Abstract

Concrete are very suitable material for construction since it has a high compressive strength. It can also withstand high temperature of fire/heat and high durability. The ingredients in the concrete such as water, aggregates, and cement are available in most places, hence this makes concrete one of the favourable materials in construction industry. The development through the century has led to many revolutions in the construction industry. Researchers try to improve the materials used in the construction such that it would come out with better result. Concrete are produced more worldwide than any other materials. It has been used in many projects. However, concrete has many disadvantages that should be improved such as; it is brittle with low tensile strength and strain capacity. Concrete is weaker in tension as compared to its compression strength. It also has major development in cracking and can lead to strength loss. The concept of adding steel fibres to the concrete mix is one way of increasing the strength of concrete and of overcoming the limitations of the concrete. The mechanical properties such as compressive strength including steel fibres are evaluated. Compressive strength of the concrete increased with the increase in the steel fibres.

Keywords: Concrete, reinforced concrete, compressive strength, flexural strength, steel fibres

Introduction

Concrete is commonly used to fabricate column, beam and slab to form a structure for shelter or multipurpose. They are all supporting members for a structure by acting as a load transmitting agent that transfers load from the top of a structure to the foundation then to the earth either live loads or dead loads. To understand whether or not the concrete produced is comfortable with the necessary requirements, a concrete test is needed. Concrete testing is used to ensure that the material specified and purchased is the same material delivered to the work site and therefore also acts as a system of quality control.

The development throughout the century has led to many revolutions in the construction industry. Researchers try to improve the materials used in the construction such that it would come out with better result. Concrete are produced more worldwide than any other materials. It has been used in many projects. However, concrete has many disadvantages that should be improved such as; it is brittle with low tensile strength and strain capacity. Steel fibre is a short discrete fibre that are used in the concrete and able to fill the cracks in the concrete such as plastic shrinkage and drying shrink cracking. The permeability of the concrete also reduced hence reducing the water flow (Van Chanh, 2004). The steel fibre can act as a bridge over the cracks which provide post cracking stage.

Steel fibre reinforced concrete or SFRC is a material that is composed of Portland cement, aggregates, sand and addition of steel fibre. Normal concrete has few disadvantages such as low tensile strength and strain capacity and it is also brittle ( Moazami, Behbahani, & Muniandy, 2011). In terms of its compressive and tensile stress, the addition of steel fibre in concrete can enhance the concrete characteristics (Moazami et al., 2011). There are few tests that are carried out to determine critical stress such as compressive stress and tensile stress.

The steel fibre reinforce concrete is believed to have better strength as compared to other unreinforced concrete. Researchers have determined the strength of reinforced concrete from the concrete’s capacity to support the stress applied, such as tensile stress or compressive stress. It has also been said that it can fortify the ability of the unreinforced concrete.

Material Properties

Materials used for this experiment are natural coarse aggregates, sand (fine aggregates), cements, hooked end steel fibre, and water. The ratio for the mixing is 1:1:3 (cement: sand: coarse aggregate) while the water-to-cement ratio is 1:2. There are three mixing in this experiment which is no addition of steel fibres, addition of 1% of steel fibres, addition of 3% of steel fibres.

Cement

Cement used for this experiment is Portland cement. Cement is one of the basic components in concrete mixing. It is a binder and powdery material that is made with calcined lime and clay. Properties of cement that are used in the construction industry are usually inorganic, lime and calcium silicate ( Mahadik, Kamane, & Lande, 2014). Cement can set harden and adhere with other material to mix them together. When cement is mixed with water, it becomes paste that will bind and submerge in water. In order to produce concrete specimen, cement will be mixed with water, sand and aggregates. Cement that is used to produce concrete is known as Ordinary Portland Cement (OPC). OPC is hydraulic cement which will set and adhere with present of water. There is chemical reaction between the dry ingredient of the cement and the water that result in setting, hardening and adhering of the cement. This Portland Cement is grey in colour (Alsop, 2007). The ingredients are the Ordinary Portland Cement includes Calcium Oxide (CaO) and Silicon Dioxide (SiO2). In this experiment OPC is supplied by Housing, Building Planning Testing Unit Concrete Laboratory of USM. Specific gravity of this cement is 3.02kg/m2 according to Table 01 below:

