Abstract

Concrete use in construction sector getting demand due to its availability, cheap rate handling malleability, flexibility and the process of development country. As the concrete is widely used in the construction practice, the time for the construction to competition was also a crucial argument. Thus, with the addition of calcium nitrate (Hardening Accelerator), this study attempts to explore the effect of silica fumes on early concrete stage. This research assessed multiple tests which are slump test, compressive strength test, flexural strength test and ultrasonic pulse velocity. The concrete mix proportioning of silica fumes in the percentage of 0%, 5%, 10%, and 15% of replacement with cement. Each specimen was being cured in water and tested according to its testing age (3 hours, 6 hours, 1 days, 7 days and 14 days). The synergistic interaction between silica fumes and calcium nitrate (Hardening Accelerator) was analysed to be used in the concrete. Thus, with the enhanced silica fumes content, the compressive strength and the flexural strength of the concrete was improved.

Keywords: Concrete, alternative supplementary cementitious materials, compressive strength, flexural strength, silica fume, calcium nitrate

Introduction

Concrete is commonly used in construction owing to high availability, low rate, high handling flexibility and high maneuverability. The design of a concrete structure requires the strength of the concrete compression to be contemplated. The highest concrete design quality is shown on 28th-day strength (Hamid-zadeh, Jamali, Nariman-Zadeh, & Akbarzadeh Kasani, 2006). Within the case of construction work, 28th-day is considered time devouring for the test comes about concrete quality, whereas moderates down the quality control process of concrete mixing, placing, proper curing etc. Concrete mix design is a method that takes advantage of code recommendations and sometimes experience. If experimental errors occurred in the mix design causing the concrete fail to attain the desired strength, it is necessary to repeat the entire process, which can consume time and cost. It is essential to wait at least 28 days for each failure. A fast and reliable concrete prediction of strength would therefore be of great significance (Kheder, Gabban, & Abid, 2003).

On top of that, strength is the design property of the concrete. In some cases, characteristics analysis such as durability, impermeability, volume stability may be essential to design concrete structure, but the most important is strength analysis. The concrete strength reflects a general image of concrete quality. The method of growing strength is called 'hardening'. This is often confused with 'setting' while setting and hardening are not the same. Setting is the stiffening of the concrete from its fluid state after it has been placed. Harding is, however, the activity of strength development and may persist for weeks or months after concrete mixing and placement. The speed of concrete setting is irrespective of its hardness. Many of the variables regulate compressive strength include mixing of the concrete, mixing and curing the addition of mixtures, waste cement ratio, quality of aggregate and type of cement. The most important factor affecting concrete strength characteristic is the water cement (W/C) ratio. For adequate chemical reaction in the concrete, a minimum quantity of water is needed, and additional water improves workability and decreases strength.

However, the factor which will be investigated in this study is the addition of admixtures. According to Khan, Nuruddin, Ayub, and Shafiq, (2014), admixture is a chemical compound added to concrete to enhance concrete quality. Apart from that, it can change the concrete properties like increasing workability, reduction of water content, accelerating setting time and enhancing resistance to weather and chemical (Jamal, 2017). Any material other than cement, water and aggregates added as concrete or mortar ingredients is regarded as an admixture. Generally, there are two main types of admixtures; chemical and mineral admixtures. Examples of chemical admixtures are plasticizers, super plasticizers, accelerator, and set retarder whereas mineral admixtures are cementitious, pozzolanic, blast furnace slag, fly ash, silica fume, and rice husk. The addition of two concrete admixtures (accelerator and silica fumes) are studied in this research whether they can work together to enhance strength of concrete.

Jamal (2017) mentioned that accelerator can shorten the setting time in concrete and increase the hardness rate and growth of strength. Various substances can be used as accelerators which are alkali hydroxides, silicates, fluorosilicates, organic compounds, calcium-based like calcium nitrate and calcium thiosulphate, aluminium chloride, and potassium carbonate. The most commonly used is calcium chloride due to its availability, cheap and predictable performances (Heikal, 2004). Calcium chloride has been shown to accelerate the setting and hardening of OPC, but when used in bigger quantities it encourages corrosion of the steel reinforcement. In comparison, mineral admixture such as silica fume is a by-product of the silicon and ferrosilicon industries, which improves the concrete strength by three major mechanisms; pore-size refinement and densification of the matrix, paste-aggregate cement interface refinement, and reaction with free lime (Khan & Siddique, 2011).

This research compares the strength of concretes with distinct percentages of silica fumes. A fixed amount of calcium nitrate (Hardening Accelerator) is used as an additional ingredient of the concrete to be produced.

