Abstract

The business environment keeps changing from time to time and unpredictable. The nature of current business environment required supply chain management in smoothen the process of business operation. Therefore, supply chain management become more and more popular in today’s dynamic business environment. The main idea of this study is to put in the concept of industrial supply chain management in managing education sector. This study proposed a conceptual framework of educational supply chain through throughout review of the literatures. The framework includes parent participation, friendship quality as main sources of influencing school education. This is continuing by tertiary education and industry internship as factors influencing high quality graduates or professional development. In educational supply chain management, student performance throughout the learning process should be measured from all aspects which include ethics and morality and knowledge and skills. Ethics and morality consists of ethics and spirituality, leadership skills, and national identity; while knowledge and skills consists of language proficiency, thinking skills, and knowledge. The products from the educational supply chain consist of job seeker as an employee and an entrepreneur that create and offer job to other. Hence, this study provides a unique conceptual diagram expected to aid researchers and practitioners to create a more comprehensive understanding on educational supply chain. The main objective of this study is attempting to identify and explain the concept of educational supply chain management in Malaysia tertiary education.

Keywords: Educational supply chain managementtertiary educationMalaysia

Introduction

The words “Supply Chain Management” (SCM) have become a common term in business operation. The significant contribution of supply chain management in improving business performance is crystal clear in current decade. Therefore, the performance of supply chain is an important factor of success in world trade. Even though supply chain is a power full tool in managing business operation, however, a supply chains itself is not enough. A successful supply chain management required a comprehensive cooperation, collaboration, or integration between all members in the supply chain (Lee, Udin, & Hassan, 2014a, 2014b). This means that the critical understanding of the features and the role played by each function in the overall supply chain is the prerequisite for achieving work efficiency and effectiveness (Janvier-James, 2012) and competitive advantages (Flynn, Hou, & Zhao, 2010). As the twenty-first century begins, supply chain management has been considered as the strategic and systematic coordination of traditional business activities that enable firms not only to reduce costs, but also enable firms struggling to enhance quality, improve customer service, and increase competitiveness (Tan, Lyman, & Wisner, 2002). Janvier-James (2012) noted that the real contribution of supply chain and supply chain management have attracted high attention from scholars and practitioners.

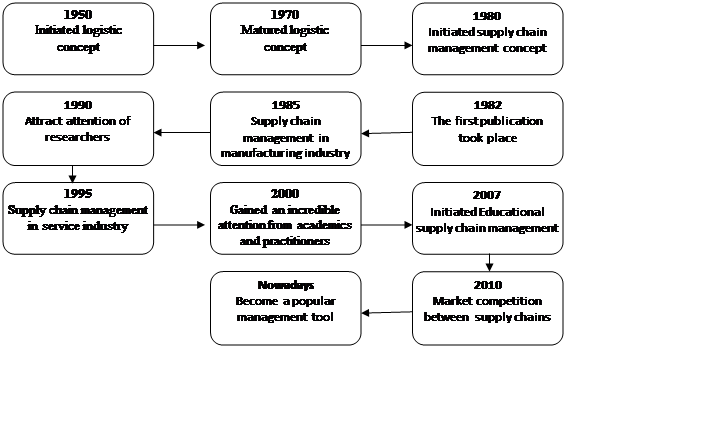

The idea of supply chain management is initially derived from logistic concept since 1950 and matured in 1970 (Habib & Jungthirapanich, 2008). The logistical concept is slowly evolving into the supply chain management concept and initiated the supply chain management concept since 1980, and the first publication took place in 1982 (Habib & Jungthirapanich, 2008). The concept of supply chain management started to emerge in the manufacturing industry since 1985 (Habib & Jungthirapanich, 2008). In the early 1990s, scholars and industry practitioners start to place attention on agile manufacturing (Cooper, 2006; Huan, Sheoran, & Wang, 2004). This is followed by the service industry initiated the supply chain management in their business operations in 1995 (Habib & Jungthirapanich, 2008). The development and continuing evolution of the supply chain management role are obvious in the last decade, which gained an incredible attention from both academics and practitioner's community since 2000 (Chan & Qi, 2003). This has led the supply chain management to enter the education industry since 2007 (Habib & Jungthirapanich, 2008). In the twenty first century, supply chain management has been considered as the most effective operations tools to improved organizational competitiveness (Gunasekaran, Lai, & Cheng, 2008). In short, supply chain management becomes a popular management tool in helping organizations to improve their performance through the ultimate goal of supply chain management which is waste elimination and increased efficiency. The evolution of supply chain management is illustrated in Figure

