Abstract

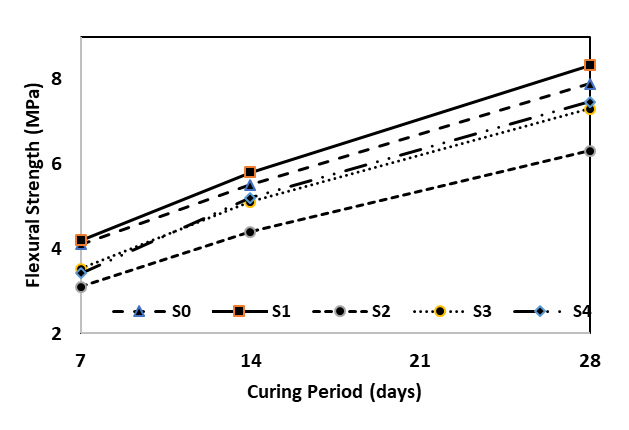

Flexural strength of concrete beam with 0.4 water-cement ratio made with waste long cans fiber and silica fume are investigated. 15 sample of concrete beam has been casted and tested for this research. The long cans fiber of 250 mm long, 10 mm wide and 1 mm thickness with various fiber directions of 0o, 0o + 90o, 0o + 45o are used. The results show that by inclusion of cans fiber produces the flexural strength of 8.3 MPa for sample S1 which is higher 5.5 % compared to control sample S0. A comparison between fiber directions indicated that fiber direction of 0o (S1) produce the highest flexural strength while sample S2 is the lowest flexural strength due to the presence cans fiber with 90o direction cannot increase the strength, even reducing the concrete beam strength.. However Sample S2, S3 and S4 produce lower flexural strength compared to control sample. This might be due to de-bonding effect between two layers of drink cans fiber that result premature failure on the beam.

Keywords: Flexural strengthwaste materialsdrink cans fiberlong fiber

Introduction

Recently there is a need of construction industry to produce high strength and high ductility concrete with low cost. This objective can be achieved by incorporating some of waste material in the concrete. Some of waste materials has been used as fibers reinforcement in concrete structures. Study on the use of plastic fibers as concrete reinforcement has been conducted by researcher (Tulaian et. al, 2016), they found that the recycle plastic (RP) ratio of 1.5% with concrete in the beam had the highest flexural strength. The RP increased flexural toughness and flexural strength by 61 times and 84 % compared to concrete beam without fiber. The use of recycled High-density polyethylene (HDPE) plastic fibres as a reinforcement on the concrete has been investigated by Pesics. They found that the use of 1.25% HDPE fiber in concrete beam has increased tensile strength as well as flexural modulus by 14 % compared to control sample without fiber (Pesics et. al, 2016). The need for applying an economical approach for enhancing concrete’s strength is in demand in the industry today. There have been a lot of studies in using recyclable materials such as plastic, tin and glass as reinforcement for concrete. These materials are very cost effective as they do not need much cost to reproduce these waste materials to become a fibre. A study by Murali and Vardhan about the use of waste materials such as waste steel lathe, waste steel powders, plastic bottle caps and waste tins as an addition to the concrete mixture. Waste tins fiber content of 1% has increase flexural strength of beam by 23.5 % [Murali et. al, 2012). The use of short cans drink fiber for impact resistance improvement of concrete slab has been investigated, where the strength increased 3 times compared to control sample without fibers (Syamsir, et. al, 2017). Uroosa et al. has studied the use of soft drink as fiber reinforcement in concrete cubes. They found that the use of 3% of fibers 1.5” long has increased the compressive strength of concrete by 49 % compared to control sample without fiber (Uroosa et. al, 2015). However none of them investigate on the effect of cans fiber on flexural strength of concrete beams.

Problem Statement

In recent years, as noted, the state of recycling in Malaysia has not been encouraging. In 2008, for example, only 5.5 percent of total wastes were recycled. This compares with recycling rates twice as high, or higher, in neighboring countries such as Singapore (11%), the Philippines (12%), and Thailand (14 %). In Malaysia 64 % of waste content is municipal solid waste where the cans drink is part of them (MHLG, 2006; Periathambi et. al, 2009). Drink cans is considered as waste materials which is normally dumped at landfills, so that it will raise environmental issues. With the rapid increasing of population in the country, the amount of these waste escalates more than 90% in every 10 years (Jalil, 2010). In order to reduce the waste drink cans at landfills, some of research on the use of these materials in concrete have been conducted and it show good improvement on mechanical properties of concrete.

Previous study on the use of steel fiber to reinforce concrete had shown good results for improving flexural strength of concrete. Significant effects of the use steel fiber on mechanical as well as impact properties of concrete beam and slabs have been conducted by previous researchers (Nili & Afroughsabet, 2010; Kim et. al, 2014). The use of steel fibers as concrete reinforcement will be costly, therefore the cheapest alternative i.e. waste materials need to be used to overcome this problem. Therefore in this research the use of drink cans fiber for improving flexural strength of concrete will be conducted.

Research Questions

-

What is the optimum can fiber content in the concrete beam to produce good improvement on flexural strength of concrete beam?

-

What is the effectiveness of cans fibers to bridging the initial crack and increasing flexural strength of beam?

Purpose of the Study

The objectives of the research are to study the effect long waste can fibres on the flexural strength of fibre reinforced concrete beam.

