Training Engineers Under Changing Conditions Of Technical, Economic Paradigm In Shipbuilding Industry

Abstract

Professional education is the key element of professional and labor socialization of younger generation. The focus of enterprises on innovative development of industrial production, implementation of digital manufacturing and administrative technologies results in increasing demand for innovative engineers possessing applied research competences. Since partner-enterprises act as main customers of engineering competences in innovations, it is extremely difficult to implement new technologies without direct involvement of real economy enterprises in scientific and educational processes. Therefore, the main objective of this study is to find rational technologies to ensure organization and informative content of engineering programs for innovative enterprises of the real sector of economy. The study covers the analysis of some R&D and educational projects implemented at the INTEX research center of technology from 2010 to 2014 at the Institute of Shipbuilding and Arctic Marine Engineering of Northern (Arctic) Federal University named after M.V. Lomonosov. Necessary data were collected via input and output testing of professional retraining students aged 27 to 46. The questionnaire covered 85 engineers of various specialties. Tests developed by the authors included questions concerning the level of students’ readiness to acquire programs of CALS technologies and their satisfaction degree with quality of professional development programs. Results allowed concluding that the “two-commodity” research center model of technology will increase flexibility and adaptability of engineering programs to requirements of innovative production.

Keywords: Engineering educationscientific-educational centerscientific-research producteducational productorganizational modelapplied scientific-research competencies

Introduction

The change of techno-economic paradigm of various spheres of industrial production and the change of technological setup as a combination of dominating technologies typical for a certain level of production development (Lopatnikov, 2003) inevitably lead to transformation of engineering education, which plays a key role in social and economic development of any developed country. According to “wave theory”, approximately every 50 years the scientific and technical progress is passing through cyclic development (Glaz’yev, 2012; Akayev, 2013). It is established that changes caused by a new technological setup “… go beyond the economy … A new economic paradigm results in … consolidation of general principles governing the relationship between participants of economic development.” (Romanova, Akberdina, & Bukhvalov. 2016). Intellectualization and digital transformation of production and management technologies modify the production and technological structure of enterprises and impose new requirements to engineering graduates from industrial partner-enterprises. The need for professional engineers in the field of digital innovations is globally increasing irrespective of the level of economic and technological progress (Simon’yants, 2014). In recent years, many scientists specializing in students’ training for innovative engineering activity note that digitalization, development, as well as complex equipment and technologies, result in the need for continuous development of new and more advanced cross-disciplinary competences (Rajala, 2012; Rios et al, 2017). The works by (Pakina, 2012; Orlova & Luts, 2015) show that professional education is the key element of professional and labor socialization of the younger generation. In the conditions of changing techno-economic paradigm of industrial production it is critical to find the optimum content of engineering programs and educational technologies of their implementation thus contributing to rapid professional socialization and adaptation of engineers.

Across the globe, the current state of engineering education is rather ambiguous. Hence, the report (UNESCO, 2010) states that all countries around the world face a shortage of engineers, which poses a threat to social development. These problems are common in the whole world. For example, the proceedings of the I International Forum devoted to the issues of modernization of engineering education in the field of aerospace engineering highlight that Chinese and Korean engineering universities place high emphasis on academic exchange programs thus maintaining tight links with industry (Department of Mechanical Engineering of Hong Kong Polytechnic University, 2012). European universities, which actively develop their “experience with industry” are not an exception (Come, Fouger, Hawwash, & Van Petengem, 2013). The USA is famous for its CDIO initiative (The CDIO Initative, 2012; Crawley, Malmqvist, Ostlund, Brodeur, & Edstrom, 2014) based on the increase in engineering practice within educational programs and closer links with the industry. The project-based approach also deserves particular attention (Petruneva, Vasilyeva, & Toporkova, 2018; Von Grabe, Dietsch, & Winter, 2010; Zamyatina, Mozgaleva, Solovjev, Bokov, & Pozdeeva, 2013). Moreover, competences in PLM systems and standards are recognized as the major applied competences for innovative productions (Mejia-Gutierrez, Carvajal-Arango & Zins, 2015; Vila, Ugarte, Rios, & Abellán, 2017).