Problem Statement

The business environment keeps changing from time to time and unpredictable. The nature of current business environment required supply chain management in smoothen the process of business operation. Therefore, supply chain management become more and more popular in today’s dynamic business environment. This situation is not only happening in industry environment, but also the educational environment. All university and institutions are straggling to get the student number. This is certainly true for most of the university and institution to survive in the education industry. However, to ensure the university or institution to produce the right graduate to the right industry is still a challenging goal for all the university or institutions.

Research Questions

Most of the tertiary education in Malaysia is reducing in term of subsidy. Thus, finding a way to generate income for the university or institution would be a part of the business operation. The activity like developing short courses, part time programme and increasing marketing activity to get more students is remaining challenging. However, the ultimate goal of a university or institute is to produce a talented graduate for industry. Hence, the research question is form as following. How to ensure the university or institution to produce the right graduate to the right industry?

Purpose of Study

The main idea of this study is to put in the concept of industrial supply chain management in managing education sector. Specifically, this study is attempting to identify and explain the concept of educational supply chain management in Malaysia tertiary education.

Literature Review

Industrial Supply Chain Management

In line with the evolution of supply chain management, the professional bodies of supply chain management are established. In 1963, the National Council of Physical Distribution Management (NCPDM) is formed to focuses on the physical distribution in which integrated transportation, warehousing, and inventory. It is non-profit association that provides guidance in the development, design and improvement in professions of physical distribution. The coverage area has been move from physical distribution to logistic management, so that National Council of Physical Distribution Management has reformed and known as Council of Logistics Management (CLM) in 1985. Council of Logistics Management stayed function professionally until year 2004. To keep updated with the current business processes, the council name has been reformed as Council of Supply Chain Management Professionals (CSCMP) in 2005 to focusing on the broad coverage of transportation and logistics function which also known as supply chain management that plan, do, check, and act on the business functions of procurement, manufacturing operation, sales, and marketing management rather than just transportation and logistics management (Council of Logistics Management, 2010).

Commonly, supply chain management must involve several terms, which included raw material extractor, supplier, manufacturer, distributor, transportation, logistics, wholesaler, merchant, retailer, customer, and end user. For easier understanding, Tan (2001) lists three simple description for supply chain management. Tan (2001) stated that public can understand supply chain management as (1) the purchasing or supply activities of a manufacturer, (2) the logistics and transportation function of the retailers and merchants, and (3) all the value added activities from the raw materials' supplier to the end users. In simple words, the goal of supply chain management is to be process efficient and cost effective through collaborative efforts over the whole system. The extent of supply chain management comprises firm’s activities from the strategic level through the tactical and operational levels since the efficient integration of suppliers, manufacturers, wholesalers, retailers, and end users are take into account (Li, 2007).

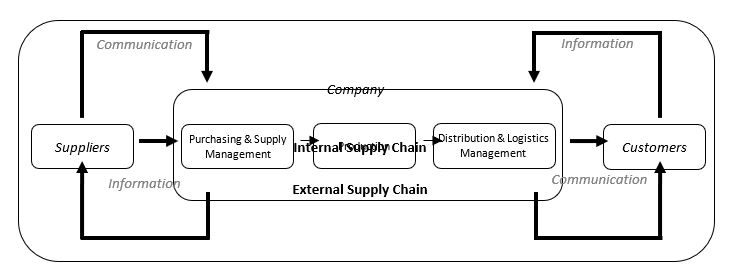

Supply chain is an organizations network that associated corporate activities and coordination within and between organization to create value for customer (Kumar, 2001) as shown in Figure

