Abstract

The transition to the next technological order requires robotics and automation in the industry. Management of such process of production is impossible without modelling of equipment, forecasting of possible emergencies based on information from various sensors. Such models are called twin models. The purpose of the study is to identify approaches to creating a platform for implementing dynamically changing models - twins of physical and technical objects that are capable of performing ongoing training and adapting to changing external conditions based on the processing of a large volume of measurement information.It is shown that the use of RBF ANN for models that allow us to obtain solutions of systems of partial differential equations to perform constant additional training and dynamic change of its structure in the process of application. The results of the development of the landing system of the module, descending to the surface of the planet using the NARX ANN, are presented. The model has the property of additional training to adapt to the composition of the underlying soil.A model of an early warning fire system for fire using the NARX ANN is developed. Model includes a 3D model of premises, a genetic algorithm for the optimal placement of sensors, and modeling fires of different type of ignition. The proposed methods and models form the basis for creating digital twins of the considered classes of physical and technical objects.The stages of the unified process of constructing similar models are formulated.

Keywords: Digital infrastructuredigital twinsmachine learningneural networks

Introduction

Digital infrastructure

The processes of globalization are associated with the creation of advanced information and communication technologies. These technologies became the basis of the new digital infrastructure of the research and production complex (Kodentsev, 2017; Benghozi,Krob, Lonjon, & Panetto, 2014). Digital transformation in the technical sphere requires the development of information technologies in the following areas: the networks of physical and technical devices, the mobile devices, the internal cloud infrastructure of the enterprise or of the collective cloud services, a platform for the analysis of big data generated at the enterprise in the production process.

Digital twin

One of the main directions is the creation of digital simulation models of physical and technical objects that do not remain unchanged but are updated and changed in accordance with the life cycle of the physical object. Such dynamically updated models are able to continuously receiving new measurement information from sensors of a technical object, from sensors of control devices and from the environment, from larger systems, to generalize newly obtained and past data and to change parameters of the model (Boschert & Rosen, 2016). Dynamically updated model of the object is essentially its digital twin.

The digital twin is constantly trained on the basis of new and historical data. It updates parameters in real time, adapts to external conditions and determines the optimal behavior of the technical object in the prevailing situations. When creating a dynamic model of a physical object, systems of partial differential equations are traditionally constructed, as well as integral equations for which the finite element method is applied. However, the finite element method does not allow to change the characteristics of the model without the participation of a specialist during the modeling of the changing object, since it does not allow dynamically adding new data, adjusting the sizes and number of grids to track the changes occurring in the object. The digital twin model must constantly learn to adjust its characteristics on the basis of updating information, and therefore the methodical basis for its creation is artificial intelligence, neural networks and machine learning (Uhlemann & Steinhilper, 2017; Uhlemann, Schock, Lehmann, Freiberger, & Steinhilper, 2017).

Dynamic digital models allow to project technical objects into the digital world, which makes it possible to use these models to optimize the operation of technical objects, automatic monitoring of technical condition, fault diagnosis and predict technical condition.

Cloud services

Digital dynamic models – the twins of technical objects apply quite complex algorithms and programs. It is advisable to perform and maintain models in a common computing environment using cloud resources providing convenient network access on demand to the general computing resources: servers, storage devices, applications and services. Services can be quickly provided and released with minimal operating cost. It is possible to implement models for a set of objects in the cloud environment (Kang et al., 2015; Chawla and Sogani, 2011).

So, in the Peter the Great Saint-Petersburg Polytechnic University (SPbPU) a center with three supercomputers was organized. The supercomputercluster “RSK Tornado" is characterized by peak performance of 943 TFlops. Massively parallel supercomputer "Polytechnic-RSK PetaStream" supports more than 70 thousand threads and has a peak performance of 291 TFlops."Polytechnic - NUMA", has a massively parallel system with memory capacity more than 12 TB, and a peak performance of 30 Tflops. The computing environment of the supercomputer center supports a cloud-based system that provides infrastructure-level services (IaaS) allowing to install and to platform an application software, and platform-level services (PaaS) allowing to host basic software.

