Abstract

With limited energy resources for sustainable and balanced national development it is becoming more and more important to solve tasks of optimization of energy consumption. This optimization is important not only for major Russian companies (which provide major share of tax inflows for the state budget), but also for homes in order toreduce the energy consumption. This article discusses a complex approach in the field monitoring and energy management of apartment buildings as part of the energy management program using an automated thermal and electrical energy management system developed by NGO VEST in Tomsk. It is shown that the power monitoring data allow to make economically effective decisions in reducing energy consumption costs in residential buildings. The creation of the Analytical Center and the use of an automated energy management system give the opportunity to reduce costs of heat consumption in apartment buildings and, as a consequence, increase the efficiency of use of budgetary funds, used for subsidizing the northern regions of Russia.

Keywords: Energy managementenergy consumptionenergy efficiencyenergy costs

Introduction

The problem of reducing energy consumption and more efficient use of available energy resources is the most urgent task for the international community. For the northern regions of Russia, this problem is also associated with the need to optimize the state budget, since the federal budget subsidizes the northern regions of Russia in terms of energy costs, used for heating and lighting of settlements. The state policy in the field of reducing energy consumption is reflected in the Federal Law № 261 "On energy saving and energy efficiency improvements and on Amendments to Certain Legislative Acts of the Russian Federation" dated by November, 23rd, 2009.

The purpose of the study is to establish an integrated approach to the management of power consumption of the northern regions of Russia, which includes organizational aspects of energy management, methodological basis of selection and study of ways to reduce the energy consumption cost of houses, automated control system for the monitoring of energy consumption and for support of decision-making in the field of management of energy consumption costs.

Methodology

Energy management in the industrial enterprise management level has been actively used since the late 1980s - early 1990s, which led to the development of relevant standards, programs and procedures. The main international standard in this area is the ISO 50001 standard: 2011. energy management systems. Requirements with guidance for use. Predecessors of ISO 50001 were national standards, such as ANSI / MSE 2000:2008 (USA), KS A 4000:2007 (South Korea), GB / T 23331:2009 (China), EN 16001:2009 - the pan-European standard for energy management systems. Experience in the application of standards of these countries showed that the energy standards are a viable tool for public policy and market mechanism, which allows to achieve a sustainable energy industry. (ISO 50001:2011) The results of the energy management programs in the US, UK and China unequivocally confirm that the potential for optimization of industrial systems and energy efficiency is not less than 20% (Nikanorov, 2012).

Energy management assumes the creation of a power management system, which operates continuously and significantly optimizes volumes of energy, forecast and control the processes of production, transportation and use of the required amount of energy to ensure economic activity of objects. (ISO 50001:2011)

An energy management system is a set of interacting and interrelated elements (software, hardware, organizational activities), which are aimed at the formation of energy policy, setting goals and development of activities to achieve these goals. The system serves as a basis for operational management decision making aimed at the consumption of the minimum required amount of fuel and energy resources (Lyahomsky, 2014).

Implementation of energy management provides a more detailed picture of the energy consumption, to compare consumption levels of the enterprise with the energy consumption in similar enterprises, to perform a more accurate assessment of energy saving measures and energy saving projects planned for implementation in the enterprise (Lifanov, 2003).

The proportion of power consumption in the manufacturing sector is 30 to 70% depending on the type of product. For apartment buildings share of payment for the consumed heat energy is 40 to 60% of all utility payments. The idea of establishing energy management projects, ie implementation of energy management, not only in industry but also in the consumer sector is an actual scientific and practical task. The article (Sauba Jos van der Burgt et al., 2015) examines the creation and testing of tools to support decision-making in the field of better matching between the power supply and power consumption in private homes. The objective of this study is to establish the need for and feasibility of an efficient apartment buildings energy management and evaluation of the economic effectiveness of measures to reduce energy consumption.