In twenty-first century, supply chain management is a crucial and significant strategy to success in the global markets (Gunasekaran et al., 2008). The extended supply chain network moves beyond the individual firm to inter-organization functions, including suppliers, customers, trading partners, service providers, retailers, manufacturers, and transporters as shown in Figure

The implementations of supply chain management paradigm and technology are one of the effective operation strategies to improving flexibility and responsiveness (Fasanghari, Mohammadi, Khodaei, Abdollahi, & Roudsari, 2007). Supply chain management grows within and across organizations by the information flow to truly support the real time communication (Boubekri, 2001). Information technology (IT) applications such as internet, intranet, and extranet based tools are becoming essential for firms to optimize the materials flow and information flow in the entire supply chain (Boubekri, 2001). Select the right supply chain technology to support business operations is the key for gaining competitive advantages. Thus, the supply chain technology is opening new doors for supply chain members, including suppliers, customers, trading partners, service providers, retailers, manufacturers, and transporters to optimize the value of the supply chain by create and develop a virtual enterprise more efficiently and effectively as well as lower cost than ever before (Boubekri, 2001). By having the supply chain technology, organization seeking to efficiently improve their operation by emphasis on the supply chain management instead of traditional cost cutting approach (Boubekri, 2001).

In complexity of the supply chain, the supply chain also can be viewed from internal and external operations as illustrated in Figure

Based on the aforementioned discussions, a comprehensive definition of the SCM is proposed. SCM can be defined as “all the activities including processes, entities, material, financial, and information flows in delivering product from raw material to the final customer through the integrated functions of supply chain technology adoption that span from internal organization to external trading partners of suppliers, manufacturers, wholesalers, retailers, and service providers with the objectives to improve supply chain reliability, responsiveness, agility, costs, and asset management in the cooperative and collaborative environment.”

Educational Supply Chain Management

Today’s supply chains are likely to respond promptly, rapidly, efficiently, and effectively to the changes, volatile, and turbulence in the marketplace to achieve, succeed, and sustain competitive advantage in the new edge of business environment that is more global, customer driven, and technological oriented by focusing on reliability, responsiveness, agility, and costs of the supply chain. There are many supply chain management studies have been conducted in Malaysia. The trends showed that supply chain management has provided many benefits to the supply chain or organization. Especially in recent years, firms have utilized supply chain to move their business over the world to become globalize in order to achieve customers’ satisfactions with high quality products and cost effective delivery (Crinis, 2012; Lam & Postle, 2006). However, there is still limited number of study that applying the philosophy of supply chain management in managing educational operation.

Generally, the concept of supply chain management can be apply and practice in manufacturing and service industry. There are many successful cases shown that supply chain management provides a huge contribution in the business performance. However, surprisingly, the practical success of supply chain management concept did not clearly practice in Malaysia’s tertiary education; even it has been practised in other service industry. The educational supply chain concept can be a critical role in the improvement of service delivery and cost reduction in tertiary operational functions (Kwinda, 2013). This statement explained that organization’s performance or output is depending on the extent of utilization of internal and external resources into the business operation. High quality of graduates required high quality of educational process. The high quality of tertiary graduates required the participation of all members in the educational supply chain in delivery the right concept and knowledge to students. This idea of study is derived from Malaysia Education Blueprint 2015-2025 (MOE, 2015).

