Abstract

High value assets were used extensively in many big organization especially in the military. Most of the assets are used more than its useful and economical life. Therefore the purpose of this paper is to discuss on initiatives that can be used in maintaining and prolong the life of aging assets in Royal Malaysian Navy (RMN). The asset life cycle stages were discussed and allows research of this area. A review of literature and experiences within the Royal Malaysian Navy was used to propose a new way in order to maintain the assets for longer period without replacement. It is proven that by applying these initiatives it has increased the performance of the aging assets and able be used extensively. Exploring the initiatives on how to remain the operational activities for the RMN ships, the best way is to manage the aging assets as suggested. These initiatives are suggested to be the guidelines in other sectors especially for logistics and transports industry in future.

Keywords: AgingAsset Life Cycle; Asset Maintenance; Life Extension; Obsolescence

Introduction

The important of assets was recorded since year 1760 during the industrial revolution era. In this period, it was the time of transition from hand production to machine manufacturing. The machine manufacturing was the starting point for managing assets owned by the organization. The assets were managed thoroughly in order to produce effective products efficiently in manufacturing industry. In this period, the history of steam power engine used on-board steam engine ships and steam engine train.

Following the industrial revolution, the manufacturing world has changed and people were focussing on machines and assets management in maximising production. Assets also known as tangible assets in accounting used in organization to perform its task in achieving the mission and vision. There are five (5) classes of assets namely real estates and facilities, plant and production, mobile assets, infrastructure and information technology (Campbell, Jardine, & Mcglynn, 2011). In order for the asset to function as required, it needs to be managed holistically. Since every asset has its life span, the role of organization is essential to fully optimise on its usage so that the owned asset is value for money and it gives return of investment.

Literature Review

Australia Department of Treasury and Finance has determine optimal asset management (Australia Department of Treasury and Finance, 2010) can be achieved through:

Identify the asset performance which will facilitate on its service delivery.

Considering the asset life cycle prior investing new assets.

Managing asset thoroughly.

Continuous improvement in managing assets.

In managing assets involve a lengthy processes where it begins with the intention of procurement and ended with disposal (Spires, 1996). There are four (4) levels of assets life cycle (Ouertani, Parlikad, & McFarlane, 2008) as in Table

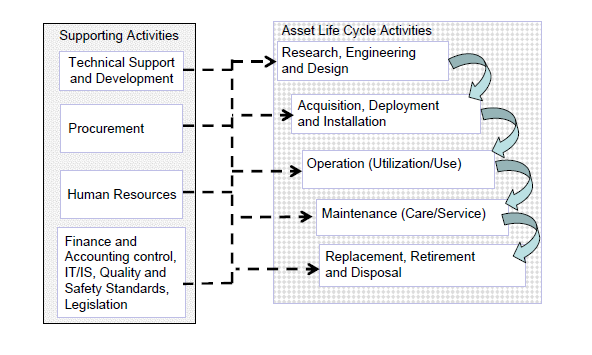

Assets life cycle stages, involve other elements in supporting the whole processes which had been introduced in the Asset Related Models (El-Akruti & Dwight, 2013). These elements are varies, multi discipline and interrelated in every stage of asset life cycle. There are strong relations between supporting activities and asset life cycle that can be illustrated in Figure

In real life situation, the Operations Stage is the longest stage of overall asset life cycle and involves high costs (Ford, McMahon, & Rowley, 2015). During the Operations Stage, organization has to maintain the assets at the highest standard of readiness which the cost of maintenance can reach up to 70% of the total costs of the ships’ procurement. Given this scenario, it is important that the organization should manage their asset thoroughly, especially organization that owned aging assets.

As discussed earlier, asset life cycle involve four (4) stages which many organization has to go through this standard processes. However this paper will focusing on the third stage of assets life cycle. The Operation is the challenging stage for organization that used the assets for a long period of time (David & Burn, 2008).

Asset that gone through the tests, commissioned and acceptance processes in the deployment stage will be fully operational. During this stage, the asset will be used to maximum level in order to achieve the output as required by the organization. It is most challenging tasks to remain the asset to be available for operation without any failures on the parts and components (Sherwin, 2006).

Therefore systematic and consistent asset maintenance are required for the organization in order to prolong the asset lifespan. Maintenance can be defined as to upkeep the asset to operation by repairing and replacement of the components of the asset (Stephens, 2010). Moreover, maintenance is the key to asset reliability. There are two (2) types of maintenance, planned and unplanned maintenance.

