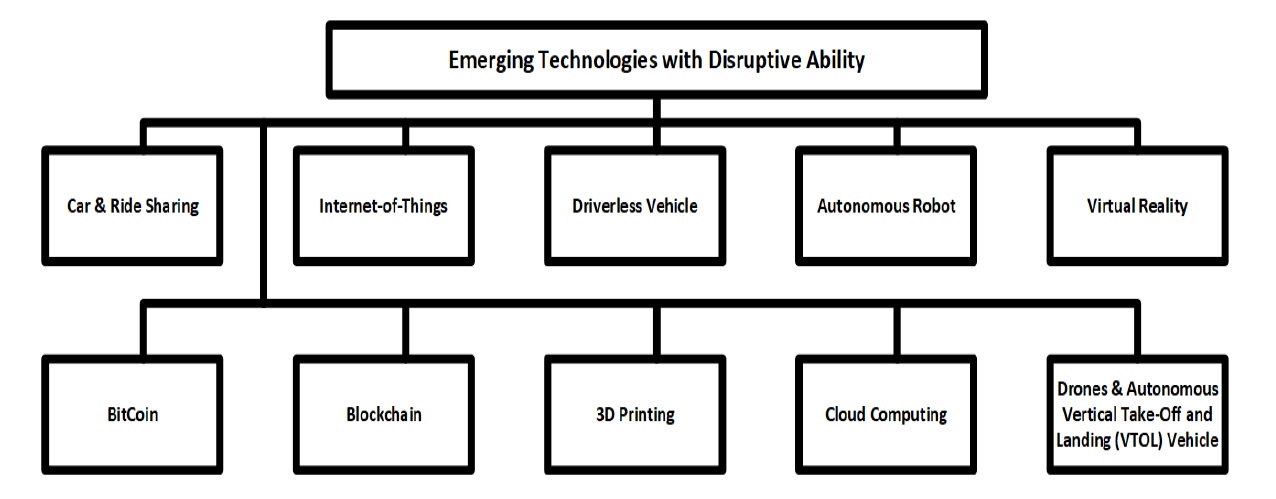

According to Christopher (2016), the 4IR due to technology will change supply chain management in a breakthrough way, which will be caused by, among others: instant manufacturing, advanced robotics and digitization of supply chains. But at the same time, researchers point out that „digitalization is not merely a continuation of the status quo at a higher level of technology; it becomes a game changer in many sectors of the economy – also in logistics and supply chain management” (Kersten, Seiter, von See, Hackius, & Maurer, 2017). We experience digital business transformation which – according to Gartner (2019a) – is the process of exploiting digital technologies and supporting capabilities to create a robust new digital business model. Innovations that cause digital business transformation can sustain an existing product, market or value network or prompt a disruption towards them. Therefore they fall into two categories – they can be sustaining or disruptive (Christensen, 1997). Ab Rahman, Hamid, & Chin (2017) give lots of examples of emerging technologies with disruptive ability (fig.

