Abstract

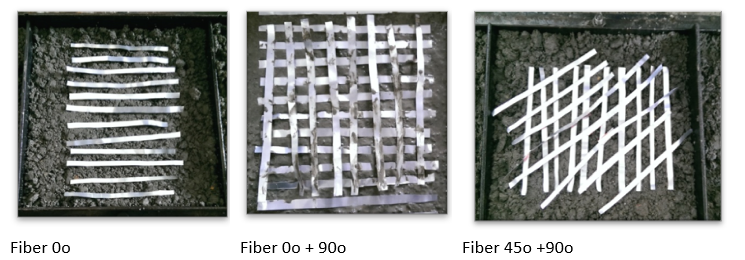

This paper focuses on the improvement of impact resistance of concrete slab by inclusion drink cans fiber. A concrete mixtures with 0.4 water-cement ratio made with waste long cans fibre and silica fume are used to produce the slabs. The long drink cans fibres are produced by cutting drink cans tin into 250 mm long and 10 mm wide. The fibres are arranged with various directions of 0o, 0o + 90o, 0o + 45o in order to find the best fibres arrangement that producing the highest impact strength. The results show that by inclusion of cans fibre improves impact performance of concrete slab. Sample S3 with fibre arrangement of 0o + 90o produced the highest impact energy of 73.575 kN mm and 127.53 kN mm for initials and failure crack, respectively. A fibre direction of 0o + 45o produce the same impact energy with the control sample, it reveal that concrete S4 provide lesser contribution to crack propagation prevention rather than concrete S3.

Keywords:

Introduction

Concrete has been used widely in structural applications to resists all applied loads. Static and dynamic load will produce different effect on concrete structures. Most of researchers have found formulated concrete to resist high static load. However the concrete behaviour will be significantly different when subjected to dynamic loads such as impact loads. The impacts loads are produced by vehicular and ship collisions with structures, missile impact, explosion, wind gust, and earthquake (Lok and Pei, 1996; Nataraja et.al, 1999). Therefore the impact resistance of concrete must be considered when designing special structures like bridge piers, columns at parking area which likely to receive impact loads. The higher concrete strength the lower its ductility, therefore the use high strength concrete is limited (Yan et.al, 1999; Banthia and Sappakittipakorn, 2007; Brand, 2008; Teng et. al, 2008). Inclusion of fibers in concrete will improve ductility of concrete as well as its impact resistance and energy absorption. The fibers will bridge the crack in concrete in order to reduce crack progression as well as increases the energy absorption of the concrete. The use of waste soft drink cans as fiber reinforcement of concrete has shown good improvement on impact resistance, compressive and flexural strength of concrete (Syamsir et.al, 2017; Uroosa et.al, 2015; Tanvir and Mustaq, 2015). However none of them investigate the use of can fibers for impact resistance improvement of concrete. The drop weight test is the simplest method that suggested by ACI Committee 544 (ACI Committee 544, 1996) can be used to determine the impact resistance of concrete slab. In the current research, the impact resistance of waste long cans fiber reinforced concrete slab with silica fume will be experimentally investigated.

Problem Statement

A study in 2008 revealed that in the UK around 42% of aluminium drinks cans are recycled. Although this is a great improvement on the 2% recycled in 1989, there were still a massive 3 billion cans that were landfilled [11]. Recycling and reusing of this cans as a fiber reinforcement is an important part of sustainable lifestyle. Therefore, waste drink cans fibres was chosen as a concrete reinforcement to provide as a solution to the current global problem on waste drink cans.

Fiber has been used widely all over the world to reinforced concrete in order to improve the mechanical properties and the impact resistance of concrete. Researcher has used steel fibers (Nili & Afroughsabet, 2010; Kim et al, 2014) to improve mechanical properties and impact resistance of concrete beam and slab. However this type of fiber is expensive. Therefore the cheaper material like waste materials are proposed to replace or to substitute this steel fiber. Waste materials such as lathe waste, soft drink botle caps, empty waste drink cans, and waste steel powder at dosage of 1% of total weight of concrete as fibers. The fibers inclusion show significant improvement in compressive and flexural strength if concrete (Murali et. al, 2012)

Research Questions

In this research, the effect of long fiber on impact resistance of concrete slab will be investigated. The effectiveness of long drink cans fibers to bridging the initial crack will be observed, and energy absorption of the concrete will be assessed.

Purpose of the Study

The objectives of the research are to study the effect of silica fume and long can fibres on impact resistance as well as energy absorption of fibre reinforced concrete.

Research Methods

Ordinary Portland cement and silica fume were used in this work. The maximum 20 mm coarse aggregate size and fine aggregate with a 3.2 fineness modulus were used in this research. The water absorption and specific gravity of the coarse and fine aggregates were 0.54% and 2.63 and 1.83 % and 2.6, respectively. Waste long cans fiber of 250 mm long and 10 mm wide as shown in Figure

Concrete slab of size 300mm x 300mm with thickness of 40 mm with and without fiber were casted as shown in Figure

Drop weight test jig was fabricated which are consisting of steel ball weighing 1 kg, support and steel rack frame as shown in Figure

The impact energy produced by the drop weight per blow can be calculated as follows:

Impact Energy

where U is the impact energy per blows of steel ball, V is the velocity of the ball at impact, g is acceleration due to gravity, and t is the time required for the steel ball to fall a height of 500 mm. H is the height of fall, m is mass of the steel ball, and W is the weight of the steel ball.

