Abstract

Currently, the volume of accumulated ash is growing continuously, and the free capacity of existing ash dumps is decreasing. Therefore, the key policy direction in relation to thermal power plants is the efficient use of waste from CHP activities instead of natural mineral raw materials. In the author's opinion, achieving this goal is possible only through comprehensive utilization of ash and slag waste. The purpose of the scientific article is to substantiate the economic feasibility of complex utilization of ash and slag waste. The methodological basis of the scientific article is a comprehensive approach to the study of the main directions of ash and slag waste disposal. The author has developed an investment project for the sale of ash and slag waste to consumers. The estimation of costs for construction of a new ash dump on an existing sample is carried out. Thus, the economic feasibility of complex utilization of ash and slag waste is justified.

Keywords: Ash dumpsash dumpsprofit analysiscost estimationeconomic feasibilitycomplex utilization

Introduction

The operation of thermoelectric power stations (TPS) with coal boilers needs specially designed warehouses to accumulate ash and slag waste (ASW) ash-disposal areas. Over time, the volume of accumulated ash and slag continuously grows, the free capacity of existing ash-disposal areas decreases. Thus, no more than 10% of annual output of ash and slag is utilized and used. If the trend continues, in the near future, we will face the overflow of ash-disposal areas, and it will become a mass phenomenon.

Ash and slag are commonly believed to be dangerous wastes of production, so they make coal TPP unsustainable, but the experts on their processing argue: this is valuable secondary raw material with special physical and chemical properties, including the newly acquired ones, which, with some technological possibilities, are advantageous, economically expedient and in this way relevant to national economy. ASW are secondary resources of raw value, i.e. they are technology-related exploitable minerals (TREM) (Monma, 1980).

Back in the 1930s, American researcher Raymond Davis introduced the idea of using fly ash to produce concrete and developed a specification for it. But until 1946, the world had no equipment to capture this ash. Both developed and developing countries started solving the problem of industrial coal combustion waste only in the 1990s, when the European Association for the Utilization of Coal Combustion products was founded. Nowadays it includes 28 energy companies from 15 countries processing 88% of ash and slag in the world.

However surprising it might appear, the Soviet scientific school was the most advanced in this field. Many institutes with the specialization in the production of building materials were engaged in developing the problem of utilization of ash and metallurgical waste in the USSR. For the first time, Kiev Construction and Industrial Institute produced the high-quality astringent cement from metallurgical slag in 1958, and 18 years later, the patent was delivered abroad.

In 2010, the countries of the Pacific (China, Indonesia, and Australia) established the Asiatic Coal Ash Association, regularly publishing reports and solutions for the processing of ash and slag waste (Lewandowski & Szczygielski 2014).

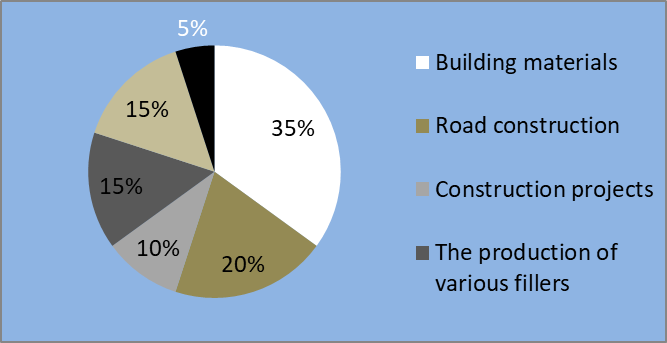

There are five main directions of ASW recycling (in descending order of popularity) (Suzuki, Kamakura & Katagiri, 2006), schematically shown in Fig.

Problem Statement

The purpose of ASW recycling projects is efficient use of TPP wastes instead of natural mineral raw materials and their realization in the commodity market in the volume of annual current output.

The main practical aim of the planned results is to increase the volume of ASW consumption in construction, agriculture and industrial sectors of the economy, to construct inclusive energy facilities for resources and energy saving, to reduce ash-disposal areas, to improve the environment and to increase safety, to lower the expenses on maintenance and development of a hydraulic ash-transport system (Jagusiewicz & Szczygielski 2013).

It is expedient for developers of projects to make a part of the investments not in construction and reconstruction of ash-disposal areas, but in the development of ASW utilization manufactures. They should allocate the economic effect of reducing the cost of maintaining ash-disposal areas in the same way.

The system of volumes growth stimulation to increase the ASW recycling and application plays an important role. In case of successful realization of the project, the developers are responsible for the research and consulting, and for technical work on the project's implementation, carrying out the monitoring of all the included procedures (Stengler, 2011).

The main task of ASW recycling projects is to obtain profit from the manufacturing of building materials produced from ASW, to sell ASW to consumers and to promote technologies of ASW processing and its application in various industries, including construction and agriculture.