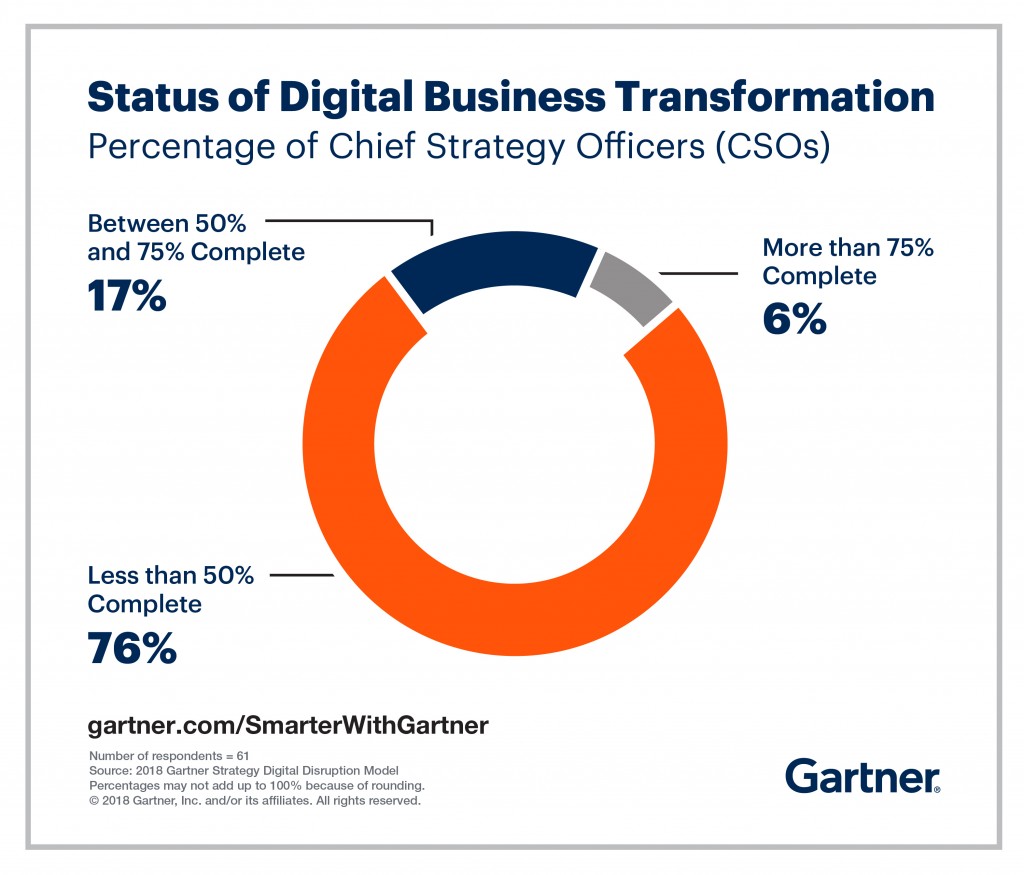

Digital technologies in supply chain management have gained a lot of interest in global research. They are carried out primarily by significant scientific centres and consulting companies. On the one hand a study by the Council of Supply Chain Management Professionals (CSCMP) shows that 93% of shippers and 98% of third-party logistics (3PL) providers think data is crucial to manage supply chain activities (Datafloq, 2018). According in turn to Gartner “87% of senior business leaders say digitalization is a company priority and 79% of corporate strategists say it is reinventing their business – creating new revenue streams in new ways” (Gartner, 2019b). However, on the other hand, 71% of 3PLs believe that big data improves quality and performance (Datafloq, 2018), and despite the rapid development of technology and its increasing availability for business, the digital transformation of business – if you believe management board members responsible for corporate strategy – is characterized by quite disappointing pace – fig. 02. The question is, however, how they understand the transformation that has already been done, what signs they recognize, that they have succeeded, that the transformation process has been completed. Nevertheless, it can be assumed that the results of the survey presented in fig.

Undoubtedly, new logistics providers will find their place in Supply Chains 4.0. These chains need new services from 4PL and 5PL providers who have evolved from 3PLs. As far as 4PLs are supply chain integrators managing resources and combining capabilities of many providers, 5PLs are dealing mainly with on-line coordination of activities and are focused on providing e-solutions for the entire supply chain (Hosie, Sundarakani, Wee Kwan Tan, & Koźlak, 2012). Popularization of 4P and 5PL services will bring significant changes to logistics systems. We can expect that they will operate at a different cost curve, new optimization opportunities will appear as well as new added value will be generated. This way new logistics providers operating within a new quality logistics systems will boost Supply Chains’ 4.0 ability to settle down in the Industry 4.0 data-driven reality.

The most promising composite components of Supply Chains 4.0 and their strategic potential

The most important and most promising components of the Supply Chain 4.0 concept, which originate from the 4IR and which are derived from SMAC (Social, Mobile, Analytics and Cloud) concept of the convergence of four technologies that drive business innovation and allow to rollout new unchecked business models (Dewan & Jena, 2014) include the following:

cloud-based collaborative platforms,

automation technologies, bots & cobots

digital twinning.

This is of course a subjective choice that applies to complex technological solutions based on the basic components of Industry 4.0. The above-mentioned technologies will be briefly discussed, taking into account their impact on supply chain management and supply chain operation in the form of new capabilities, as well as delimitations of these solutions and possible barriers they put up for Supply Chains 4.0, which is in line with the objectives of the paper. In this context, references to supply chain strategy will be important. Examples and applications will also be given where it is possible.