Coarse Aggregates

Coarse aggregates are usually stone or crushed gravel. Their strong and hard properties make it become the most favourable in making the concrete in this industry. Course aggregates are generally are bigger than 4.75mm and the diameter range is between 9.5mm to 37.5mm (Zanotti, Banthia, & Plizzari, 2014). In BS 812: Part 1:1975, the maximum size of coarse aggregates should not exceed 20mm. The size of 0.003m3 should not exceed 20mm. The cube’s volume should be bigger than 0.003m3 if the aggregates are bigger than 20mm.

Fine Aggreagates

Fine aggregates are the aggregates that can pass through 4.75mm sieve. Usually, fine aggregates are the natural sand, silt and clay (Zanotti et al., 2014). These fine aggregates are used basically in completing the concrete mix. Natural sand that passed through 4.75mm sieve are considered as the fine aggregates however the bigger size stuck at 75µm sieve. As mentioned above, aggregates are filled 60-80% of the concrete which is about three-four of the concrete’s volume.

Water

In BS3148:1980, water is needed in mixing the aggregates and cement. Cement will become a paste when mixed with water, after that, it will bind the aggregates altogether. The concrete will go through a hydration process which it will harden that is caused by the water. Hydration is the chemical reaction which chemical bond is form between the cement compound and water molecules and become hydrates (Mahadik et al., 2014). The water should be free from other impurities to avoid side reactions that may weaken the concrete or impact the process of hydration. The ratio of water to cement is the critical factor that controls the production of good concrete. The presence of water affects the strength and workability of the concrete mix. If water is added too much, the strength of the concrete will reduce, while too little water can reduce the concrete workability. Workability of the concrete is very important since concrete needs to be shaped into different kind of forms such as walls and domes. Acids, alkaline or lime water are not suitable for mixing such that it will affect the properties of the concrete (Zanotti et al., 2014). The water cement ratio must be carefully balanced since concrete needs to be both strong and workable (Alsop, 2007). In this experiment, the water is supplied by Perbadanan Bekalan Air (PBA). The water cement ratio is fixed at 0.5 which is 9.387kg. The water is fixed for every mixing.

Steel Fibres

Steel fibres are short discrete particle that are mixed together with then concrete. Steel fibres help to control the crack propagation in concrete accordance to rule of thumb (Zanotti et al., 2014). The percentage volumes of the steel fibres used in this construction are 1% and 3%. The length of the steel fibres is about 3cm. The TYPE OF steel fibres (Figure 01) used is hooked end steel fibres.

Materials used for this experiment are natural coarse aggregates, sand (fine aggregates), cements, hooked end steel fibres, and water. The ratio for the mixing is 1:1:3 (cement: sand: coarse aggregate) while the water-to-cement ratio is 1:2. There are three mixing in this experiment which is no addition of steel fibres, addition of 1% of steel fibres, addition of 3% of steel fibres.

Problem Statement

Concrete has many advantages as a construction material. However, it is still lacking in few aspects. Concrete is very good in compressive strength, but it has a poor tensile strength. It is very brittle and can develop micro cracks during curing (Karththekeyan & Baskaran, 2016). The rapid propagation of the micro cracks made the concrete a low tensile material. This cracking is also due to the low tensile strength of the concrete (Mahadik et al., 2014). The cracking in concrete can be caused by many reasons. For example, excess of water may lead to this problem. Excess of water will increase the slump test; hence the workability of the concrete would also be higher and make the concrete easier to handle. However, this will give long a term effect – cracking. The other possible issue that makes the concrete crack is that the restraint either internally or externally. The restraint comes from many combination factors for example the drying shrinkage, thermal contraction, curling, settlement, and the load that are applied to the concrete ( Caggiano, Cremona, Faella, Lima, & Martinelli,, 2012). However, weather and chemical attacks also contribute to this problem (Soulioti et al., 2009). Since concrete is a brittle material, and the inability of the concrete to flex under the stress makes the concrete crack. Cracks also spread throughout the plain concrete because there are no fibres that bind the concrete substances together (Caggiano et al., 2012).