Planned Maintenance

Planned maintenance consists of preventive or known also as scheduled maintenance. This type of maintenance performed periodically according to Original Equipment Manufacturer (OEM) recommendations based on running hours or calendar period to avoid asset failure or low performance. It is the initiatives of the organization to schedule its maintenance to avoid interruption while operating the assets.

Unplanned Maintenance

Unplanned maintenance is also known as corrective maintenance is performed on the parts and components that breakdown which is the unforeseen and happen unpredicted by the organization. Therefore the action taken for corrective maintenance were based on the defect and caused of the asset breakdown.

Many big organizations that uses high value asset will maintain their asset completely. Since good maintenance will prolong the life cycle of the assets. Mostly organization such as military used their assets for decades (Glas, Hofmann, & Eßig, 2013). There are many reason that hinder the process of replacement of asset such as holding high stocks of spares (Blöndal, 2003) and limitation of budget (Md.Som, Keling, Ajis, Shuib, & Othman, 2011). Therefore the military will continue using their asset even though the assets are aging and faced with obsolescence problems.

Methodology

This paper presents on empirical experience in managing and maintaining the Royal Malaysia Navy ships. Based on selection on criteria and focuses on maintenance activities, a single case methodology is used to support the study (Yin, 2013). Case study is a methodology of analysing a phenomena, that bound by pace and time (Creswell, 2003). The data were collected through interviews. An informal and semi-structured types of interview was conducted from 21 research participants that involves directly in asset management. This approach is flexible where questions are predetermined however it allows the researcher to raise new questions which she think is applicable during the interview session (Yin, 2013). This types of interview also allows the research participant to express their experience and views without any disruption and pressure. Document review also used as the data collection method subsequently with literature review on previous study which supported the key findings of the research.

Discussion and Findings

In line with maintenance activities there are also broader perspective in maintaining aging assets. Dealing with aging asset, maintenance activities involved several activities especially scheduled maintenance. The assets has been in-service in a very long period and sometimes the asset were used over its estimated useful life which therefore the probability for failure will become higher.

Military is mostly maintained an expensive aging assets along their services (Council & Research & Committee on Benchmarking the Technology and Application of Lightweighting ; National Research Council, 2012). The decision replacing the breakdown assets are almost impossible since to procure the new assets are very costly. Therefore they will continue using the asset even it has reached the end of life cycle and recorded zero value (Blöndal, 2003).

The definition of the aging assets is first to be established prior venturing the asset maintenance processes. Aging can be defined as grow older or causes to become older (Oxford English Dictionary, 2013). Although there are no exact definition on aging asset especially in term of maintenance, this paper defined as asset that has been used overtime and having higher probability to breakdown. Asset aging are caused by:

Aging caused by time. This type of aging were based of running hours or operating hours. Replacement are acquire when it reaches certain time period or when it breakdown, whichever comes first (Wijaya, 2012).

Aging caused by performance. When the asset is deteriorating it becomes aging which will give impact on the asset performance (Pham & Wang, 1996) and subsequently the downtime of the asset will be very high (Block, Ahmadi, Tyrberg, & Söderholm, 2014)(Grover & Christine, 2015).

Aging caused by over usage. This cause of aging were usually the effects of over usage. Most of OEM will estimate the useful life of the asset, however organization that used high cost assets will used over its recommended period that implies cause of aging.

The Royal Malaysian Navy (RMN) has maintained their ships systematically that not only focuses on planned and unplanned maintenance, nonetheless many initiatives have been introduced with the aim of extending the life of the assets. Some of the initiatives are:

Operational Reserve Equipment. RMN has used the strategies of having additional spare that are used as floating or pool equipment. This operational reserve equipment are very crucial in replacing the parts or component which breakdown during operation.

Obsolescence Management. Since the RMN maintaining aging asset which most of the asset has reached more than 20 years old, the problem of getting spares in the market become crucial. Therefore the RMN has identified the parts and component that are essential to be replaced immediately. This obsolescence management takes a maximum of three years to complete for a squadron of ships.

Ship Life Extension Programme (SLEP). This initiatives were used to modernize, refurbish and extend the life of the assets. During the SLEP process, the parts and component that usually classified as wear and tear were replaced. It also involved the main component. It does not involved in modification the structure of the ships.

All these initiatives were subject to decision made by the Capabilities Management Board and the Modernization Equipment Board. The board will be having the quarterly meeting every year to discuss and monitor the performance of the RMN assets.

Conclusion

The RMN have moving forward in maintaining their aging assets. The RMN asset were still in-service even though most of the assets has reached 20 years of usage. The initiatives taken are the interim approach in order to have the budget of replacement in obtaining the new assets. Although defence sector is highly important for the country in protecting its sovereignty, however the limitation of budget has discontinue for future acquiring the new RMN assets (Md.Som et al., 2011).