Problem Statement

It is not simple to achieve high quality and lasting concrete. To produce concrete that can fulfil the demands of strength and durability, the choice of appropriate materials and mixture ratios is required. Adding polymer admixtures was considered to enhance plastic performance and hardness. However, few are established about synergistic activity between two or more admixtures in improving concrete strength. In specific, the effect on concrete strength is not studied when district percentages of silica fumes and a set quantity of calcium nitrate are used as concrete materials. Besides, the optimized content of each admixture is needed individually and in combination to produce high-quality concrete. Accelerated construction plans with financial benefits have contributed to disastrous building errors owing to an insufficient early-stage understanding of concrete performance. Therefore, important knowledge of premature concrete behaviour is crucial to guarantee building safety and appropriate durability and long-term characteristics.

Research Questions

The deficiencies in the current literature led to further research on the efficient use of silica fume with the inclusion of calcium nitrate as any other building material. In view of the above situation, the previous research question arises:

- What is the contribution of silica fume incorporate calcium nitrate to the improvement of early-stage strength and durability of the concrete?

Purpose of the Study

The aim of this research is to compare the strength of concretes containing different percentages of silica fume. A fixed amount of calcium nitrate (Hardening Accelerator) is also used as an additional ingredient. The specific objectives for the research are:

- To analyse the effect of different silica fumes percentages on the strength of concrete.

- To find out whether there is synergistic interaction between silica fumes and calcium nitrate (Hardening Accelerator) in enhancing the strength of concrete.

- To find out the optimum percentage of addictive (silica fumes) when used in combination with fixed amount of calcium nitrate (Hardening Accelerator).

Research Methods

Materials

Concrete is made by mixing several economically accessible components such as cement, aggregates and water. Typical commercial Ordinary Portland Cement (OPC) was used which exceed the quality requirement specified in the Malaysian Standard MS 522: Part 1: 1989 and commercial silica fume (SF) was employed as a reference pozzolanic material.

Testing Methods

Slump Test

To evaluate the uniformity or workability of fresh concrete, slump test was carried out as per procedures mention in ASTM C143. The slump test is the simplest workability test for concrete because it involves low cost therefore provides immediate result.

Ultrasonic Pulse Velocity (UPV)

The ultrasonic pulse velocity test is a type of nondestructive test. This test is used to assess the variation in the strength of concrete, as well as detecting voids or other discontinuity, which will provide information on the uniformity of concrete, cavities, cracks, and defects. UPV test was determined according to MS EN12504: Part 4 by using 100 x 100 x 500 mm prisms.

Compressive Strength Test

Concrete specimen's compressive strength was assessed at age 3, 7 and 28 days. The compressive strength test was conducted using cube samples of 100x 100x 100x 100 mm according to BS 1610: part 1:1992. The compressive strength of any mix was drawn as an average of three samples of strength for each age. This experiment uses the compressive machine ELE-ADR-AUTO.3000 with 3000kN capacity.

Flexural Strength Test

Flexural strength of concrete specimens was tested at the age of 3, 7 and 28 days. Under MS EN 12390-5:2012 the flexural strength test was performed using prism specimens sized 100 x 100 x 500 mm. The average strength of three samples for each age was the flexural strength of any mixing. Flexural machine been use in this experiment was ELE 1683D0001 flexural testing machine. The flexural strength was calculated by suing simply supported prism with clear span of 26.5mm under four-point loading.

Findings

Slump Test

The Table 1 above showed that the slump test that has been conducted in this research. The test was conducted after production of concrete. The increase of silica fume as the replacement of cement will increase the value of slump.

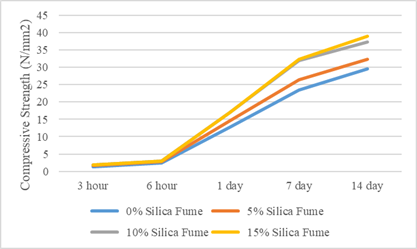

Compression Strength Test

Table 2 and Figure 1 revealed the results of compressive strength. The mould used for this test is cube in shape with size 100mm x 100mm x 100mm. The compressive strength (14 days) of control mix (0% silica fumes) is 29.55 N/mm2, (5% silica fumes) is 32.25N/mm2, (10% silica fumes) is 37.26N/mm2 and (15% silica fumes) is 39.0N/mm2. The target compressive strength for this research is 30N/mm2 and most of the mix design achieved it on 14 days.

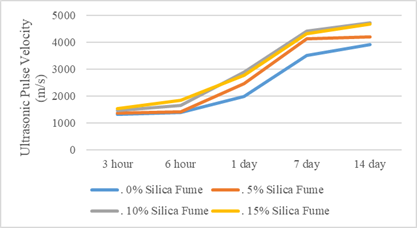

Ultrasonic Pulse Velocity Test (UPV)

Table 3 and Figure 2 above show the results of ultrasonic pulse velocity. The mould used for this test is cubical shape with size 100mm x 100mm x 100mm. The value of UPV for control mix (0% silica fumes) is 1321m/s in the early age (3 hours) and it was increased to 3910m/s at the age of 14 days. Besides, the value of UPV in (5% silica fumes) is 1370m/s, (10% silica fumes) is 1458m/s and (15% silica fumes) is 1544m/s at the age of 3 hours. Moreover, the other 3 different silica fumes (5%, 10%, 15%) which was added into the specimen showed a directly proportional increment of value of UPV at the age of 6 hours, 1 day, 7 days and 14 days as shown in the Figure 2. The highest value of UPV recorded was 4720m/s for the specimen which contain 10% silica fumes at the age of 14 days.