Among the Russian technical universities, there are such prominent engineering schools as the Bauman Moscow State Technical University and the Moscow Institute of Physics and Technology. The first one is famous for the so-called “Russian method” of engineering education with its practical focus (Fedorov, & Kolesnikov, 2005; Simon’yants, 2013). Through the involvement of junior students in R&D at various research institutes and knowledge-intensive enterprises, the Moscow Institute of Physics and Technology pays special attention to research and development (Medovnikov, & Sarayev, 2013).

The programs and strategies of the RF policy form the basis for national innovative system aimed to promote innovative development of higher education and research at universities. Thus, the target program on research and academic staff development for 2009-2013 resulted in the creation and approbation of state support mechanisms and development of scientific and educational structures of modern research. During this period, a number of research and educational centers (REC) were established as separate structural divisions at leading universities and research organizations of the Russian Federation. Fifty-two projects from 300 organizations received financial support totaling to 6 billion rubles. Over 54% of all applications were from universities subordinate to the Federal Education Agency (Bederdinova, Kremleva, Malygin, & Protasova, 2016). The activities of established REC supplemented target development programs of universities regarding the implementation of educational tasks related to training of highly qualified staff and conducting fundamental and applied research. Currently, Russian and foreign universities continue to improve their organization, methods and technologies of engineering education and shift towards practice-based approach. The establishment of about 1,000 backbone departments at enterprises of the real sector of economy also demonstrates this. Nevertheless, the existing experience in developing a network of research and educational centers at Russian universities makes it possible to confirm that the resources of REC as structural divisions of universities integrating scientific and educational activities are not completely depleted (Venkateswarlu, 2017).

Problem Statement

The development of professional engineering competences, on the one hand, shall be followed by active implementation of methods and technologies expanding the culture of engineering thinking. On the other hand, engineering education shall engage a student into research and production activities (Baydenko, 2004; Stepanova, 2009; Won, Menezes, Sharif, Ragusa, & Pacheco-Vega, 2017). Therefore, the development of practice-based research competences is a long iterative process shifting from acquisition of new knowledge to practical activities (Savelieva & Bogolyubova. 2015). This is considered the most complex aspect due to a number of reasons. First, the structure of the majority of curricula is rather rigid and does not ensure the required “flexibility” and fast adaptability of educational technologies to requirements of modern industries. This problem is especially typical and acute for higher educational institutions providing “small series” training of specialists for specific industries according to a variety of specialties and profiles. A typical example of such kind is the Northern (Arctic) Federal University named after M.V. Lomonosov, which provides staff training for enterprises of the United Shipbuilding Corporation on the basis of the Institute of Shipbuilding and Arctic Marine Engineering (Sevmashvtuz) in Severodvinsk. Second, the majority of Russian engineering schools face a big shortage in practical teachers-scientists. This happens since partner-enterprises act as the main customers and consumers of applied and scientific engineering competences (Mishurina, Chuprova, & Mullina, 2016). Thus, it is extremely difficult to implement innovative technologies at universities without direct involvement of enterprises of the real sector of economy in research and education.

Research Questions

The issues related to establishing long-standing relations between universities and industrial partners deserve particular attention. The model supporting project-based technologies is perceived as the most advisable. The model is widely tested and presented in various information sources (Von Grabe, Dietsch, & Winter, 2010; Zamyatina, Mozgaleva, Solovjev, Bokov, & Pozdeeva, 2013). The concept of project-based activity is often considered as the development of innovative and entrepreneurial aspects within the university structure (Venkateswarlu, 2017). At the same time, the optimum model of interaction between the enterprise and the university shall accumulate the best practices of both research centers and backbone departments of universities, but shall not duplicate them completely.

Purpose of the Study

The main purpose of the study is to find rational technologies to ensure training of engineers for innovative enterprises of the real sector of economy through the creation of the model of research center of technology reflecting mechanisms of optimum relations between enterprises and universities.

Research Methods

The study covered the project results of INTEX research center of technology (Innovative technologies of design-engineering and economic support of knowledge-intensive productions). The project was implemented from 2010 to 2014 on the basis of Sevmashvtuz (since 2012 – the Institute of Shipbuilding and Arctic Marine Engineering of Northern (Arctic) Federal University named after M.V. Lomonosov) within the analytical target program