Research Questions

The deficiencies in the current literature led to further research on the performance of concrete when steel fibres is added into the conventional concrete. In view of the above situation, the previous research question arises:

- What is the contribution of steel fibres amount in conventional concrete to minimize crack?

Purpose of the Study

The aim of this research is to study the performance of concrete when steel fibres are added in different amount. The specific objectives for the research are:

- To evaluate the effect of the steel fibres on the compressive and flexural strength

- To observe the optimum percentage of steel fibres in concrete

Research Methods

For the whole laboratory test, the ratio of the cement to sand to coarse aggregate is fixed as 1:1:3. Besides, the ratio of the water to cement is also determined as 1 to 2. Then, the mixture of the concrete is used to prepare 9 cubes with dimension 10mm×10mm×10mm and 6 prisms with 100mm×100mm×500mm. The steel fibres that are used are about 1.5cm to 2cm. About 1% and 3% of the steel fibres are used in this experiment. One mixture is without steel fibres. The concrete is tested for 7, 21 and 28 days. These concretes that have mixed are used to prepare to test including slump test, compaction test, bulk density test, compression test, flexural test and ultrasonic non-destructive test.

The total mass of ingredients needs to be prepared is 93.87kg. Hence, 93.87kg of the mixture divided into 5 portions since the total ratio of 1:1:3 is 5. Thus, the mass of the component of the concrete mixture has been calculated. Since the water cement ratio required is 0.5, then the mass of water has been calculated. Total ratio of the mixture = 1+1+3= 5

Findings

Slump test

This test is aimed to determine the workability of fresh concrete with different percentage of steel fibre addition in the admixtures. There are three type of slump which is true slump, shear slump and collapse. A collapse slump means the mix are too wet. Very dry mix will give slump value of 0-25mm and the concrete are suitable for road making. The slump readings between 25mm to 50mm are suitable for the construction of foundation with light reinforcement. For 50mm to 100mm slump give medium workability mixes. For normal reinforced concrete with vibration and give high workability is about 100mm to 175mm. The additional water in every mix is constant to 0.5 of water-cement-ratio. The results for the slump test are decreased with increasing percentage of steel fibre (Table 02).

Compressive Strength Test

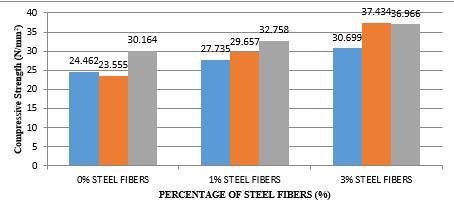

The compressive strength is tested in 7, 21 and 28 days. Three concrete cubes are tested in a set itself. The cube specimen’s size is 150mm x 150mm x 150mm. Figure 2 below shows the concrete specimen with and without steel fibres addition. As in Figure 3, compressive strength result, when the addition of the steel fibre is increase, the compression strength also increase. The highest average value for compression is for the addition of 3% of steel fibre which is 30.699 kg/m³ , 37.434 kg/m³ and 36.966 kg/m³ respectively. Whilst the plain concrete gives the average of lowest compressive strength.

Flexural Strength Text

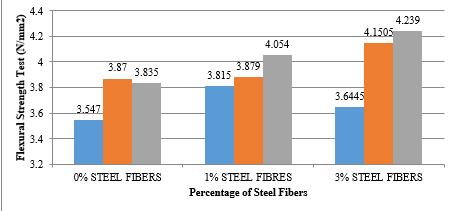

The flexural test is tested in 7, 21 and 28 days. Two prims are tested in a set. The rectangular dimension is 500mm x 100mm x 100mm. The results of flexural test are given in Figure 4.

