Abstract

The issues, related to production of special purpose agents, intended for dust control in pits and on temporary highways, were considered and solved in this work. The agents are developed on the basis of high-aromatic distillate fractions and black oil fuel. In order to achieve qualitative and optimum compositions of finished preventive agents, the physical and chemical properties and hydrocarbon composition of source raw material - gas oils of thermodestructive and thermocatalytic processes and black oil fuel, as well as a depressing ability of the last, were examined in detail in the work. The prepared compositions will allow us to increase a crude oil upgrading index in the oil-processing plant and to increase profit of the enterprise. Along with economic benefit of a manufacturer, an application of preventive agents is also beneficial for a consumer. Application of these products will allow improving the general ecological situation both in pits and on temporary highways.

Keywords: Dust controldepressor effectthermodestructive processesgas oils of delayed cokinggas oils of catalytic cracking

Introduction

According to the energy strategy of Russia by 2020, the issue of increasing of crude oil upgrading indices in oil-processing plants remains relevant. Production of new products in the manufacturer’s product line will allow us to significantly increase the enterprise's profit and will give a competitive advantage in the consumer market.

It is important to note that production of special-purpose agents has positive effect on improvement of an ecological situation. On the one hand, an inclusion of hazardous black oil fuel as a depressant in the mix composition of the finished preventive agent leads to their recovery. On the other hand, an application of preventive agents by a consumer will improve the sanitary and hygiene environment of the mining and transport industry.

Problem statement

An expansion of surface mining operations and increase of productive capacities of the ore-dressing and transport industries predetermine improvement of transportation technologies for unconsolidated overburden rocks, minerals and fine goods. Several billion cubic meters of rocks are processed by surface mining in our country every year. It is the most cost-effective and high-efficiency method.

A share of the open-cast mining method of minerals and ore fields in the overall output is about 70%. However, drilling and blasting in pits and also active transportation of raw materials on temporary highways promotes intensive dust formation in open pits. The main dangerous sources of a technical dust are blasting (34%) and transportation (29%) works of the mining and processing complex.

Dusting leads to reduction in road traffic speed, severe wear of combustion engines and occupational lung diseases of employees of the mining industry (Oleschenko 2001; Soltani 2015; Lee 2010).

Research questions

A lot of dust suppression methods were suggested in our country and abroad. For example, a use of expensive equipment for open drilling, blasting and transportation is proposed in the work (Luo, 2016), the use of which reduces a dust formation. The listed methods are practically not applied in view of their processing complexity and costliness.

With relation to the resource-saving technology, an application of preventive agents will solve the problem of freezing of wet fine goods. Freezing of minerals and soft overburden rocks with high humidity to a metal surface of dump cars, cars and dump trucks, as well as their ad freezing in a load weight, are observed during their transportation by rail and road transport in autumn and winter. This leads to significant losses of transported materials. Application of preventive agents (PA) is the most effective among many methods of prevention and protection from freezing and dust formation. The PA forms a strong hydrocarbon film on surfaces of metal cars, dump cars and dump trucks, and also on pieces of bulk material. The hydrocarbon film allows 5-7 time reduction of strength of freezing of rocks to surfaces of transport equipment and promotes effective dust suppression, by preventing the separation of dust particles.

Purpose of the study

For successful introduction of the preventive agent at the place of production, in addition to high rates of wetting, adhesive characteristics, determined, first of all, by a viscosity, low-temperature and fire-prevention characteristics, it should be rather "pure" and should be developed on the basis of an available raw materials base. However, the raw materials for production of the PA are limited due to dipping of oil refining and their aiming at increase in production of motor fuels and commercial light oil products. Production of current lubricants and fixants is also complicated by the fact that components of these products are produced with the use of different installations of oil-processing plants (OPP) that requires additional capital and operating costs (Khosrosereshki, 2014; Entin 1998). That is why, the purpose of this study is a development of new compositions of current lubricants and fixants from by-products of oil refining and petrochemistry. For rational and complex use of heavy oil products and oil residues, the technology of PA production on the basis of thermal cracking and delayed coking products is considered in this research. Heavy gas oils and heavy cracking residue, which are released as a fuel oil, will allow us to significantly increase net profit of the plant and to achieve the required physical and chemical properties of the finished composition.