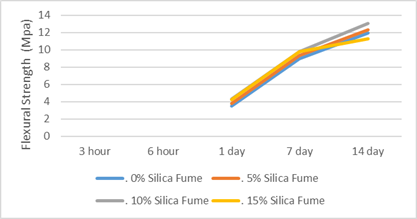

Flexural Strength Test

Table 4 and Figure 3 above indicate the results of flexural test. The mould used for this test is prism with size 100mm x 100mm x 500mm. and the test was conducted only on a day, 7 days and 14 days. This is because the specimen was found unsuitable to conduct testing at the age of 3 and 6 hours. Based on Figure 3, the flexural strength for the control mix 0% silica fumes is 3.49Mpa at 1 day and the strength increased at age 7 days and 14 days, 8.98Mpa and 11.98Mpa respectively. Therefore, same trend was observed the other specimen using silica fumes with different mixture. For example, for specimen containing 10% silica fumes, the flexural strength for 1 day was 4.33Mpa, 7 days was 9.83Mpa and 14 days was 13.06Mpa. These were the highest flexural strength that was recorded. Hence, specimen using silica fumes as cement replacement has higher flexural strength compared to the control mix, 0% silica fumes.

Conclusion

In this study, the impacts of silica fumes on the strength of early age concrete with the addition of calcium nitrate (Hardening Accelerator) were investigated. The study reveals the optimum use of silica fumes in the concrete mix was at 10% composition. This is due to its characteristic of compressive strength and flexural strength concrete. The results also show significant differences in strength compared with the control mix, 5% silica fumes, and 15% silica fumes. Besides, the optimum compressive strength recorded was 37.26 N/mm2 from the 10% silica fumes on the 14 days. The target strength of compressive strength in this study is 30 N/mm2 and most of the specimen achieved the targeted strength at the age of 14 days. The highest flexural strength was recorded 13.06Mpa which was also from the 10% of silica fumes added into the concrete mix. Therefore, the higher the percentages of silica fumes added in the concrete mix, the greater the strength of the concrete.

Acknowledgments

The authors would like to thank the funding bodies of this research: Universiti Sains Malaysia and FRGS Grant. No. 203/PPBGN/6711516.

References

Hamid-zadeh, N., Jamali, A., Nariman-Zadeh, N., & Akbarzadeh Kasani, H. (2006). A Polynomial Model for Concrete Compressive Strength Prediction using GMDH-type Neural Networks and Genetic Algorithm. 5th WSEAS Int. Conf. on System and Simulation in Engineering, Tenerife, Canary Island, Spain, 13-16.

Heikal, M. (2004). Effect of calcium formate as an accelerator on the physicochemical and mechanical properties of pozzolanic cement pastes. Cement and Concrete Research, 34(6), 1051-1056. DOI:

Jamal, H. (2017). Types of Admixtures of Concrete & Cement. Retrieved from https://aboutcivil.org/concrete-technology-admixtures.html#ac.

Khan, M. I., & Siddique, R. (2011). Utilization of silica fume in concrete: Review of durability properties. Resources, Conservation and Recycling, 57, 30-35. DOI:

Khan, S. U., Nuruddin, M. F., Ayub, T., & Shafiq, N. (2014). Effects of Different Mineral Admixtures on the Properties of Fresh Concrete. The Scientific World Journal, 11. DOI:

Kheder, G. F., Gabban, A. M. A., & Abid, S. M. (2003). Mathematical model for the prediction of cement compressive strength at the ages of 7 and 28 days within 24 hours. Materials and Structures, 36(10), 693. http://doi.org/10.1007/bf02479504

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

26 December 2017

Article Doi

eBook ISBN

978-1-80296-950-4

Publisher

Future Academy

Volume

2

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-882

Subjects

Technology, smart cities, digital construction, industrial revolution 4.0, wellbeing & social resilience, economic resilience, environmental resilience

Cite this article as:

Abas*, N. F., Hui, K. T. C., & Frederick, J. (2017). Analysis Of Strength Characteristics Of Concrete With Silica Fumes And Calcium Nitrate. In P. A. J. Wahid, P. I. D. A. Aziz Abdul Samad, P. D. S. Sheikh Ahmad, & A. P. D. P. Pujinda (Eds.), Carving The Future Built Environment: Environmental, Economic And Social Resilience, vol 2. European Proceedings of Multidisciplinary Sciences (pp. 623-630). Future Academy. https://doi.org/10.15405/epms.2019.12.62