Cyber-physical systems

To implement the monitoring of technical condition, diagnostic and prediction functions, the technical object must interact with its digital model via the Internet using TCP/IP protocols. Technical systems that use a global network and corresponding protocols to interact with each other and with their digital counterparts belong to the class of cyber-physical systems. A special role in the cyber-physical systems is played to measurement tools that fill the computing environment with meaningful information (Ide et al., 2015). A wide range of measuring instruments from elementary sensors to complex integrated measuring systems is used. Sensors integrated in wireless networks or measuring systems with wireless data transmission are efficient, fault-tolerant, adaptive and capable of self-organization. The main interest in this capacity is the IEEE 802.15.4 standard, which defines the organization of energy efficient sensor networks, such as ZigBee (Kühnert, Schleipen, Okon, Henben, & Bischoff, 2016).

Cyber-physical systems use the current technology of the Internet of Things that complements the technology of the Internet of People and is able to rebuild technological, research, operational processes, significantly reducing or eliminating human participation (Rellermeyer et al., 2008). The Internet of things develops the paradigm of cloud computing, transferring calculations from data centers to a large number of interacting distributed devices. This approach to the organization of calculations was called "foggy calculations.

Problem Statement

The research objective is to develop methods and technologies for transition to the management of complex physical and technical objects based on digital twins. It is importantto determine the possibility of a transition from classical modeling to machine learning using specific examples of developments carried out in SPbPU. These examples help us to identify ways of developing modeling methods and their implementation by means of a supercomputer center using cloud computing.

Research Questions

To solve the task, it is necessary to carry out the following studies:

Identify the benefits of machine learning and develop methods and tools for its implementation based on projects carried on in SPbPU.

Identify the most promising architectures of neural networks capable of performing training on data obtained as a result of simulation and full-scale experiment.

Show the possibility of additional training of artificial neural network (ANN) taking into account archival and updating data, dynamic change of ANN size and avoidance of overfitting.

Summarize the experience of colleagues and our own experience in the field of creating digital dynamic models.

Purpose of the Study

The objective of the study is to identify approaches to creating a platform for implementing dynamically changing models of physical and technical objects that can process big amounts of measurement information, perform ongoing training, and adapt to changing conditions.

Research Methods

The creation of digital twins of physical and technical objects requires the integration of diverse technologies. First, it is necessary to integrate the entire solution of all technical tasks into a common computing environment based on a system of sensors and cloud computing. Secondly, it is necessary to create a complex of mathematical models of objects, based on fundamental knowledge about the physical, chemical and other processes occurring in the object. Thirdly, it is necessary to create a set of algorithms that allow to adapt the above-mentioned models to the observational data, and also to develop and implement the optimal control of the object.The methods of research are based on the theory of neural networks that have the properties of supervised learning and additional learning on the basis of measurement data, as well as information coming from the engineer and based on his experience.

From our point of view, the main problem of creating digital twins consists of choosing a class of mathematical models and methods. Traditionally, differential equations (ordinary and partial derivatives), supplemented by boundary and other conditions, constitutethe basic class of models of physical and technical objects. However, the solution of each such equation for an individual element is already a rather resource-intensive task. Even more resource-intensive and difficult task is to identify the coefficients of differential equations using the measurement data. Even if such a task can be solved in a reasonable time, the connection of hundreds and thousands of obtained solutions with the refinement of the parameters in real time can not be carried out.

We propose to create models in the form of neural networks that have the properties of training and post-training on the basis of measurement data, as well as information obtained from the engineer and based on his experience. Training neural networks is a very resource-intensive procedure, but the trained neural network works quickly, especially when it uses the appropriate software and hardware.

Also, we generalize our own research in the field of neural network application for modelling of specific physical and technical objects and research of our colleagues from SPbPU. The studies were carried out for neural networks having different architectures. In particular, ANNs with Radial Basis Functions (RBF) were used to implement flexible dynamic models based on solving differential equations of mathematical physics with partial derivatives. We developed and tested a set of methods and algorithms for training neural networks based on a combination of their structural and parametric adaptation.