Steel fibres give the concrete a form of bridging action. As load is applied on the structural element of the concrete, steel fibres bridge the cracks. This bridging action provides more tensile strength and give damage tolerance towards the concrete specimen. As in Figure 4, the conditions of the beams without steel fibres (left) are cracked after load is being applied to it. Different from the beam with 3% of steel fibres, after load is being applied, the steel fibres act as bridge to the cracks. As in Figure 5, the flexural test result shows that the flexural strength of the concrete inclined when percentage of steel fibre are increased. 3% of steel fibre gave the highest value of flexural strength. The lowest value of flexural strength would be 3.547 kN/mm² for plain concrete of day 7th. The addition of the steel fibre helps in increasing the flexural strength of the concrete. Hence, the hypothesis is accepted which the increase of addition steel fibre enhances the flexural strength of the concrete. The addition of steel fibre also gives pull-out resistance (dowel action) for the concrete. The pull-out strength of the steel fibre helps improving the post-cracking tensile strength of the concrete specimen.

Conclusion

The results above show that the addition of the steel fibres in concrete improves several concrete properties such as its compressive and ductility. Steel fibres also act as a bridge towards the concrete so that the cracks can be reduced. The changes of performance depend on the ability of the fibre to react with the concrete and it is also influenced by the amount of addition of the steel fibres. For compressive test result, when the addition of the steel fibre is increase, the compression strength also increases. The highest average value for compression is for the addition of 3% of steel fibre which is 30.699 kg/m³ , 37.434 kg/m³ and 36.966 kg/m³ respectively. Whilst the plain concrete gives the average of lowest compressive strength.

Acknowledgments

The author would like to thank the funding body of this research: Universiti Sains Malaysia under USM RUI Grant, No. 1001/PPBGN/814248

References

Alsop, P. A. (2007). Cement plant operations handbook: for dry process plants, Tradeship Publications Ltd.

Caggiano, A., Cremona, M., Faella, C., Lima, C., & Martinelli, E. (2012). Fracture behavior of concrete beams reinforced with mixed long/short steel fibers. Construction and Building Materials, 37, 832-840.

Karththekeyan, T., & Baskaran, K. (2016). Experimental study on steel fibre reinforced concrete. Moratuwa Engineering Research Conference (MERCon), 272-276.

Mahadik, S., Kamane, S., & Lande, A. (2014). Effect of Steel Fibres on Compressive and Flexural Strength of Concrete. International Journal of Advanced Structures and Geotechnical Engineering, 3, 388-392.

Moazami, D., Behbahani, H., & Muniandy, R. (2011). Pavement rehabilitation and maintenance prioritization of urban roads using fuzzy logic. Expert Systems with Applications, 38, 12869-12879.

Soulioti, D., Barkoula, N., Paipetis, A., Matikas, T., Shiotani, T., & Aggelis, D. (2009). Acoustic emission behavior of steel fibre reinforced concrete under bending. Construction and Building Materials, 23, 3532-3536.

Van Chanh, N. (2004). Steel fibre reinforced concrete. Faculty of Civil Engineering Ho chi minh City university of Technology. Seminar Material, 108-116.

Zanotti, C., Banthia, N., & Plizzari, G. (2014). A study of some factors affecting bond in cementitious fibre reinforced repairs. Cement and Concrete Research, 63, 117-126.

Copyright information

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

About this article

Publication Date

26 December 2017

Article Doi

eBook ISBN

978-1-80296-950-4

Publisher

Future Academy

Volume

2

Print ISBN (optional)

-

Edition Number

1st Edition

Pages

1-882

Subjects

Technology, smart cities, digital construction, industrial revolution 4.0, wellbeing & social resilience, economic resilience, environmental resilience

Cite this article as:

Abas*, N. F., Zulpatah, W. N. H. B. M., Ghani, Z. A., & Frederick, J. (2017). Mechanical Properties Of Steel Fibres Reinforced Concrete. In P. A. J. Wahid, P. I. D. A. Aziz Abdul Samad, P. D. S. Sheikh Ahmad, & A. P. D. P. Pujinda (Eds.), Carving The Future Built Environment: Environmental, Economic And Social Resilience, vol 2. European Proceedings of Multidisciplinary Sciences (pp. 615-622). Future Academy. https://doi.org/10.15405/epms.2019.12.61