In the world practice, there is a mechanism of implementation of energy management system in an enterprise, which begins with the appointment of energy manager, who is responsible for carrying out this work on the enterprise level. All current activities concerning energy saving are planned by energy manager with mandatory evaluation of the necessary energy costs. He collects the data on production and use of raw materials, calculation of specific indicators for energy consumption per unit of production, on the level of the whole enterprise and for individual power plants and systems. Daily or weekly energy manager can use the calculated data as "indicators" for quick response to the events of a sudden increase in energy consumption. For this purpose, a mathematical model of energy consumption in the enterprise is developed. This model allows to make easy comparisons of the estimated and actual consumption levels. The collected data can be used for development of energy efficiency budget for upcoming years. After the initial audit and development of energy consumption map, main enterprise indicators of energy consumption should be monitored. Based on their analysis priority measures to improve energy efficiency should be planned. Further, after the implementation of priority measures, key indicators (i.e. achieved results) should be monitored and analyzed and new energy-saving measures should be planned to be implemented in the established order (Kharchenko, & Tikhomirov, 2010).

The main task of the energy management is to organize the production process so that the cycle is repeated continuously as described above. In this case, changes in the conditions of the enterprise, the introduction of new technologies, launch of new products, the company will not withdraw from its energy-efficient mode (Mil, 2013).

As a basis for the organization of information support of energy management the method of target energy monitoring (TEM) can be used.

TEM method was developed and is widely used in large industrial plants in Western Europe and the United States. It is a part of the overall management of the enterprise structure. According to the estimates of British Energy Efficiency Agency, the introduction of targeted monitoring of energy reduces the current energy costs by 10-20% without any additional costs for the modernization of technology. The most common implementation of TEM is recommended as a first event in a comprehensive program to improve energy efficiency (Sinitsyn, & Babich, 2009).

This method requires a clear organizational structure responsible for its functioning. The core of such a structure is often an energy management department or energy manager, and peripheral units – energy accounting centers (ISO 50001:2011).

In order to adapt energy management mechanism to energy management in residential buildings, it was proposed to implement TEM through the creation of analytical center that have been used on the test sites in the city of Surgut.

Creating a centralized Analytical Center to monitor and manage energy consumption of apartment buildings in the northern regions of Russia in our opinion is the task of the Federal level. The northern regions of Russia are subsidized by the Federal budget in terms of energy costs, used for heating and lighting of settlements. Energy consumption monitoring and analysis system will make budget funds allocation more targeted and efficient. It should be noted that it is advisable to consider the energy costs not only as current costs of heat and electricity, but to address the problem in a more complex way, i.e. taking into account costs for repairs of buildings in order to reduce heat losses and installation of automated control system.

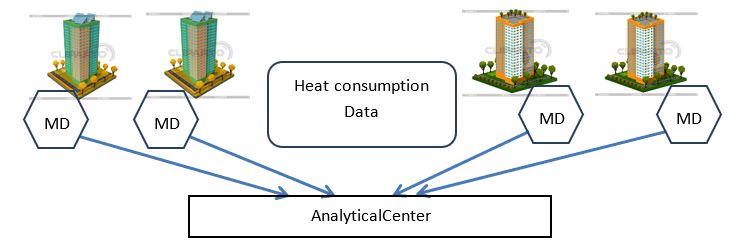

Application of the method of TEM for residential apartment buildings requires energy management system. This system has the following elements: 1) the collection of data on physical parameters from the accounting center using devices and equipment, 2) a method and hardware for transmitting information to the Analytical Center, 3) software for recording, structuring and storing of information, which also allows to analyze and make decisions about changing parameters of the heat transfer agent at the inlet to the heating system at the building and 4) equipment to provide feedback and automatic change of parameters of the heat transfer agent.

Thus, the functions of the Analytical Centre are the collection and analysis of information on energy consumption and decision-making to optimize the power supply to ensure the most efficient use of energy (Fig. 2). Analytical Center, in fact, performs the functions of the energy manager (department of energy management) in a manufacturing enterprise.