5.1.Cloud-based collaborative platforms

Cooperation is a key issue for the functioning of supply chains. Supply chain entities need to cooperate, and the scope of this cooperation depends on the number and scale of jointly implemented processes and projects. There are many technical solutions that serve communication and have been facilitating cooperation in supply chains for years. Platforms and collaborative networks are at the heart of the new digital economy, with 60–70% of new value created in the next ten years expected to be based on data-driven digitally enabled networks and platforms (WEF, 2018). This includes platforms that enable industries and supply chains.

Cloud technology is the best way to integrate the supply chain. This is not only about the communication itself, which can be ensured this way between cooperating entities and their units, but also about sharing data, integration of various devices that generate these data, as well as creating a single channel for data retrieval. All this takes place without significant expenditure, considering that services in the cloud can be purchased in the form of access to external infrastructure. There is no need to build own infrastructure. Different devices can simultaneously use the cloud both in the process of data capture (upload) and data retrieval (download). This means the integration of various hardware platforms, different operating systems and a variety of user applications, including ERP systems. The cloud contributes significantly to the creation of a unified ICT platform for the supply chain – a platform that enables real-time supply chain management (with on-line visibility), contributes to the creation of cyber-physical systems, and allows real and active inclusion of field service processes in the supply chain as well as the final customer. The communication and integration value of cloud solutions is reflected in the CaaS (Communication as a Service) and IPaaS (Integration Platform as a Service) solutions, which complement the existing and well-known cloud services such as: IaaS, PaaS, and SaaS (Baun, Kunze, Nimis, & Tai, 2011). Cloud technologies have contributed significantly to the popularity of mobile devices that can be directly used in supply chain management. It is thanks to these technologies that mobile supply chain management (mSCM) became a reality (Eng, 2006), as well as integration of various resources, including implementation of the idea of sharing resources in the supply chain (Gong, Liu, & Lu, 2015; Becker & Stern, 2016) or – from a customer perspective – implementation of new service and value creation models, including subscription-based models (Sorescu, Frambach, Singh, Rangaswamy, & Bridges, 2011).

Examples of the implementation of cloud-based cooperation platforms in supply chains can be multiplied. In each and every industry sector there would be many inspirational examples that have been described in professional magazines. They have now become the enabler for the smooth execution of cross-company processes and efficient operation of supply chains. Coordination of planning and executing tasks in the supply chain with the help of cloud-based solutions has become a standard in leading supply chains. This is also confirmed by the observation of supply chain management software market. Vendors such as SAP SE, Oracle Corporation, Epicor Software Corporation, Infor or Manhattan Associate have implemented cloud solutions in their flagship products for the supply chain for a long time now. It can be said that supply chain management is a natural process that has moved to the cloud. As it seems, there is no better way to coordinate activities dispersed in both space and time. There are virtually no restrictions on the application of cloud-based solutions in supply chains.

5.2.Automation technologies, bots & cobots

A crop of various automation technologies allows them to be used for a variety of tasks related to supply chains. Appropriate use of them allows for numerous operational improvements, but the saturation of the supply chain with these technologies makes it possible to achieve a new quality of operation and so far unprecedented results.

Bots mean a huge convenience for buyers in electronic channels. Bots can communicate with the buyer (chatbots), for example via Messenger or Facebook, in the way a human would do. In this way they allow to increase the level of customer service, because such a bot is available 24 hours a day and 7 days a week. Bots can advise you when shopping. They can also contact the customer at the exact time indicated by him/her and provide him/her with the status of the order and/or the current location of the shipment. It can also be done by voice (voice assistants) if need be. From the perspective of the seller, bots allow for quick collection of data that could not be collected online through web forms. Using them, you can generate brand new services for customers. As it turns out, most customers use bots when shopping for cosmetic, body and face care products. However, not all bots are equally popular. In Poland, although 36% of Internet users declare that they are indifferent, whether they talk to people or machines, the interest in bots among customers is quite small and at the same time few online stores use this facility (Kostro, 2019).