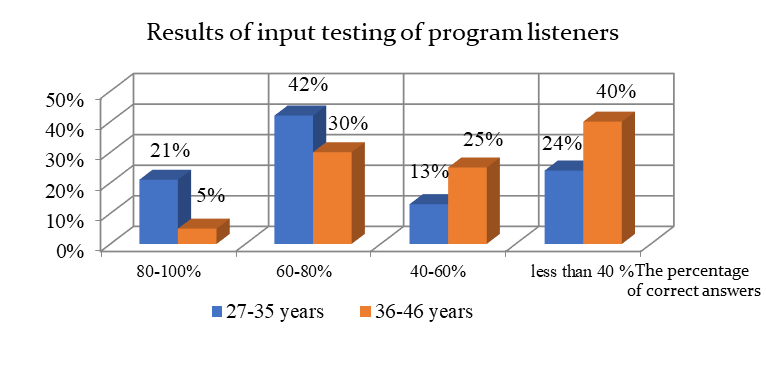

Various methods of data collection and information analysis were used in the study. The data was collected via sociological survey presented as input and output testing of program students. Eighty-five engineers from different industrial divisions, among them 76% at the age of 27-35 years and 24% at the age of 36-46 years took part in the survey. The objective of questions within the input testing developed by the authors was to determine the level of interdisciplinary knowledge and define the students’ readiness to master the core content of educational programs. The tests (in total 25 questions) included the issues of geometric simulation of technical objects, CAD, database management systems (DBMS), electronic workflow, data formats and basic concepts of CALS technologies. The statistical significance of dependence of different factors on students’ age was estimated by means of the Pearson criterion χ2 (p<0.05). Then the percentage ratio was defined. The objective of output testing was to determine students’ satisfaction with educational programs according to the following criteria: theoretical part (general methodology of CALS standardization); practical part (laboratory course); training program in general and teachers’ performance. The tests included students’ observations (both positive and negative) and recommendations on program improvement. The evaluation was based on a 1-5 scale. The output testing showed average estimates, dispersion and coefficient of variation. The significance of the output testing was defined against the t-criterion at p<0.05.

The analysis of tests and R&D performance indicators formed the basis for structural and functional model of the research center alongside with recommendations to enterprises on mechanisms of the most effective relations with partner-universities.

Findings

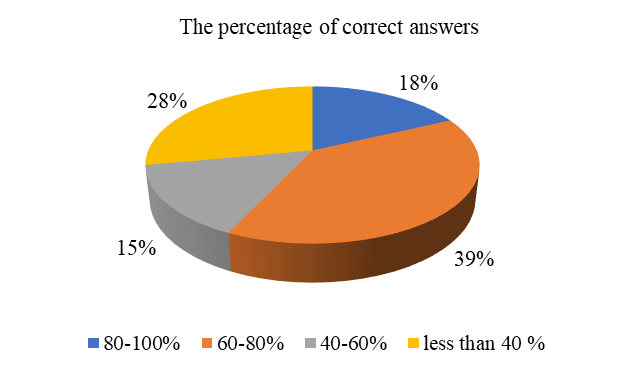

The results of input testing regarding the level of students’ readiness to perceive educational programs are shown in Table

More than a half of students – 48 people (57%) gave correct answers to test questions (60-100% of correct answers). The percentage of correct answers in the age group under 36 years is significantly higher than in the age group of 36-47 years (63% against 35%). It is noteworthy that 40% of students of the senior age group failed the input testing. Questions related to fundamentals of theory of data structures (databases), data exchange formats between CAD systems and Internet-technologies were difficult to answer despite the fact that 96% of all students were experienced users of computer engineering geometry. The fact is that engineers of this age group earned their main education in the late 1980s of the last century. During this period, the availability of information technologies was extremely limited, and engineering programs did not pay enough attention to information technologies.

Table

The majority of students noted that the most useful part of all programs was the general methodology of CALS-standardization and practical skills related to 3D computer-aided engineering systems, integration of data and description of product structures without specific IT platforms, electronic workflow. Approximately 82% of students of all enterprises were positive to recommend the program to their colleagues. Ninety-two percent of students highlighted the quality of practical tasks closely linked to real problems of enterprises. Despite some disadvantages in program implementation, the general results shall be considered positive.