The degree of ash and slag waste utilization is as one of the important indicators characterizing ecological activity of the TPP, i.e. the degree of TPP impact on the environment and of the use effectiveness of natural resources (Tung, Tomazic & Brown, 1992).

Research Questions

In view of the foregoing, the article presents the author's investment project to sale ash and slag waste to consumers. For this purpose, it is necessary to create a mini-enterprise based on CJSC "Irkutskzoloprodukt", engaged in direct shipment of ash and slag.

The location of it is an ash-disposal area of Novo-Irkutsk TPP, having a form of a gull and introduced into operation in 1976. Its capacity is 350 thousand m3 with the total area of 1.25 million m2. According to the terms of the project, the ash-disposal area remains in the ownership of the Novo-Irkutsk TPP, which means that the mini-enterprise is free from the rent for the ground. In addition, the owner provides the mini-enterprises with construction equipment (an excavator and dump trucks) on the terms of payment of wages to the operator of the excavator and the cost of renting dump trucks. These two components are the capital costs of this investment project to sum up (Monma, 1980).

The invited investor is ready to implement the project if the profitability of the investments will be not less than 30%, and the payback period is no longer than 2 years.

The excavator operator will carry out loading of dump trucks at the mini-enterprise for sending ash and slag waste to consumers. The loading takes only 4 hours a day, so to calculate the salary of the excavator operator they use a piece-work wage system (table

The regulation on bonuses provides for the payment of a monthly premium of 40% of the hourly tariff rate, so the final value of the temporary salary of the excavator driver will be:

Table

The required number of dump trucks was determined by dividing the excavator's operational productivity by the volume of the dump truck body:

The number of dump trucks trips on a working day was taken as 4, as the time for the medical clearance, loading and unloading of the truck, breaks for lunch and rest, etc. is included in the 12-hour working day of the truck driver.

To determine the mass of transported ash and slag waste, we use bulk weight of dry ash (wet ash is not supplied to the consumer for technological reasons).

Renting dump trucks will cost the mini-enterprise:

.

The total cost of the mini-enterprise will be:

.

For this money, it is possible to transport the consignment of ash and slag waste with the volume:

.

and mass:

.

According to the reports of the Siberian Federal District, the greatest demand for ASW is in the spring-summer period, when the load the TPP is minimal. Believing that from April to September, the enterprise sells 35 840 tons of fly ash at the price of 531 roubles per ton (including VAT), let us calculate the income from ASW sales:

.

Let us calculate the indicators of investment efficiency.

Net profit of the enterprise:

.

Return on investment:

Payback period of investments:

.

Since the profitability and payback period of the project are consistent with the conditions of the investor, the investor is likely to recommend this project for adoption.

Purpose of the Study

For comparison, we have also made a rough estimate for the construction of a new ash-disposal area that is an analogue of Novo-Irkutsk CHP ash-disposal area mentioned before. The priority items of costs are in table

The construction of ash-disposal area includes the following stages (Lewandowski & Szczygielski, 2014):

calculation of the necessary volume and preparation of the project;

selection of the optimal location of the object;

excavation works;

preparation of the ground surface for the installation of geotextile material;

installation of geotextile membrane;

pipeline system installation for supply and suction of working liquids.

For the sake of simplification, we suppose that the first two stages are over, so we consider the four subsequent positions.

The distance required to take the soil out of the excavation was supposed to be equal to 10 km, and the distance from Novo-Irkutsk CHP to the new Ash is 2 km, or 2,000 linear meters. The concept of

Digging of an excavation pit with the volume of 350 thousand m3 will cost:

.

At the same time, the removal of soil at a distance of 10 km is relatively inexpensive:

.

Layout of areas, tops and slopes of the pit:

.

The purchase of a geomembrane will require:

.

and its installation:

.

Finally, the laying of double sewage pipes (taking into account the increased costs of construction) takes more:

.

The total cost of building a new ash-disposal area will be:

It should be noted that this estimate did not take into account the cost of installation the barrier dam of ash-disposal area, building in the process of filling the ash, as well as the cost of installation of suction systems of working liquids, applied only after the introduction of ash-disposal area in operation. These factors would increase the cost of the construction of the new ash-disposal area for another few million roubles (Stengler, 2011).

Meanwhile, the net profit from the sale of ash and slag to the consumer is almost 100 times less; it is only 8 256 864 roubles. This amount simply cannot cover the costs of building a new ash-disposal area. Therefore, the investment project for the construction of a new ash-disposal area even with the simultaneous sale of ash and slag waste from the existing dumps does not make economic sense due to the bankruptcy risk of the mini-enterprise, so the investor cannot accept it to implement under any circumstances.