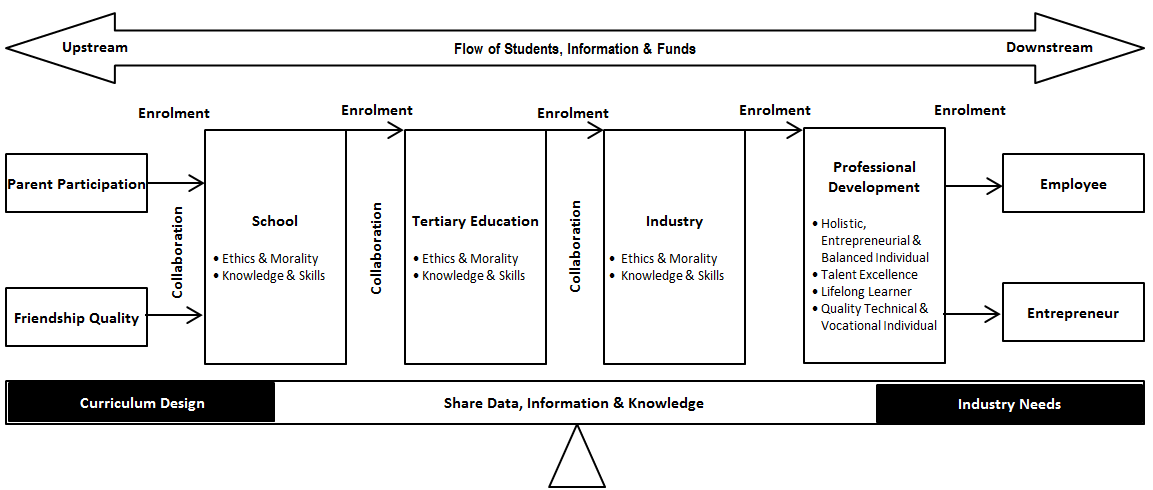

Basically the concept of educational supply chain management is similar to the current practices of industrial supply chain management. There are also an upstream and downstream of supply chain. Upstream educational supply chain is referring to the flow of students, information, and funds starting from the very early stage of education (i.e., kindergarten and pre-school) until primary school, secondary school, higher education, and tertiary education. However, parent participation and friendship quality of the children are critically important and it can give a huge impact for the quality generation of the graduates. This stage can be considered as a foundation of making a high quality graduates in future. This is because both factors are considered as a raw material supplier’s supplier. It is impossible to produce a high quality product with low quality of raw material and weak operation processes. While, downstream educational supply chain is referring to the delivery process of graduates to the industry as an employee or to the business world as an entrepreneur. In line with the latest Malaysia Education Blueprint 2015-2025 (MOE, 2015), the graduates not necessary a job seeker to be an employee, but also can be a job creator to be an entrepreneur that provides job opportunity to job seeker. The conceptual framework of educational supply chain management is illustrated in Figure

Parent participation and friendship quality are considered as the prerequisites for producing high quality graduates (Daniel, Wang, & Berthelsen, 2016; Fan, 2001; Griffith, 1996; MOE, 2015; Pittman & Richmond, 2008; Sebanc, Guimond, & Lutgen, 2016). Parent able to gives a huge impact to their children since born. They have the longer hours together before sending their children to school. Even in school, the hours in school are shorter if compare to the hours the children stay with parents. Statistically proofs that parent participation is playing a critical role in educational supply chain (Daniel et al., 2016; Fan, 2001; Griffith, 1996). Besides, friendship quality is also one of the critical sources in influencing the process of producing high quality graduates (Pittman & Richmond, 2008; Sebanc et al., 2016). Friendship quality didn’t provide direct influence to academic performance, but it is significantly direct link to reducing the level of individual’s problem behaviour (Pittman & Richmond, 2008). It is believed that the problem behaviour leading to negative academic performance (Bernt & Bugbee, 1993). However, the collaboration between parent participation, friendship quality, and school are required in order to smooth the process of enrolment.

The collaboration between school and tertiary education is a must. The collaboration can ensure the right sources been prepared and ready for tertiary education. This is not only improving the capability and ability of the student while entering to the tertiary education, but also increases potentiality of the student to groom further. In supply chain management, the high quality input is believed to have a high quality of output. Some of the problems in the process of tertiary education are derive from the student’s performance in school. School’s academic performance of the student is one of the foundations issues for the student to survive in tertiary education. Weak foundation is generating a gap for the student to have a speed learning process. This is not only affected the students with weak foundation, but also affected the overall teaching and learning process as a whole. It might affect the process of teaching of a lecturer and also the learning process of other students that study in the same class.