Models of technical objects are developed within the framework of two projects: model of the descent module motion control system and model of the fire alarm system. The first model is based on the Klein-Nishina-Tamm equation for the photon scattering description and the nonlinear autoregressive exogenous (NARX) ANN. The second model is based on the Navier-Stokes equations, the evolutionary algorithm, and the supervised trained NARX ANN. Model was developed for the fire detection system.

Findings

Continuous learning of the digital twin model with the possibility of adding new data leads to the need to abandon the classical simulation and move on to machine learning. In classical modeling with respect to input data and rules the output values will be obtained. For example, on the base of partial differential equations and input data the output result may be obtained. In machine learning, based on obtained input data and target output result, the model itself will be obtained as shown in Figure

Machine learning usually deals with large sets of complex data obtained from a variety of sensors (Nilsson,1996). The data represent the results of measuring different physical quantities, as well as data obtained from a person on the basis of his experience, for example, data on the occurrence of an event that affects operation of the system. The goal of machine learning is to create generalized models that are true not only for the data used for learning, but also for any data specific to the current state of the object. As a result, it is necessary to maximize the generalizing possibilities of the model. Of particular importance is the method of evaluating the generalizing ability of the model (Barber, 2012).

Neural networks

The digital twin updates its models and parameters of models in real time, constantly learning on the basis of new and historical data obtained from measuring devices and from specialists. It predicts the optimal behavior of the technical object in the next period of time. Automatic updating of not only parameters, but also models by increasing or decreasing complexity, can be realized on the basis of artificial neural networks. In SPbPU, the development of dynamically changing twin models of physical and technical objects is carried out by several groups of scientists (Lazovskaya et al., 2017; Lazovskaya and Tarkhov, 2016).

Neural network approach has the following advantages with respect to creation of models.

The ability to increase and decrease the complexity of the model flexibly, in accordance with objective criteria that do not allow to reduce the generalizing ability of the model.

The ability to take into account the updating data without a complete re-training of the ANN. It is sufficient to perform several steps to adapt the existing model. This process is called additional training. Depending on the task to be accomplished, additional training can be performed quickly enough because only necessary layers of the network should be drawn; the remaining layers can be frozen.

A variety of ANN architectures, allowing to determine the best model for objects.

RBF ANN allows the creation of dynamically changing, constantly learning models-twins of physical and technical objects characterized by partial differential equations. RBF-networks allow to learn a model on the basis of updating measuring information, automatically increase or decrease the number of neurons, have a relatively small size, and a good generalizing ability.

Neural networks with input and feedback delays, so-called NARX ANN, characterize the physical and technical object as a dynamic system in the state space, can be used for monitoring and prediction. Unlike RBF networks, if necessary, NARX networks can have a large number of layers. Networks having a large number of layers (from 10 to 100) are called deep ANN. Deep ANN allow solving more complex problems, for example, to simulate computer vision and computer hearing, but they require supercomputing. When new information is received, deep networks allow for additional training. To increase the speed of simulation in real time, it is possible to perform additional training of a part of the network without restarting.

Let's consider examples of development of models- twins of physical and technical objects executed in SPbPU.

A new approach to neural network models of dynamic objects

We proposed amethodology for constructing neural network models based on heterogeneous data, which may be presented by differential equations, boundary conditions, symmetry conditions, measurement data, etc. (Lazovskaya, Tarkhov, & Vasilyev, 2017). This methodology can be considered as a basis for the twin models. Methodology allowed us to develop a unified process for the problem solving. Solution includes the following stages.

Specification of the quality characteristic of the model in the form of a functional or a set of functional. This stage is based on information about the models of the studied phenomena (these models can be refined in the process of constructing and operation of the object) and can be implemented by a specialist in the subject area.

Selection of a functional basis or bases. This stage can be performed by a specialist in the subject area based on information about the nature of the phenomena being simulated, and automatically, using evolutionary algorithms.

Selection and implementation of methods for selecting parameters and structure of the model. This stage can be completely automated and does not require mandatory intervention of a specialist, although his information on the operation of the object can be easily taken into account when building the model.

Implementation of methods for refining models in the process of their functioning and appropriate adjustment of their control algorithms. These methods and algorithms can be implemented in a software package that will be used by specialists without further development to solve a wide range of problems.