However, robots are more associated with machines that perform tasks in the area of manufacturing and warehousing than with software solutions. But there has been also a significant progress in this area. Such industrial robots no longer have to work isolated in cages, but alongside humans like their peers. We call them cobots which stands for collaborative robots. They are slightly lighter and smaller than traditional industrial robots. They are programmable and equipped with vision systems, positioning systems and a lot of sensors. Since they were invented in 1996, they are used in a diverse range of applications. Nalipak Healthcare Packaging implemented cobots to assist with loading trays and lidding to their heat tray sealer (Little, 2018). In 2017 DHL Supply Chain – a contract logistics operator – started a pilot programme at a facility in Tennessee using LocusBots cobots from Locus Robotics. Cobots had to communicate with pickers and integrate with the warehouse management systems there (i-scoop, 2017). A human may perform a preliminary part of a task while the cobot finishes the rest. A human may make cobots do all the handling for him/her especially when it is loading, unloading, picking or moving heavy parcels in today’s warehouses. Collaborative robots allow humans and robots work together in the supply chain thus they integrate machine and human work, they integrate human-programmed and human-controlled work with strictly human work.

A much more advanced solution in the field of automation technology is cognitive agents, that is software agents, which – being pieces of machinery designed and commanded by humans – they behave much like people and exhibit beliefs, knowledge, desires, and intentions in their behaviour (Huhns & Singh, 1998). They base on a model of their environment. Therefore, they are able to plan their actions and to act target-oriented (Büttner, 2011). Software agents have been known for many years and their popularity is constantly growing. Cognitive agents are the most advanced sort of them, which is currently being considered in various research projects in the field of logistics and supply chain management. An example can be a project that addresses the development of an autonomous decision-making system for scheduling purposes of a controlled disposition system for SMEs in the field of event logistics (Harjes & Scholz-Reiter, 2013). Advanced cutting-edge solutions usually appear quickly in the military field. In this respect, a good example can be a cognitive agent framework architecture in the Sense and Response Logistics (SRL) domain. SRL supports coherence of command and control of the full range of warfare and military operations, including logistics. This concept demonstrates its greatly increased effectiveness in following moving targets by adapting to a changing environment over systems that incorporate agents that do not adapt (Greene et al., 2006).

5.3.Digital twinning

Digital twins are digital world entities that are replications of physical entities (living as well as non-living) in the real world that enable data to be transmitted between the two worlds (El Saddik, 2018). They bridge the real and the virtual world make it possible to transmit data seamlessly and to make remote adjustments through the digital component of twins. Digital twins contain sensors that collect data and are reprogrammable making a physical entity behave like a smart device. One may say digital twins technology combines modelling and the IoT.

AspenTech gives an example how digital twinning can help supply chain planning in the chemical industry. In terms of supply chain planning, factory machinery is the key area where an asset's failure leads to increased manufacturing costs and service failures for customers. AspenTech provides a low-touch machine learning solution that incorporates digital twinning. It’s called Aspen Mtell and can accurately forecast a hyper compressor failure in a low-density polyethylene (LDPE) process with more than 25 days of advance (Banker, 2018). Shutting down and then restarting the process is extremely expensive and has many adverse implications in the chemical industry including environment, health and safety.

Digital twinning can allow straightforward less expensive planning and scheduling in supply chains. This is not only chemical industry where downtime maintenance is far less costly than reacting to an unplanned disruption. Other asset-intensive industries or industries where assets provide the backbone of the business like power, utilities, rail, road and mining could similarly obtain significant value from optimizing maintenance across the supply chain. Also solving complex optimization problems taking into account manufacturing economics, job sequencing constraints and demand priorities is an area where digital twinning can be especially useful.

But there are even more possibilities. In the pharmaceutical industry using digital twinning researchers can test how different variations of a drug perform in real time in a given patient’s body, speeding up the time from test to market resulting in higher level of service which is paramount in this business (Newman, 2019) and – on the other hand – opening the door to personalized medicine where refined mathematical models of patients, supported by big biodata, will drive more precise and effective medical interventions (Bruynseels, Santoni de Sio, & van den Hoven, 2018). Pharmaceutical companies can use the technology to monitor the data for patterns in prescriptions and distributions so that their supply chains can adapt to demand requirements in shorter time. Higher responsibility of supply chains in health industry leads to a built-in ability to solve quickly emerging health problems and widespread epidemics (Newman, 2019). This is a very desirable feature of supply chains in this industry. Going a little bit further, it would lead to a transfer of the smart convenience idea (Szymczak, 2014) known from FMCG supply chains to health care. As it results from the projects being carried out, digital twinning can be easily supported by blockchain technology. Combining the two technologies pharmaceutical companies can then track shipments of drugs in order to secure the shipments themselves as well as transport and storage conditions throughout the supply chain. Using blockchain they can ensure the integrity of the parts used in their vehicles, reducing the number of product recalls worldwide and, most importantly, saving lives (Newman, 2019). Digital twinning is helping farmers grow better, as well. Using a digital twin of a farmer’s agricultural portfolio, data can help track things like soil quality, harvest rate, waste rate, growth rate, weather patterns, etc. (Newman, 2019). This is reflected on supply chain performance in such a way that it will allow it to prepare adequate resources and capacities to perform tasks related to the processing of these products and the subsequent distribution of finished goods.