In addition, the collaboration between tertiary education and industry cannot be terminated throughout the education process. The two way communication between both parties is crucial for the process of transformation from student to employee or entrepreneur. This is because the industry needs is only able to meet if the industry share the requirement to the tertiary education which is the producer of graduates for the industry. All the graduates produced are not necessary looking for a job to be an employee, however, the graduates can be an entrepreneur that create and offer job to other. This is aims to reduce the level of unemployment of graduates that currently emphasized in the Malaysia Education Blueprint 2015-2025 (MOE, 2015).

Based on above mentioned discussion, the data, information and knowledge sharing throughout the process in educational supply chain are critical. The sharing must equally and balance between curriculum design and industry needs as shown in Table

In educational supply chain management, student performance throughout the learning process should be measured from all aspects which include ethics and morality and knowledge and skills. Ethics and morality consists of (1) ethics and spirituality, (2) leadership skills, and (3) national identity; while knowledge and skills consists of (1) language proficiency, (2) thinking skills, and (3) knowledge. However, the measurements can be defined in two stages in which school level and tertiary education and industry level as explained in Table

Resource Based View Theory

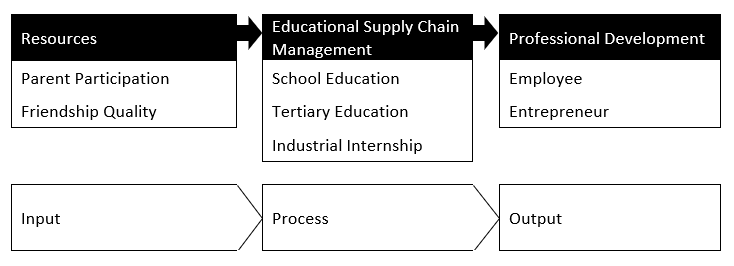

Resource Based View (RBV) theory becomes an important guide for this study. The RBV deals with the coordination and application of relational assets, internal competences, heterogeneous resources, and capabilities (Wernerfelt, 1984, 1995; Grant, 1991; Peteraf, 1993; Barney, 2001; Halldorsson et al., 2007). The construct of these resources helped an institution to gained competitive advantages and further transforms the short run competitive advantage into a sustainable competitive advantage (Wernerfelt, 1984, 1995; Grant, 1991; Peteraf, 1993; Barney, 2001; Halldorsson et al., 2007). The application of RBV theory in educational supply chain management is shown in Figure

In RBV, parent participation and friendship quality are considered as resources and input for educational supply chain. However, the supply of the sources within the educational supply chain management is a process that moving the students from school education to tertiary education to industrial internship. The output is the graduates from the completion of educational supply chain who can be an employee as a job seeker or an entrepreneur as job creator that offer the job opportunity to job seeker.

Research Methods

This study proposed a conceptual framework of educational supply chain through throughout review of the literatures. The framework includes parent participation, friendship quality as main sources of influencing school education. This is continuing by tertiary education and industry internship as factors influencing high quality graduates or professional development. In educational supply chain management, student performance throughout the learning process should be measured from all aspects which include ethics and morality and knowledge and skills. Ethics and morality consists of ethics and spirituality, leadership skills, and national identity; while knowledge and skills consists of language proficiency, thinking skills, and knowledge. The products from the educational supply chain consist of job seeker as an employee and an entrepreneur that create and offer job to other. Hence, this study provides a unique conceptual diagram expected to aid researchers and practitioners to create a more comprehensive understanding on educational supply chain.

Conclusion

This is a preliminary study on educational supply chain management. The main idea of this study is to put in the concept of industrial supply chain management in managing education sector, since it is also one of the service industries. Therefore, this study has proposed a conceptual framework of educational supply chain management in which to transform the benefits that gained from the industrial supply chain management in to educational supply chain. As at today, there is very limited number of study that investigates in this particular field. Therefore, it is very difficult to get reference to form this study. This study can be a reference to future researcher to study further in this area. As a suggestion, future researcher can have an empirical study in this area. As a conclusion, educational supply chain management framework is proposed by the study to strengthen the educational business operation and gain benefits as well as avoid problem in education sector.

References

- Barney, J. (2001). Is the resource based view a useful perspective for strategic management research? Yes. Academy of Management Review, 26(1), 41–56.