Updating the database of models, algorithms and programs.

Neural network models of the standard type have significant shortcomings, such as a long training procedure and single-layered nature of the neural network. We have developed a new approach (Lazovskaya and Tarkhov, 2016), which allows us to form quickly a sufficiently accurate multi-layered neural network solution of the differential equation. The strong side of the method is the automatic inclusion in the final formula of the model parameters. It gives us possibility to apply model without reiteration of the solution if it is necessary to investigate the effect of parameters on the result. This is especially important for constructing an individual model of a particular object, taking into account its unique features. This approach allowed to construct simple models in three problems of modelling real objects. Obtained models displayed measurement data with fewer errors than the exact models based on the original differential equations solutions.

Descent Module Measuring System

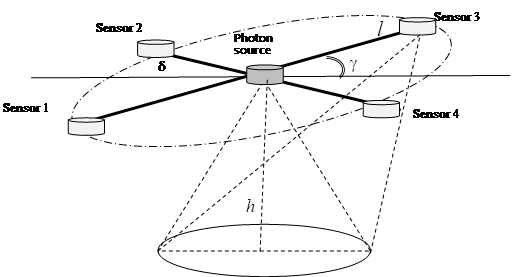

Let us consider an example of the descent module landing on the surface of the planet. Measuring system intends for measure the movement parameters of descent module (Malykhina and Kislitsyna, 2017). At the bottom of the descent module, a photon source and four photocell detectors are installed. Measurment of altitude above the surface of the planet is carried out by recording the flux of photons scattered by the surface of the planet in the opposite direction. For this, four detectors of scattered photons are installed on the descent device. The geometrical arrangement is shown in Figure

The peculiarity of the descent module is the impossibility to perform full-scale experiment on the planet surface. Therefore, it was necessary to develop a mathematical model that takes into account the geometry of the source and four detectors location, the characteristics of the radiation source, and the composition of the soil of the underlying surface in the conjectural site of landing. The model is based on the processes of interaction of gamma radiation with matter in accordance with the Compton Effect.

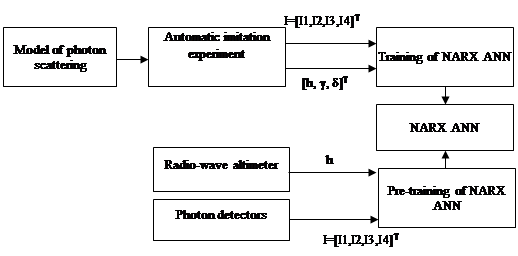

To determine the altitude, the velocity and the inclination of the descent module, we proposed the NARX network using three layers of three neurons. Network is trained on the Earth using a model of interaction of photons with surface in the conjectural landing site. However, the scattering of photons is described by a cross section of the underlying surface, it can not be known before descent. Since deviations from the calculated landing site and the actual landing site the composition of the ground is not known exactly. Therefore, the NARX ANN must be post-trained in the process of descent according to the data of the photon detectors and the radio wave altimeter. The scheme is shown in the Figure

At altitude from 20 m to 10 m, sensors detect scattered intensity. The output vector of the scattered gamma-ray detectors and the altitude h obtained with the radio-wave altimeter are used for the neural network post training. Based on the post-trained neural network, a current value of Compton scattering property will be obtained. This network characterizes the composition of the soil at the landing site. For measure at altitude from 10 m to 0.3 m, the trained NARX neural network, adapted to the composition of the soil allows to obtain motion parameters. Thus, the model of interaction of photons with underline soil in combination with post-trained NARX ANN can be considered as a digital twin of the descent module landing system.