Research Methods

To assess the effectiveness of investment projects on ash and slag, waste disposal uses the international system of methods and relevant economic criteria, which can be classified in two groups (Suzuki, Kamakura & Katagiri, 2006):

criteria that do not take into account discounted prices;

criteria determined on the basis of discounted value.

The first group includes:

Investment profitability.

A simple (undiscounted) payback period demonstrates how long the investor is reimbursed for the investment and is an indicator that assesses the investor's risk of investing.

The criterion of the net income of the black hole is accumulated (undiscounted) balance of cash flow for the billing period.

Return on investment index.

The profitability index cost.

The second group includes:

Method of the pure discounted income.

Discounted payback period method.

Method of internal rate of return on investment.

Method of profitability index of discounted costs.

However, according to the author, in assessing the effectiveness of investment projects on ash and slag waste disposal, this technique does not take into account the hidden profit due to the lack of the need for the construction of a new ash dump.

Findings

Based on the above-mentioned, it can be concluded that the net profit from the sale of ash to the consumer is almost 100 times less than it is only 8 256 864 rubles. This amount simply cannot cover the cost of the construction of a new ash dump. Consequently, the investment project for the construction of a new ash dump even with the simultaneous sale of ash dumps from existing dumps is economically impractical to the established mini-enterprise in order to avoid its bankruptcy and cannot be adopted for implementation under any circumstances. The analysis of the profit from the sale of ash to consumers confirmed the economic benefit of the enterprise interested in releasing the area of the ash dump.

The estimation of the costs for the construction of a new ash dump modelled on existing ones revealed the economic inexpediency of such projects, since they are unprofitable even with simultaneous realization of ash dumps to consumers. But on the other hand, this is what determined the approximate value of hidden profits due to the lack of the need for the construction of a new ash dump, which should be considered in the author's modified method for evaluating the effectiveness of projects for the disposal of ash and slag waste.

Conclusion

In general, two important aspects of ash and slag waste disposal can be distinguished:

1. The environmental aspect is that the organization of recycling of ash and slag wastes contributes to reducing the release of harmful substances into the environment, reducing the negative impact of production on the state of the landscape, flora and fauna, etc. All this is accompanied by a decrease in pollution of air and water basins, preserving the landscape, releasing the territory as a result of elimination of dumps, etc.

2. The economic aspect reflects the possibility of obtaining an additional source of useful products to meet the needs of the national economy, the possibility of reducing the cost of the resulting recycling of ash and slag products through the use of cheaper raw materials, etc.

Complex utilization of ash and slag waste is effective from the socio-economic point of view and is of great environmental importance as one of the ways to reduce environmental pollution and improve the situation in large industrial cities. Full utilization of ash and slag waste (especially industrial waste) is one of the best ways of rational use of natural resources. In this regard, it is important to develop the industry of the use of secondary resources, state support for the organization of closed cycles "production and consumption", the development of low-waste and waste-free industry.

References

- Jagusiewicz, A., & Szczygielski, T. (2013). The National Reform Programme for the implementation of Europe 2020 strategy in Poland. Davos, Secondary first.

- Lewandowski, J., & Szczygielski, T. (2014). Bezodpadowa Energetyka Węglowa (BEW. Warsaw, Przyczyny warunki – działania.

- Lewandowski, J., & Szczygielski, T. (2014). Coal&Anthropogenic Minerals A Global Perspective, Warsaw, Przyczyny warunki – działania.

- Monma, H. (1980). Preparation of octacalcium phosphate by the hydrolysis of tricalcium phosphate. J.Mater. Sci., 1, 2428-2434.

- Stengler, E. (2011). Waste to energy: contributing to resource and energy efficiency. CEWEP Factfinding Visit, 3, 101-106.

- Suzuki, O., Kamakura, S., & Katagiri, T. (2006). Bone formation enhanced by implanted octacalcium phosphate involving conversion into Ca-deficient hydroxyapatite. Biomaterials, 5, 2671-2678.

- Tung, M.S., Tomazic, B., & Brown, W.E. (1992). The effects of magnesium and fluoride on the hydrolysis of octacalcium phosphate. Arch. Oral Biol, 8, 585-591. Retrieved from http://echa.europa.eu/regulations/reach/understanding-reach.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

17 December 2018

Article Doi

eBook ISBN

978-1-80296-049-5

Publisher

Future Academy

Volume

50

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-1464

Subjects

Social sciences, modern society,innovation, social science and technology, organizational behaviour, organizational theory

Cite this article as:

Peregudova, I. (2018). Rationale For Economic Expediency Of Complex Utilization Of Ash And Slag Waste. In I. B. Ardashkin, B. Vladimir Iosifovich, & N. V. Martyushev (Eds.), Research Paradigms Transformation in Social Sciences, vol 50. European Proceedings of Social and Behavioural Sciences (pp. 924-932). Future Academy. https://doi.org/10.15405/epsbs.2018.12.113