- Bernt, F. M., & Bugbee, A. C. (1993). Study practices and attitudes related to academic success in a distance learning programme. Journal of Distance Education, 14(1), 97–112. http://doi.org/doi.org/10.1080/0158791930140108

- Boubekri, N. (2001). Technology enablers for supply chain management. Integrated Manufacturing Systems, 12(6), 394–399.

- Bratić, D. (2011). Achieving a competitive advantage by SCM. IBIMA Business Review Journal, 2011, 1–13. http://doi.org/10.5171/2011.957583

- Chan, F. T. S., & Qi, H. J. (2003). An innovative performance measurement method for supply chain management. Supply Chain Management: An International Journal, 8(3), 209–223. http://doi.org/10.1108/13598540310484618

- Cooper, W. D. (2006). Textile and apparel supply chain management technology adoption. Journal of Textile and Apparel, Technology and Management, 5(2), 1–22.

- Council of Logistics Management. (2010). History of Council of Logistics Management.

- Council of Supply Chain Management Professionals. (2013). CSCMP Supply Chain Management.

- Crinis, V. (2012). Global commodity chains in crisis: The garment industry in Malaysia. Institutions and Economies, 4(3), 61–82.

- Daniel, G. R., Wang, C., & Berthelsen, D. (2016). Early school-based parent involvement, children’s self-regulated learning and academic achievement: An Australian longitudinal study. Early Childhood Research Quarterly, 36, 168–177. http://doi.org/10.1016/j.ecresq.2015.12.016

- Fan, X. (2001). Parental involvement and students’ academic achievement: A meta-analysis. Educational Psychology Review, 13(1), 1–22. http://doi.org/10.1023/A:1009048817385

- Fasanghari, M., Mohammadi, S., Khodaei, M., Abdollahi, A., & Roudsari, F. H. (2007). A conceptual framework for impact of information technology on supply chain management. In 2007 International Conference on Convergence Information Technology (pp. 72–76). IEEE. http://doi.org/10.1109/ICCIT.2007.385

- Flynn, B. B., Hou, B., & Zhao, X. (2010). The impact of supply chain integration on performance: A contigency and configuration approach. Journal of Operations Management, 28(1), 58–71.

- Grant, R. M. (1991). The resource-based theory of competitive advantage: Implications for strategy formulation. California Management Review, 33(33), 114–135.

- Griffith, J. (1996). Relation of parental involvement, empowerment, and school traits to student academic performance. The Journal of Educational Research, 90(1). http://doi.org/doi.org/10.1080/00220671.1996.9944441

- Gunasekaran, A., Lai, K. H., & Cheng, T. C. E. (2008). Responsive supply chain: A competitive strategy in a networked economy. The International Journal of Management Science, 36(4), 549–564. http://doi.org/10.1016/j.omega.2006.12.002

- Habib, M. M., & Jungthirapanich, C. (2008). An integrated framework for research and education supply chain for the universities. In 4th IEEE International Conference on Management of Innovation and Technology (pp. 1027–1032). Ieee. http://doi.org/10.1109/ICMIT.2008.4654509

- Halldorsson, A., Kotzab, H., Mikkola, J. H., & Skjott-Larsen, T. (2007). Complementary theories to supply chain management. Supply Chain Management: An International Journal, 12(4), 284–296. http://doi.org/10.1108/13598540710759808

- Huan, S. H., Sheoran, S. K., & Wang, G. (2004). A review and analysis of supply chain operations reference (SCOR) model. Supply Chain Management: An International Journal, 9(1), 23–29. http://doi.org/10.1108/13598540410517557

- Janvier-James, A. M. (2012). A new introduction to supply chains and supply chain management: Definitions and theories perspective. International Business Research, 5(1), 194–208. http://doi.org/10.5539/ibr.v5n1p194

- Kumar, K. (2001). Technology for supporting supply chain management. Communications of the ACM, 44(6), 58–61.