Multisensory early fire detection system

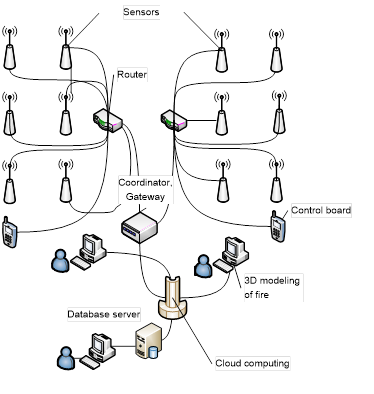

Let us consider the result of development a multisensory early fire detection system that integrates sensors measuring temperature, smoke concentration, carbon monoxide concentration and forming a mesh network according to the ZigBee standard (Malykhina et al., 2017). The sensors transmit measurement results to the nearest router, which collect the measurement data and transmit it to the gateway connected to the corporative network (Figure

The possibility of early warning of a fire depends on the number and type of sensors, their placement in space, the speed of information exchange and algorithms for data analysis. The system proposed to use sensors for measuring temperature, gas concentration and smoke. In the process of monitoring the fire situation, the system makes decisions on the presence of fire, on the location of the fire, predicts the development of a fire and controls fire extinguishing devices. External conditions, such as normal heating, the presence of dust in the air, the presence of combustible materials, ventilation, affect the decision. To get the right decisions, we should continuously model the premises if situation changes.

The model is based on the solution of the Navier-Stokes equations in three-dimensional space. The desire to build a more accurate model of the room leads to increasing the complexity of calculations, increasing time and computational resources. Therefore, it is possible to perform the simulation only in the supercomputer center of “Polytechnic”.In the simulation process, an open standard for parallelizing programs the Open Multi-Processing (OpenMP) service was used. It defines the compiler directives, for programming multi-threaded applications on multiprocessor systems with shared memory. The tasks performed by threads were described using special preprocessor directives of the for distributed memory systems

To simulate the dynamics of fire development, the FDS (Fire Dynamics Simulator) program was used (Malykhina et al., 2017). To solve the equations the method of computed rectangular grids was used. If the position of the object does not exactly match the grid, the object automatically moves to the edge of the grid, which can negatively affect the accuracy of calculations. Modeling fires of thin objects, cables, wires, requires reducing the size of grid cells, which leads to an increase in modeling time.

Significant impact on the operation of the fire system is affected by changes of the production cycles, for example, the normal heating of equipment, the location of equipment and materials. The model must constantly monitor changes in external conditions in order to correctly determine the onset of ignition. The results of measurements accumulated in the normal state of the premises allow one to obtain a model that monitors the normal state and predicts the following. The decision of ignite is possible with a significant difference between the measured results and the predicted results of normal state.

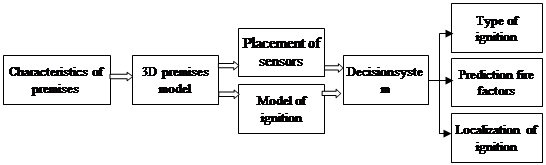

Such solutions can be obtained using the NARX network, in the block “Decision system” of the scheme shown in the Figure

The neural network is a multi-layered perceptron with feedbacks and delays at the input. It allows to make decision on the beginning of the process of ignition, on the type of ignition, and allows to localize the focus of fire in the space of premises. For each type of ignition, effective extinguishing agents must be selected.

Information Security

Application of production management systems based on open standards and protocols dramatically increases the risks of information security (Taubmann et al., 2017).

It is required to ensure the integrity of information, including measurement data. Therefore, the measurement results must have digital signatures. Increased requirements should be presented to the availability of historical data stored on servers, to the availability of current information received from sensors, and to the availability of cloud services (Po-Ching, Hsu, & Hwang, 2017).

The human actions may be destructive to the digital production model, so it is imperative to identity and access management.

The role of engineering ethics increases with the introduction of a new information technologies (Bernd et al., 2009). Engineers deal with the virtual world, in which, perhaps, there is no sense of danger acquired by mankind during its existence in the technological environment. When working in a virtual environment, which is the projection of a real production process into a digital model, the engineer must constantly perform a backward projection mentally in order to better understand his responsibility for the decisions making.

Engineers work at the intersection of their competence in the field of technical objects and their projections in the digital world. This requires the extension of the engineer's competencies and their responsible execution. Engineers must continue their professional development throughout their careers.

When creating digital twin of technical object in the form of dynamically changing models, the adequacy of models is of particular importance. Therefore, the engineer requires an honest verification of adequacy of the model at all possible stages of its operation.