Based on the general principles of the TEM (Fortov, 2013) the following main elements of the Analytical Center functioning have been developed:

individual centers of energy accounting are energy consumption systems of apartment buildings (gas, heat, electricity, water);

registration of technical parameters on the input and output of the system of energy consumption is performed using measuring equipment;

registration of the climate parameter to assess the quantity of heat required for heating - the number of degree-days (for heating, ventilation, hot water, air conditioning);

registration of lighting parameter, "lux-days" (for lighting);

registration of population parameter, number of man-hours of the presence of people in the building;

information transmission system for the monitoring and analysis;

software for integrated assessment and decision-making on the regulation of power supply,

feedback system to regulate the flow of heat transfer agent in the heat system.

As a hardware for implementation of TEM method a system of dispatching of engineering systems was suggested. It has an analytical tool that allows automated energy consumption management for the system. The automated control system of thermal and electric energy (ACSTEE) allows for precise and fast control of the heat and electricity consumption, to perform energy analysis of the object, taking into account the individual characteristics of the object and, as a consequence, to introduce a culture of energy consumption, optimizing costs and allowing to obtain the most comfortable living conditions.

The problem of energy efficiency of residential building is solved on the basis of the analysis of the inside temperature, heat transfer agent temperature at the inlet and outlet of the heating system of the house, the outside temperature and other environmental parameters for each object (building). To stabilize the room temperature, an algorithm for forming the input influence on the heat transfer agent consumption taking into account outside temperature has been developed and used.

The main problems that must be solved in the construction of modern ACSTEEs are:

Territorial remoteness of the control and accounting of technological objects and their distance from the information center of the system,

Variety of existing means of communication with the devices,

Diversity of measuring devices, for which different protocols, drivers and interfaces are required (Lifanov 2003).

The first two problems can be solved by justification of used means of communication. To ensure the communication of registration device with the Analytical Center (Fig. 2) and the transmission of information for monitoring and decision-making on most effective choice heat medium supply is a GPRS-connection.

The problem of co-operation of the various devices in ACSTEE was solved with the use of a modular structure of the software, which is based on the principle of IP-addressing.

ACSTEE can display current information about the parameters of heat medium, electricity costs, the state of thermal automation on the analyzed object, and also provides an opportunity of historical analysis of processes (Shilin et al., 2013).

Results and Discussion

The consumption of different types of energy for life support of an apartment building are closely linked. Therefore, an objective analysis of the joint energy efficiency in one house can be provided only by system, with comprehensive data on the consumption of energy resources within specified period of time.

Scientific-production association "Development of energy saving technologies» Tomsk (NGO "VEST") carried out a research on the analysis of the effectiveness of interventions designed to reduce the heat consumption. This activity was carried out in the framework of the "Energy Saving Program" to provide most effective measures for the practical implementation of the Federal Law #261.

One of the related tasks of this project was to increase the awareness and interest of the residents of the need to implement the provisions of the Federal Law of 23.11.2009 # 261-FZ "On energy saving and energy efficiency improvements and on amendments to some legislative acts of the Russian Federation", namely:

on the effectiveness of the installation of metering devices and automated heating control units;

on capital repairs of apartment buildings.

Analysis of the effectiveness of activities was conducted in the city of Surgut on the example of two series of homes in February 2011.

The point of the study was to analyze the cost-effectiveness of implementation of options to reduce energy consumption, namely:

1. Measures to optimize heat systems

2. Measures for the protection of buildings from energy losses.

Measures to optimize the heating systems are implemented using ACSTEE and method of TEM.

In most parts of the city of Surgut a few typical series of houses were built, therefore, by comparing the two houses of one series, it was possible to determine the most effective measures to reduce energy consumption.

Here is the description of organization of the study.