Research Methods

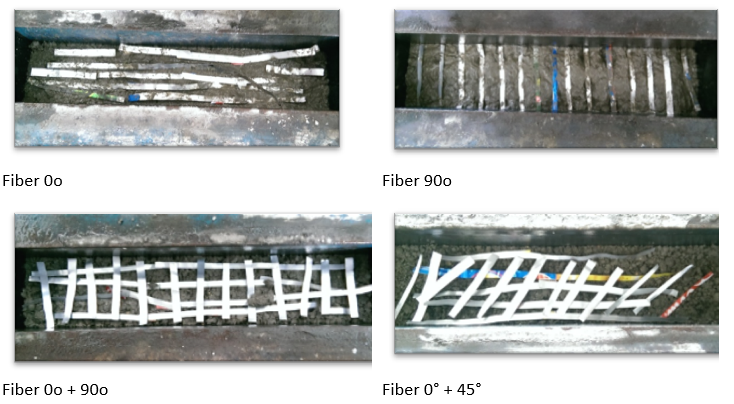

Ordinary portland cement and selected silica fume have been selected to be used in this study. The fine aggregate with water absorption and specific gravity of 1.83 % and 2.6, respectively were used. Coarse aggregates with maximum 20 mm diameter were selected for this research. The long cans fibers were produced by cutting drink cans into size of 250 mm long and10 mm wide. Water-cement and silica fume ratio of 0.4 has been selected based on result that obtained from previous study by Syamsir et al. (Syamsir, A et. al, 2017). In order to ensure that cement, silica fume and fine aggregate can be mixed properly, these three materials were mixed first for one minutes. After that add fibres, coarse aggregate and water and mix again for three minutes to ensure the consistency of mixing. The mix compositions are given in Table

Figure

Findings

The results of flexural test of beam can be observed in Table

where F is the maximum applied load before failure occur, L is the distance of the support which is measured from center to center of the support in this study was taken as 300 mm, b is width of beam is equal to 100 mm, and d is the depth of beam is equal to 100 mm.

From Table

Figure

Conclusion

The inclusion of can fibers has increased flexural strength of concrete beam by 5.5 % if compared to the control beam without cans fiber. Fibers direction 0o for sample S2 has more contribution on flexural strength improvement compared 45o and 90o for sample S3 and S4, respectively. Sample S2, S3 and S4 produce lower flexural strength compared to control sample. This might be due to de-bonding effect between two layers of drink cans fiber that result premature failure on the beam.

Acknowledgments

The authors express their gratitude to Universiti Tenaga Nasional (UNITEN), Malaysia for supporting this research under UNIIG 2016, through Project No: J510050679

References

- Al-Tulaian, B.S., Al-Shannag, M.J. and Al-Hozaimy, A.R. (2016). Recycled plastic waste fibers for reinforcing Portland cement mortar. Construction and Building Materials, 127, 102–110.

- Jalil, A. (2010). Sustainable development in Malaysia: A case study on household management. Journal of sustainable development. 3(3). Pp. 91-102.

- Kim, H. M, Soon, P. Y., Alengaram, U. J., Jumaat, M. Z., Bu, C. H. (2014). Impact resistance of hybrid reinforced oil palm shell concrete, Construction and Building Materials. 499-507.

- Ministry of Housing and Local Government, (2006). The Study of National Waste Minimization in Malaysia, Final Report. In cooperation with Japan International Cooperation Agency (JICA).

- Murali, G., Vivek Vardhan, C.M., Prabu, R., Khan, Z. M.S.A, Mohamed, T. A., and Suresh, T. (2012). Experimental Investigation on fibre Reinforced Concrete Using Waste Materials, International Journal of Engineering Research and Applications (IJERA, 2(2), 278-283.

- Nili, M., & Afroughsabet, V. (2010). Combine effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. International Journal of Impact Engineering, 37, pp. 879-886.

- Periathamby.A and Hamid.S.F & Khidzir.K. (2009). Evolution of solid waste management in malaysia: impacts and implications of the solid waste bill. Journal of Material Cycles Waste Management, 11. 96-103.

- Pešić, N., Živanović, S., Garcia, R. & Papastergiou, P. (2016). Mechanical properties of concrete reinforced with recycled HDPE plastic fibres. Construction and Building Materials, 115, 362–370.

- Syamsir, A., Anggraini, V., & Z Che Muda., (2017). Impact resistance performance of waste short cans fibers reinforced concrete slab. Eco.Env&Cons.23 (Special Issue), 37-40

- Uroosa, I., Muhammad, A., and Abdullah, S. (2015). Soft drink tins as fibre reinforcement in concrete. Proceedings of AMPE, 14-15 2015, Karachi, Pakistan

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

31 July 2018

Article Doi

eBook ISBN

978-1-80296-043-3

Publisher

Future Academy

Volume

44

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-989

Subjects

Business, innovation, sustainability, environment, green business, environmental issues, industry, industrial studies

Cite this article as:

Syamsir, A., Muda, Z. C., Itam, Z., Kamal, N. L. M., Mubin, N., & Zainoodin, M. (2018). Flexural Strength Of Long Waste Cans Fibers Reinforced Concrete Beam. In N. Nadiah Ahmad, N. Raida Abd Rahman, E. Esa, F. Hanim Abdul Rauf, & W. Farhah (Eds.), Interdisciplinary Sustainability Perspectives: Engaging Enviromental, Cultural, Economic and Social Concerns, vol 44. European Proceedings of Social and Behavioural Sciences (pp. 971-976). Future Academy. https://doi.org/10.15405/epsbs.2018.07.02.102