Ensuring information security is impossible without solving ethical problems. The information environment is most vulnerable to the hostile actions of experienced users working in the enterprise (insiders). Therefore, employees of the enterprise should be interested in performing correlated strategies to protect the information environment.

Conclusion

-

The creation of a new digital infrastructure of scientific and production complexes is based on digital transformation in the technical sphere, which requires the development of information technology.

-

Digital transformation of production is supported by Internet Technologies of Things and cyber-physical systems. It is based on sufficiently powerful computing facilities provided by supercomputer centers that allow the cloud services.

-

Development of dynamic digital models of physical and technical objects, allows to monitor the correct operation of equipment, to search defects, to predict the operation of equipment in the future.

-

Twin-models of physical and technical objects can be trained during the whole lifetime of the object and therefore should be based on methods of machine learning.

-

Methods for solving equations of mathematical physics, using RBF ANN, are the basis for creating dynamic twin models of physical and technical objects.

-

The developed model of the descent vehicle movement system using the NARX INS, which is trained on simulation data and additionally trained on real data, has the properties of a twin model of a technical object.

-

The developed model of early warning of a fire, including an ignition model and NARX INS, which allows monitoring changes in rooms, in the location of sensors, has the properties of model - twin of physical and technical objects.

-

Digital transformation in the technical sphere is connected with the solution of new ethical problems caused by the following peculiarities of the digital environment: working in a virtual environment, careful checking of the adequacy of models, ensuring information security.

Acknowledgments

The authors are grateful to the administration of the Supercomputer Center of the Peter the Great Polytechnic University for the opportunity to perform the calculations necessary for modeling objects.

References

- Barber, D. (2012). Bayesian Reasoning and Machine Learning. Cambridge: Cambridge University Press.

- Fernando, I.A. (2014). Journey from Big Data to Smart Data. Digital Enterprise Design & Management. In Benghozi, P., Krob, D., Lonjon, A., & Panetto, H. (Eds.) Proceedings of the Second International Conference on Digital Enterprise Design and ManagementDED&M. (pp 25-33). Cham, Switherland: Springer International Publishing.

- Bernd, C., Stahl, S., Rogerson, K.J., &Wokunuma, J. (2009). Understanding Ethical issues of emerging AmI Technologies in Europe. In M., Schneider, A. Kröner, J.E. Alvarado.M., Schneider, A. Kröner, J.E. Alvarado (Eds.) Workshops Proceedings of the 5th International Conference on intelligent environments. Springer Lecture Notes in Computer Science. vol 4952, (pp.26-28). Zurich, Switzerland: Springer.

- Boschert, S., & Rosen, R. X. (2016). Digital Twin—The Simulation Aspect. In Hehenberger P., Bradley D. (Eds.) Mechatronic Futures. Cham: Springer

- Chawla, V., & Sogani, P. (2011) Cloud Computing – The Future. In: Mantri A., Nandi S., Kumar G., Kumar S. (Eds.), High Performance Grid Computing.HPAGC 2011. Communications in Computer and Information Science, vol 169, (pp. 113-118). Berlin, Heidelberg: Springer.

- Ide, C., Nick, M., Kaulbars, D., & Wietfeld, C. (2016). Forecasting Cellular Connectivity for Cyber-Physical Systems: A Machine Learning Approach. In O., Niggemann, J., Beyerer, (Eds.), Machine Learning for Cyber Physical Systems ConferenceML4CPS (pp.15-22). Berlin, Heidelberg: Springer Vieweg.

- Kang, D.-K., Alhazemi, F., Kim, S.H., & Youn, C.-H. (2015). A Study of Resource Management for Fault-Tolerant and Energy Efficient Cloud Datacenter. In Y., Zhang, L., Peng, L., C.-H., Youn (Eds.), Cloud Computing, 6th International Conference, CloudComp, (pp.22-29). Daejeon, South Korea: Springer.

- Kodentsev, D. (2017). Infrastructure for digital transformation. Network Solutions Journal. LAN. 4, 7-12. [In Russian].