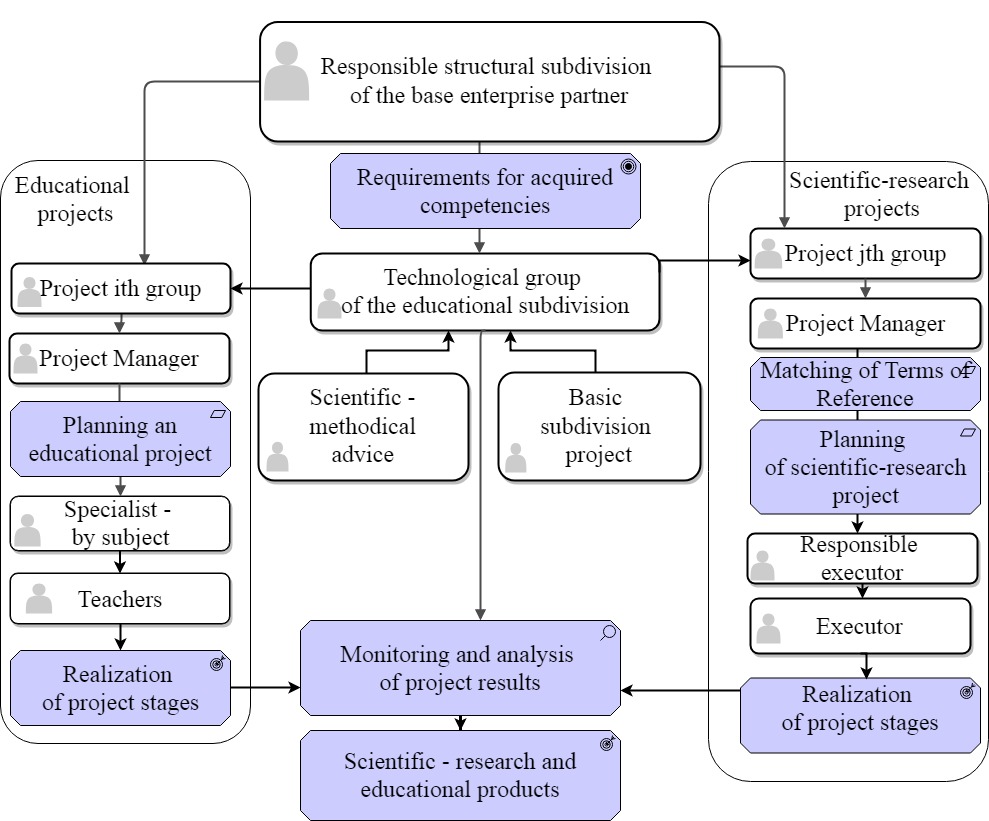

The R&D resulted in 12 patents for inventions, 2 candidate’s theses, 10 scientific articles published in various journals. The results of R&D projects and implementation of professional development programs at INTEX research center of technology allowed creating the functional structure of “two-commodity” scientific and educational division presented in Figure

A variety of educational programs forms the core of any educational division of the university (faculty, institute, department). The product of such division is the development of certain students’ competences confirmed with the corresponding certificate (diploma). The design of “educational products” is one aspect within the range of activities of the university educational division. On the other hand, the need for research forces scientists, teachers, post-graduate students, masters or specialists of the university to unite into interest teams or groups united by a joint contract. These teams are usually temporal and include workers and students from different departments and faculties to fulfill the project. As a rule, these are experts of various engineering profiles.

It should also be noted that the result of such teams in the form of commercialized products and technologies (“scientific product”) may not only support the educational process, but also supplement it organically thus providing students with invaluable knowledge and expertise through the search of research solution. In spite of the fact that the main task of research divisions is to provide research services through R&D, the knowledge shall be transformed into the “educational product”. The work of project teams is monitored by the Scientific and Methodical Council (SMC), which not only makes recommendations regarding performers of scientific and educational projects, but also provides material, technical, information and intellectual resources. SMC also serves the collegial body of project management. It personalizes the list of project performers, defines roles and level of responsibility of every member in order to achieve the project goals. The structure of Scientific and Methodical Council shall include representatives of the enterprise. Besides, the council includes the project manager, program supervisor (supervisors), research supervisor. The methodical council shall perform expert functions and try to solve the matter in case of contradictions and conflicts. The main organizational substructure of a project-based model ensuring implementation of a specific project is a design group. The task of the design group is to create and implement a new “product” (educational and/or research). The technological group is engaged in a very important task related to search and initiation of new projects and their analytical support. The technological group is established to support projects and its activity is aimed to maintain various project-related works thus allocating “serial” products. Such “serial” programs or developments contribute to stability within the research center of technology and provide for its independence from various external conditions.