Substituting the relevant values in Eq. (1) yields:

so that value of t = 0.3193 s and v = 9810 x 0.3193 = 3132.33 mm/s

The impact energy per blow, U, of the steel ball can be obtained by substituting the values in Eg. (3)

= 4905 N mm or 4.905 kN mm

Findings

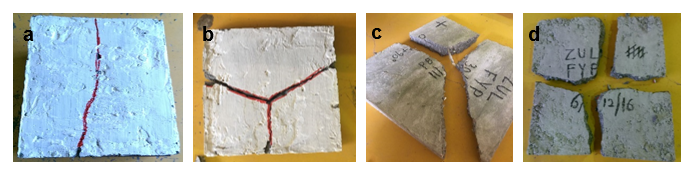

The results of impact test of slab can be observed in Table

From Table

The highest value (N2-N1) or post-peak resistance of 11 is shown for concrete S3. This result reveal that the use of cans fiber with 0o + 90o fiber orientation can increase ductility of the concrete slab.

Impact energy of 44.145 kN mm was produced by control sample. Impact energy is increased for samples with fiber. Concrete S2, S3, and S4 produce impact energy of 98.1kN mm, 127.53 kN mm, and 49.05 kN mm, respectively. The result reveals that by inclusion of fiber to the slab, increases the impact energy up to 2.9 for concrete S3 as compare to concrete S1.

Figure

Conclusion

The number of blows N1 and N2 increased for sample with cans fibers. The concrete with 0o+90o fiber (S3) shows the highest number of blows, while the control sample (S1) without fiber shows the lowest number of blows. Concrete S2, S3, and S4 produce impact energy of 98.1kN mm, 127.53 kN mm, and 49.05 kN mm, respectively. The result reveal that by inclusion of fiber to the concrete slab, increase the impact energy up to 2.9 (for 0o + 90o) as compare to the control sample.The highest value (N2-N1) or post-peak resistance of 11 is shown for concrete S3. This result reveal that the use of cans fiber with 0o + 90o fiber direction can increase the ductility performance of the concrete slab.

Acknowledgments

The authors express their gratitude to Universiti Tenaga Nasional (UNITEN), Malaysia for supporting this research under UNIIG 2016, through Project No: J510050679

References

- ACI Committee 544. (1996). State-of-the-art report on fiber reinforced concrete. ACI Committee 544 report 544.1R-96. Detroit: American Concrete Institute.

- Banthia, N. Sappakittipakorn, M. (2007). Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cement and Concrete Research, 37, 1366-1372.

- Brand, A.M. (2008). Fiber reinforced cement-based (FRC) composites after over 40 years development in building and civil engineering. Composite structures. 86, 3-9.

- Green, (2008). Why recycle aluminium cans, Retrieved from http://myzerowaste.com/articles/food/why-recycle-tins-and-cans/.

- Kim, H.M., Soon, P. Y., U. Johnson, A., Jumaat, M.Z., Chun, H. B. .(2014). Impact resistance of hybrid reinforced oil palm shell concrete, Construction and Building Materials, 499-507.

- Lok, T.S., & Pei, J.S. (1996). Impact resistance and ductility of steel fibre reinforced concrete panels. HKIE Trans, 3(3), 7-16.

- Mahmoud, N., & Afroughsabet, V. (2010). Combine effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. International Journal of Impact Engineering, 37, 879-886.

- Murali, G., C.M. Vivek, C. M., Vardhan, R. P., Khan, Z.M.S.A, Mohamed, T. A. & Suresh, T. (2012). “Experimental Investigation on fibre Reinforced Concrete Using Waste Materials”, International Journal of Engineering Research and Applications (IJERA), 2(2), 278-283

- Nataraja, M.C., Dhang, N., Gupta A.P. (1999). Statistical variations in impact resistance of steel-fiber reinforced concrete subjected to drop weight test. Cem Concr Res, 29, 619-622.

- Syamsir, A., Anggraini, V., Z. C. Muda. (2017). Impact resistance performance of waste short cans fibers reinforced concrete slab. Eco.Env & Cons. 23 (Special Issue), 37-40

- Tanvir, Q., & Mustad, A. (2015). Waste Metal for Improving Concrete Performance and Utilisation As An Alternative Of Reinforcement Bar. Int. Journal of Engineering Research and Applications, 5, 97-107.

- Teng, T.L., Chu, Y.A., Chang, F.A., Shen, B.C., Cheng, D.S. (2008). Development and validation of numerical model of steel fiber reinforced concrete for high-velocity impact. Computational Materials Science 2008; 42, 90-9.

- Uroosa, I., Muhammad, A., & Abdullah, S. (2015). Soft Drink Tins as Fibre Reinforcement in Concrete. Proceedings of AMPE, 14-1, Karachi, Pakistan

- Yan, H, Sun W, Chen H. (1999). The effect of silica fume and steel fiber on the dynamic mechanical performance of high-strength concrete. Journal Cement and Concrete Research; 29: 423–426.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

31 July 2018

Article Doi

eBook ISBN

978-1-80296-043-3

Publisher

Future Academy

Volume

44

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-989

Subjects

Business, innovation, sustainability, environment, green business, environmental issues, industry, industrial studies

Cite this article as:

Syamsir, A., Mohamad, D., Muda, Z. C., Beddu, S., Malik, Z. F. A., & Nadhirah, A. (2018). Impact Resistance Performance Of Waste Long Drink Cans Fibres Reinforced Concrete Slab. In N. Nadiah Ahmad, N. Raida Abd Rahman, E. Esa, F. Hanim Abdul Rauf, & W. Farhah (Eds.), Interdisciplinary Sustainability Perspectives: Engaging Enviromental, Cultural, Economic and Social Concerns, vol 44. European Proceedings of Social and Behavioural Sciences (pp. 977-982). Future Academy. https://doi.org/10.15405/epsbs.2018.07.02.103