Research methods

Physical and chemical researches were conducted with use of modern equipment and in strict accordance with the state standards. Viscosity determination was carried out with use of the HVM 472 automatic capillary viscometer on the basis of the HLIS32 software. The flash-point test for samples was conducted in an open crucible in accordance with GOST 4333-2014 with use of the HFP 386 flash-point analyzer and HFP 380 flash-point analyzer with a closed crucible in accordance with GOST 6356-75.Freezing point measurement was conducted in accordance with GOST 20287-91. Determination of a mass fraction of sulfur in oil products was carried out with the use of the Spectroscan S X-ray fluorescent analyzer. Hydrocarbon composition was analyzed using the Agilent 5973 gas chromatograph/mass spectrometer with the DB-Petro non-polar column 100 m long.

Findings

The PA's composition was developed based on the need to provide the required viscosity, low-temperature and fire-fighting properties of the PA.

The PA's freezing point for protection against freezing of wet fine materials should not exceed minus 35°C in accordance with the current technical regulations (TR 381 055). The PA's freezing point for dust suppression is up to minus 15°C. The flashpoint (FT) is also strictly regulated by TR and sanitary standards: for PAs, preventing freezing, isn't less than 75°C, and for dust suppressants - not less than 150°C. Such characteristics as viscosity, content of mechanical impurities and content of water, are also strictly regulated by TR for PAs. The indicator of relative viscosity at 50 °C for the PA, preventing freezing, is within 1,0 - 1,5° E, and for dust suppression compositions - 15 – 25 ° E. Viscosity is an important indicator, having an impact on consumption of the agent, its quality of application and speed of spraying of a preventive composition. Mechanical impurities affect the service life of nozzles, used for applying of PAs, so the smaller their quantity, the higher a quality of the finished PA. This value ranges from 0.2 to 0.35% wt. for both products. The water content promotes liquid compound stratification, mix deterioration, composition freezing, so the presence of water traces is possible according to TR. Dust suppression agents may be composed of up to 0.5% water.

Light and heavy gas oils of catalytic cracking (CCLGO and CCHGO) and delayed coking (DCLGO and DCHGO), and also a cracked residue of the viscosity breaking (VB) process wereanalyzed. Results of the physico-chemical studies are given in Table

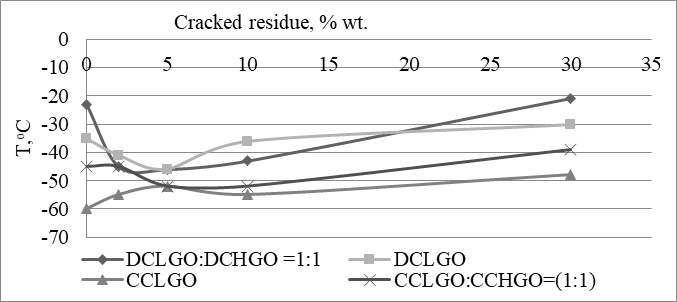

The VB's action, as a depressing additive, was tested on PA samples on the basis of light and heavy gas oils of the delayed coking and catalytic cracking. Freezing point change dependences for gas oil mixes on VB's content are presented in Figure

At decrease in the system temperature, resinous-asphaltenic compounds of the VB, which is characterized by their high content (% wt.: asfalten – 4,8 and resins - up to 12,1; 0,87% wt. of sulfur), are adsorbed on a surface of growing crystals of normal paraffin hydrocarbons, which are present in a solvent, resulting in shift of the freezing point towards lower values.

Application of different additives as depressants is considered in many works. Application of silicate additives to reduce a freezing point is described in the article (Zhang, 2010). The effect of depressant additives on diesel fuels is examined in the work (Smirnova, 2003). Inorganic additives are studied in the work (Figueroa-villar, 2011).

However, all works confirm dependence of low-temperature characteristics both from hydrocarbon composition of gas oil, used as a solvent, and from a depressor. Influence of the hydrocarbon composition of gas oil fractions on quality of the produced product is showed in detail in the works (Gorelova 2015; Ronze et al., 2002). For determining of qualitative and quantitative compositions of gas oil fractions, used as solvents in mixes of finished PAs, their hydrocarbon compositions (Table

Results of an interpretation of CCLGO and CCHGO chromatographs, given in Table

Comparison of the hydrocarbon composition of gas oil fractions (Table

The economic analysis was made for confirmation of practicability of the PA's introduction for protection against freezing of transported freights. It showed that the payback period for a consumer's invested funds is 4 years. Reduction of a value of operating costs will allow the enterprise-consumer to increase freight turn-over volumes, and also to increase the specific heat of thermal coals for 1.5% -2%. Application of the PA for dust removal on highways in opencast coal mines will allow not only to reduce dust content of air, but also to gain economic benefit - 1, 8 million rubles respectively with the annual production volume of 10 thousand tons. The manufacturer is Universin who gains 650 million rubles for Niogrin, with respect to the selling price of fuel oil with the annual PA's production volume of 10 thousand tons.