- Kühnert, C., Schleipen, M., Okon, M., Henben, R., & Bischoff, T. (2016). A Modular Architecture for Smart Data Analysis using Automation ML, OPC-UA and Data-driven Algorithms. In J., Beyerer, O., Niggemann, C., Kühnert (Eds.), Machine Learning for Cyber Physical Systems, Selected papers from the International Conference ML4CPS. (pp. 25-33). Berlin: Springer Vieweg.

- Lazovskaya, T. N., Tarkhov, D. A., & Vasilyev, A. N. (2017). Parametric Neural Network Modeling in Engineering.Recent Patents on Engineering, Vol. 11, 10–15.

- Lazovskaya, T., &Tarkhov, D. (2016). Multilayer neural network models based on grid methods, IOP Conf. Series.Materials Science and Engineering, 158, 012061 https://doi.org/10.1088/1757-899X/158/1/012061

- Malykhina, G., & Kislitsyna, I. (2017). Simulation of an on-the-fly measuring system of a descent module under uncertainty of the lunar-surface composition. St. Petersburg Polytechnical University Journal: Physics and Mathematics, Vol.3, 3, 1-11.

- Malykhina, G.F., Guseva, A.I., & Militsyn, A.V. (2017). Early fire prevention in the plant. In I.V. Bolotin Yu.N. Egorov (Eds.). Proceedings of the International Conference onIndustrial Engineering, Applications and Manufacturing (ICIEAM). Saint Petersburg: IEEE. Retrieved from https://ieeexplore.ieee.org/ abstract/document/8076375/

- Nilsson, N.J. (1996). Introduction to Machine Learning. Stanford: Stanford University. Retrieved from http://www.cs.ubbcluj.ro/~gabis/ml/ml-books/MLBOOK.pdf

- Po-Ching, L.. Hsu, Y.T., Hwang, R.-Y. (2017). Detecting and Preventing DDoS Attacks in SDN-Based Data Center Networks. In X., Sun, H.-C., Chao, X., You, E., Bertino (Eds.), Proceedings of the Third International Conference Cloud Computing and Security, ICCCS 2017, Part II, (pp. 50-61). Nanjing, China: Springer.

- Rellermeyer, J. S., Duller, M., Gilmer, K., Maragkos, D., Papageorgiou, D., & Alonso, G. (2008). The Software Fabric for the Internet of Things. In C. Floerkemeier, M. Langheinrich, E. Fleisch, F. Mattern, S.E. Sarma (Eds.), The Internet of Things, First International Conference, IOT. (pp. 87-104). Zurich, Switzerland: Springer.

- Rakotondravony, N., Taubmann, B., Mandarawi, W., Weishäupl, E., Xu, P., Kolosnjaji, B., Protsenko, M, de Meer, H., & Reiser, P. (2017). Classifying malware attacks in IaaS cloud environments. Journal of Cloud Computing Advances, Systems and Applications. 6: 26. doi: 10.1186/s13677-017-0098-8 Springer Open.

- Uhlemann, T. H.-J., & Steinhilper, C.L.R. (2017). The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. In S. Takata, Y.Umeda, S. Kondoh (Eds.), Proceedings of the 24th CIRP Conference on Life Cycle Engineering, Procedia CIRP. Vol. 61, (pp. 335–340), Kanagawa, Japan: Elsevier.

- Uhlemann T.H.-J., Schock C., Lehmann C., Freiberger S., & Steinhilper R. (2017). The Digital Twin: Demonstrating the Potential of Real Time Data Acquisition in Production Systems. In J. Metternich, R. Glass (Eds.) Procedia Manufacturing, Vol. 9, (pp. 113-120). Darmstadt: Elsevier.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

30 December 2018

Article Doi

eBook ISBN

978-1-80296-050-1

Publisher

Future Academy

Volume

51

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-2014

Subjects

Communication studies, educational equipment,educational technology, computer-aided learning (CAL), science, technology

Cite this article as:

Malykhina, G., & Tarkhov, D. (2018). Digital Twin Technology As A Basis Of The Industry In Future. In V. Chernyavskaya, & H. Kuße (Eds.), Professional Сulture of the Specialist of the Future, vol 51. European Proceedings of Social and Behavioural Sciences (pp. 416-428). Future Academy. https://doi.org/10.15405/epsbs.2018.12.02.45