Conclusion and Discussions

The paper addresses managing supply chain under conditions of Industry 4.0. It’s about the new logistics, new supply chains (Supply Chains 4.0), and digital transformation. The paper meets the intensified interest confirmed by the number of publications on the use of modern technologies in supply chain management, but after a systematic literature review it was found that it is lacking in what regards the impact of some composite technological solutions that derive from Industry 4.0. The most inspiring technologies were chosen that can add the most to value creation and strategic management. Therefore, the emphasis was put on such attributes of the supply chain as: digital, mobile and smart. A lot of data is generated in supply chains that can be stored affordably and which can be easily available (Digital). They are supplemented with data that comes from remote processes, e.g. field service processes, and is available in every place for everyone, including the final customer (Mobile). But these data resources should be able to use wisely in order to create managerial value to be exploited in managing supply chains (Smart). Sometimes the result is surprising and reveals the power of strategic possibilities, since all companies today have access to the same technologies and may seemingly manage their supply chains in a similar way. Companies and their supply chains need to disrupt and survive or be disrupted and perish. This is probably the biggest strategic challenge in the 4IR era. But still there are smaller strategic challenges, known from the practice of strategic supply chain management for years, which the 4IR environment seems to supports. It is necessary to mention here the following strategic initiatives:

real-time visibility and on-line end-to-end process management,

the adoption of demand-driven planning and the so-called flow logistics concept,

reliable process execution to meet SLA (Service Level Agreement) conditions,

building an adaptive and yet resilient supply chain,

implementing sustainability to supply chain operations,

creation of an unique value proposal to customers.

The digitization of supply chain processes and workflows, automation of the operations and co-operation between entities must be in line with the strategic vision of the entire system. That is why the issues of supply chain maturity and supply chain excellence are so important in the light of adaptation of new technologies and the process of digital transformation. This is undoubtedly worth taking in further research, as this is a very significant issue in the face of modelling and programming supply chain operations in the digital era. New research trails in the field are needed to be blazed for researchers to follow, and this paper is intended to be an inspiration for searching them.

References

- Ab Rahman, A., Hamid, U. Z. A., & Chin, T. A. (2017). Emerging Technologies with Disruptive Effects : A Review, PERINTIS eJournal, 7(2), 111-128.

- Baheti, R., & Gill, H. (2011). Cyber-physical systems; in: Samad, T., Annaswamy, A. (eds.), The Impact of Control Technology. Overwiev, Success Stories, and Research Challenges, IEEE Control Systems Society, 161-166.

- Banker, S. (2018, 12). Digital Twins Support Supply Chain Optimization. Retrieved from https://www.forbes.com/sites/stevebanker/2018/11/22/digital-twins-support-supply-chain-optimization/#563f813a7bae

- Barreto, L., Amaral, A., & Pereira, T. (2017). Industry 4.0 Implications in Logistics: An Overview, Procedia Manufacturing, 13, 1245-1252.

- Baun, C., Kunze, M., Nimis, J., & Tai, S. (2011). Cloud Computing. Web-Based Dynamic IT Services. Berlin Heidelberg: Springer-Verlag.

- Becker, T., & Stern, H. (2016). Impact of Resource Sharing in Manufacturing on Logistical Key Figures, Procedia CIRP 41, 579-584.

- Bruynseels, K., Santoni de Sio, F., & van den Hoven, J. (2018). Digital Twins in Health Care: Ethical Implications of an Emerging Engineering Paradigm. Frontiers in Genetics, 9(31). DOI:

- Bryan, L. A., & Bryan, E. A. (1997). Programmable Controllers. Theory and Implementation, 2nd ed., Atlanta, GA: Industrial Text Company.