Conclusion

The present study and R&D piloted at the project-based INTEX research center of technology may result in the following recommendations to industrial enterprises ensuring complex technological modernization, mastering new types of equipment or implementing new technologies:

- within production modernization programs it is necessary to involve interdisciplinary core business units of partner-universities to perform research and R&D works within project teams with simultaneous involvement of advanced young production workers to such activities;

within implementation of research and R&D projects there is a need to develop joint educational modules both as part of basic and additional educational programs;

to ensure continuous search of new R&D application areas in order to carry out joint studies in the field of advanced production technologies with simultaneous design of new educational programs.

The implementation of the above recommendations on the basis of interdisciplinary core business units will strengthen the integration of universities with industry, support and improve qualification of research and academic staff, and provide industries with competitive engineers.

References

- Akayev, A. A. (2013). Large cycles of conjuncture and innovation-cyclical theory of economic development Shumpeter-Kondratyeva, Economic science of modern Russia, 2 (61), 7-29.

- Baydenko, V. I. (2004). Competences in vocational education (To mastering the competence approach), Higher education in Russia, 11, 3-14.

- Bederdinova, O.I., Kremleva, L.V., Malygin, V.I., & Protasova, S.V. (2016). Organization of competence centers of high-technology productions. Arkhangelsk: Institute of Management Publ. Retrieved from https://elibrary.ru/item.asp?id=26100022 (date of access 20.11.2017).

- Come, F., Fouger, X., Hawwash, K. & Van Petengem, W. (Eds.). (2013). Driving Engineering Education to Meet Future Challenges. Brussels: Published by SEFI aisbl, Retrieved from: http://sefibenvwh.cluster023.hosting.ovh.net/wp-content/uploads/2017/06/SEFI@40-Driving-EE-to-Meet-Future-Challenges.pdf (date of access 23.11.2017).

- Crawley, E. F., Malmqvist, J., Ostlund, S., Brodeur, D. R., & Edstrom, K. (2014). Rethinking engineering education: The CDIO approach, second edition. Springer International Publishing. doi:10.1007/978-3-319-05561-9.

- Department of Mechanical Engineering of Hong Kong Polytechnic University. (2012). The 1st International Education Forum on Aeronautical and Astronautical Engineering. Retrieved from: http://www.polyu.edu.hk/me/en-us/Staffevents/detail/44 (date of access 23.11.2017).

- Fedorov, I. B. & Kolesnikov, K. S. (2005). Scientific schools of Bauman Moscow State Technical University. History of development. Moscow: Bauman MSTU Publ.

- Glaz’yev, S. Yu. (2012). The modern theory of long waves in the development of the economy. Economic Science of modern Russia, 2 (57), 27-42.

- Lopatnikov, L. I. (2003). Technological structure. Economic and mathematical dictionary: dictionary of modern economic science. Moscow: Delo Publ.

- Medovnikov, D., & Sarayev, V. (2013). Innovative system of the Physicotechnical Institute. Expert Online, 4 (874). Retrieved from: http://expert.ru/expert/2013/44/innovatsionnaya-sistema-fizteha/ (date of access 20.11.2017).

- Mejia-Gutierrez, R., Carvajal-Arango, R., & Zins, J. (2015). Engineering education through an intercontinental PLM collaborative project: The Global Factory case study. Proceedings - Frontiers in Education Conference, 2015-February, no. 7044159. doi: 10.1109/FIE.2014.7044159.

- Mishurina, O.A., Chuprova, L.V., & Mullina, E. R. (2016). Research work of students as a means of forming professional competencies, International Journal of Experimental Education, 4 (3), 412-415. Retrieved from: https://www.expeducation.ru/ru/ article/view?id=9812 (date of access 12.10.2017).

- Orlova, V.V, & Luts, Yu. A. (2015). Labor socialization of youth: the theoretical aspect. Concept. Electronic Journal, 30, 36–40. Retrieved from: http://e-koncept.ru/2015/65078.htm (date of access 20.01.2018).

- Pakina, T.A. (2012). Labor Socialization of Youth in Current Conditions of Employment. Bulletin of the Nizhny Novgorod State University named after N.I. Lobachevsky. Series Social Sciences, 2 (26), 39-46.

- Petruneva, R., Vasilyeva, V., & Toporkova, O. (2018). Elements of the foresight technology in design project-oriented training of prospective engineers. Advances in Intelligent Systems and Computing, 622, 89-96. doi:10.1007/978-3-319-75383-6_12.