In the course of the study data from two pairs of the same type of apartment buildings in the city of Surgut were analyzed. On one of the pair of houses activities were carried out, and on the other one measuring devices were installed and it served as a benchmark for measuring.

First pair of houses were:

House # 1.1 - apartment building on the street Bakhilova 9a (benchmark).

House # 1.2 - apartment building on the street Bakhilova 4,

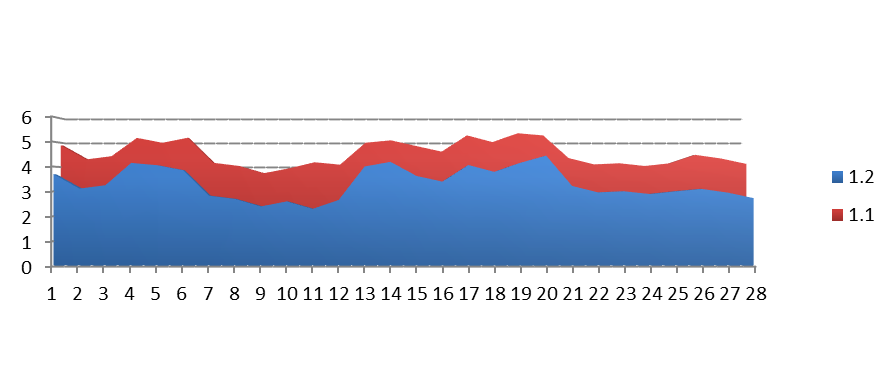

At one of the houses (#1.1) were installed only energy metering devices, on the other (#1.2) were carried out measures to optimize heat systems, namely the installation of automated heat control unit.

Here are the results of measurement of heat homes during February 2011

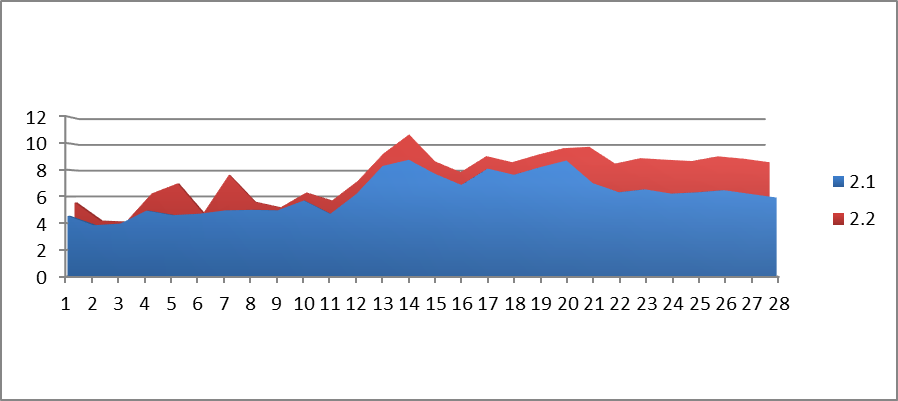

The second pair of houses.

House # 2.1 - apartment building on the street of Energetikov 23

House # 2.2 - apartment building on the street of Energetikov 25 (benchmark)

On one of the other pair of houses (# 2.1) measures to protect against energy loss on walling, roofing and ventilation were fully implemented, plus ventilated front and energy-saving lamps were installed. Bothe apartment buildings had the same condition of heating systems and had automated thermal management components installed.

The graphs clearly show the value of reduction of energy consumption in the buildings with realized activities, but the total effect on the economy is different.

Maximum power consumption for apartment building #1.1. is about 6 Gcalper day and for #1.2. is approximately 4 Gcal (Fig. 4). The difference of heat consumption for both buildings is almost consistent throughout the schedule and is about 2 Gcal or 20-27%.

The maximum power consumption per day at home # 2.2 is approximately 11 Gcal. The house # 2.1 peak consumption is about 9 Gcal (Fig. 4). The graphs of heat consumption are not very uniform, and the difference between the buildings is only 12 - 19%.