- Büttner, R. (2011). Organisation, Akteure und Agenten [Organization, Actors and Agents], in: Büttner, R., Automatisierte Verhandlungen in Multi-Agenten-Systemen [Automated Negotiations in Multi-Agent Systems]. Wiesbaden: Gabler Verlag / Springer Fachmedien, 7-52.

- Christensen, C. M. (1997). The Innovator’s Dilemma. When New Technologies Cause Great Firms to Fail. Boston, MA: Harvard Business School Press.

- Christopher, M. (2016). Logistics and Supply Chain Management, 5th ed. Harlow: Pearson Education.

- Conti, M., Passarella, A., & Das, S. K. (2017). The Internet of People (IoP) : A New Wave in Pervasive Mobile Computing, Pervasive and Mobile Computing, 41, 1-27.

- Crandall, R. E. (2017). Industry 1.0 to 4.0: The Evolution of Smart Factories, SCM Now, September/October.

- CSCMP (2013). Supply Chain Management Terms and Glossary. Lombard, IL: Council of Supply Chain Management Professionals.

- Datafloq (2018, 10). How Big Data & Analytics Are Changing the Logistics Sector. Retrieved from https://datafloq.com/read/big-data-analytics-changing-logistics-industry/4593

- Dewan, B., & Jena, S. R. (2014). The State-of-the-art of Social, Mobility, Analytics and Cloud Computing. An Empirical Analysis, in: 2014 International Conference on High Performance Computing and Applications (ICHPCA). Piscataway, NJ: Institute of Electrical and Electronic Engineers.

- Eng, T.-Y. (2006). Mobile Supply Chain Management: Challenges for Implementation, Technovation, 26(5-6), 682-686.

- El Saddik, A. (2018). Digital Twins: The Convergence of Multimedia Technologies, IEEE MultiMedia, 25(2), 87-92.

- Gartner (2019, 3). Gartner IT Glossary. Retrieved from https://www.gartner.com/it-glossary/

- Gartner (2019, 4). Speed up Your Digital Business Transformation. Retrieved from https://www.gartner.com/smarterwithgartner/speed-up-your-digital-business-transformation/

- Gilchrist, A. (2016). Industry 4.0. The Industrial Internat of Things. New York, NY: Apress.

- Gong, D., Liu, S., & Lu, X. (2015). Modelling the Impacts of Resource Sharing on Supply Chain Efficiency, International Journal of Simulation Modelling, 4, 744-755.

- Greene, K., Cooper, D. G., Buczak, A. L., Czajkowski, M., Vagle, J. L., & Hofmann, M. O. (2006). Cognitive Agents for Sense and Respond Logistics, in: Thompson, S.G., Ghanea-Hercock R. (eds), Defence Applications of Multi-Agent Systems. DAMAS 2005. Lecture Notes in Computer Science, vol. 3890, 104-120. Berlin Heidelberg: Springer-Verlag.

- Harjes, F., & Scholz-Reiter, B. (2013). Agent-based Disposition in Event Logistics, Research in Logistics & Production, 3(2), 137-150.

- Haverkort, B. R., & Zimmermann, A. (2017). Smart Industry: How ICT Will Change the Game!, IEEE Internet Computing, 21(1), 8-10.

- Hosie, P., Sundarakani, B., Wee Kwan Tan, A., &Koźlak, A. (2012). Determinants of Fifth Party Logistics (5PL): Service Providers for Supply Chain Management, International Journal of Logistics Systems and Management, 13(3), 287-316.

- Huhns, M. N., & Singh, M. P. (1998). Cognitive Agents, IEEE Internet Computing, 2(6), 87-89.

- i-scoop, (2017, 11). Robots and Cobots in Logistics – The Next Stage of Growth – Industry 4.0. Retrieved from https://www.i-scoop.eu/robots-cobots-logistics-4-0/.

- Kagermann, H. (2014). Industrie 4.0 und Smart Services [Industry 4.0 and Smart Services], in: Brenner, W., Hess, T. (eds.), Wirtschaftsinformatik in Wissenschaft und Praxis [Business Computing in Science and Practice]. Berlin Heidelberg: Springer-Verlag.

- Kagermann, H., Lukas, W.-D., & Wahlster, W. (2011). Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution [Industry 4.0: Towards the 4th Industrial Revolution with the Internet of Things], VDI nachrichten, No. 13, 1 April 2011, p. 2.