As conclusion, in case of assets breakdown or even aging, there are solutions rather than disposal or in other hand sought for replacement with the new assets. There are other initiatives for organization that deals with expensive assets rather than replacement since investment on assets are not the only decisions. Hence, exploring the initiatives on how to remain the RMN ships operational, the best way is to manage aging assets as suggested. This paper is not only crucial for the defence sectors but also to other organization that involved in managing and maintaining transportation and logistics sectors.

References

- Australia Department of Treasury and Finance. (2010). Sustaining Our Assets: Government Asset Management Policy Statement. Melbourne: Department of Treasury and Finance.

- Block, J., Ahmadi, A., Tyrberg, T., & Söderholm, P. (2014). Part-Out Based Spared Provisioning Management: A Military Aviation Maintenance Case Study. Journal of Quality in Maintenance Engineering, 20(1), 67–95.

- Blöndal, J. R. (2003). Accrual Accounting and Budgeting : Key Issues and Recent Developments. OECD Journal on Budgeting, 3(1), 1987–1996.

- Campbell, J. D., Jardine, A. K. S., & Mcglynn, J. (2011). Asset Management Excellence: Optimizing Equipment Life-Cycle Decisions (Second). United States America: Taylor and Francis Group.

- Council, R. & C. on B. the T. and A. of L. ; N. R., & Research & Committee on Benchmarking the Technology and Application of Lightweighting ; National Research Council, 2012. (2012). Application of Lightweighting Technology to Military Vehicles , Vessels , and Aircraft Committee on Benchmarking the Technology and Application of Lightweighting ; National Research Council. Washington: National Academies Press.

- Creswell, J. W. (2003). Research Design Quantitative, Qualitative and Mixed Methods Approaches (Second Edi). University of Nebraska, Lincoln: Sage Publication.

- David, R. M., & Burn, S. (2008). Effective use of condition assessment within asset management. American Water Works Association, 100(1), 54 – 63.

- El-Akruti, K., & Dwight, R. (2013). A framework for the engineering asset management system. Journal of Quality in Maintenance Engineering, 19(4), 398–412.

- Ford, G., McMahon, C., & Rowley, C. (2015). An Examination of Significant Issues in Naval Maintenance. Procedia CIRP, 38, 197–203.

- Glas, A., Hofmann, E., & Eßig, M. (2013). Performance-based logistics: a portfolio for contracting military supply. International Journal of Physical Distribution & Logistics Management, 43(2), 97–115.

- Grover, R., & Christine, G. (2015). Article information : Journal of Property Investment & Finance, 33(3), 299 – 314.

- Md.Som, H., Keling, M. F., Ajis, M. N., Shuib, M. S., & Othman, M. F. (2011). The Malaysian Government’s Efforts In Managing Military And Defence Development. International Journal of Business and Social Science, 2(12), 180–194.

- Ouertani, M. Z., Parlikad, A. K., & McFarlane, D. (2008). Asset information management: research challenges. In 2008 Second International Conference on Research Challenges in Information Science (pp. 361–370).

- Oxford English Dictionary. (2013). Oxford English Dictionary Online. Retrieved from http://dictionary.oed.com

- Pham, H., & Wang, H. (1996). Imperfect maintenance. European Journal of Operational Research, 94(3), 425–438.

- Sherwin, D. (2006). Journal of Quality in Maintenance Engineering Article information :

- Spires, C. (1996). Asset and maintenance management – becoming a boardroom issue. Managing Service Quality: An International Journal, 6(3), 13 – 15.

- Stephens, M. P. (2010). Productivity and Reliability-Based Maintenance Management. Indiana: Purdue University Press.

- Wijaya, A. R. (2012). Robust-optimum multi-attribute age-based replacement policy. Journal of Quality in Maintenance Engineering, 18(3), 325–343.

- Yin, R. K. (2013). Case Study Research Design and Methods (Third). United States America: Sage Publication.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

22 August 2016

Article Doi

eBook ISBN

978-1-80296-013-6

Publisher

Future Academy

Volume

14

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-883

Subjects

Sociology, work, labour, organizational theory, organizational behaviour, social impact, environmental issues

Cite this article as:

Mohd, H., & Mustakim, M. (2016). Initiatives to Prolong the Life Cycles of Aging Assets in the Royal Malaysian Navy. In B. Mohamad (Ed.), Challenge of Ensuring Research Rigor in Soft Sciences, vol 14. European Proceedings of Social and Behavioural Sciences (pp. 198-203). Future Academy. https://doi.org/10.15405/epsbs.2016.08.29