- Kwinda, T. (2013). Learning material supply chain practices at public schools in Limpopo. University of Johannesburg. Retrieved from https://ujdigispace.uj.ac.za/handle/10210/10502

- Lam, J. K. C., & Postle, R. (2006). Textile and apparel supply chain management in Hong Kong. International Journal of Clothing Science and Technology, 18(4), 265–277. http://doi.org/10.1108/09556220610668491

- Lee, K. L., Udin, Z. M., & Hassan, M. G. (2014a). A review of relational capabilities on supply chain performance in textile and apparel industry. In International Conference on Management & Business Sustainability 2014: 4th International Conference on Technology and Operations Management (pp. 169–178).

- Lee, K. L., Udin, Z. M., & Hassan, M. G. (2014b). Global supply chain capabilities in Malaysian textile and apparel industry. International Journal of Supply Chain Management, 3(2), 31–40. http://doi.org/10.11648/j.ijber.s.2014030601.13

- Li, L. (2007). Supply chain management: Concepts, techniques and practices: Enhancing value through collaboration. Singapore: World Scientific Publishing Co. Pte. Ltd.

- Mentzer, J. T., Keebler, J. S., Nix, N. W., Smith, C. D., & Zacharia, Z. G. (2001). Defining supply chain management. Journal of Business Logistics, 22(2), 1–25.

- MOE, M. of E. M. (2015). Malaysia Education Blueprint 2015-2025 (Higher Education). Ministry of Education Malaysia. Retrieved from https://www.um.edu.my/docs/default-source/about-um_document/media-centre/um-magazine/4-executive-summary-pppm-2015-2025.pdf?sfvrsn=4

- Peteraf, M. A. (1993). The cornerstones of competitive advantage: A resource based view. Strategic Management Journal, 14(3), 179–191.

- Pittman, L. D., & Richmond, A. (2008). University belonging, friendship quality, and psychological adjustment during the transition to college. The Journal of Experimental Education, 76(4), 343–362. http://doi.org/10.3200/JEXE.76.4.343-362

- Rabelo, L., Helal, M., & Lertpattarapong, C. (2004). Analysis of supply chains using system dynamics, neural nets, and eigenvalues. In Proceedings of the 2004 Winter Simulation Conference (Vol. 2, pp. 81–89). IEEE. http://doi.org/10.1109/WSC.2004.1371440

- Sebanc, A. M., Guimond, A. B., & Lutgen, J. (2016). Transactional relationships between Latinos’ friendship quality and academic achievement during the transition to middle school. The Journal of Early Adolescence, 36(1), 108–138. http://doi.org/10.1177/0272431614556347

- Tan, K. C. (2001). A framework of supply chain management literature. European Journal of Purchasing & Supply Management, 7(1), 39–48. http://doi.org/10.1016/S0969-7012(00)00020-4

- Tan, K. C., Kannan, V. R., & Hanfield, R. B. (1998). Supply chain management: Supplier performance. International Journal of Purchasing and Materials Management, 34(2), 2–9.

- Tan, K. C., Lyman, S. B., & Wisner, J. D. (2002). Supply chain management: A strategic perspective. International Journal of Operations & Production Management, 22(6), 614–631. http://doi.org/10.1108/01443570210427659

- Wernerfelt, B. (1984). A resource based view of the firm. Strategic Management Journal, 5(2), 171–180.

- Wernerfelt, B. (1995). The resource based view of the firm: Ten years after. Strategic Management Journal, 16(3), 171–174.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

31 July 2018

Article Doi

eBook ISBN

978-1-80296-043-3

Publisher

Future Academy

Volume

44

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-989

Subjects

Business, innovation, sustainability, environment, green business, environmental issues, industry, industrial studies

Cite this article as:

Loon, L. K., Bakar, Z. A., Hanaysha, J. R., & Deraman, S. (2018). A Review Of Educational Supply Chain Management In Malaysia Tertiary Education. In N. Nadiah Ahmad, N. Raida Abd Rahman, E. Esa, F. Hanim Abdul Rauf, & W. Farhah (Eds.), Interdisciplinary Sustainability Perspectives: Engaging Enviromental, Cultural, Economic and Social Concerns, vol 44. European Proceedings of Social and Behavioural Sciences (pp. 249-260). Future Academy. https://doi.org/10.15405/epsbs.2018.07.02.26