- Kersten, W., Seiter, M., von See, B., Hackius, N., & Maurer, T. (2017). Trends and Strategies in Logistics and Supply Chain Management. Digital Transformation Opportunities. Bremen: BVL International.

- Kostro, P. (2019). Rewolucja w obsłudze klienta omija Polskę [The Customer Service Revolution Is Bypassing Poland], Puls Biznesu, 14.02.2019, p. 12.

- Laughton, M. A., & Warne, D. J. (2003). Electrical Engineer’s Reference Book, 16th ed. Burlington, MA: Newnes.

- Little, A. (2018, 11). Cobots for the Next Generation of Manufacturing. Retrieved from https://www.automation.com/automation-news/article/cobots-for-the-next-generation-of-manufacturing.

- Liu, Ch. (2017). International Competitiveness and the Fourht Industrial Revolution, Entrepreneurial Business and Economics Review, 5(4), 111-133.

- Lucke, D., Constantinescu, C., & Westkämper, E. (2008). Smart Factory – A Step towards the Next Generation of Manufacturing, in: Mitsuishi, M., Ueda, K., Kimura, F. (eds.), Manufacturing Systems and Technologies for the New Frontier. The 41st CIRP Conference on Manufacturing Systems. London: Springer-Verlag, 115-118.

- Mühlhäuser, M. (2008). Smart Products: An Introduction, in: Mühlhäuser, M. et al. (eds.), AmI 2007 Workshops, CCIS 11, 158–164. Berlin Heidelberg: Springer-Verlag.

- Newman, D. (2019, 4). Three Technology Trends Enabling Digital Transformation of the Supply Chain. Retrieved from https://www.forbes.com/sites/danielnewman/2019/04/10/3-technology-trends-enabling-digital-transformation-of-the-supply-chain/#44b716456239

- Puffer, S. M. (1999). Global Executive: Intel’s Andrew Grove on Competitiveness, Academy of Management Executive, 13(1), 15-24.

- Silverio-Fernández, M., Renukappa, S., & Suresh, S. (2018). What Is a Smart Device? – A Conceptualisation within the Paradigm of the Internet of Things, Visualization in Engineering, 6(3).

- Sorescu, A., Frambach, R.T., Singh, J., Rangaswamy, A., & Bridges, C. (2011). Innovations in Retail Business Models, Journal of Retailing 87S, 1, S3-S16.

- Szymańska, O., Adamczak, M., & Cyplik, P. (2017). Logistics 4.0 – A new paradigm or set of known solutions, Research in Logistics and Production, 7(4), 299-310.

- Szymczak, M. (2014). Smart Convenience in Food Supply Chains, in: Conference Proceedings, The International Forum on Agri-Food Logistics, 2nd National Scientific Conference AGROLOGISTYKA, “Agri-Food Logistics as a Chance of Efficient Consumer Response in the Agri-Food Sector”, Poznań, 9-13 September, 178-180.

- Timm, I. J., & Lorig, F. (2015). Logistics 4.0 – a challenge for simulation; in: Yilmaz, L., Chan, W.K.V., Moon, I., Roeder, T.M.K., Macal, C., Rossetti, D. (eds.), Proceedings of the 2015 Winter Simulation Conference, IEEE Press, Piscataway, NJ, pp. 3118-3119.

- Uckelmann, D. (2008). A Definition Approach to Smart Logistics, in: Balandin, S. et al. (eds.), Next Generation Teletraffic and Wired/Wireless Advanced Networking, 273-284. Berlin Heidelberg: Springer-Verlag.

- WEF (2018). Our Shared Digital Future. Building an Inclusive, Trustworthy and Sustainable Digital Society, Cologny: World Economic Forum.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 October 2019

Article Doi

eBook ISBN

978-1-80296-070-9

Publisher

Future Academy

Volume

71

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-460

Subjects

Business, innovation, Strategic management, Leadership, Technology, Sustainability

Cite this article as:

Szymczak*, M. (2019). Digital Smart Logistics. Managing Supply Chain 4.0: Concepts, Components and Strategic Perspective. In M. Özşahin (Ed.), Strategic Management in an International Environment: The New Challenges for International Business and Logistics in the Age of Industry 4.0, vol 71. European Proceedings of Social and Behavioural Sciences (pp. 356-368). Future Academy. https://doi.org/10.15405/epsbs.2019.10.02.33