- Presidential program for the training of engineering personnel. (2012). Life-cycle management of products in shipbuilding. The basis of CALS-technologies. Retrieved from: http://engineer-cadry.ru/node/23174 (date of access 12.02.2017).

- Rajala, S. A. (2012). Beyond 2020: Preparing engineers for the future. Proceedings of the IEEE, 100 (SPL Content), 1376-1383. doi:10.1109/jproc.2012.2190169.

- Ríos, J., Mas, F., Marcos, M., Vila, C., Ugarte, D., & Chevrot, T. (2017). Accelerating the adoption of industry 4.0 supporting technologies in manufacturing engineering courses. Materials Science Forum, 903 , 100-111. doi: 10.4028/www.scientific.net/MSF.903.100.

- Romanova O. A., Akberdina V. V., & Bukhvalov N. Yu. (2016). Common values in the formation of a modern technical and economic paradigm. Economic and social changes: facts, trends, forecast, 3 (45), 173-190. doi: 10.15838/esc/2016/3/45/10.

- Savelieva, N.N., & Bogolyubova, M.N. (2015). Development of research competence of students of machine-building profile. Modern problems of science and education: electronic scientific journal, 1. Retrieved from: https://www.science-education.ru/ru/article/view?id=19924 (date of access 28.12.2017).

- Simon’yants, R. P. (2014). Problems of engineering education and their solution with industry participation. Science and Education: an electronic scientific and technical journal, 3, 394-413. doi: 10.7463/0314.0699795.

- Stepanova, S. N. (2009). Competence Approach as an Instrument for Modernizing the Russian Education. Izvestiya Tomsk Polytechnic University, 314 (6), 133-136. Retrieved from: https://core.ac.uk/download/pdf/53066859.pdf (date of access 23.01.2018).

- The CDIO Initative. (2012). CDIO Standards 2.0: Chalmers University of Technology. Retrieved from: http://www.cdio.org/implementing-cdio/standards/12-cdio-standards (date of access 15.10.2017).

- UNESCO. (2010). Engineering: issues, challenges and opportunities for development. UNESCO Publ. Retrieved from: http://unesdoc.unesco.org/images/0018/001897/189753e.pdf (date of access 23.01.2018).

- Venkateswarlu, P. (2017). Establishing a ‘Centre for Engineering Experimentation and Design Simulation’: a step towards restructuring engineering education in India. European Journal of Engineering Education, 42 (4), 349-367. doi: 10.1080/03043797.2016.1158794.

- Vila, C., Ugarte, D., Ríos, J., & Abellán, J. V. (2017). Project-based collaborative engineering learning to develop Industry 4.0 skills within a PLM framework. Procedia Manufacturing, 13, 1269-1276. doi: 10.1016/j.promfg.2017.09.050.

- Von Grabe, J., Dietsch, P., & Winter, S. (2010). Interdisciplinary design projects in the education of civil engineers. Proceedings from WCTE 2010: 11th World Conference on Timber Engineering, 3, 2635-2644.

- Won, D., Menezes, G. B., Sharif, A. A., Ragusa, & G. Pacheco-Vega, A. (2017). Boosting engineering identity of rising sophomore engineering majors through service learning based bridge program. ASEE Annual Conference and Exposition, Conference Proceedings, 2017-June.

- Zamyatina, O. M., Mozgaleva, P. I., Solovjev, M. A., Bokov, L. A., & Pozdeeva, A. F. (2013). Realization of project-based learning approach in engineering education. World Applied Sciences Journal, 27(13A), 433-438. doi: 10.5829/idosi.wasj.2013.27.elelc.89.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

17 December 2018

Article Doi

eBook ISBN

978-1-80296-049-5

Publisher

Future Academy

Volume

50

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1464

Subjects

Social sciences, modern society,innovation, social science and technology, organizational behaviour, organizational theory

Cite this article as:

Kremleva, L., & Bederdinova, O. (2018). Training Engineers Under Changing Conditions Of Technical, Economic Paradigm In Shipbuilding Industry. In I. B. Ardashkin, B. Vladimir Iosifovich, & N. V. Martyushev (Eds.), Research Paradigms Transformation in Social Sciences, vol 50. European Proceedings of Social and Behavioural Sciences (pp. 622-631). Future Academy. https://doi.org/10.15405/epsbs.2018.12.76