Economic efficiency of actions for reduction of heat consumption should be considered, taking into account the costs of the measures themselves. Table

Estimated cost of measures to optimize the operation of the heating system 1 is 1,5mln. rubles, the payback period of is from 1.5 to 4 heating seasons, depending on the thermal load. Estimated cost of measures to protect buildings from energy losses (wall warming, ventilated facades, roofs, etc.) is 10 million rubles, but the payback period is now 25 heating seasons, depending on the area of warming surface and the heat load. In addition there are quite justified opinions that the insulation material, used for ventilated facades, when approaching the break-even point can completely lose its insulating properties.

Thus, the study showed that the reconstruction of utilities in the framework of the Federal Law № 261 is the more effective, because payback period (depending on the type of the building) lies between 1 and 4 years.

Conclusion

This article discusses a complex approach in the field of apartment buildings monitoring and energy management as part of the energy management program using an automated thermal and electrical energy management systems. The information about the validation of this approach through the creation of the Analytical Center and the use of an automated energy management system has shown real opportunity to reduce the cost of heat consumption in apartment buildings and, as a consequence, the possibility of increasing the efficiency of use of budgetary funds, used for subsidizing the northern regions of Russia. This approach can also be used by large Russian companies (which provide a significant share of tax inflows to the state budget), for their stability and balance.

Acknowledgements

This research was financially supported by Russian Foundation for Basic Research (RFBR) in the frame of the project for scientific studies (Mathematical modeling of the formation activities consolidated group of taxpayers to harmonize the interests of the state and taxpayers), project No. 16-36-00184.

References

- Fortov, V.E. (2013). Energy conservation in scientific institutions - research profileAS miles. Energy management to improve product quality. Energy saving, 1, 14-18

- ISO 50001: (2011). Energy management systems.Requirements with guidance for use.

- Kharchenko, V.V., Tikhomirov, A.V. (2010). Energy management as a means to intensify work on energy efficiency at the AIC facilities. Energy saving and energy supply in agriculture, 117-123.

- Lifanov, E.I. (2003). Principles of construction of modern metering. Measurment.RU number 8, 16-19.

- Lyahomsky, A.V.,Perfilieva, E.N., Petukhov, S.V., & Korobkina, G.Z. (2014). Energy management - an innovative way to improve energy efficiency.

- Nikanorov, P.A. (2012). Energy Management Systems. Dairy industry, 10, 22-23.

- Sauba, G., van der Burgt J., Schoofs, A., Spataro, C., Caruso, M., Viola, F. & Miceli, R. (2015). Novel Energy Modelling and Forecasting Tools for Smart Energy Networks. 4th International Conference on Renewable Energy Research and Applications Palenno

- Shilin, A.A., Boukreev, V.G., BED, K.I. (2013). Principles of automated energy-efficient heat consumption control system. Devices and systems. Management, monitoring, diagnostics: scientific-technical and industrial journal number, 8, 1-7

- Sinitsyn, S.A., Babich, V.I., (2009). Organization of the energy management system in the enterprise. Energy security and energy saving, 6, 24-28

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

20 July 2017

Article Doi

eBook ISBN

978-1-80296-025-9

Publisher

Future Academy

Volume

26

Print ISBN (optional)

Edition Number

1st Edition

Pages

1-1055

Subjects

Business, public relations, innovation, competition

Cite this article as:

Zhdanova, A., Rakhimov, T., Bannova, K., Khudyakova, G., & Krivoshein, Y. (2017). Optimization of Energy Consumption in The Residential Sector, Using Automated Control Systems. In K. Anna Yurevna, A. Igor Borisovich, W. Martin de Jong, & M. Nikita Vladimirovich (Eds.), Responsible Research and Innovation, vol 26. European Proceedings of Social and Behavioural Sciences (pp. 611-619). Future Academy. https://doi.org/10.15405/epsbs.2017.07.02.78