Conclusions

It is fair to say that the proposed scientific developments will be useful for the enterprise, because they will allow increasing efficiency of transportation of wet fine freights and starting production of a new, demanded product type without significant changes in the existing flowsheet of the plant. Production of new products will allow using oil residues and heavy distillates more efficiently. And a viscosity breaking installation, which stands idle during the spring and autumn period (because of insufficient demand for fuel oil), will be used for production of a cracking residue for the new type of products. The proposed compounds have a simple composition, simple way of preparation and available components, which fit to the existing OPP's regimes and balances of technological processes. The release of such products will be demanded, in particular, in the Siberian Federal District due to severe climatic conditions of the region, concentration of a large number of open-type deposits and availability of railway communication with them.

References

- Entin, V.I., Entin V.I., Anzheurov N.M., & Kraaovitskii YU.V.,(1998).Aerodynamic methods for increasing the efficiency of dust catchers in the production of refractories. Refractories and Industrial Ceramics, 375-378.

- Figueroa-villar, J.D.,Figueroa-villar J.D., Vieira A.A., Gomes N.M., Matheus M.E., & Fernandes P.D., (2011). Synthesis and in vivo evaluation of 5-chloro-5-benzobarbiturates as new central nervous system depressants.In the Journal of the Brazilian Chemical Society.364-371.

- Gorelova, O.M.,Gorelova, O.M., & Komarova, L.F.,(2015). Fractional distillation of pyrolysis of straight-run gasolines for production of feedstock for synthesis of petropolymeric resins. Chemistry and Technology of Fuels and Oils, 14-18.

- Khosrosereshki, L., Khosrosereshki L., Irannejad P., & Aliakbari-Bidokhti A.A.,(2014). A comparison of dust emission schemes in estimation of vertical dust flux in dust source regions of iran, ISSN: 0378-1046, 201-216.

- Lee, B.K., Lee B.K., & Dong T.T.T., (2010). Effects of road characteristics on distribution and toxicity of polycyclic aromatic hydrocarbons in urban road dust of ulsan, Elsevier Science Publishing Company, Inc., 540-550.

- Luo, Y.,Y.A, Peng, J.A , Li, L.A, He, J.A, Gan, X.A, Yin, K.A, & Zhao, Z.B.(2016). Development of a specially designed drill bit for down-the-hole air hammer to reduce dust production in the drilling process. In the Journal of Cleaner Production. Elsevier Limited, Inc. Luo, 1040-1048.

- Oleschenko, A.M., Oleshchenko A.M., Surzhikov V.D., Bol'shakov V.V., Panaiotti E.A., (2001). Hygienic evaluation of health risk in open cast coal miners, 26-29.

- Ronze, D.,Ronze D., Fongarland P., Pitault I., & Forissier M., (2002). Hydrogen solubility in straight run gasoil. In the Chemical Engineering science.547-553.

- Smirnova L.A.,Smirnova L.A., Bashkatova S.T., Vinokurov V.A., Shapkina L.N., & Bezgina A.M. (2003). Effect of pour depressants on the optical and low-temperature properties of diesel fuels.In the Chemistry and technology of fuels and Oils. 64-66.

- Soltani, N., Soltani N., Keshavarzi B., Moore F., Tavakol T., Lahijanzadeh A.R., Jaafarzadeh N., & Kermani M. (2015). Ecological and human health hazards of heavy metals and polycyclic aromatic hydrocarbons (pahs) in road dust of Isfahan metropolis. In the science of the total environment. Elsevier Science Publishing Company, Inc., 712-723.

- Zhang G.F., Zhang G.F., Ma J.E., Zhu Y.G., Feng G.M., & Wang W.Q., (2010). Depressant effect on titanaugite by silicon-containing depressants.In the Zhonggue Youse Jinshu Xuehui. 2419-2424.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

20 July 2017

Article Doi

eBook ISBN

978-1-80296-025-9

Publisher

Future Academy

Volume

26

Print ISBN (optional)

Edition Number

1st Edition

Pages

1-1055

Subjects

Business, public relations, innovation, competition

Cite this article as:

Kondrasheva, N. K., Zyryanova, O. V., & Kireeva, E. V. (2017). Special Purpose Products for Mining Industry Enterprises. In K. Anna Yurevna, A. Igor Borisovich, W. Martin de Jong, & M. Nikita Vladimirovich (Eds.), Responsible Research and Innovation, vol 26. European Proceedings of Social and Behavioural Sciences (pp. 451-456). Future Academy. https://doi.org/10.15405/epsbs.2017.07.02.58